Patents

Literature

74results about How to "Play a role in deoxygenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas shield welding wire with high strength and tenacity

ActiveCN101722386AHigh strengthImprove toughnessWelding/cutting media/materialsSoldering mediaImpurityREL

The invention relates to a gas shield welding wire with high strength and tenacity, which is suitable for the welding of 800MPa-grade high-strength steel. The gas shield welding wire comprises the following ingredients in percentage by weight: 0.02-0.05 percent of C, 0.30-0.80 percent of SiO, 2.0-2.50 percent of Mn, less than 0.010 percent of P, less than 0.010 percent of S, 0.70-1.2 percent of Cr, 0.70-1.2 percent of Mo, 0.02-0.12 percent of Ti, 0.003-0.005 percent of B, 2.0-3.2 percent of Ni, 0.05-0.1 percent of RE, 0-0.06 percent of Nb, and the balance of Fe and unavoidable impurities. The welding wire has the advantages of simple ingredient design, low cost, good manufacturability, and the like; in addition, and weld metal has high tenacity and is suitable for the welding at the position with higher low-temperature tenacity requirement. Experiments show that the Rm of the weld metal welded by the welding wire is not less than 800MPa, and the ReL is more than 760MPa; and the impact energy at -50 DEG C of the weld metal is not less than 37J.

Owner:SHOUGANG CORPORATION

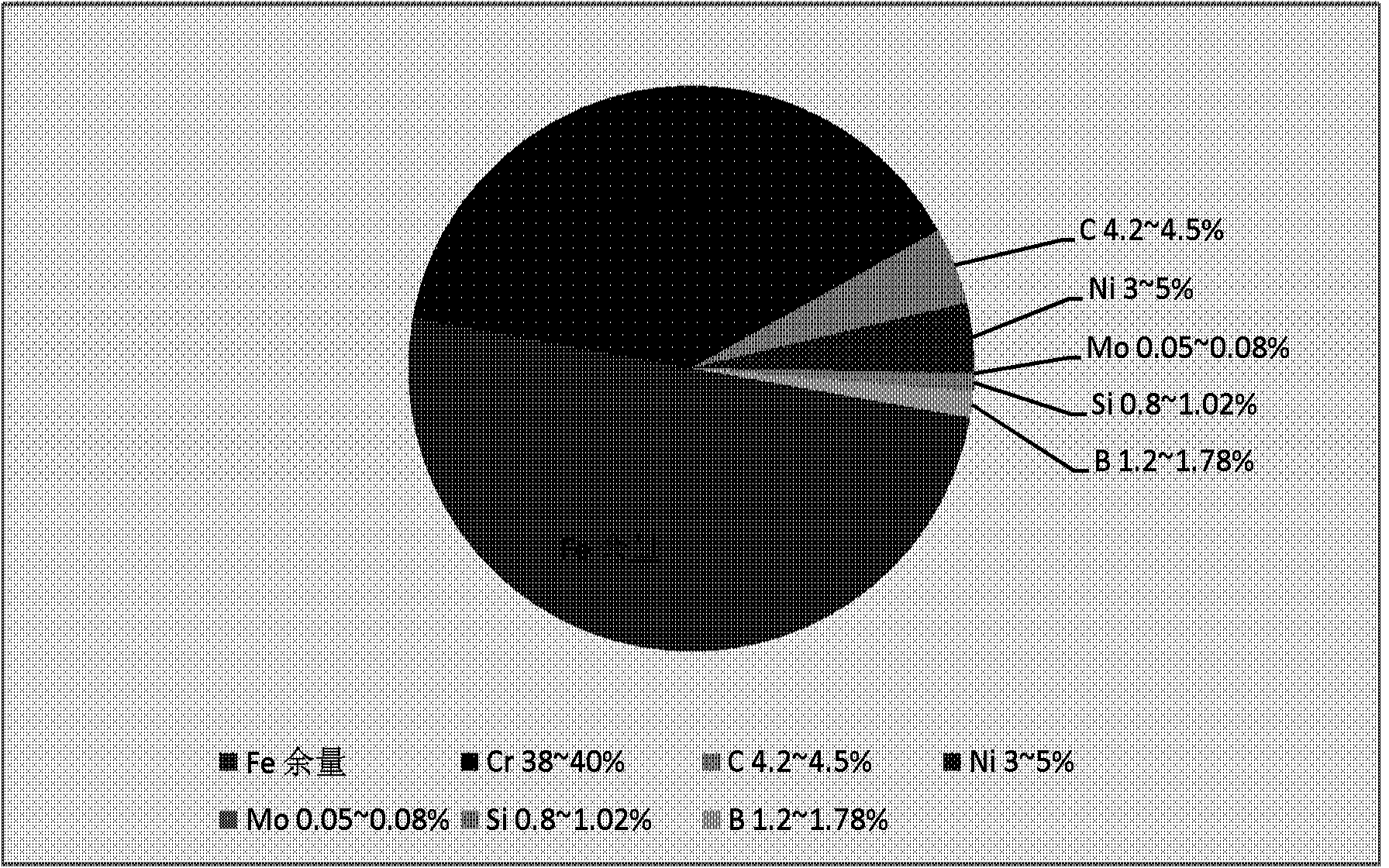

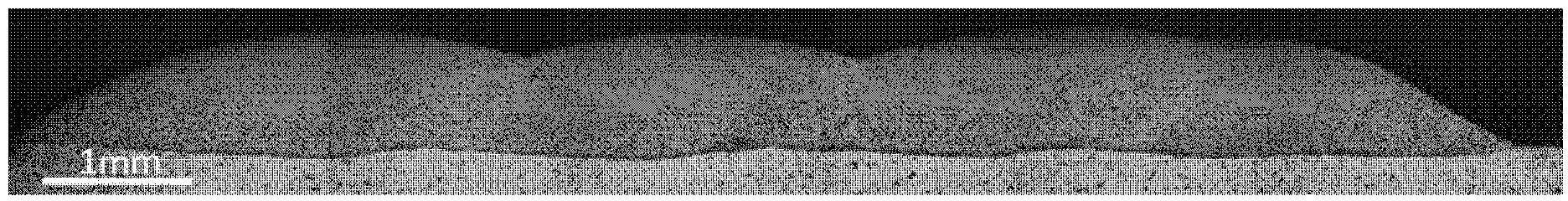

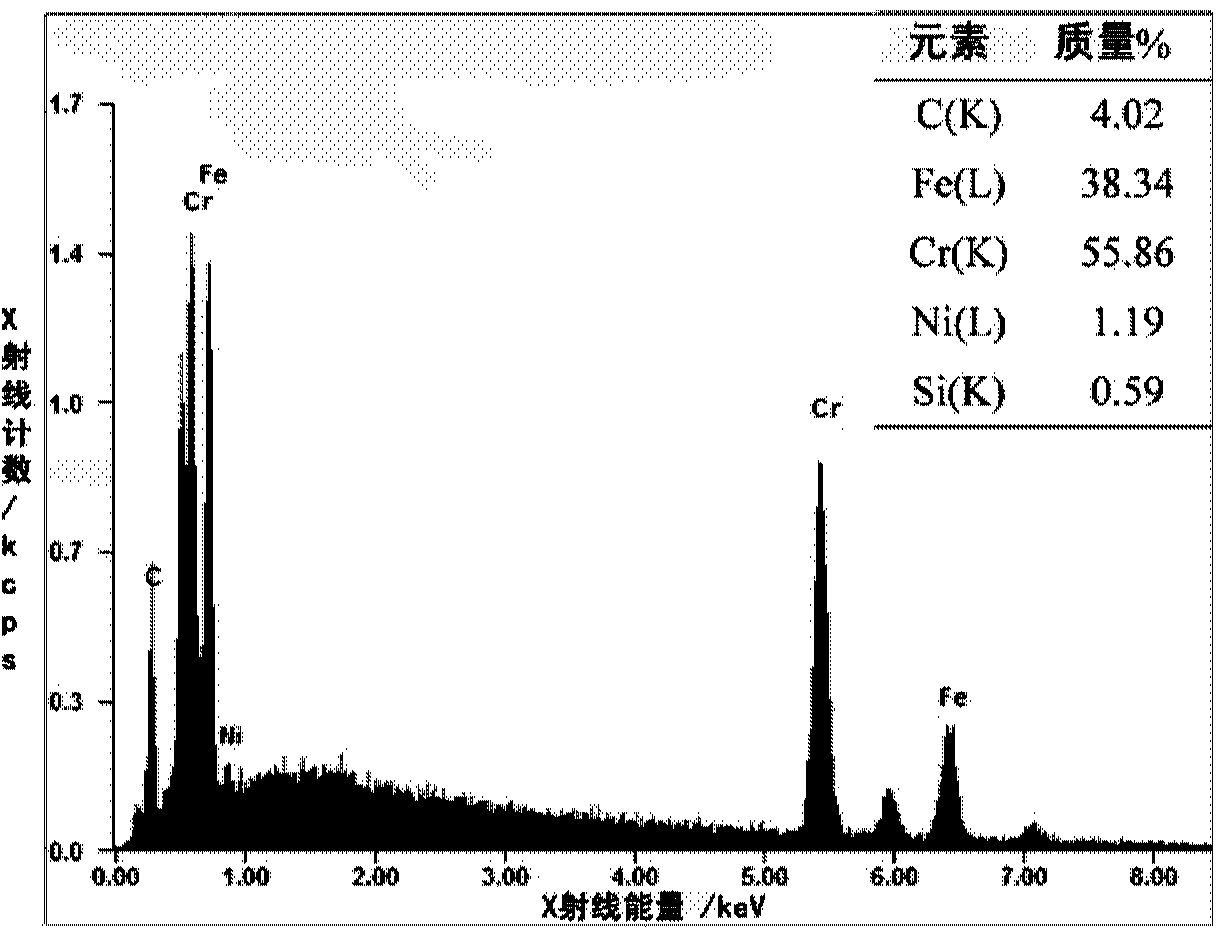

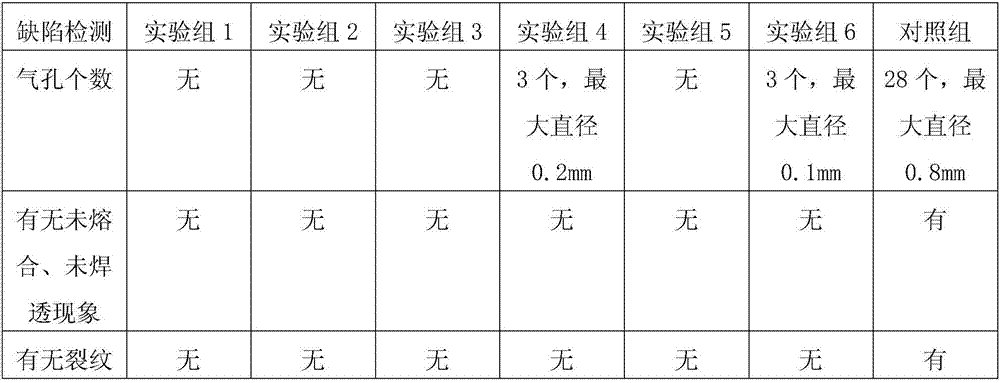

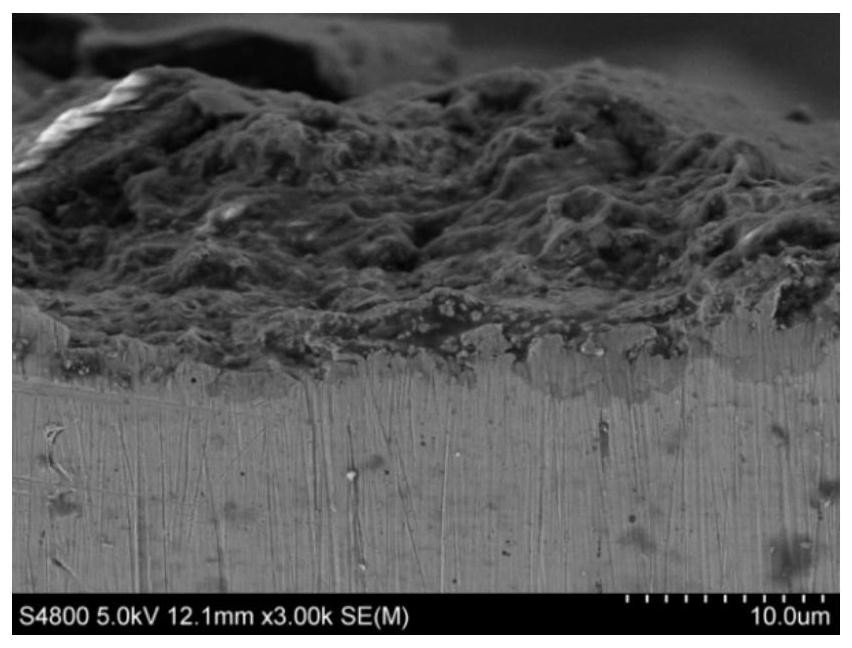

Iron-based composite powder high in chromium content for laser cladding

ActiveCN103752818AHigh hardnessImprove wear resistanceMetallic material coating processesCrack freeHardness

