A method for preparing calcium silicate powder by liquid-phase dynamic hydrothermal synthesis

A dynamic hydrothermal, calcium silicate powder technology, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problem of the large difference in the composition and microstructure of fly ash, affecting the structural properties and performance of materials, powder The stability requirements of coal ash components are relatively high, and the effects of easy industrialization and promotion, small changes in synthesis process and equipment, and simple and feasible preparation process are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

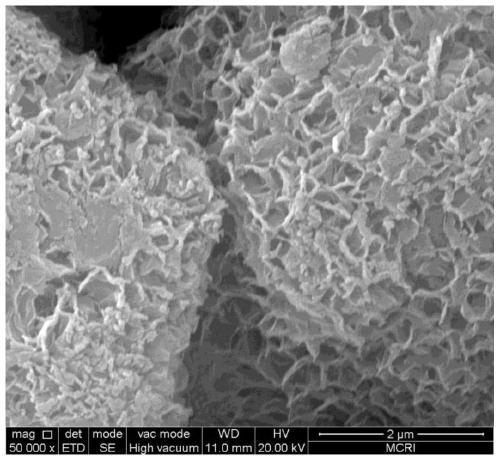

Embodiment 1

[0041] Take SiO 2 Content 99.2%, Fe 2 o 3 Content of 0.015%, MgO content of 0.01%, 20g of high-purity quartz sand with a moisture content of 2.5%, use a pulverizer to finely grind the particle size below 0.1mm, and then add it to 81.43g of sodium hydroxide solution with a concentration of 14%, and stir Finally, a slurry is formed. Under this condition, the mass ratio of sodium oxide and quartz sand on a dry basis is controlled to be 0.5:1. The temperature of the slurry is raised to 185°C and 1.2Mpa. The reaction is carried out for 2.5 hours under this condition. After the reaction, the slurry is solidified. The liquid is separated, and the crude sodium silicate solution is finely filtered through a leaf filter, and the solid waste is returned to the quartz sand feed port for recycling, and the obtained sodium silicate solution has a SiO 2 The concentration is 115g / L, and it is used as the siliceous raw material for the hydrothermal synthesis of calcium silicate.

[0042] Af...

Embodiment 2

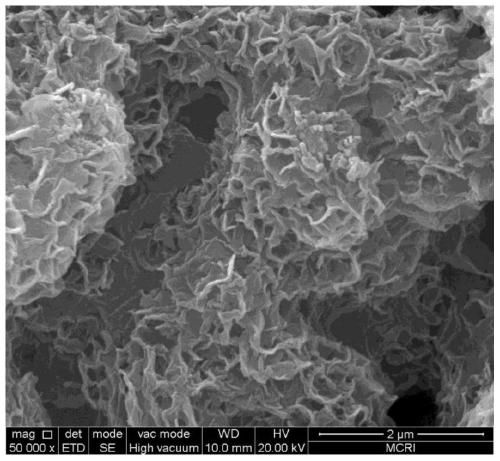

[0050] Take SiO 2 Content 99.6%, Fe 2 o 3 Content 0.010%, MgO content 0.008%, 20g of high-purity quartz sand with a moisture content of 2.8%, use a pulverizer to finely grind to a particle size of less than 0.1mm, then add it to 81.43g of a 14% sodium hydroxide solution, and stir Finally, a slurry is formed. Under this condition, the mass ratio of sodium oxide and quartz sand on a dry basis is controlled to be 0.6:1. The temperature of the slurry is raised to 195°C and 1.9Mpa. The reaction is carried out for 3 hours under this condition. After the reaction, the slurry is subjected to solid-liquid Separate, and finely filter the crude sodium silicate solution through a leaf filter, and return the solid waste to the quartz sand feed port for recycling, and the obtained sodium silicate solution has a SiO 2 The concentration is 95g / L, and it is used as a siliceous raw material for hydrothermally synthesizing calcium silicate.

[0051] After crushing, stone washing and grading, ...

Embodiment 3

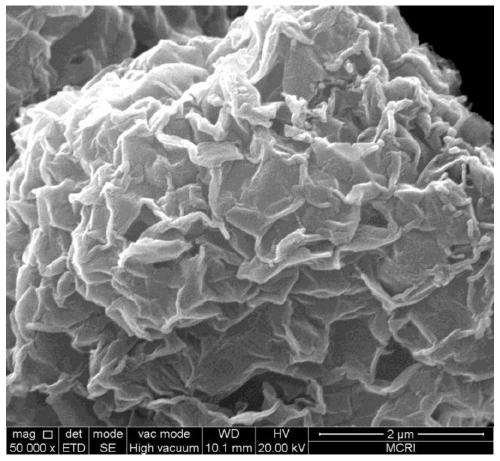

[0054] Take SiO 2 Content 98.9%, Fe 2 o 3 Content of 0.009%, MgO content of 0.006%, 20g of high-purity quartz sand with a moisture content of 2.2%, use a pulverizer to finely grind to a particle size of less than 0.1mm, and then add it to 75g of a sodium hydroxide solution with a concentration of 16%. After stirring Form a slurry. Under this condition, the mass ratio of sodium oxide and quartz sand on a dry basis is controlled to be 0.6:1. The temperature of the slurry is raised to 205°C and 2.1Mpa. The reaction is carried out for 3.5 hours under this condition. After the reaction, the slurry is subjected to solid-liquid Separate, and finely filter the crude sodium silicate solution through a leaf filter, and return the solid waste to the quartz sand feed port for recycling, and the obtained sodium silicate solution has a SiO 2 The concentration is 115g / L, and it is used as the siliceous raw material for the hydrothermal synthesis of calcium silicate.

[0055] After crushin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com