Patents

Literature

82results about How to "Promote alloying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

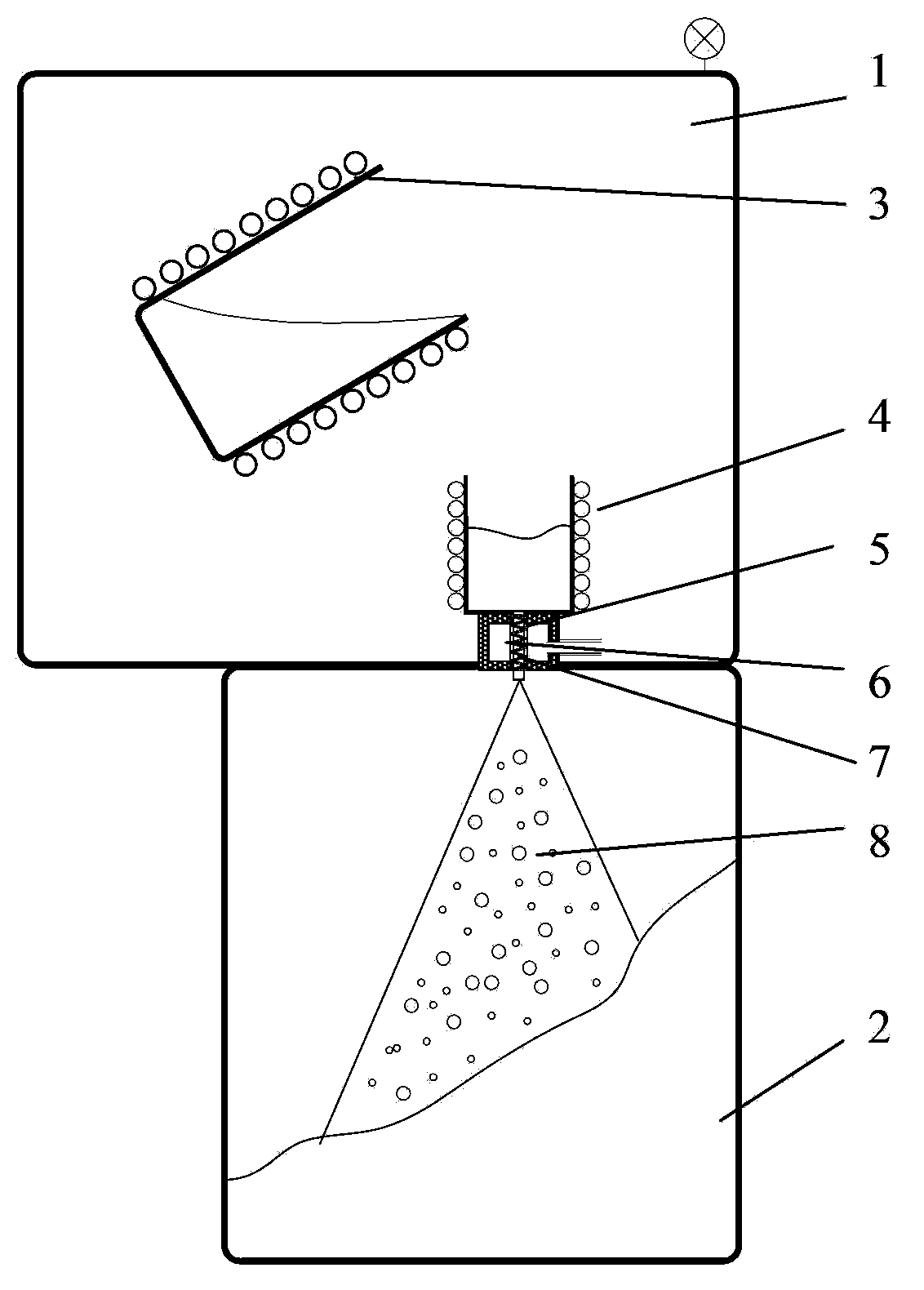

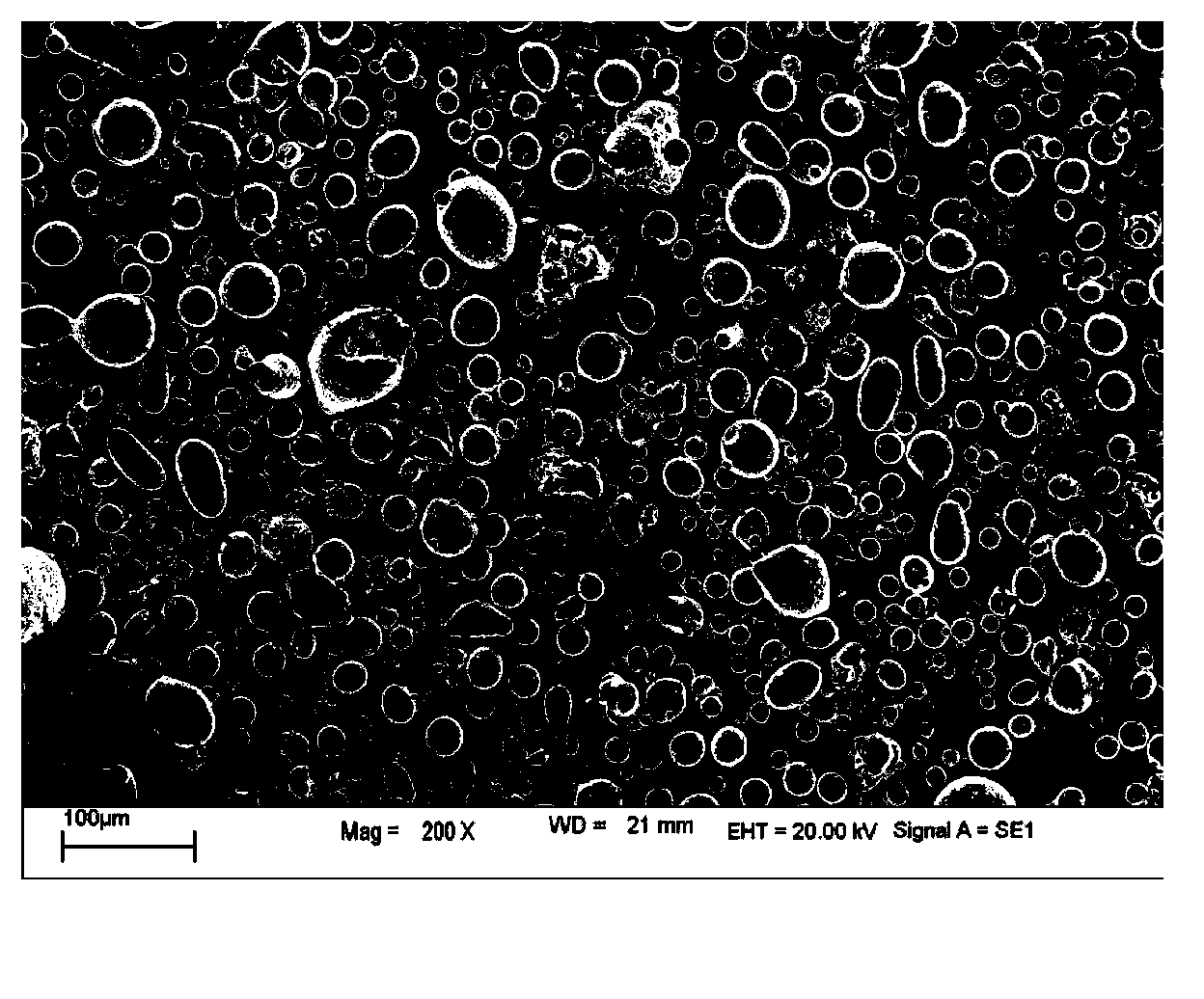

Metal powder atomization device and method for the device to prepare FeCoTaZr alloy powder

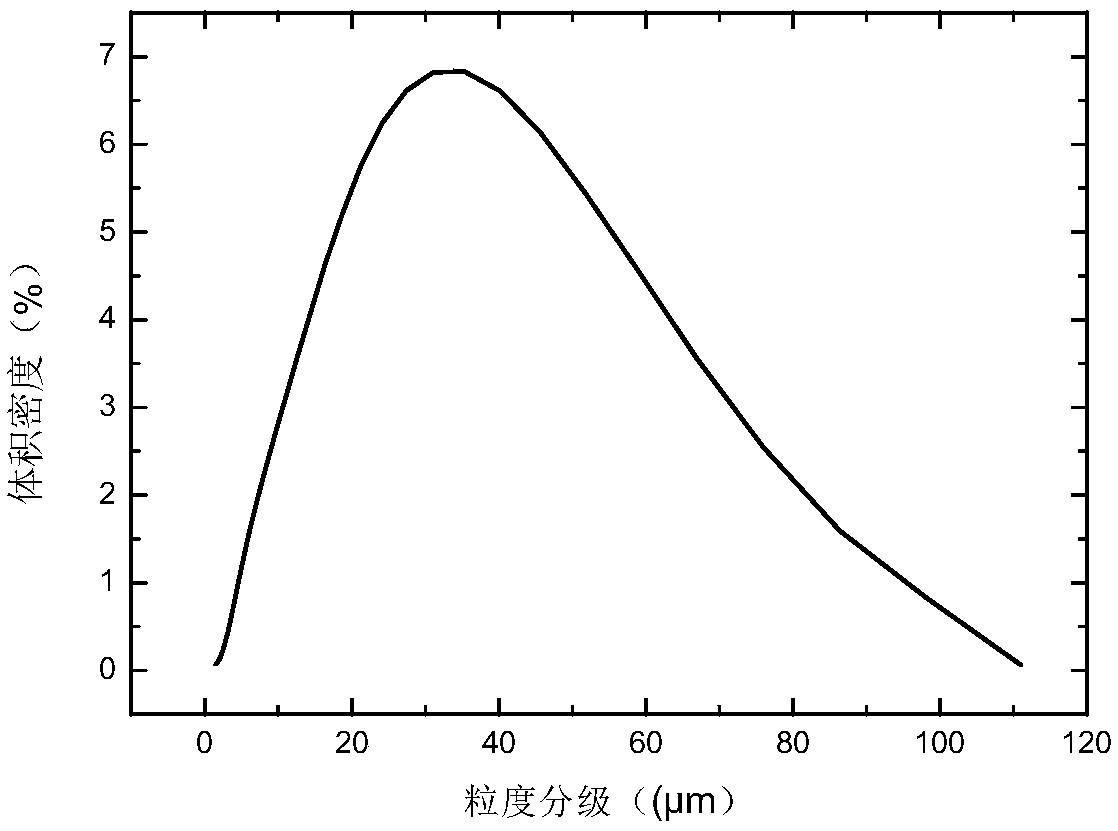

The invention discloses a metal powder atomization device and a method for the device to prepare FeCoTaZr alloy powder. The FeCoTaZr alloy powder prepared by the device comprises the components of, by weight, the balance of Fe, 20%-35% of Co, 5%-25% of Ta and 5%-15% of Zr. Materials are distributed according to the designed alloy components. Protected by insert atmosphere, raw materials are melted and are casted into prefabricated ingots. Protected by the insert atmosphere, the prefabricated ingots are melted. After heat preservation is conducted for a while, inert gas is used as atomization media, and the metal powder atomization device is used for atomization. The atomization pressure is 1.0-5.0MPa. The FeCoTaZr powder prepared by the metal powder atomization device is high in spherical degree, small in grain size, low in impurity content, low in oxygen content, small in crystal particle, even in component, and good in alloying.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