The invention discloses iron-based composite powder high in chromium content for laser cladding. The iron-based composite powder high in chromium content for laser cladding is composed of the chemical compound of Cr3C2, Cr and Fe, Ni, Mo, Si and B. The iron-based composite powder high in chromium content for laser cladding comprises, by mass, 38%-40% of Cr, 4.2%-4.5% of C, 3%-5% of Ni, 0.05%-0.08% of Mo, 0.8%-1.02% of Si, 1.2%-1.78% of B and the balance Fe. The particle size of the iron-based composite powder is between +140 meshes and -325 meshes. The iron-based composite powder is high in carbon content and chromium content, the hardness of a coating can be effectively improved, requirements of the laser cladding technology of iron-based base materials such as carbon steel and stainless steel can be met, a cladding layer of a sample of the iron-based composite powder is free of cracks and macroscopic pores, all the components are distributed evenly, the hardness of the iron-based composite powder can reach HV0.21000 and is five times that of a base body, the corrosion resistance of the iron-based composite powder cladding layer is improved due to the high chromium content, and the iron-based composite powder is suitable for normal temperature, high temperature, abrasion resistance and corrosion resistance working conditions.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for preparing high-purity high-temperature alloys by using returned materials

InactiveCN110106374AConducive to environmental protectionReduce energy consumption and costsProcess efficiency improvementYttriumPre treatment

The invention discloses a method for preparing high-purity high-temperature alloys by using returned materials. The method is characterized by comprising the following steps in sequence: charging: pretreated high-temperature alloy returned materials are fed in a yttrium oxide crucible; and a door of a vacuum induction smelting furnace is closed; smelting: the vacuum induction smelting furnace is vacuumized to reach the furnace internal vacuum degree of 0.005-0.05 Pa; then, the smelting is started until all burdens are molten; when the burdens are heated to reach 1600-2000 DEG C, redundant argon in a hearth is extracted to maintain the hearth internal vacuum degree of 0.3-0.5 Pa; metal yttrium blocks are fed from a secondary feed port; the feeding quantity of the yttrium blocks is 0.01-0.2%of the weight of the high-temperature alloy returned materials; the refining is performed; and the molding by casting is performed after refining. The O and N contents of purified and smelted high-temperature alloys are reduced below 4 ppm; the purity reaches the level of high-quality and high-purity high-temperature alloy new materials; and the utilization rate of resources is increased.

Owner:BEIHANG UNIV +2

Aluminum-manganese-carbon alloy ball for steelmaking deoxidization and recarburization and preparation method thereof

The present invention discloses one kind of steelmaking deoxidizing and carburizing Al-Mn-C alloy pellet and its preparation process. The lumpy alloy pellet contains Mn 30- 40 wt%, C 25-35 wt%, Al 10-20 wt%, H2O 0-1 wt%, S 0-0.35 wt% and P 0-0.3 wt%. It is used in steelmaking to reach the aims of deoxidizing and carburizing in low labor strength, less environmental pollution and low cost.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

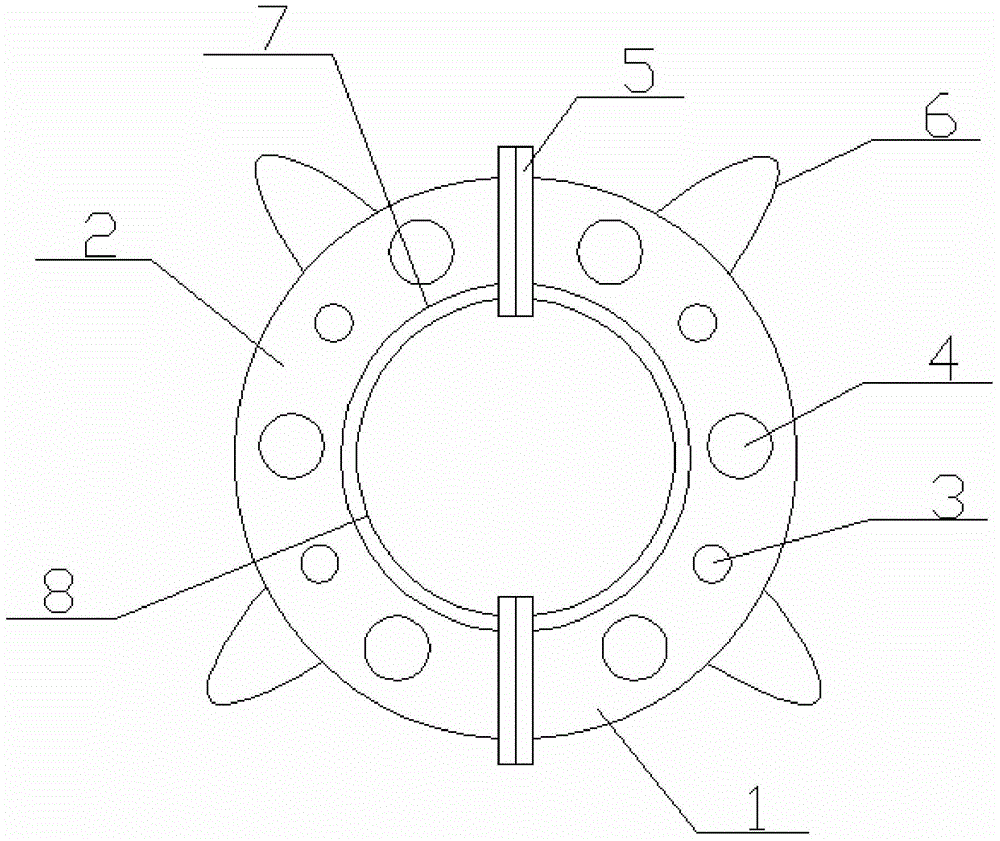

Casting process for high-temperature water-pressure-resisting combined flange

InactiveCN105689653AImprove heat resistanceHigh thermal conductivityFoundry mouldsFoundry coresFlangeHigh heat

The invention discloses a casting process for a high-temperature water-pressure-resisting combined flange. The cast high-temperature wear-resisting combined flange mainly comprises a flange body. The flange body is composed of a first flange plate and a second flange plate. The shape and the size of the second flange plate are the same as those of the first flange plate. The first flange plate and the second flange plate are each of a saddle-shaped structure. Threaded holes and through holes are evenly distributed in the first flange plate and distributed at intervals. The two ends of the first flange plate extend outwards to form fixing edges. Fixing holes are formed in the fixing edges. At least two lug plates are arranged on the edge of the outer side of the first flange plate. The first flange plate and the second flange plate are connected together in a fastened manner through bolts after butting the fixing holes in the fixing edges, and the first flange plate and the second flange plate are connected in the fastened manner to form a mounting hole. The casting process is simple and easy to implement. The cast combined flange is simple in structure and has good high-temperature water-pressure-resisting performance, the service life of the flange is prolonged, and cost is lowered.

Owner:DAFENG HONGLIAN CAST STEEL

Environmental-protecting and energy-saving premelting refining slag conditioning agent

The invention proposes an environmental-protecting and energy-saving premelting refining slag conditioning agent. The environmental-protecting and energy-saving premelting refining slag conditioning agent comprises the following chemical components in percentage by weight: 20-28% of Al, 29-37% of CaO, 33-41% of Al2O3, MgO not more than 2.5%, SiO2 not more than 2.5%, FeO+MnO not more than 0.7%, S not more than 0.2%, P not more than 0.2%, TiO not more than 0.30%, and H2O not more than 0.7%. The refining slag conditioning agent is premolten beforehand, wherein CaO and Al2O3 are combined to generate a lot of low-melting-point 12CaO-7Al2O3; the melting point of the refining slag conditioning agent is lowered; the slag can be quickly molten at the earlier stage of LF furnace refining; the power supply time is shortened; and the energy is saved; and as aluminum is uniformly distributed in the slag conditioning agent, the earlier deoxidation speed is quicker, and the deoxidation effect is excellent. The refining slag conditioning agent is lower in content of TiO, balances the [Ti] element in molten steel, and has a certain capacity of absorbing the [Ti] element in the molten steel.

Owner:QINGDAO SPECIAL STEEL CO LTD

Copper series purifying agent and preparation method thereof

ActiveCN102390807AEfficient removalPlay a role in deoxygenationHydrogen separation using solid contactCoprecipitationMethanol

The invention relates to a copper series purifying agent and a preparation method thereof. The purifying agent is a carrier system, is loaded with Cu and also loaded with one or more metals, such as Zn, Al, Mg, Zr and Mn or metal oxides thereof; and the prepared purifying agent can effectively eliminate Fe(CO)5 and Ni(CO)4 in a synthesis gas and plays a role of removing O2. The preparation methodcomprises the following steps of: mixing, cocurrent flow coprecipitation, ageing, carrier loading, drying, tableting and forming and the like. The purifying gent prepared by the preparation method issuitable for the synthesis gas containing CO, CO2 and H2 and is especially suitable for a device for synthesizing methanol by using the synthesis gas.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

