High zinc-silicon-boron-ferro copper alloy

A technology of iron-copper alloy and copper alloy, which is applied in the field of high-zinc-silicon-boron-iron-copper alloy, can solve the problems of expensive production equipment, complicated preparation process, and increased production cost, and achieve fast moving speed, good deoxidation performance, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

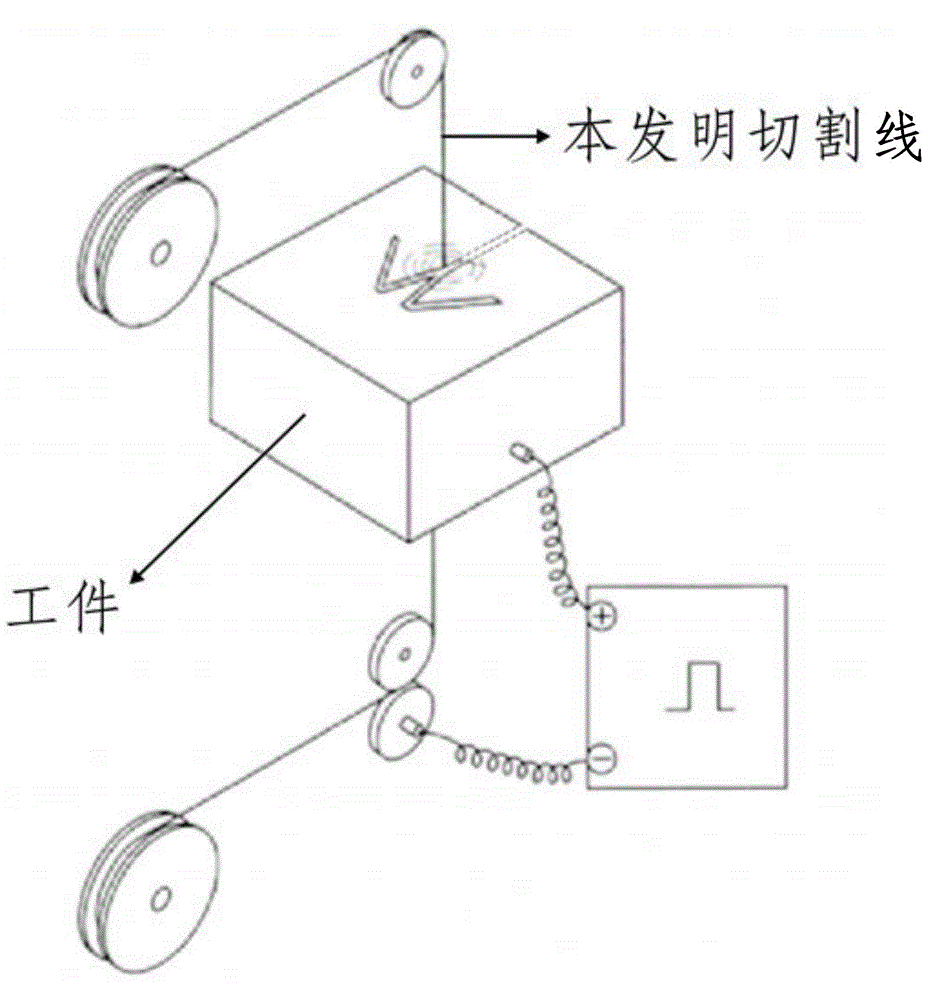

Image

Examples

Embodiment

[0034]1.1. Purchasing copper, zinc, silicon, boron, iron and rare earth raw materials at an appropriate price in the market, and start batching after passing the chemical analysis;

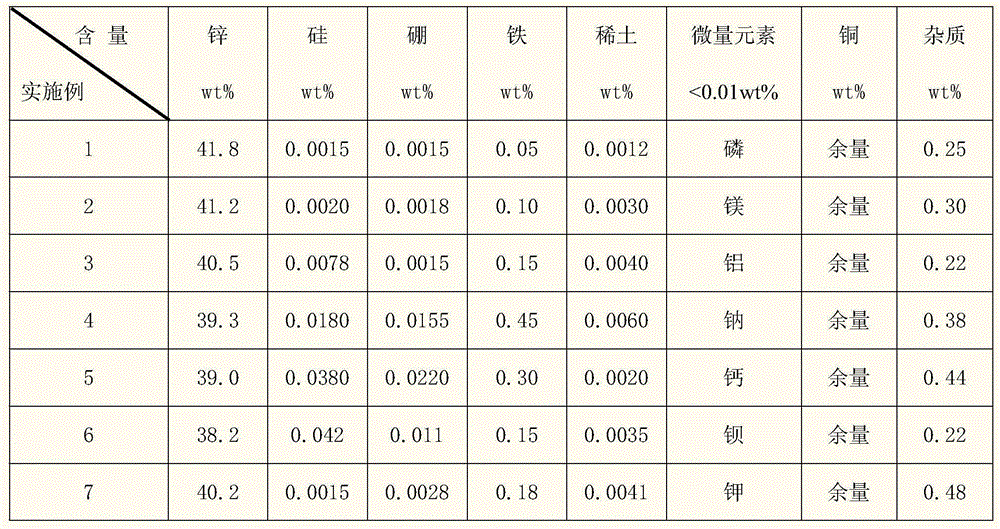

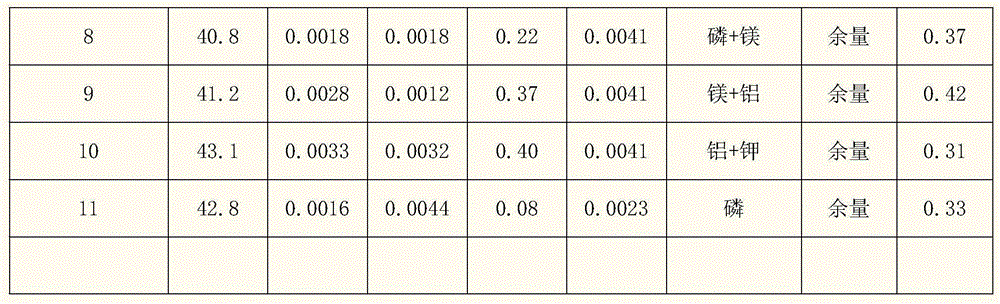

[0035] 1.2. Carry out alloying ingredients according to the alloy composition shown in Table 1, and transport the prepared raw materials to the smelting site for smelting;

[0036] 1.3. Melting is an important process for manufacturing cutting wire materials. The addition of all alloying elements is completed in this process. The smelting adopts upward continuous casting, the casting temperature is selected as 950-1100 degrees Celsius, and the total amount of alloy raw materials added is 0.1%. Cryolite and charcoal are mixed and covered, and the covering thickness is greater than 5cm. Using the above covering method can purify the metal solution;

[0037] 1.4. Plastic processing and recrystallization annealing: This process mainly refers to the plastic processing of the manufactured upward continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com