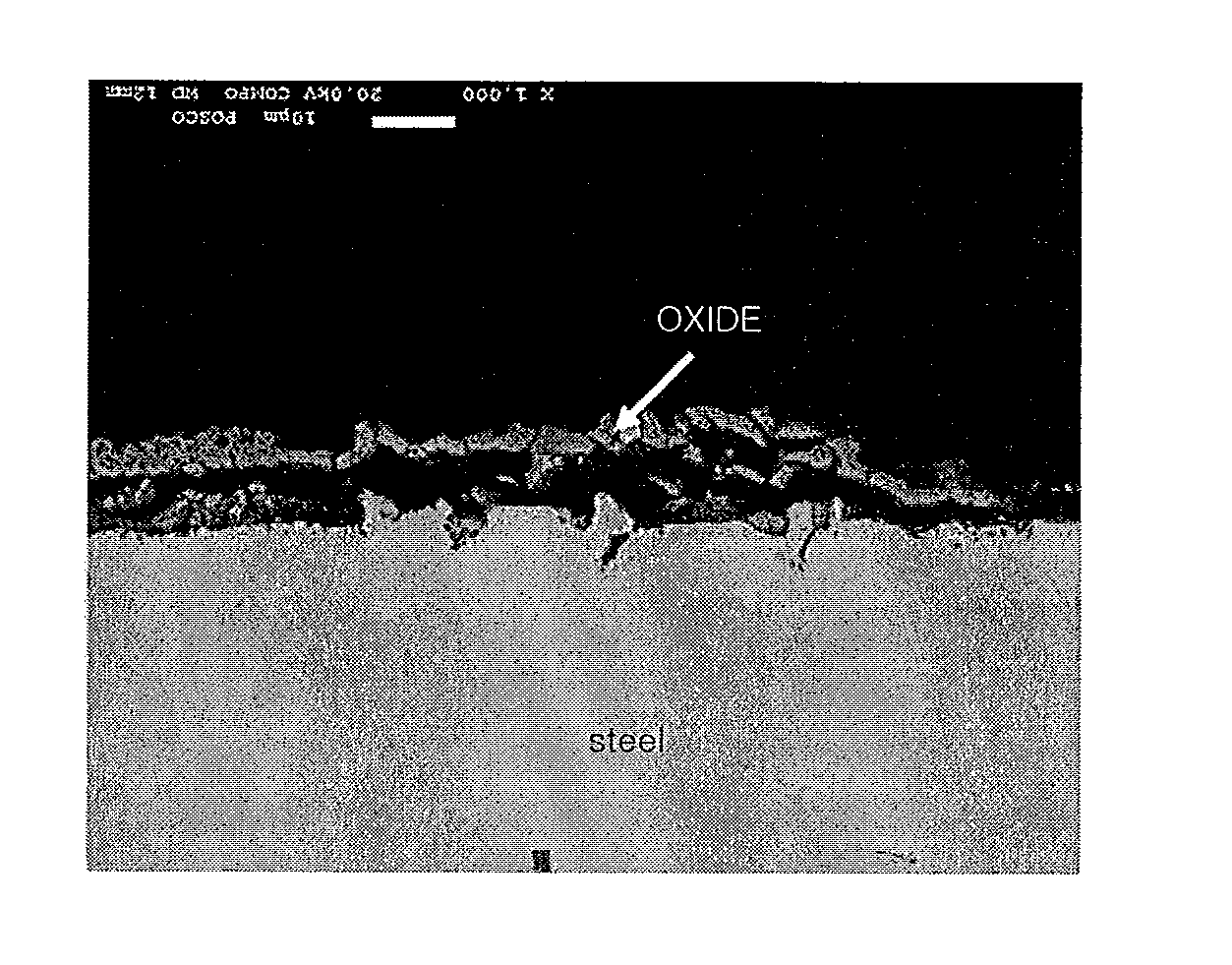

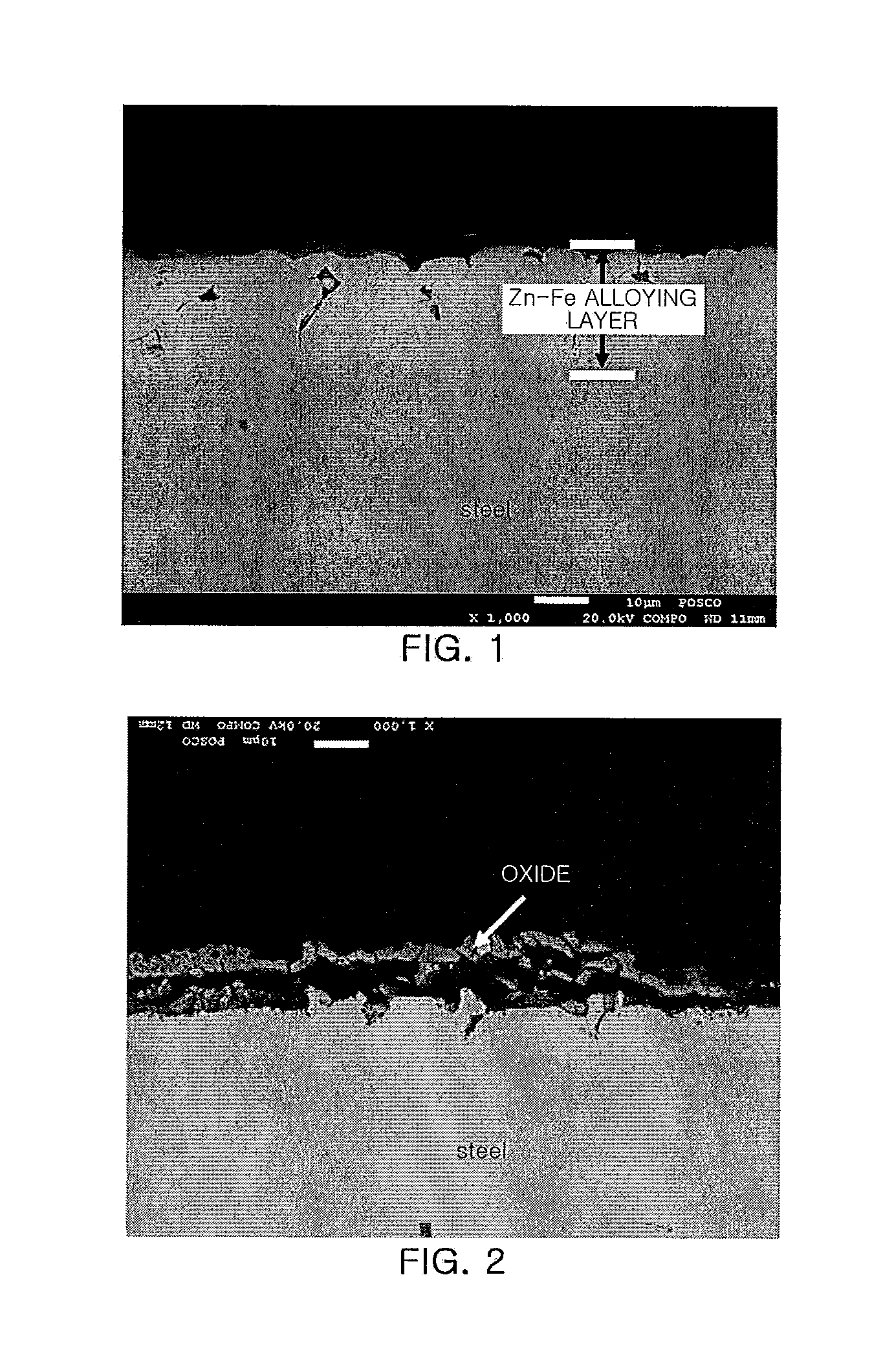

Zinc-plated steel sheet for hot pressing having outstanding surface characteristics, hot-pressed moulded parts obtained using the same, and a production method for the same