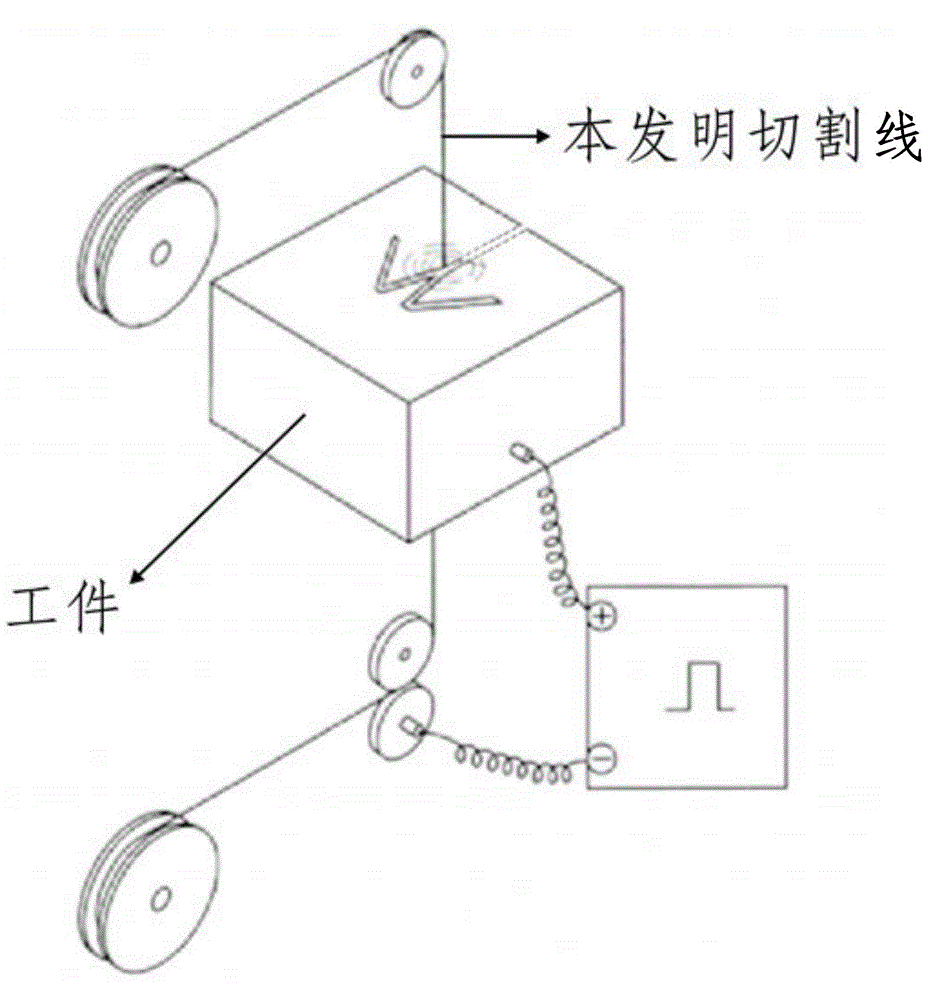

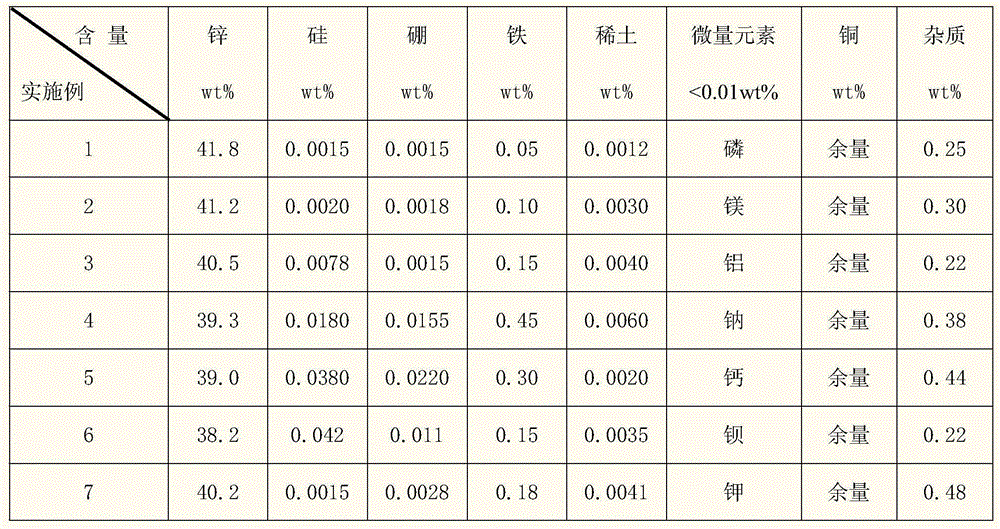

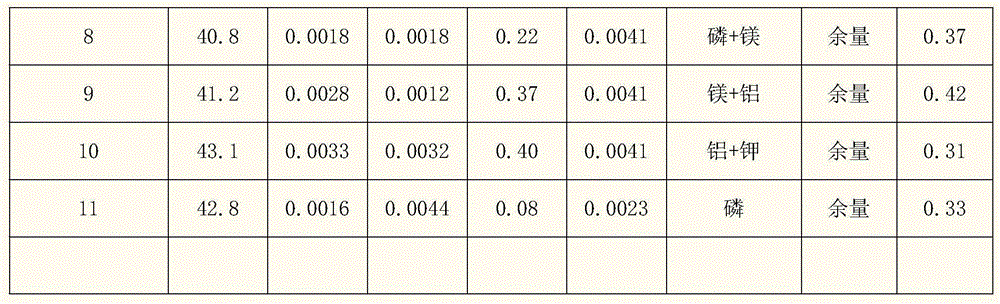

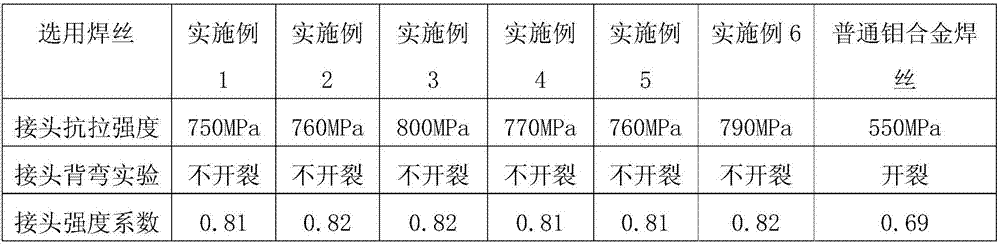

High zinc-silicon-boron-ferro copper alloy

The invention discloses a high zinc-silicon-boron-ferro-copper alloy. The copper alloy is characterized by comprising the components in percentage by weight: 38.0-44.0 percent of zinc, 0.001-0.5 percent of silicon, 0.001-0.025 percent of boron, 0.005-0.5 percent of ferro, 0.001-0.01 percent of rare earth, 0.0005-0.1 percent of other element including at least one of phosphorus, magnesium, potassium, calcium, sodium, aluminum and barium, and the balance of copper and inevitable impurity elements. The copper alloy is used for manufacturing a cutting line for one-way wiring; compared with the prior art, the copper alloy has the advantages that the manufactured cutting line for one-way wiring is high in mechanical performance, stable in discharging performance and high in cutting speed; the cutting line is simple in processing procedures, wide in application and low in cost and has wide market prospect.

Owner:NINGBO BODE HIGHTECH CO LTD

High-strength and high-plasticity hollow aluminum profile and preparation method thereof

InactiveCN110453111AAvoid overheatingImprove mechanical propertiesAnodisationElectrophoretic coatingsMechanical propertyToughness

The invention discloses a high-strength and high-plasticity hollow aluminum profile and a preparation method thereof, and belongs to the field of aluminum profile preparation. The high-strength and high-plasticity hollow aluminum profile comprises the following raw materials of, in percentage by weight (wt%), 2.0-4.0 of Mg, 2.0-4.0 of Cu, 0.4-0.8 of Si, 0.4-1.0 of Gu, 0.8-1.0 of As, 0.2-0.6 of Ti,0.4-1.0 of Mn, 1.0-3.0 of Fe, 0.4-0.6 of Cr, 0.4-0.6 of Zn, 0.6-0.8 of Li, and the balance aluminum and inevitable impurities. By controlling the content of elements in aluminum alloy components, strengthening phases such as Al2Cu, Al2CuMg, Mg2Si and MgZn2 are formed in an aluminum alloy, the strengthening phases act synergistically, so that the effects of deoxidizing and refining grains are achieved, the obvious strengthening effect on the aluminum profile is achieved, the cracking sensitivity of a material is effectively reduced, the mechanical properties such as plasticity, toughness and fatigue resistance of the aluminum profile and the good machining performance are improved, and the performance requirement of the aluminum profile for alternate transportation can be met.

Owner:ANHUI XIN FA ALUMINUM PROD

Method for welding molybdenum alloy

ActiveCN106862732AInhibition of sensitization tendencySmall mechanical propertiesArc welding apparatusWelding/cutting media/materialsActive agentDirect current

The invention discloses a method for welding molybdenum alloy, belonging to the technical field of metal welding. The method comprises the steps: (1) after cleaning, drying the welding area of molybdenum alloy; (2) manufacturing a special welding wire for the molybdenum alloy; (3) degassing at high temperature; (4) taking out a molybdenum alloy workpiece, spraying an active agent until the thickness is 0.2-0.8mm on the he welding area of molybdenum alloy, heating the special welding wire for the molybdenum alloy to dry, and then welding the molybdenum alloy workpiece, wherein the welding method adopts TIG wire filling welding, adopts a direct-current straight polarity power supply and determines welding process parameters; (5) cooling; (6) inspection. The method can reduce the quantity of joint holes, improve weldability, reduce cracks, refine parent crystalline grains so as to improve the tensile property of welded joints, and obtain good welding quality.

Owner:宝鸡市蕴杰金属制品有限公司

Method for smelting ultra-low carbon steel

ActiveCN106929633AIncrease temperatureHigh target temperatureManufacturing convertersLiquid steelOxygen

The invention discloses a method for smelting ultra-low carbon steel. The method comprises a desulfurization procedure, a converter blowing procedure, an RH vacuum treatment procedure and a continuous casting procedure. After converter blowing, the temperature of tapping is 1680 DEG C-1700 DEG C, then ferroaluminum is added into liquid steel so that the liquid steel is subjected to preliminary deoxygenation; then the temperature is measured, oxygen activity is determined, and the liquid steel is fed with an aluminium wire according to a determined oxygen activity result, so that the oxygen activity is fine-tuned, and it is ensured that the oxygen activity is at 550 ppm-650 ppm; and the liquid steel meeting conditions enters the RH vacuum treatment procedure directly. A high target temperature of the converter tapping, with the partial ferroaluminum deoxygenation conducted after the converter tapping, enables the liquid steel to be kept at a high temperature level, and the temperature level meets the requirement for the temperature when the liquid steel enters the RH vacuum treatment procedure, so that an existing electric heating procedure is omitted; and the liquid steel can enter the RH vacuum treatment procedure directly, so that energy consumption in the steel making process is reduced greatly, and steel making efficiency is enhanced effectively after the heating procedure is omitted.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

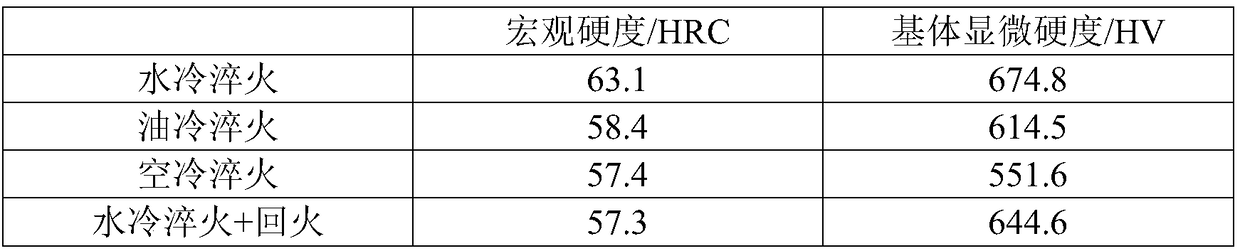

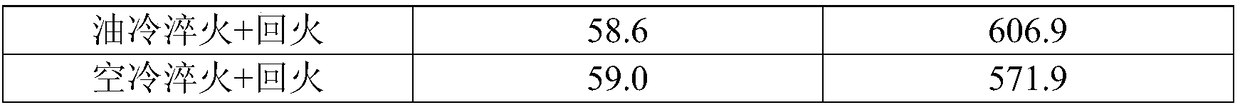

High red hard boron-containing high speed steel and preparation method thereof

InactiveCN108251755AImprove red hardnessIncrease hardnessProcess efficiency improvementChemical compositionWear resistant

The invention discloses a high red hard boron-containing high speed steel and a preparation method thereof, and belongs to the technical field of wear-resistant material. The high red hard boron-containing high speed steel comprises the compositions of, by weight, 1.0-3.0 of B, 0.2-0.8 of C, 5.0-7.0 of Cr, 3.0-6.0 of Mo, 0.5-2.0 of Al, 0.5-1.5 of Si, 0.5-1.5 of V, 0.5-1.5 of Mn, and the balance Fe. The high red hard boron-containing high speed steel has excellent wearresistance, red hardness, and excellent harden ability. High hardness can be obtained by cooling only in the air, thus the highred hard boron-containing high speed steel is very suitable for the preparation of parts for use in high temperature wear conditions such as rolls. In addition, the production cost is low, productionprocess is simple, and promotion and application value is good.

