High red hard boron-containing high speed steel and preparation method thereof

A high-speed steel and red hardness technology, applied in the field of high red hardness boron-containing high-speed steel and its preparation, can solve the problems of increased tendency of decarburization, decreased material toughness, segregation of solidified structure components, etc., to improve red hardness and anti-oxidation Enhanced hardenability and excellent hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] It is melted in a 10kg vacuum induction melting furnace. Furnace materials are ferroboron, pig iron, ferrochrome, ferromolybdenum, pure aluminum, ferrosilicon, ferrovanadium, ferromanganese and steel scrap. All furnace materials are broken into about 15mm blocks. The furnace is filled with ferrochromium, ferromolybdenum, pig iron and steel scraps and starts heating, and heat preservation starts when the temperature rises to 1600°C. Keep warm until the 4th minute, add ferromanganese and ferrosilicon; add ferrovanadium at the 6th minute; add ferroboron and pure aluminum at the 9th minute. After the molten steel comes out of the furnace, the temperature is lowered to about 1500°C, and the slag is removed and poured into the preheated metal mold. When pouring, use a ceramic foam filter to purify the molten steel at the gate.

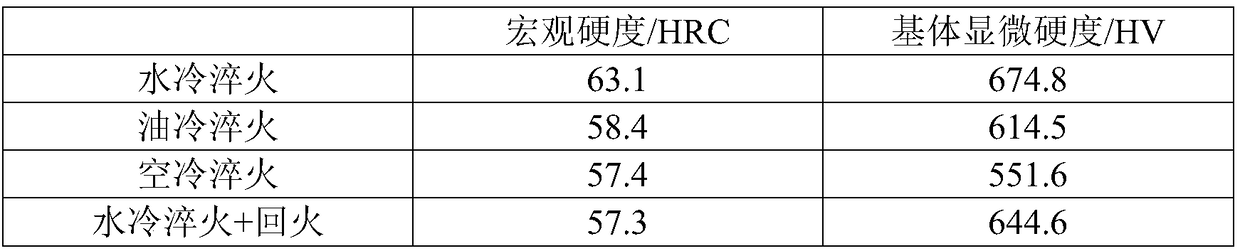

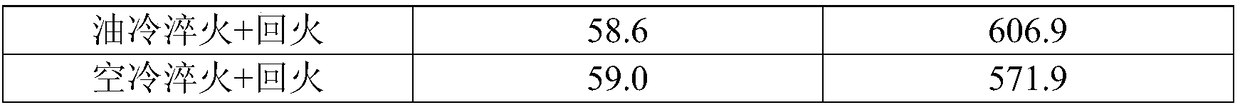

[0035] After the casting is obtained, it is divided into 3 parts on average, and after being kept at 1050°C for 2 hours, water cooling, oil coolin...

Embodiment 2

[0037] It is melted in a 500kg induction melting furnace. Furnace materials are ferroboron, pig iron, ferrochrome, ferromolybdenum, pure aluminum, ferrosilicon, ferrovanadium, ferromanganese and steel scrap. The furnace is filled with ferrochromium, ferromolybdenum, pig iron, and steel scraps and starts heating, and heat preservation starts when the temperature rises to 1600°C. Keep warm until the 4th minute, add ferromanganese and ferrosilicon; add ferrovanadium in the 6th minute; add ferroboron and pure aluminum in the 9th minute. After the molten steel comes out of the furnace, the temperature is lowered to about 1500°C, and the slag is removed and poured into the mold. The chemical composition of the castings is shown in Table 1.

[0038] After the casting is cleaned, it is water-cooled and quenched at 1050 ° C for 2 hours, and then it is tempered at 600 ° C for 1 hour and then furnace-cooled four times to investigate its red hardness.

[0039] The macrohardness and mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com