Method for conducting boron alloying in electro-slag remelting process

A technology for electroslag remelting and boron alloying, which is applied in the field of electroslag remelting and can solve the problems of low boron yield in steel and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

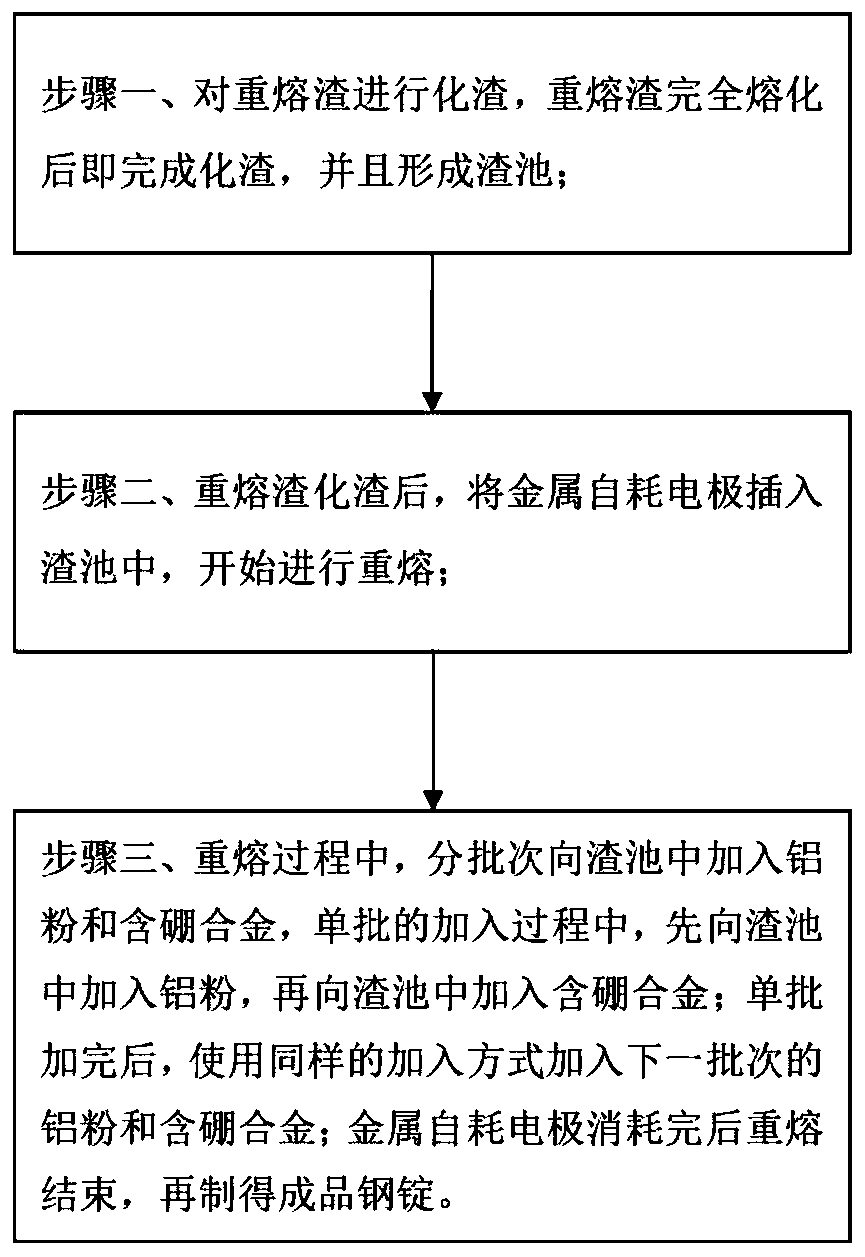

Method used

Image

Examples

Embodiment 1

[0041] The steel type produced in this embodiment is S32205 duplex stainless steel, and its B content is 0.001%-0.004%. The target content of B in the finished steel ingot produced in this embodiment is 0.003%. The concrete production steps of this embodiment are:

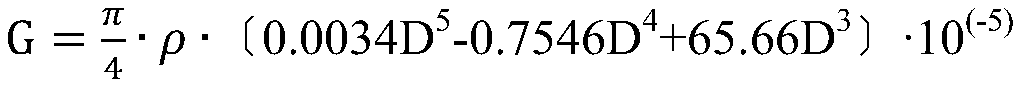

[0042] Step 1. Deslagging the heavy slag. In this embodiment, graphite electrodes are used to deslag the heavy slag; and aluminum powder is added during the slag melting process. The amount of aluminum powder added can be: 100KG slag plus 0.2-04kgAl pink. In this embodiment, the slag system composition of the heavy melting slag is: CaF 2 :60%, Al 2 o 3 : 10%, CaO: 25%, B 2 o 3 :5%, its density is 2.5g / cm 3 , the added amount of heavy slag is:

[0043]

[0044] Where G is the amount of heavy slag added, in kg; ρ is the density of heavy slag, in g / cm 3 , the heavy slag density in this example is 2.50g / cm 3 D is the crystallizer diameter, the unit is cm, and the crystallizer diameter is 50cm in the present...

Embodiment 2

[0059] The steel type produced in this embodiment is 10Cr11Co3W3NiMoVNbNB steel for blades of ultra-supercritical units, and its B content is 0.010%-0.025%. The target content of B in the finished steel ingot produced in this embodiment is 0.020%. The concrete production steps of this embodiment are:

[0060] Step 1. Deslagging the heavy slag. In this embodiment, graphite electrodes are used to deslag the heavy slag; and aluminum powder is added during the deslagging process. In this embodiment, the slag system composition of the heavy slag is: CaF 2 :62%, Al 2 o 3 : 15%, CaO: 20%, B 2 o 3 :3%, its density is 2.48g / cm 3 , the added amount of heavy slag is:

[0061]

[0062] Where G is the amount of heavy slag added, in kg; ρ is the density of heavy slag, in g / cm 3 , the heavy slag density in this example is 2.48g / cm 3 , D is the crystallizer diameter, the unit is cm, and the crystallizer diameter is 80cm in the present embodiment. After calculation, the amount of h...

Embodiment 3

[0077] The steel type produced in this embodiment is S30815 super austenitic stainless steel with a B content of 0.002%-0.010%, and the target content of B in the finished steel ingot produced in this embodiment is 0.006%. The concrete production steps of this embodiment are:

[0078] Step 1. Deslagging the heavy slag. In this embodiment, graphite electrodes are used to deslag the heavy slag; and aluminum powder is added during the deslagging process. In this embodiment, the slag system composition of the heavy slag is: CaF 2 :66%, Al 2 o 3 : 10%, CaO: 20%, B 2 o 3 : 4%, its density is 2.53g / cm 3 , the added amount of heavy slag is:

[0079]

[0080] Where G is the amount of heavy slag added, in kg; ρ is the density of heavy slag, in g / cm 3 , the heavy slag density in this example is 2.53g / cm 3 , D is the crystallizer diameter, the unit is cm, and the crystallizer diameter is 60cm in the present embodiment. After calculation, the amount of heavy slag added in this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com