Owner:XI AN JIAOTONG UNIV +1

Magnesium-containing steel 45 and preparation process thereof

PendingCN113957338AIncreased level of controlIncrease ratingsTemperature control deviceProcess efficiency improvementOxide compositeMolten steel

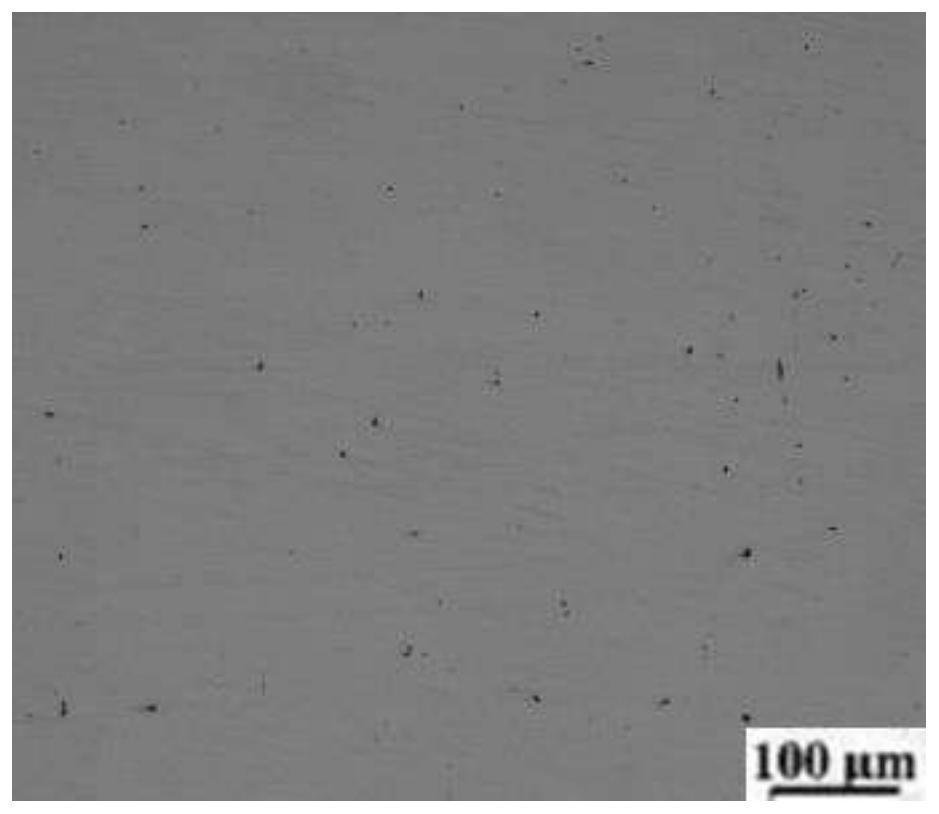

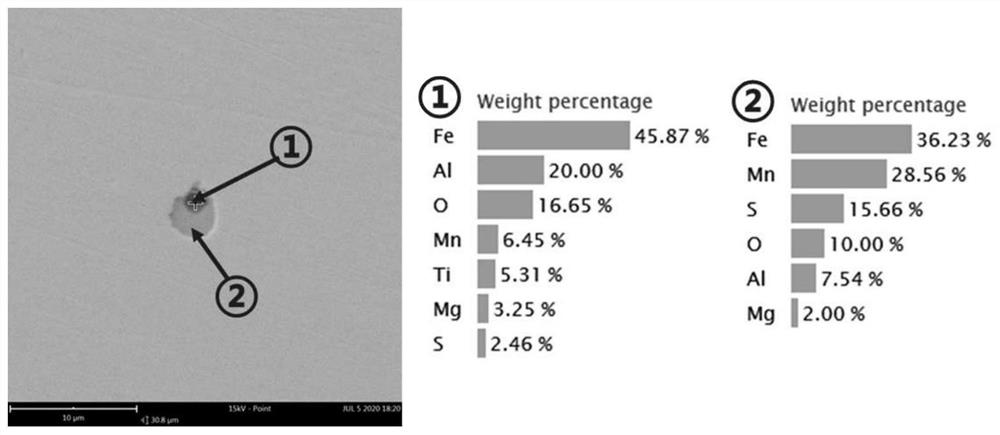

The invention discloses magnesium-containing steel 45 and a preparation process thereof, and relates to the technical field of steel production. The steel 45 comprises the following chemical components of, in percentage by mass, 0.45%-0.48% of C, 0.17%-0.37% of Si, 0.65%-0.80% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, 0.0005%-0.0020% of Mg, and the balance iron and inevitable impurities. On the basis of ensuring the safe production of the steel 45, the inclusion in the steel is modified by feeding a magnesium-silicon cored wire into molten steel at the final stage of refining, so that the inclusion in the steel is converted into the fine and dispersively distributed sulfide-oxide composite inclusion, the rating of the inclusion is optimized, and the comprehensive mechanical property of the steel 45 is improved.

Owner:NANJING IRON & STEEL CO LTD

High-pressure internal thread ball valve and machining process thereof

InactiveCN109055807AHigh tensile strengthIncreased freezing temperature rangePlug valvesFurnace typesRare-earth elementEngineering

The invention provides a high-pressure internal thread ball valve. The high-pressure internal thread ball valve comprises a valve body, a valve cap, a valve rod, a valve ball and a pressing cap, and is characterized in that the valve body, the valve cap, the valve rod, the valve ball and the pressing cap are made from the same main material, wherein the main material comprises, by mass, 7-9% of Zn, 1-3% of Pb, 2-4% of Si, 0.12 -0.15% of Ti, 0.1-0.3% of Fe, 0.1-0.3% of Al, 0.15-0.19% of C, 0.05-0.07% of B, 1.0-2.0% of Cr, 0.01-0.03% of Sb, 0.25-0.28% of Mn, 0.05-0.07% of Nb, 0.01-0.03% of V, 0.001-0.002% of Bi, 0.003-0.005% of S, 0.005-0.006% of P, 0.01-0.02% of rare earth elements, and the balance Cu and inevitable impurities, and the sum of the components is 100%. A machining process of the high-pressure internal thread ball valve is simple and easy to implement, and low in cost, and the machined ball valve has good high-temperature resistance and corrosion resistance performance, andis long in service life.

Owner:JIANGSU HUATAI ELECTRIC POWER ELECTRONICS INSTR

Ageing strengthening copper alloy strip and preparing method thereof

The invention relates to an ageing strengthening copper alloy strip. The copper alloy strip is composed of components including, by weight, 0.4%-1.3% of Si, 2%-4.5% of Ni, 0.06%-0.2% of Cr, 0.2%-0.8%of Zn, 0.05%-0.2% of Mg and the balance copper and inevitable trace impurities. Preparing steps include that burdening and smelting are carried out; Mg is added for deoxygenation treatment; when the temperature of a holding furnace reaches the casting temperature being 1220 DEG C-1300 DEG C, and a horizontal continuous casting red ingot casting technology is adopted; face milling, rough rolling and solution treatment are carried out; intermediate rolling is carried out after surface washing; second solid solution is carried out; finished product finish rolling is carried out after surface washing; finished product aging is carried out; surface washing and surface grinding polishing are carried out; and finished stripping, checking and packaging are carried out. The ageing strengthening copper alloy strip has the good processability and casting performance, has the advantages of high strength, high elasticity, high conductivity, excellent resistance to high temperatures and good stressrelaxation resistance and is an ideal material for a lead frame, and the preparing technology is simple.

Owner:JINTIAN COPPER GROUP CORP NINGBO

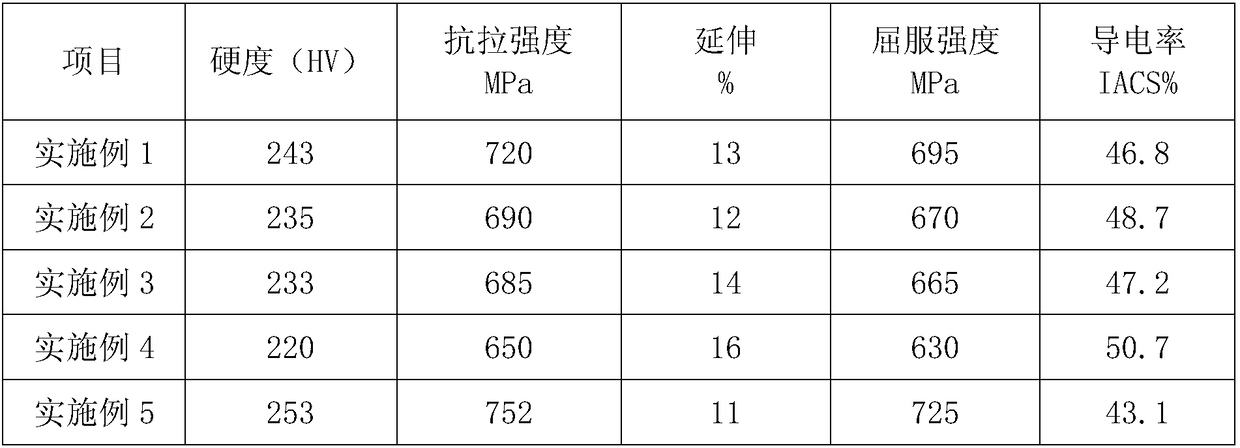

A kind of high-strength and high-conductivity cucrzrmg series copper alloy wire material and preparation method thereof

ActiveCN108060323BHigh strengthIncrease the number ofConductive materialMetal/alloy conductorsPower flowIngot casting

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

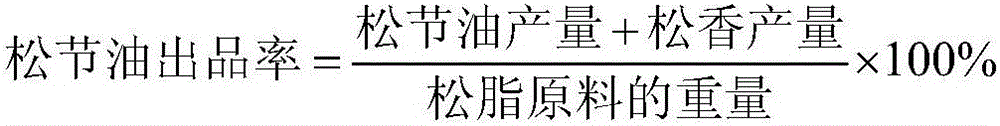

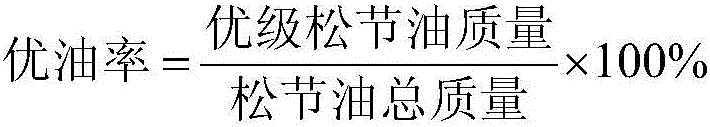

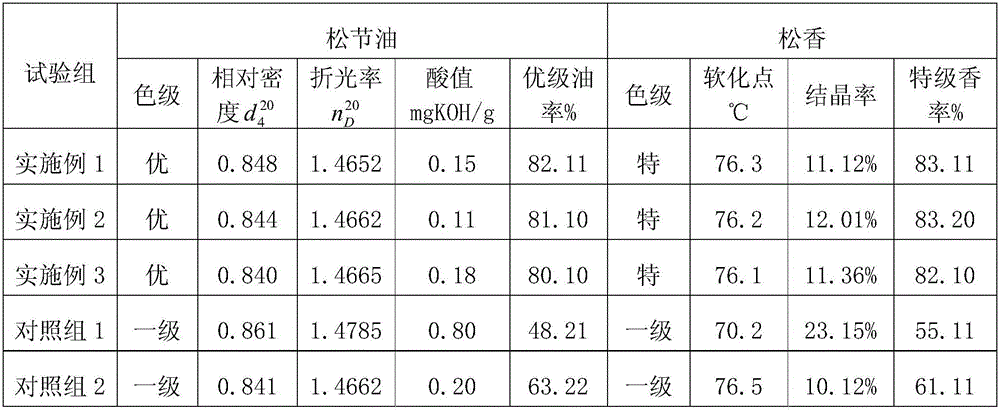

Pine resin processing method with pine resin processing yield increased

The invention relates to the field of pine resin processing and discloses a pine resin processing method with pine resin processing yield increased. The method includes the steps of pre-treatment, dissolution, water washing, clarification, residue recovery, distillation, and finish product collection. In the method, a raw material is pre-treated and is water-washed under supersonic wave; and during the dissolution, an internal heating coil is employed for heating the raw material, zeolite added to break the raw material; and meanwhile, through the residue recovery, vacuum distillation and the like, efficiency of pine resin processing is improved and yield of pine resin is increased. The method is free of big modification on devices and can achieve stable control, thereby achieving stable production and yield increasing.