ActiveUS20120267012A1High melting temperatureDeterioration of layer be preventedHot-dipping/immersion processesSolid state diffusion coatingGibbs free energyOxygen

Provided is a zinc-plated steel sheet for hot pressing having outstanding surface characteristics, comprising: a steel foundation plate comprising a metal surface diffusion layer of which the Gibbs free energy reduction per mole of oxygen during oxidation is less than that of Cr; an aluminum-rich layer containing at least 30 wt. % of aluminium formed on the surface diffusion layer, and a zinc plating layer formed on the aluminum-rich layer. In this way, a metal having a low affinity for oxygen is coated to an effective thickness prior to annealing and thus the creation of annealing oxides at the surface of the steel sheet is suppressed and a uniform zinc plating layer is formed, and alloying of the zinc plating layer is promoted during press-processing heat treatment. Cracking in the steel foundation plate during hot press molding is prevented.

Owner:POHANG IRON & STEEL CO LTD

Aluminum alloy composite material and preparation method thereof

The invention discloses an aluminum alloy composite material and a preparation method thereof. The aluminum alloy composite material is prepared from the following components in parts by weight: 89-93 parts of aluminum, 4-6 parts of iron, 3-6 parts of manganese dioxide, 3-5 parts of magnesium, 1-2 parts of titanium dioxide fibers, 1-1.5 parts of tin, 0.5-1 part of tungsten carbide, 0.05-1 part of zinc oxide and 0.05-0.1 part of graphene nanosheets. The invention also provides a method for preparing the material. The method comprises the following steps: (1) weighing the following components in parts by weight: 89-93 parts of aluminum, 4-6 parts of iron, 3-6 parts of manganese dioxide, 3-5 parts of magnesium, 0.05-1 part of zinc oxide, 0.05-0.1 part of graphene nanosheets and 0-0.5 part of vanadium pentoxide, heating to the temperature of 660-690 DEG C under an inert atmosphere, and uniformly mixing; (2) adding 0.5-1 weight part of tungsten carbide subjected to ball milling into the product in the step 1 under the inert atmosphere, and heating to the temperature of 1100-1200 DEG C; and (3) sequentially adding 1-2 weight parts of titanium dioxide fibers and 1-1.5 parts of tin into the product in the step 2 under the inert atmosphere, preserving the temperature at the temperature of 800 DEG C for 0.5-2 hours, removing the slag, and degassing, thereby obtaining the aluminum alloy composite material.

