Iron-based composite powder high in chromium content for laser cladding

A technology of composite powder and laser cladding, which is applied in the coating process and coating of metal materials to achieve the effect of improving smoothness and brightness, preventing electrochemical corrosion, and combining well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

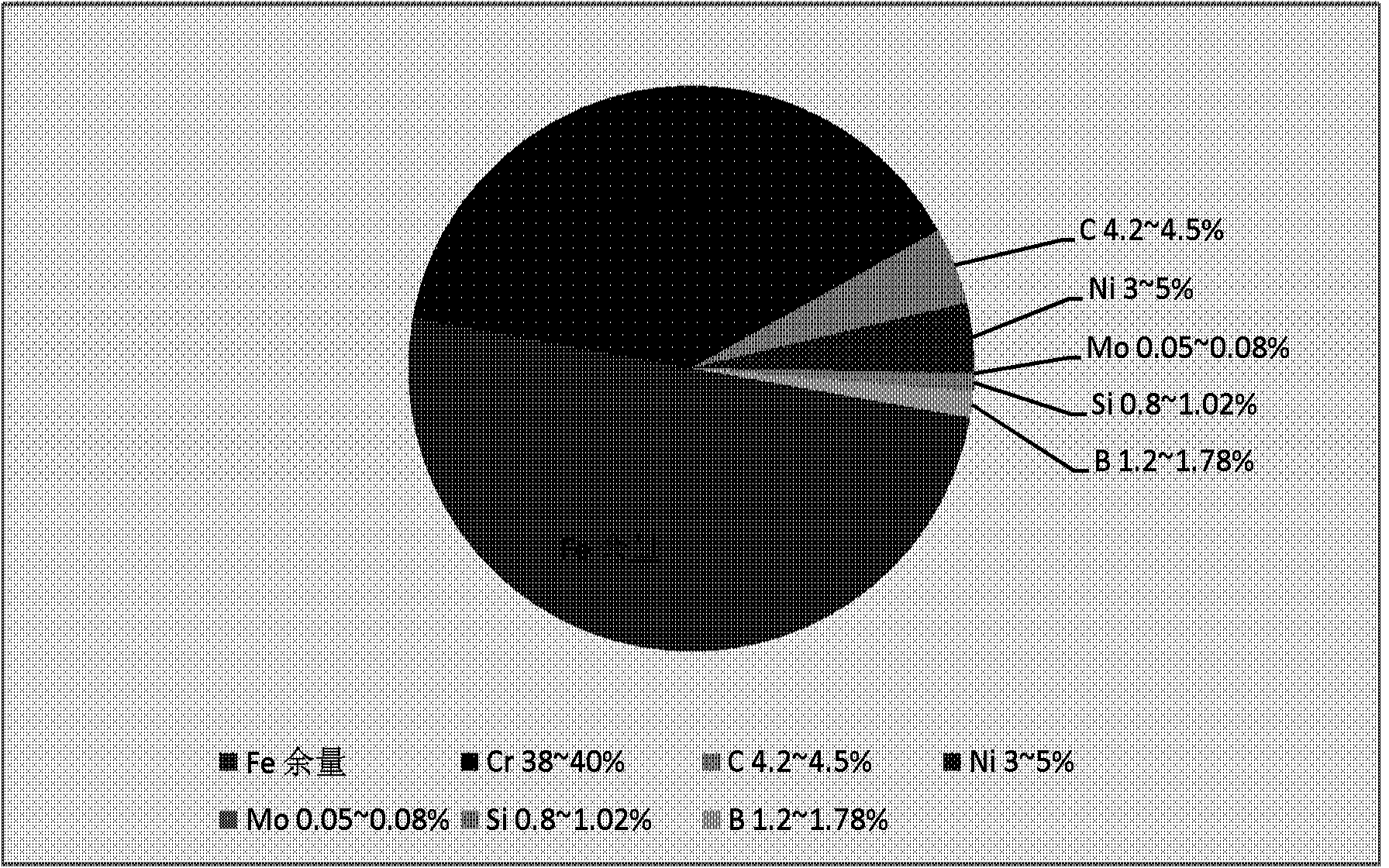

[0026] Such as figure 1 as shown, figure 1 It is a schematic diagram of the composition ratio of the iron-based composite powder containing high chromium content for laser cladding provided by the present invention. The iron-based composite powder is composed of Cr 3 C 2 , Cr and Fe compounds, and Ni, Mo, Si and B elements. Wherein, the mass percentage of each element in the iron-based composite powder is: Cr: 38-40%; C: 4.2-4.5%; Ni: 3-5%; Mo: 0.05-0.08%; Si: 0.8-1.02%; B: 1.2-1.78%; the rest is Fe. The particle size of the iron-based composite powder is between +140 mesh and -325 mesh.