Owner:广西兴业县新贵松脂厂

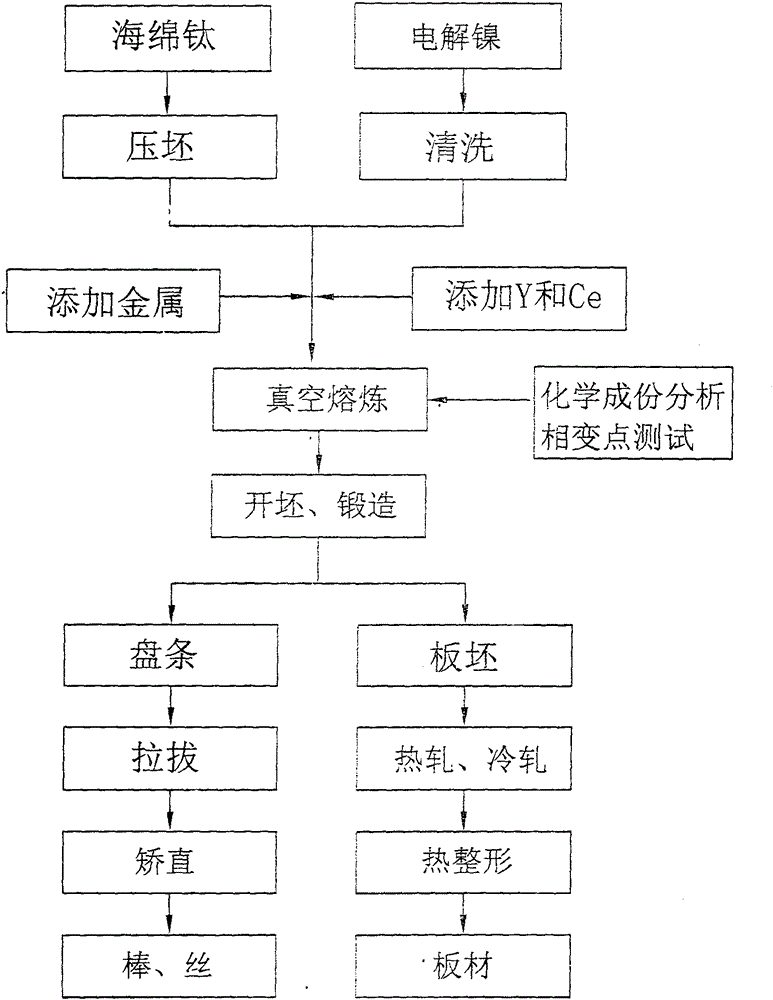

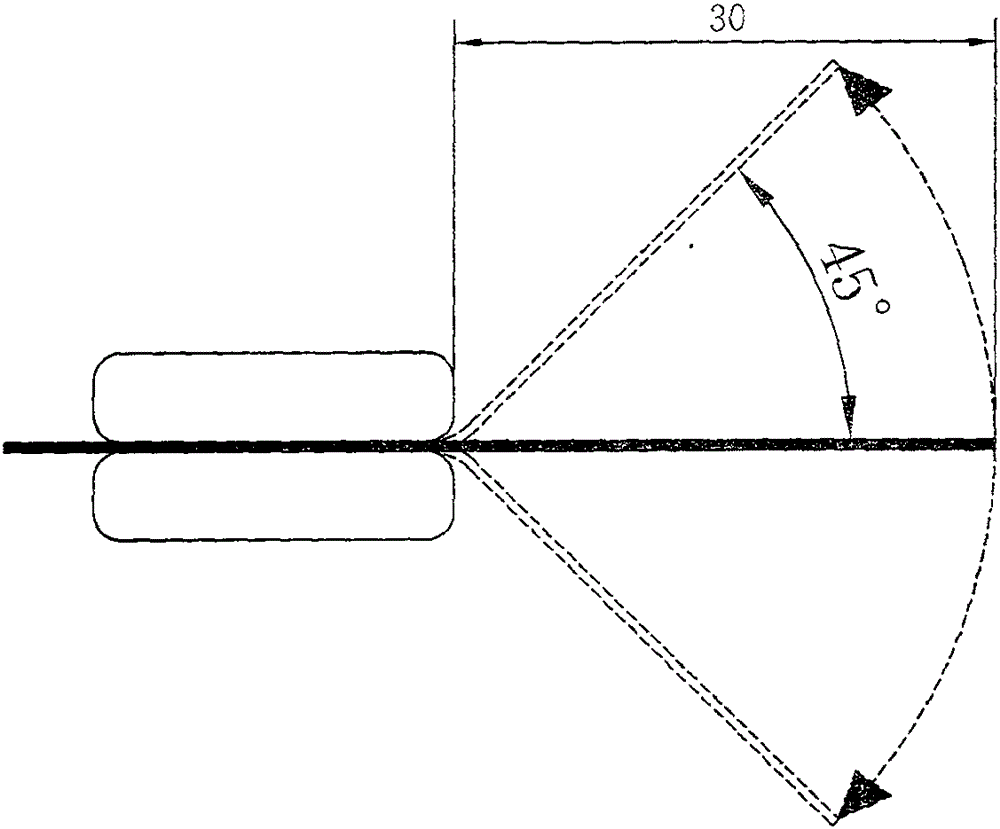

High-fatigue resistance titanium-nickel shape memory alloy

The invention relates to high-fatigue resistance titanium-nickel shape memory alloy and a preparation method thereof. The main components of the high-fatigue resistance titanium-nickel shape memory alloy comprise 43.5-46.0wt% of titanium (Ti), 54.0-56.5wt% of nickel (Ni), 0.1-0.8wt% of yttrium (Y) and cerium (Ce) and 0.5-1.0wt% of vanadium (V) and niobium (Nb); impurities comprise smaller than or equal to 0.05wt% of carbon, smaller than or equal to 0.05wt% of oxygen and nitrogen, smaller than or equal to 0.005wt% of hydrogen, and smaller than or equal to 1.5wt% of other few added elements and inevitable impurities. The high-fatigue resistance titanium-nickel shape memory alloy has relatively high fatigue resistance, has a variety of industrial and medical applications, and is especially applicable to devices requiring relatively good fatigue resistance.

Owner:深圳市星河泉新材料有限公司

Automatic slag splashing control method and system for converter

ActiveCN112981033AHigh viscosityHigh melting pointManufacturing convertersProcess efficiency improvementSlagControl system

The invention discloses an automatic slag splashing control method and system for a converter, and belongs to the technical field of converter slag splashing furnace protection. The control method comprises the steps that firstly, final slag conditions are classified according to the end point oxygen content, the end point carbon content and the residual manganese yield range in molten steel; secondly, according to different final slag conditions, slag adjusting materials with the corresponding weights are selectively added into the converter to adjust the viscosity of the slag, and the content of magnesium oxide in the final slag is made to be 10%-15%; and thirdly, corresponding slag splashing gun position curves are selected according to different final slag conditions, and the control system is used for carrying out automatic slag splashing operation. The automatic slag splashing control method and system have the beneficial effects that the slag adjusting materials with corresponding weights are added according to the different final slag conditions for slag adjusting, the corresponding slag splashing gun positions are automatically selected, the automatic slag splashing operation is completed, and the slag splashing operation is standardized. The labor intensity of workers is lowered, the slag splashing time is shortened, the nitrogen consumption is reduced, and the furnace profile can be more stable to maintain.