Owner:中山市乘盟金属制品有限公司

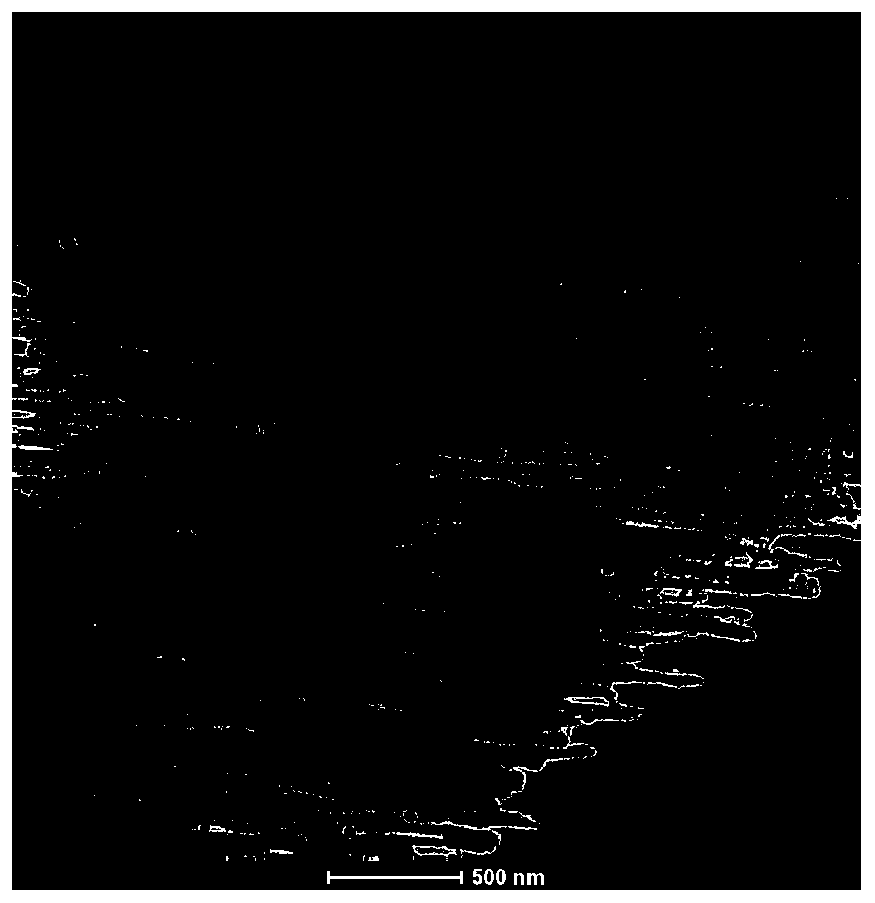

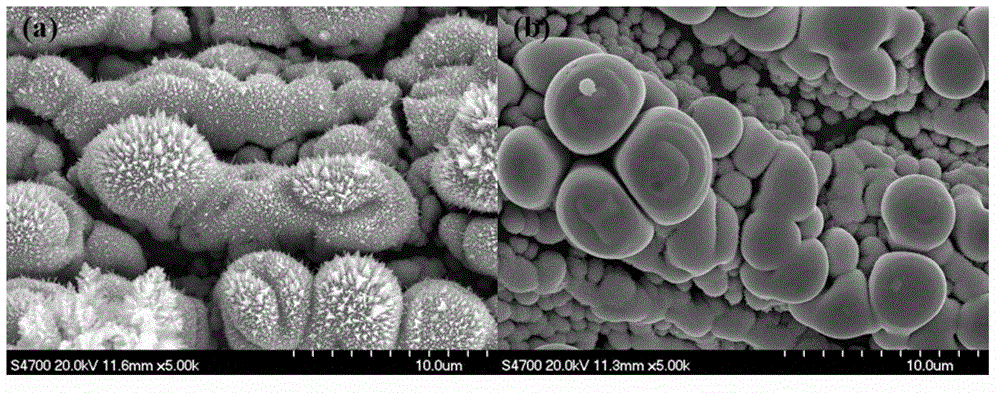

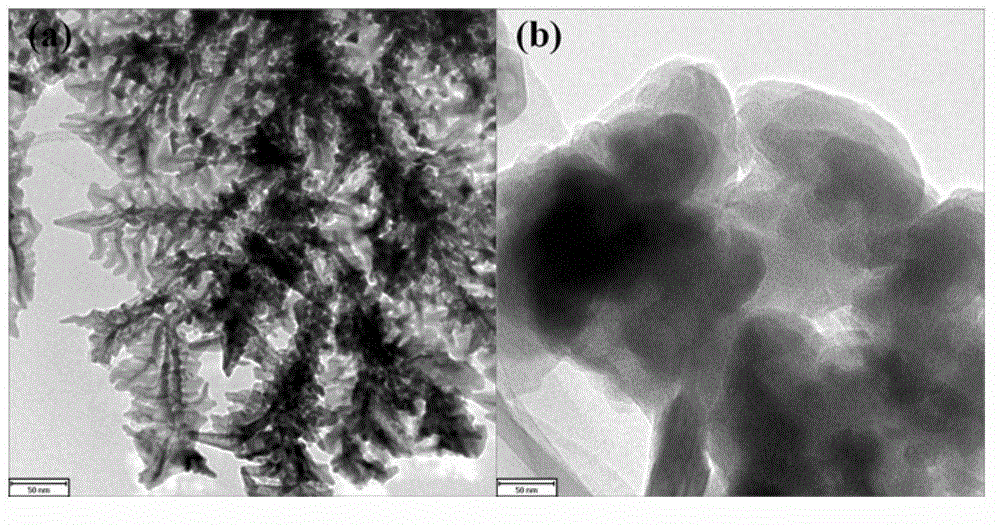

Core-shell structure type tungsten carbide-cobalt hard alloy raw material powder and preparation method thereof

The invention provides a method for preparing core-shell structure type tungsten carbide-cobalt composite powder. Hard phase tungsten carbide in the composition powder is completely and evenly coated by binding phase metal cobalt to form a core-shell structure. The method comprises the steps of: performing ultrasonic dispersion on tungsten carbide powder; then adding the tungsten carbide powder into a cobalt-containing reducing solution; adjusting the pH value of the solution, and controlling the temperature; then adding a reducer solution in a dripping mode; reducing an even cobalt coating layer on the surface of hard phase tungsten carbide powder; and forming the core-shell structure type tungsten carbide-cobalt composite powder. Hard alloy raw material powder obtained by adopting the method has high dispersivity; a hard phase and a binding phase have even distribution so as to ensure that the powder is easy for alloying; and obtained hard alloy has high obdurability.