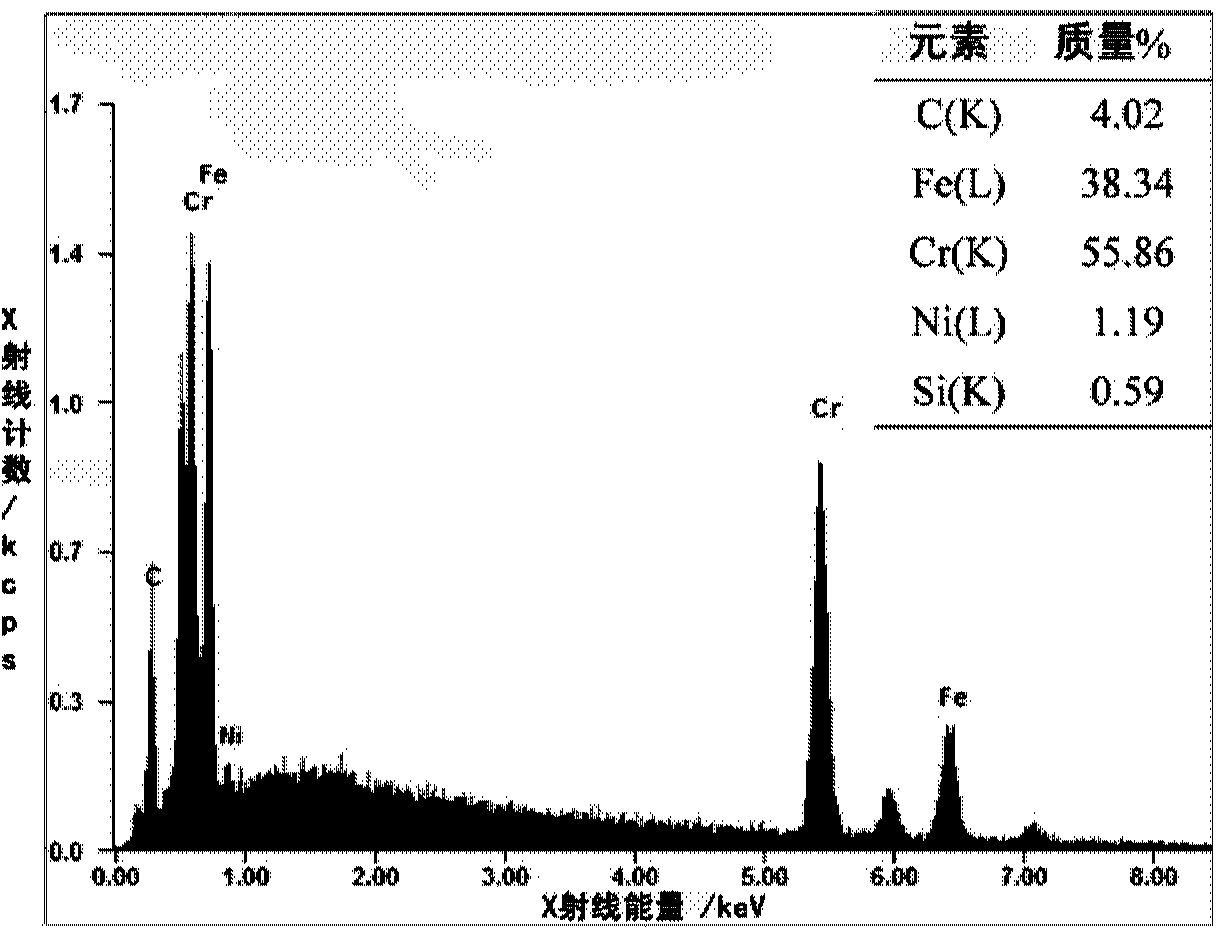

[0027] For the above-mentioned iron-based composite powder with high chromium content used for laser cladding, the analysis of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com