Owner:新余钢铁股份有限公司

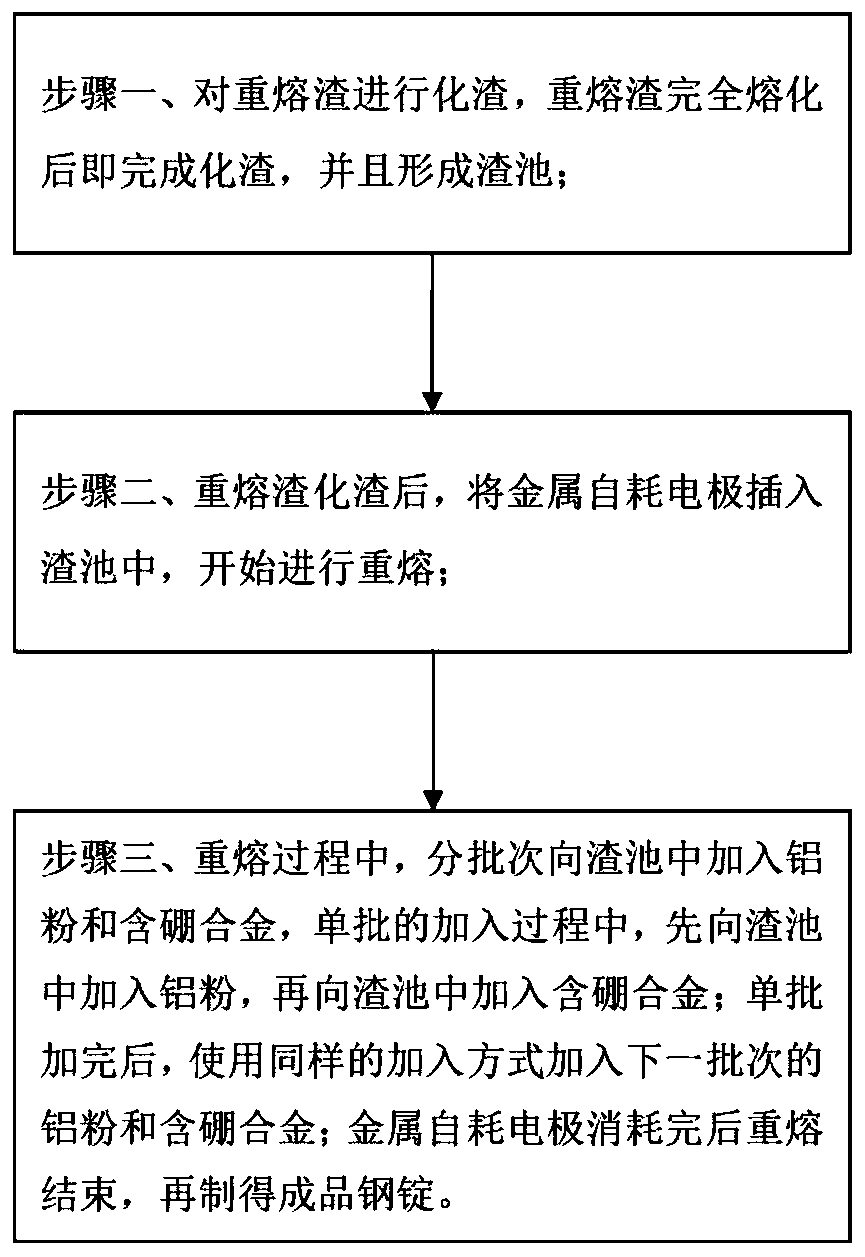

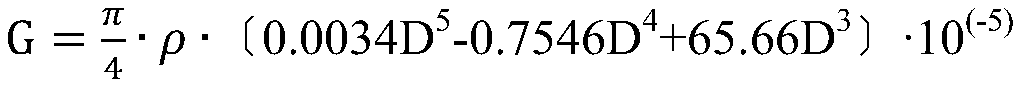

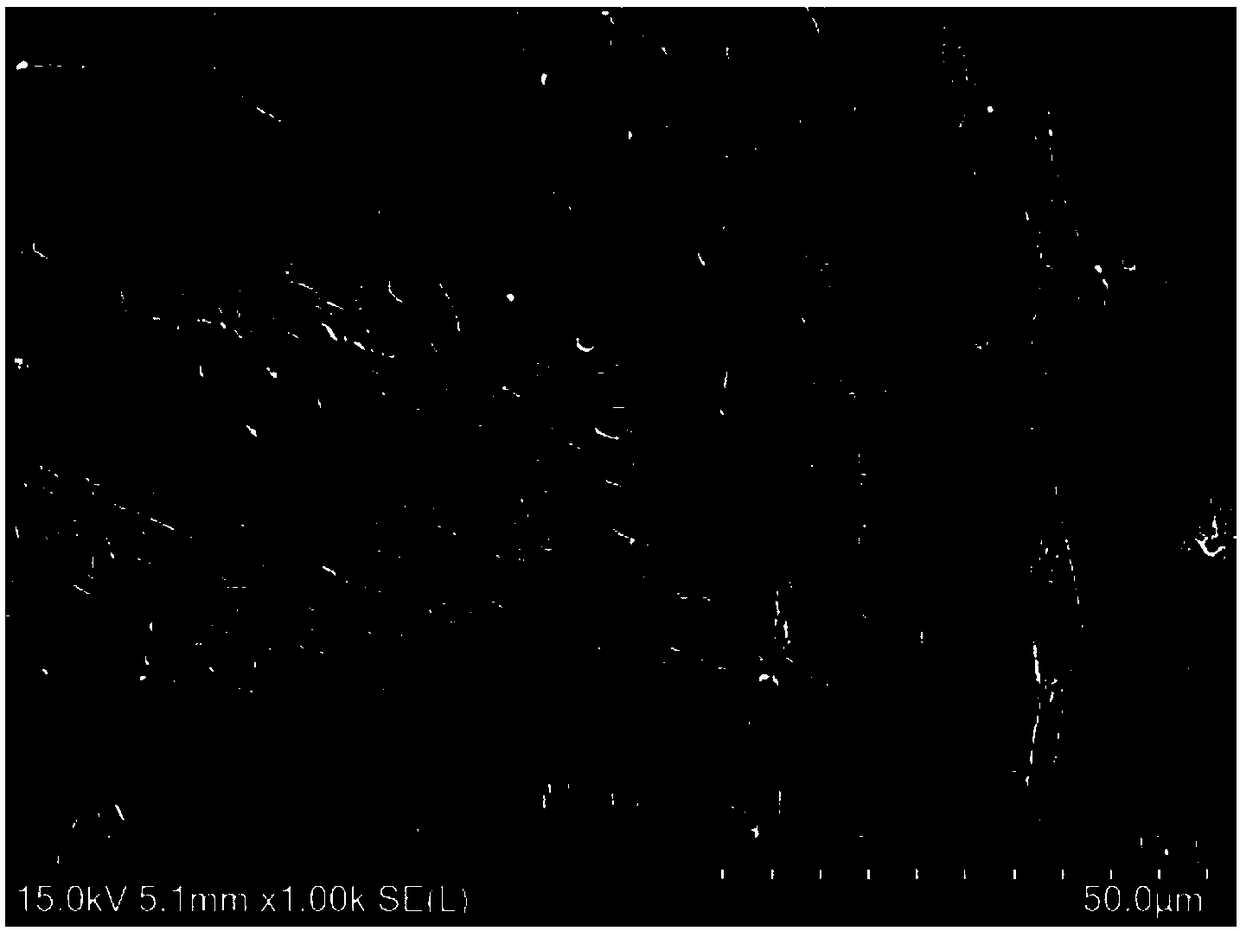

Method for conducting boron alloying in electro-slag remelting process

The invention discloses a method for conducting boron alloying in the electro-slag remelting process and relates to the technical field of electro-slag remelting. In the electro-slag remelting process, after a metal consumable electrode is inserted into a slag bath and starts remelting, boron-contained alloy composed of Al-B-Fe is added to the slag bath, and then boron alloying is conducted on steel of metal consumable electrode. The boron alloy is added into the slag bath, so that Al in the boron-contained alloy can locally conduct targeted deoxidation around the B element, it is avoided thatthe B element is oxidized in the adding process, and therefore the final yield of the B element is improved; in addition, after the boron-contained alloy composed of the Al-B-Fe is added, the boron-contained alloy can rapidly pass across the slag bath to float between interfaces of the slag bath and a melting bath, on one hand, doping can be avoided, and on the other hand, rapid alloying of molten steel is facilitated.

Owner:马鞍山市中桥金属材料有限公司

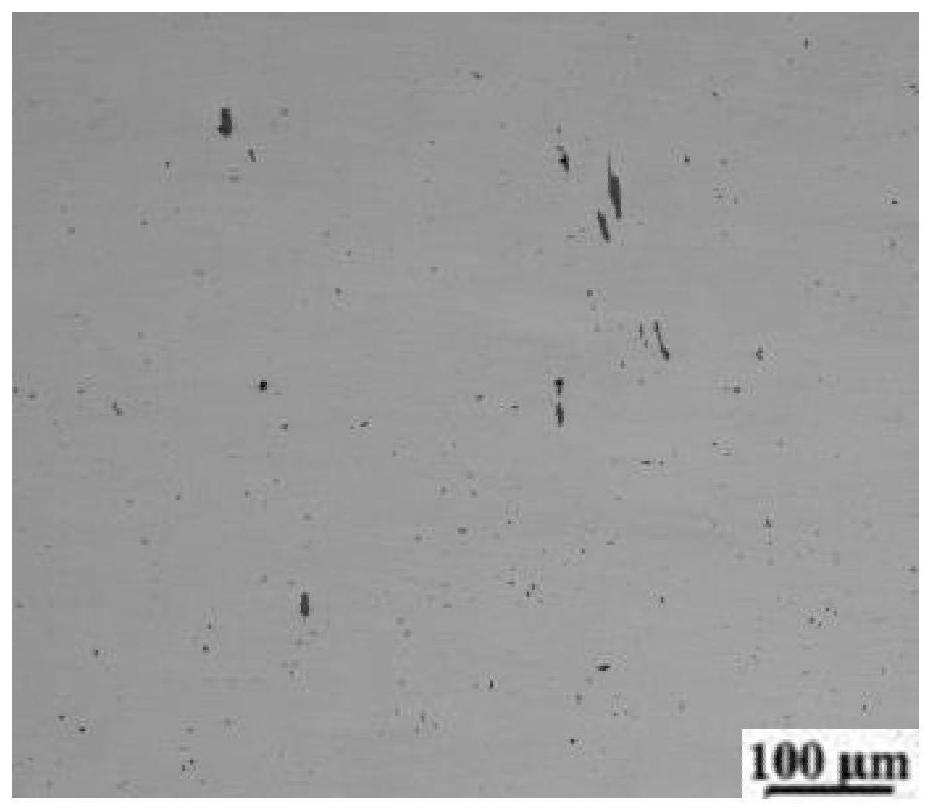

Novel martensitic heat-resistant steel alloy powder and method for manufacturing laser additive with complex flow channel structure by using same

ActiveCN108504928AControl oxygen contentGuaranteed not to be oxidizedAdditive manufacturing apparatusIncreasing energy efficiencySlagCerium

The invention relates to a novel martensitic heat-resistant steel alloy powder and a method for manufacturing a laser additive with a complex flow channel structure by using the same. The novel martensitic heat-resistant steel alloy powder comprises the following components in percentage by weight: 0.05-0.15% of carbon, 0.1-0.4% of silicon, 0.3-0.6% of manganese, 8.0-12.0% of chromium, 1.5-1.9% oftungsten, 0.1-0.8% of molybdenum, 0.1-0.3% of vanadium, 0.1-0.3% of tantalum, A% of lanthanum, B% of cerium and the balance of iron, wherein A is more than or equal to 0, B is more than or equal to0, and A+B is more than or equal to 0.05 and is less than or equal to 0.3. The novel martensitic heat-resistant steel alloy powder for manufacturing a laser additive, provided by the invention, has excellent forming process performance, the manufactured structure of the laser additive is a martensite+carbide structure, crystal grains are fine and uniform without a columnar crystal structure; and lanthanum and cerium are added to the alloy powder provided by the invention, so that not only can deoxidization be carried out during alloy forging, but also, by controlling the contents of lanthanumand cerium, the residual lanthanum and cerium will continue to play a role of deoxidizing and slagging in a micro-melting pool in a manufacturing process of the additive, so as to ensure that alloy elements are not oxidized and avoid the formation of oxide slag inclusion.

Owner:SUZHOU UNIV

Manufacturing process of seamless steel tube top

The invention discloses a manufacturing process of a seamless steel tube top. The seamless steel tube top is manufactured through the steps of wax mould manufacturing, mud mould manufacturing, air drying, roasting and casting, wherein when a mud mould is manufactured, silica sol, quartz sand and rice husks in a mass ratio of 100 to 100 to 50 are added to the mud mould. A ceramic mould obtained after roasting has high strength and good air permeability. The performances of the manufactured seamless steel tube top have superiority compared with the performances of the seamless steel tube tops manufactured by traditional methods. The manufacturing process has the advantages of simple steps, safety, practicability, and the like.

Owner:六安市春晖精密铸造有限责任公司

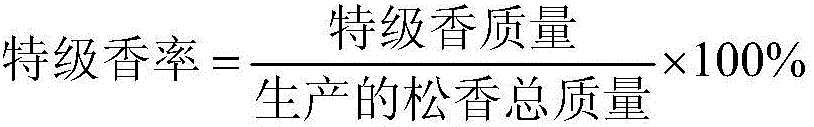

Processing method for improving rosin product quality

InactiveCN106349936AAct as a spectrum bactericidalImprove the bactericidal effectTurpentine spiritsNatural resin purificationDistillationWater quality

The invention relates to the field of rosin processing, and discloses a processing method for improving the rosin product quality. The processing method comprises the processes of pretreatment, dissolution, water washing, clarification, distillation and finished product segmented recovery; water for production is pretreated; low-oxygen sterile water is used for rosin storage and cleaning; meanwhile, an ultrasonic cleaning process is added for improving the turpentine oil and rosin quality; for the pretreatment, rosin is crushed, and is soaked and flushed by the low-oxygen sterile water; the processing method solves the problems that in the pretreatment process in the prior art, the low-oxygen sterile water quality treatment is complicated, the reagent treatment can cause secondary pollution, and substances such as pigment in the rosin cannot be fully removed in the water washing process of commonly used resin processing; the goals of simply and efficiently treating the low-oxygen sterile water, avoiding secondary pollution and improving the turpentine oil and rosin quality are achieved.