Owner:SICHUAN UNIV

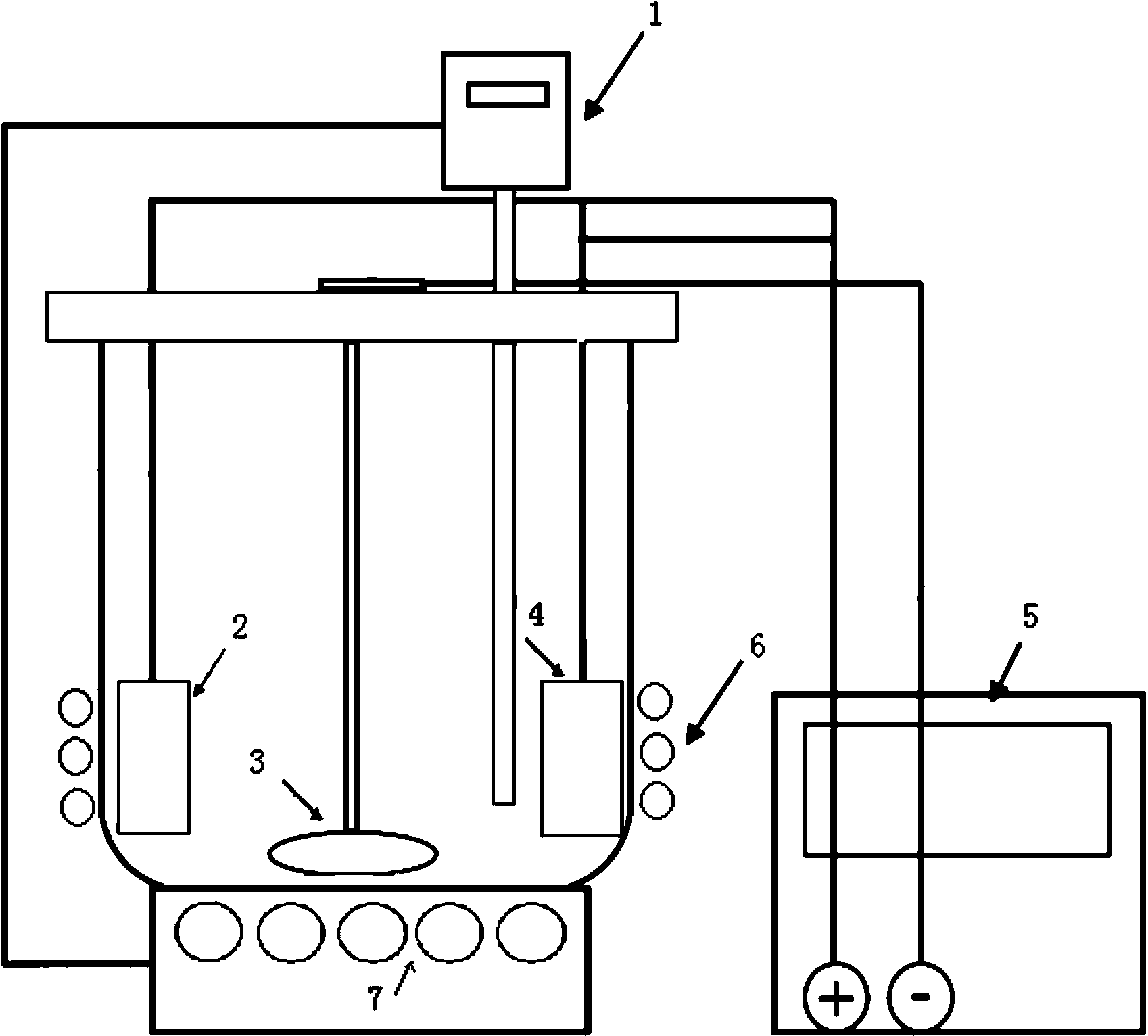

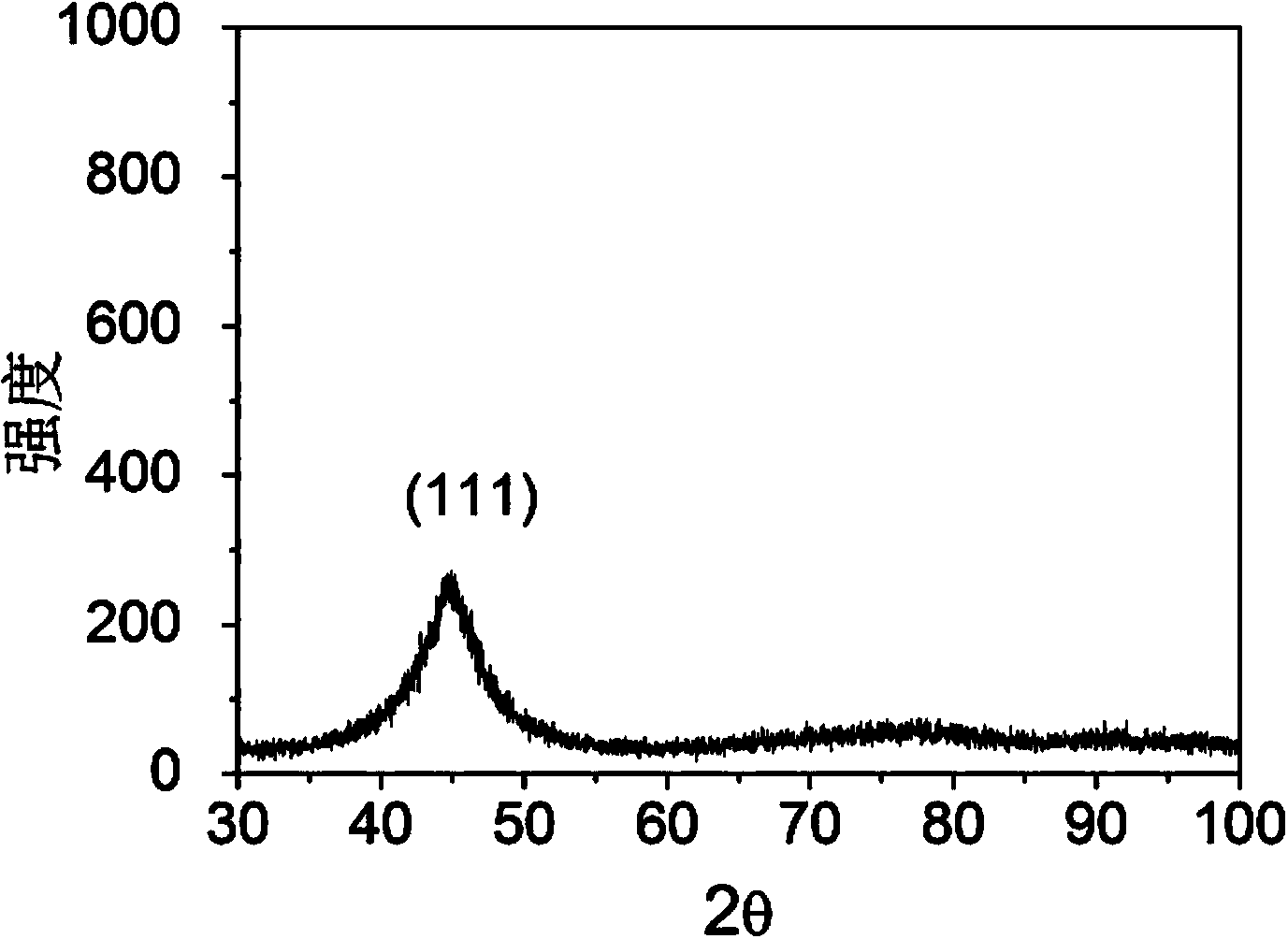

Preparation method of amorphous nickel-tungsten alloy coating layer

The invention relates to a preparation method of an amorphous nickel-tungsten alloy coating layer. The method combines ultrasonic wave with direct current, and uses a synergistic effect of the two to perform electroplating for preparing the amorphous nickel-tungsten alloy coating layer. Compared with the prior art, the method uses the ultrasonic wave to passivate defects of the coating layer, and accelerates solute mixing to promote alloying of nickel and tungsten; the device structure is simple; the easily-controlled direct current is adopted in the electroplating process; and the method can prepare the amorphous nickel-tungsten alloy coating layer with excellent surface quality. The method can improve the production efficiency of the amorphous nickel-tungsten alloy coating layer, reduces the production and operation costs, and has excellent application prospect.

