High alloy cutting tool steel for wood-working machine rotary cutter blades and hot processing process of high alloy cutting tool steel

A technology of alloy cutting tool steel and woodworking machinery, applied in the direction of metal rolling, etc., can solve the problems of not meeting the needs of slicing and rotary cutting thin veneer, low strength, toughness and wear resistance, etc., to achieve improved strength and toughness, good red hardness , the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A high-alloy cutting tool steel, the cutting tool steel includes: carbon 0.69%, silicon 0.95%, manganese 0.55%, chromium 8.20%, vanadium 0.40%, tungsten 1.45%, molybdenum 1.90%, sulfur 0.003, phosphorus 0.002, The remaining content is iron.

[0039] A hot working process for high-alloy cutting tool steel, comprising the steps of:

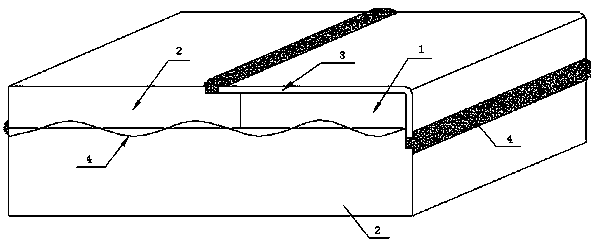

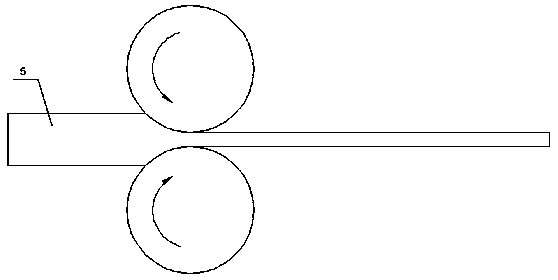

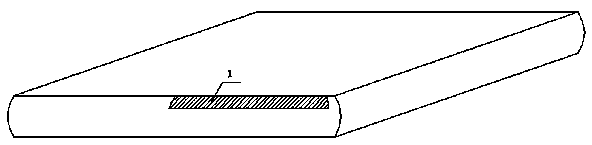

[0040] (1) Ingredients: place the cutting tool steel 1 in the cavity formed by welding and sealing the carbon steel plate (Q235) 2 and the iron plate 3 4, the cutting tool steel 1 is closely combined with the carbon steel plate 2 and the iron plate 3 to form a composite plate 5.

[0041] The "composite plate" mentioned in the present invention refers to the composite plate formed by placing the cutting tool steel of the present invention in a cavity formed by welding and sealing plates different from the cutting tool steel. Any welding oxide layer, the air volume in the cavity is quite small (such as figure 1 shown). Wherein the iron pla...

Embodiment 2

[0049] A high-alloy cutting tool steel, the cutting tool steel includes: carbon 0.58%, silicon 0.75%, manganese 0.35%, chromium 7.20%, vanadium 0.20%, tungsten 0.95%-1.45%, molybdenum 1.55%, sulfur 0.003%, Phosphorus 0.003, the remaining content is iron.

[0050] A hot working process for high-alloy cutting tool steel, comprising the steps of:

[0051] (1) Ingredients: place the cutting tool steel 1 in the cavity formed by welding and sealing the carbon steel plate (Q235) 2 and the iron plate 3 4, the cutting tool steel 1 is closely combined with the carbon steel plate 2 and the iron plate 3 to form a composite plate 5.

[0052] The "composite plate" mentioned in the present invention refers to the composite plate formed by placing the cutting tool steel of the present invention in a cavity formed by welding and sealing plates different from the cutting tool steel. Any welding oxide layer, the air volume in the cavity is quite small (such as figure 1 shown).

[0053] (2) ...

Embodiment 3

[0059] A high-alloy cutting tool steel, the cutting tool steel includes: carbon 0.65%, silicon 0.85%, manganese 0.45%, chromium 7.70%, vanadium 0.30%, tungsten 1.15%, molybdenum 1.78%, sulfur 0.003%, phosphorus 0.002% by weight percentage %, and the rest is iron.

[0060] A hot working process for high-alloy cutting tool steel, comprising the steps of:

[0061] (1) Ingredients: place the cutting tool steel 1 in the cavity formed by welding and sealing the carbon steel plate (Q235) 2 and the iron plate 3 4, the cutting tool steel 1 is closely combined with the carbon steel plate 2 and the iron plate 3 to form a composite plate 5.

[0062] The "composite plate" mentioned in the present invention refers to the composite plate formed by placing the cutting tool steel of the present invention in a cavity formed by welding and sealing plates different from the cutting tool steel. Any welding oxide layer, the air volume in the cavity is quite small (such as figure 1 shown).

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com