Owner:广西兴业县新贵松脂厂

Powder core wire for electric arc spraying and preparing method of powder core wire

InactiveCN107557717AAvoid the problem of grain coarseningHigh mechanical strengthMolten spray coatingAl powderHigh density

The invention belongs to the technical field of alloy material preparing, and particularly relates to a powder core wire for electric arc spraying and a preparing method of the powder core wire. B powder and Zn powder serve as raw materials for preparing Zn-B alloy powder, Mg powder, Al powder and B powder serve as raw materials, Mg-Al alloy powder is prepared, and after the Al powder, the Zn powder, the Zn-B alloy powder and the B2O3 powder are heated and melted, a Zn-Al alloy belt is prepared through continuous casting, hot rolling, coiling and other procedures and is bent and dried, and then a dry U-shaped groove is prepared through drying; and then, the Zn powder, the Al powder, the Mg-Al alloy powder and the rare earth powder are mixed and dried to be added into the dry U-shaped groove, after the dry U-shaped groove is sealed, the wire is prepared through level-by-level drawing, and then the powder core wire for electric arc spraying is obtained. The obtained wire is high in hardness and good in mechanical performance, reliable wire feeding can be achieved during spraying, long-time stable spraying can be guaranteed, and the coating obtained after spraying has good mechanicalperformance, excellent corrosion resisting performance and high density.

Owner:常州市丰瑞电子有限公司

Aluminum alloy smelting process

InactiveCN109097611AReduces adverse effects of porosityImprove mechanical propertiesDehydrogenationOxygen

The invention relates to an aluminum alloy smelting process. The aluminum alloy smelting process is characterized by comprising the following steps of S1, preparing an aluminum alloy smelting tool; S2, cleaning a crucible; S3, carrying out aluminum ingot treatment; S4, smelting aluminum ingots; S5, carrying out treatment of a refining agent and a modifying agent; S6, adding the refining agent; S7,adding the modifying agent; S8, sampling and testing; and S9, casting products; and the surface of an appliance is treated before melting, temperature is controlled in the melting process, the refining agent is added in three times and is used as an additive, and a small amount of inert gas generated in the melting process can effectively bring tiny nonmetallic inclusions in a melt body to the liquid surface to easily react with oxygen, hydrogen and the like, so that roles of dehydrogenation, deoxidation, descaling and the like can be realized, and aluminum liquid is purified. In the meltingprocess, the modifying agent is added to promote the nucleation of metal liquid and change the crystal growth process, so that the mechanical property and corrosion resistance of aluminum alloy obtained according to the aluminum alloy smelting process are greatly improved.

Owner:HAIMEN HUHAI NONFERROUS CASTING

Preparation method for V-Ti-based hydrogen storage alloy

InactiveCN105441985AHigh porosityIncrease the solid-liquid contact areaCell electrodesElectrolysisSlag

The invention discloses a preparation method for V-Ti-based hydrogen storage alloy. The preparation method comprises the steps that preparation of the V-Ti-based hydrogen storage alloy is conducted sequentially through a molten salt electrolysis method and a vacuum melting method; a cathode of the molten salt electrolysis method is prepared from vanadium oxide, titanic oxide, addition agents and binding agents through sintering, the cathode obtained through sintering and a graphite anode are subjected to a molten salt electrolysis reaction in a molten slat electrolyte, and V-Ti intermediate alloy is obtained; and vacuum refining is conducted on the V-Ti intermediate alloy, and the V-Ti-based hydrogen storage alloy is obtained. According to the preparation method, cheap metallic oxides serve as raw materials for preparing the V-Ti-based hydrogen storage alloy, and thus the preparation cost of the alloy is reduced easily; the alloy prepared through the method is flexible and adjustable in content, simple in technique and low in impurity content; no waste slag or smoke is generated, and environmental friendliness is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Antioxidant red mud doped coating for high-temperature steel billet

InactiveCN113025094AAvoid contactEnhanced Antioxidant ProtectionFireproof paintsAlkali metal silicate coatingsRed mudOxidation resistant

The invention relates to an antioxidant red mud doped coating for a high-temperature steel billet. The coating comprises red mud, silicon dioxide, carboxymethyl cellulose, aluminum oxide, magnesium oxide, graphite powder, sodium silicate and water. The mixed powder comprises the following main components in percentage by mass: 15-50% of red mud powder, 20-60% of silicon dioxide powder, 15-75% of aluminum oxide powder, 1-20% of graphite powder, 1-20% of magnesium oxide powder, 5-15% of a high-temperature binder and 0.4-1% of a dispersant. According to the invention of the anti-oxidation coating, the utilization value of the red mud is improved, the treatment capacity of red mud waste is increased, and the pressure of the red mud on the environment is reduced; The antioxidation coating is low in preparation cost and small in environmental pollution, does not pulverize or crack in a high-temperature environment after being brushed, sprayed or dip-coated on a steel billet, forms a layer of compact protection film on the surface of the steel billet, and has good anti-oxidation performance in the heating and heat preservation processes of the steel billet.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

High-strength steel submerged-arc stranded wire and welding method thereof

InactiveCN110614458AImprove toughnessBest Match Chemical CompositionArc welding apparatusWelding/cutting media/materialsManganeseWeld seam

The invention discloses a high-strength steel submerged-arc stranded wire. The high-strength steel submerged-arc stranded wire comprises the following components of, by mass percentage, 0.08-1.2% of carbon, 0.4-0.8% of manganese, 0.05-0.1% of copper, 0.1-0.2% of nickel, 0.1-0.2% of zirconium, 0.11-0.18% of silicon, 0.02-0.08% of molybdenum, 0.01-0.02% of titanium, 0.2-0.4% of boron, less than 0.01% of phosphorus, not larger than 0.005% of sulfur and the balance iron and inevitable impurities. The invention discloses a welding method of the high-strength steel submerged-arc stranded wire. The welding method comprises the steps that a steel plate to be welded is pretreated, then the inner side welding and the outer side welding are carried out, and then heating, heat preservation and air cooling are carried out. A welding seam formed by welding has the beneficial effects of being good in low-temperature impact toughness, low in yield ratio, high in strength, attractive in forming and thelike; and moreover, the welding spatter is small, and the welding process performance is excellent.

Owner:河北联之捷焊业科技有限公司

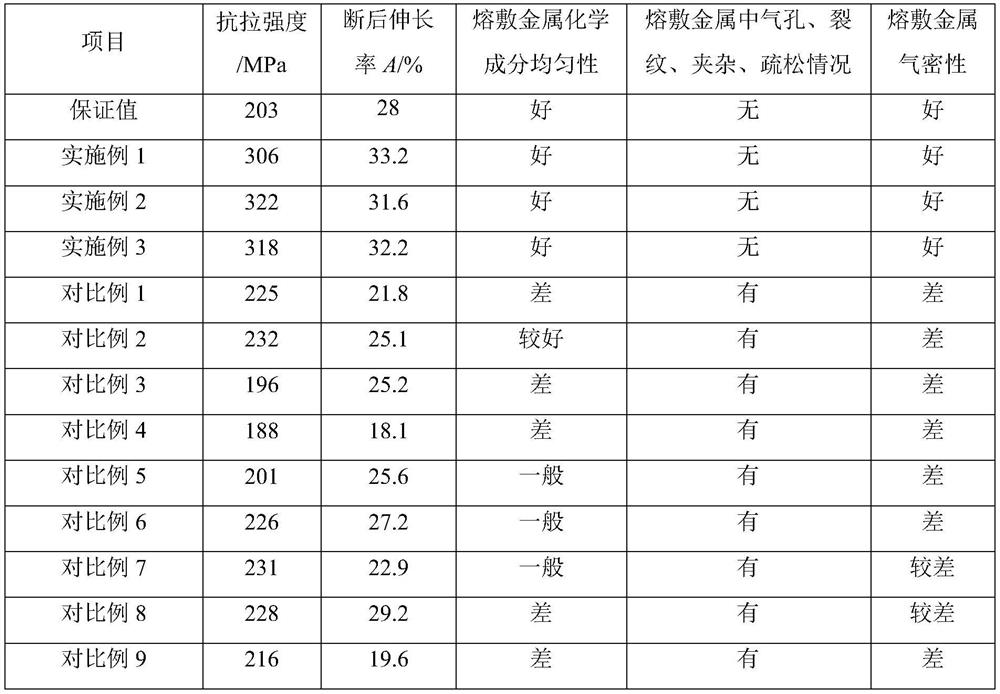

Matched flux-cored wire for medical gas and vacuum seamless copper pipe fusion welding

ActiveCN112077476AUniform chemical compositionHigh droplet temperatureWelding/cutting media/materialsSoldering mediaPipeFusion welding

The invention belongs to the field of welding materials, and particularly relates to a matched flux-cored wire for medical gas and vacuum seamless copper pipe fusion welding. The matched flux-cored wire comprises a TU1 semi-hard copper alloy sheath and a flux core; the flux core comprises 2.1%-3.2% of CuSi16 powder, 2.2%-3.0% of CuMn30 powder, 1.5%-2.2% of CuP12 powder, 3.0%-3.8% of AlSr40 powder,2.8%-3.6% of nanometer F3Ti powder, 3.2%-4.5% of nanometer NdF3 powder, and the balance FTD1 electrolytic copper powder; and the filling rate of the flux core is 32%-38%. Chemical components of deposited metal are uniform, inclusion, cracks and air hole defects are avoided, the air tightness is good, the minimum value of the tensile strength of the deposited metal is 306 MPa, the minimum value ofthe percentage elongation after fracture is 31.6%, and a component formed by fusion welding the seamless copper pipe completely meets the medical gas and vacuum requirements.