Owner:TONGJI UNIV

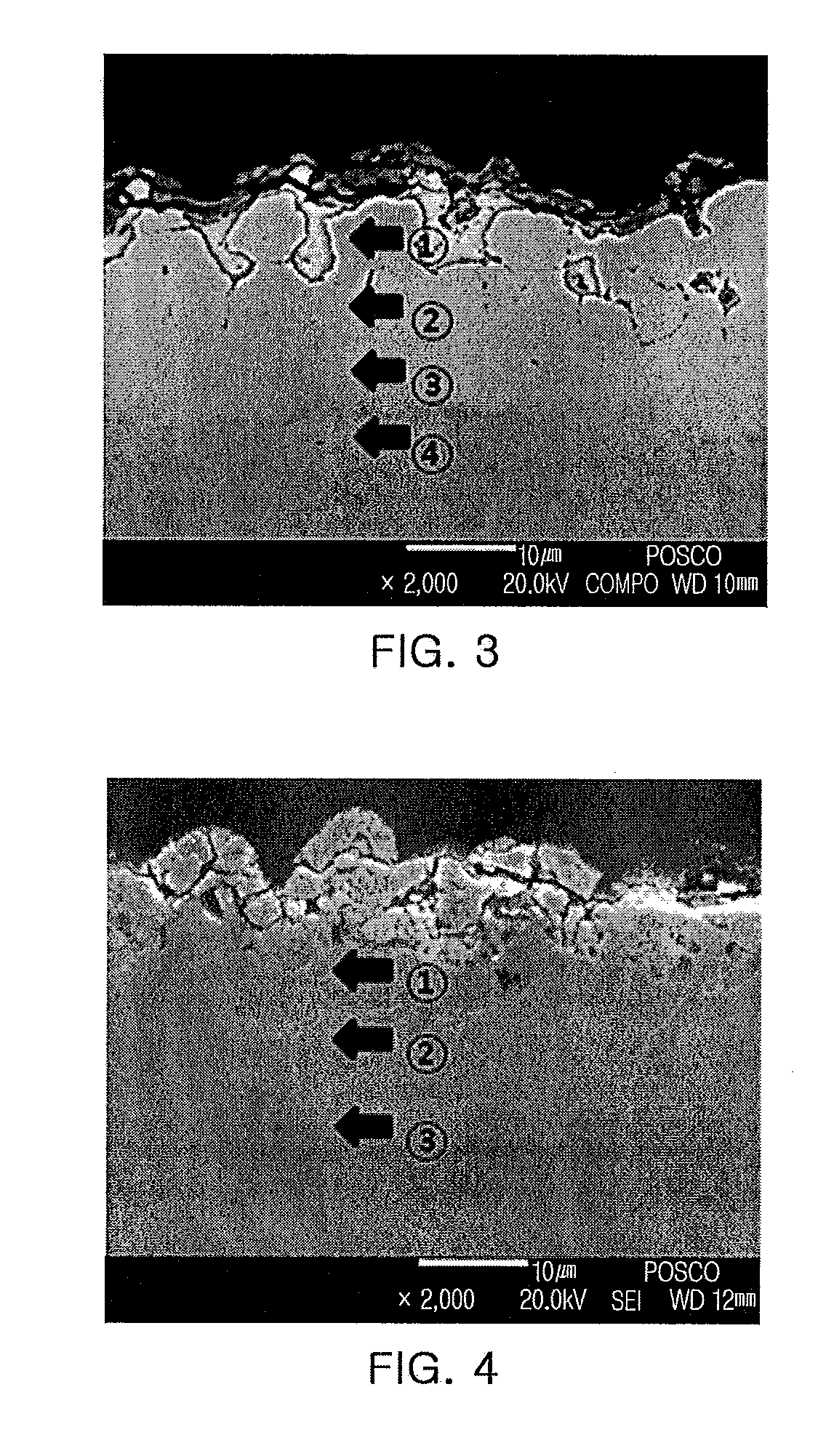

Hot dip alloyed zinc coated steel sheet and method for production thereof

ActiveUS20060269776A1Good shapeabilityHigh strengthHot-dipping/immersion processesLiquid surface applicatorsAlloyUltimate tensile strength

