High-fatigue resistance titanium-nickel shape memory alloy

A memory alloy and fatigue performance technology, applied in the field of titanium-nickel shape memory alloy, can solve problems such as fatigue fracture, accidental injury of patients, loss of function of tracheal stent, etc., and achieve good fatigue resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: Preparation of a titanium-nickel shape memory alloy with high fatigue resistance of the present invention

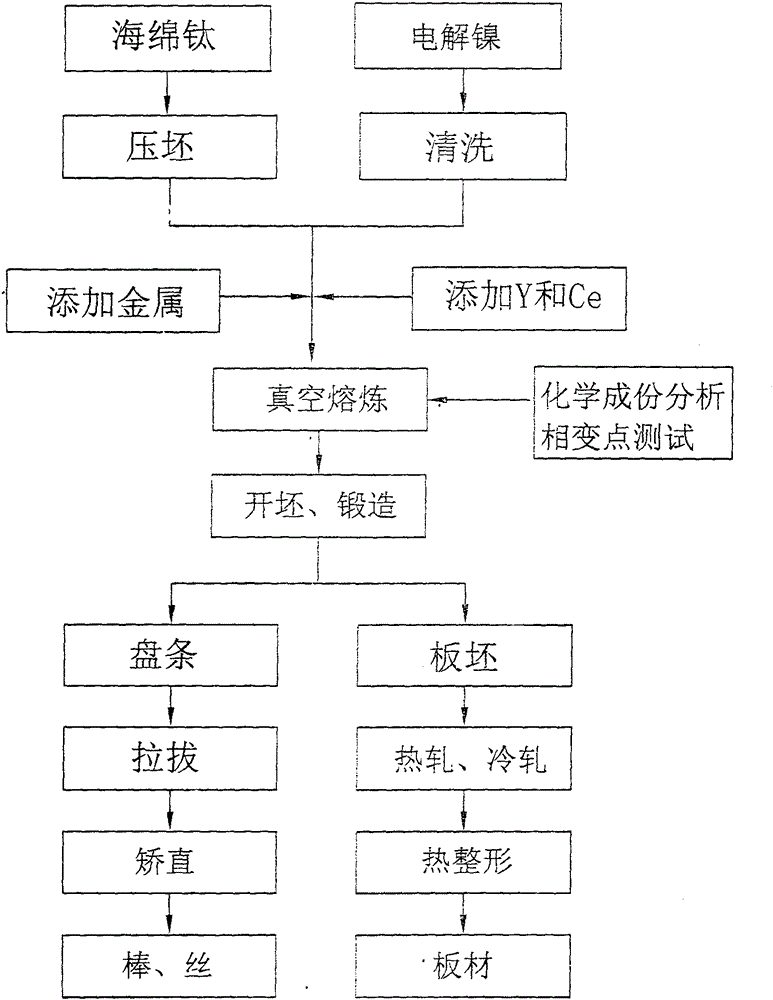

[0011] refer to figure 1 , in this embodiment, the titanium-nickel shape memory alloy is proportioned according to the following components: titanium Ti is 44.5%wt, nickel is 54%wt, yttrium Y+cerium Ce is 0.7%wt, vanadium V+niobium Nb is 0.8% wt. The impurity content of the titanium-nickel shape memory alloy is controlled as follows: carbon≤0.05%wt, oxygen+nitrogen≤0.05%wt, hydrogen≤0.005%wt, other minor added elements and unavoidable impurities≤1.5%wt.

[0012] The preparation method of titanium-nickel shape memory alloy described in this embodiment is as follows:

[0013] 1. Weigh grade 0 sponge titanium Ti with a purity of 99.9%, grade 1 electrolytic nickel Ni with a purity of 99.9%, pure yttrium Y, pure cerium Ce, titanium vanadium alloy TiV and titanium niobium alloy TiNb according to the proportioning ratio.

[0014] 2. Press the titanium sp...