Owner:ZHENGZHOU UNIV

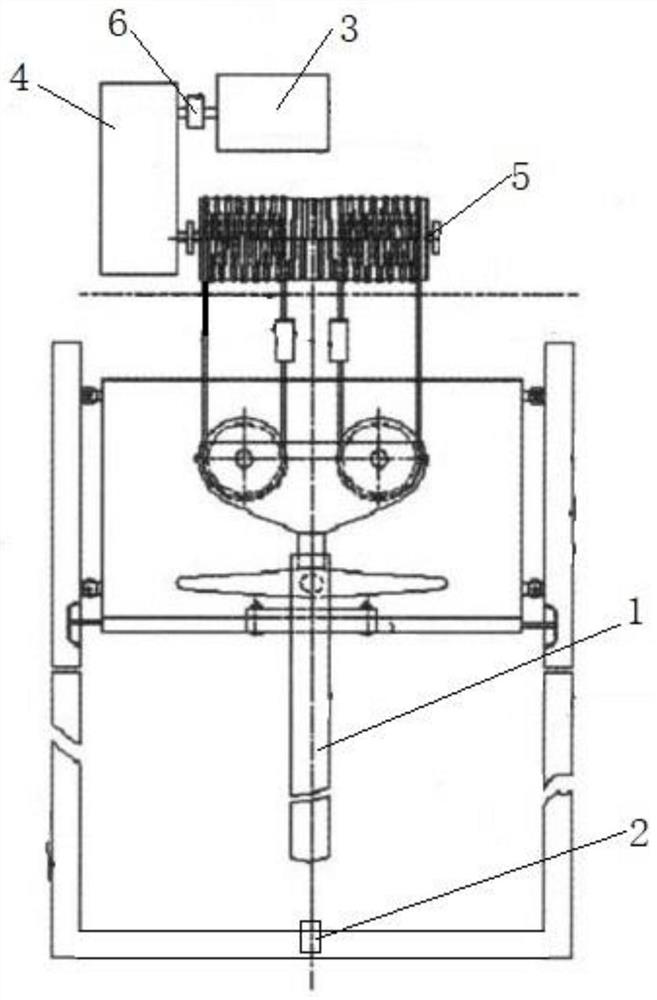

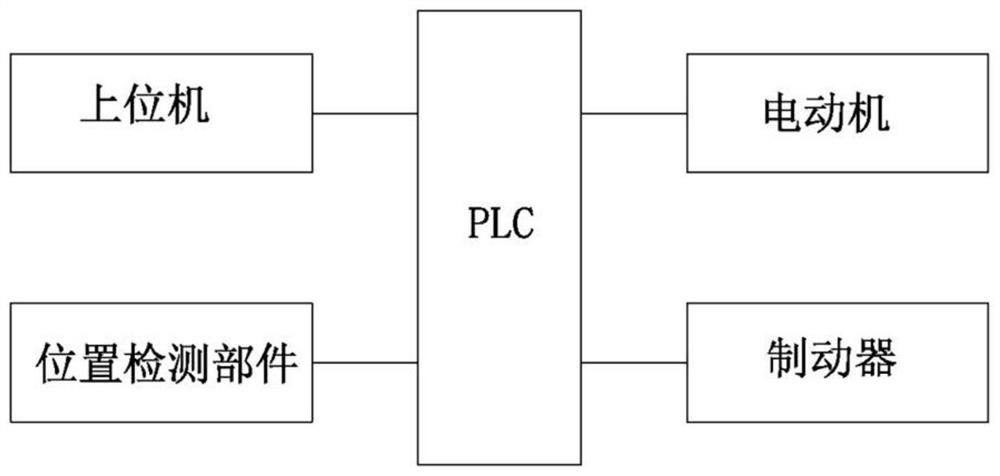

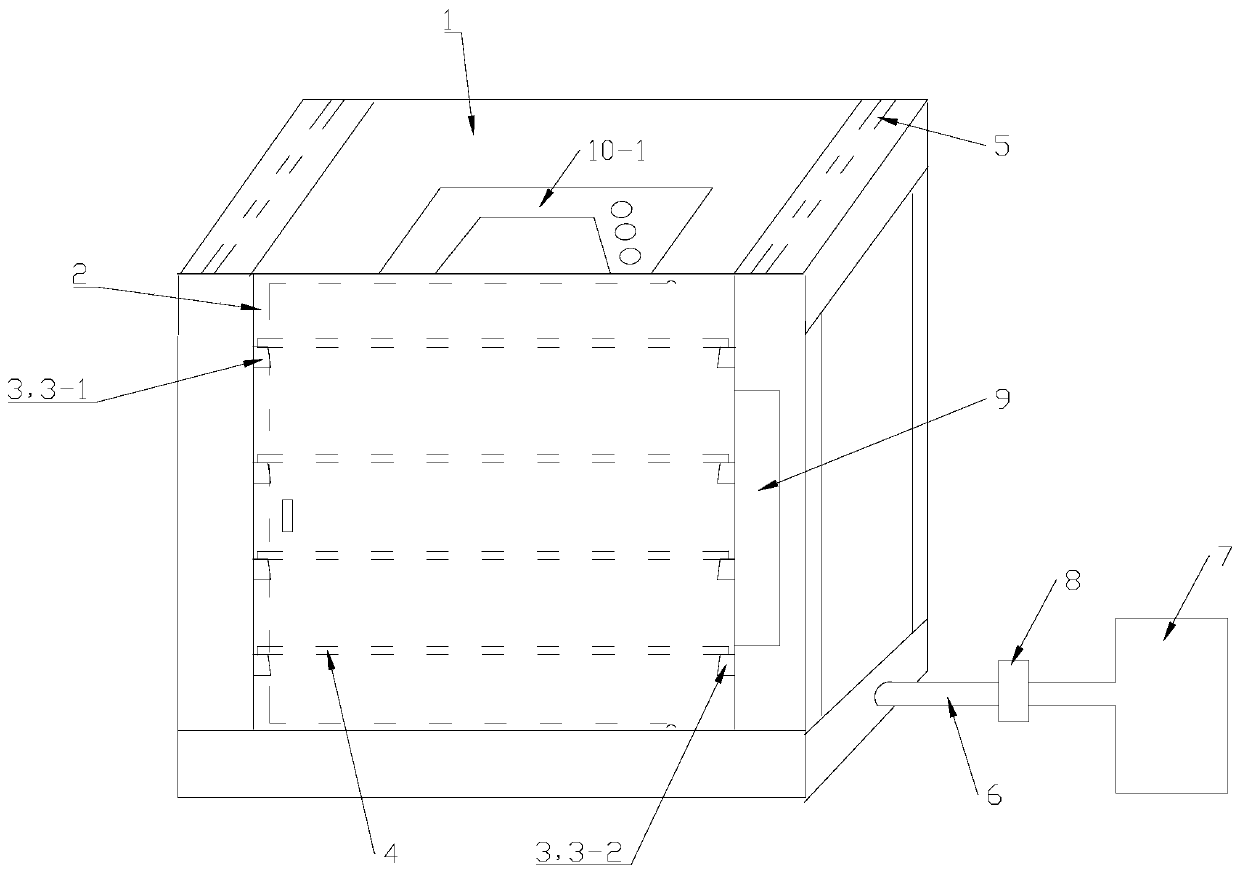

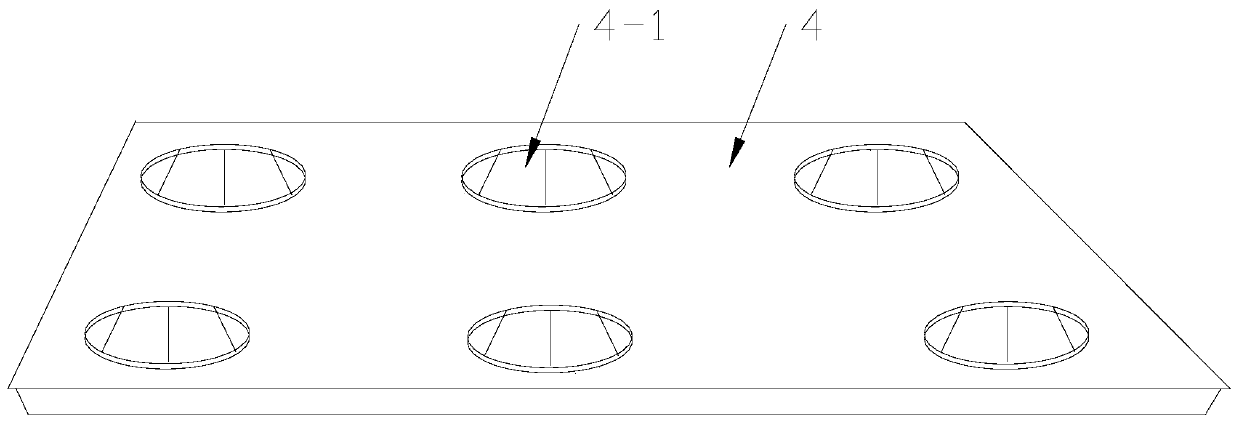

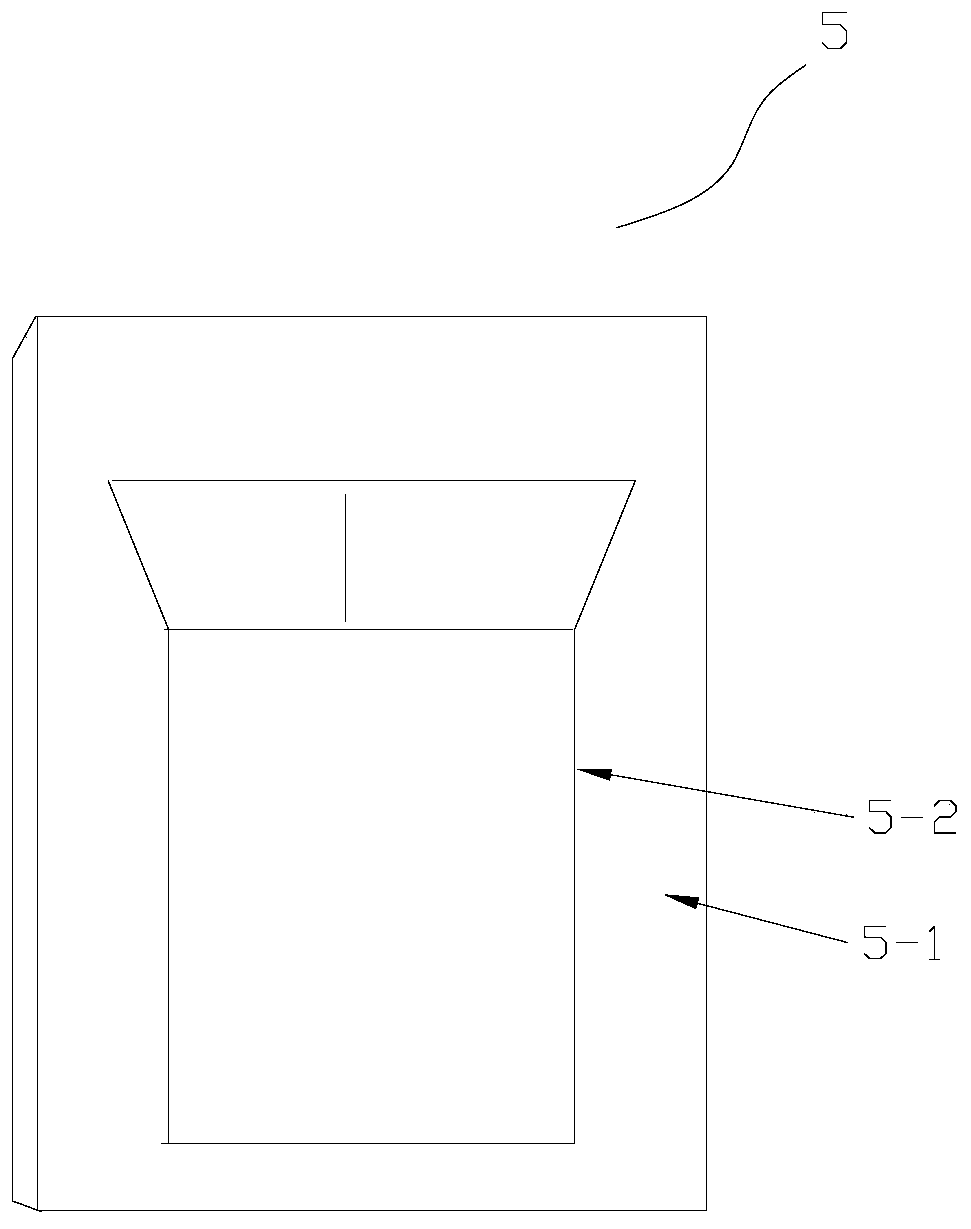

An anaerobe incubator

PendingCN109706055AAccurate on-site detectionImprove timelinessBioreactor/fermenter combinationsBiological substance pretreatmentsNitrogen sourceControl valves

An anaerobe incubator is disclosed, including a tank body the front surface of which is hinged with a tank door. A layer isolating rack is disposed in the tank body and provided with a plurality of microbe culture trays the tops of which are provided with a plurality of tray holes for receiving culture. Deoxygenizing plates are disposed in the tank body and include fixing plates for matched installation with the tank body. The fixing plates are provided with drug bins containing deoxygenizing agents. The bottom side surface of the tank body is hermetically connected to a nitrogen source through a pipe provided with a control valve. The tank body is provided with a temperature and humidity control device. The anaerobe incubator can provide a sealed anaerobic environment for anaerobe, is simple in structure, flexible to operate and low in cost, can improve timeliness of samples to be detected and achieve in-time accurate on-site detection of the anaerobe.

Owner:NANTONG SCI & TECH VOCATIONAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com