Embodiment 2

[0016] Embodiment 2, the fatigue performance test of a plate of a titanium-nickel shape memory alloy with high fatigue resistance of the present invention

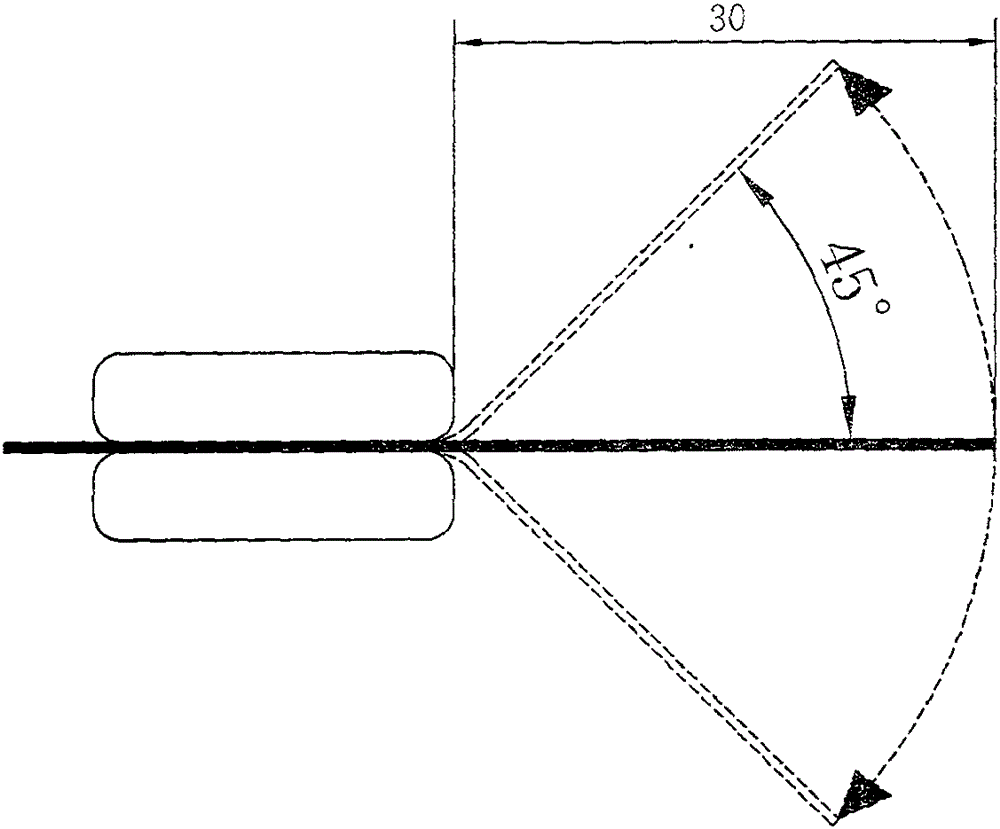

[0017] In this embodiment, a plate of titanium-nickel shape memory alloy with high fatigue resistance of the present invention and a common titanium-nickel shape memory alloy are respectively selected for a comparative test of fatigue performance, and the schematic diagram of the test principle is referred to figure 2 .

[0018] Test material specifications: length 50mm, width 3mm, thickness 0.8mm.

[0019] The test process is as follows:

[0020] Clamp and fix the plates of a titanium-nickel shape memory alloy with high fatigue resistance of the present invention and a common titanium-nickel shape memory alloy at 30 mm from the test end, and swing back and forth at ±45° perpendicular to the length direction. The frequency is 10 round trips / minute, and the number of times the material finally fails or breaks is recorded...

Embodiment 3

[0024] Embodiment 3, the fatigue performance test of the wire material of a kind of high fatigue resistance titanium-nickel shape memory alloy of the present invention

[0025] In this embodiment, a high fatigue resistance titanium-nickel shape memory alloy of the present invention and a common titanium-nickel shape memory alloy wire are respectively selected for a comparative test of fatigue performance, and the schematic diagram of the test principle is referred to figure 2 .

[0026] Test material specifications: length 50mm, diameter 0.8mm.

[0027] The test process is as follows:

[0028] The wires of a titanium-nickel shape memory alloy with high fatigue resistance of the present invention and a common titanium-nickel shape memory alloy are respectively clamped and fixed at 30 mm from the test end, and are perpendicular to the length direction to swing back and forth at ±45°. The oscillation frequency is 10 times / minute, and the number of times the material finally fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com