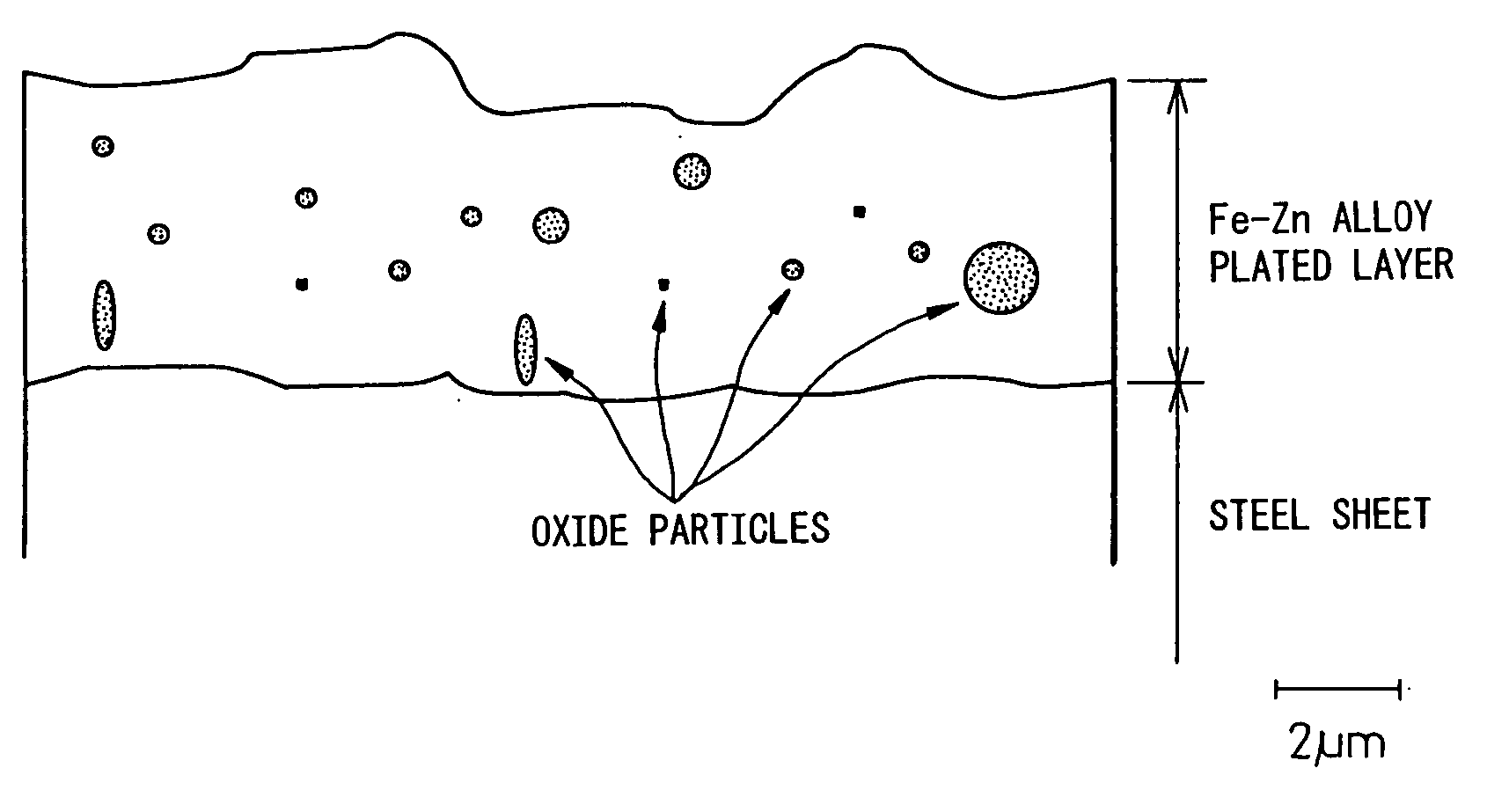

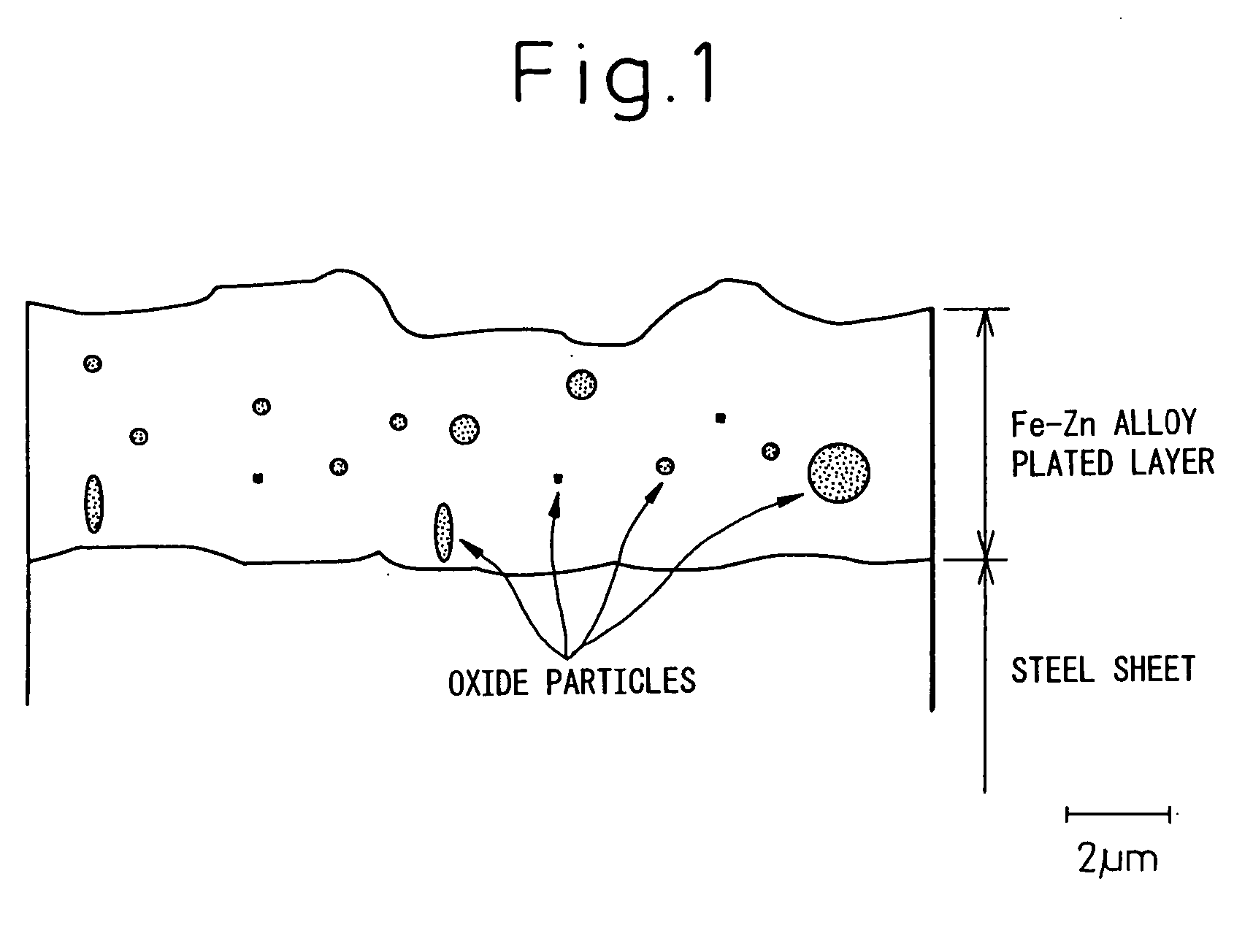

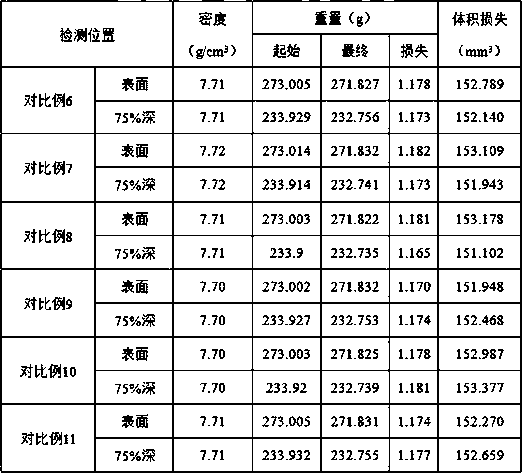

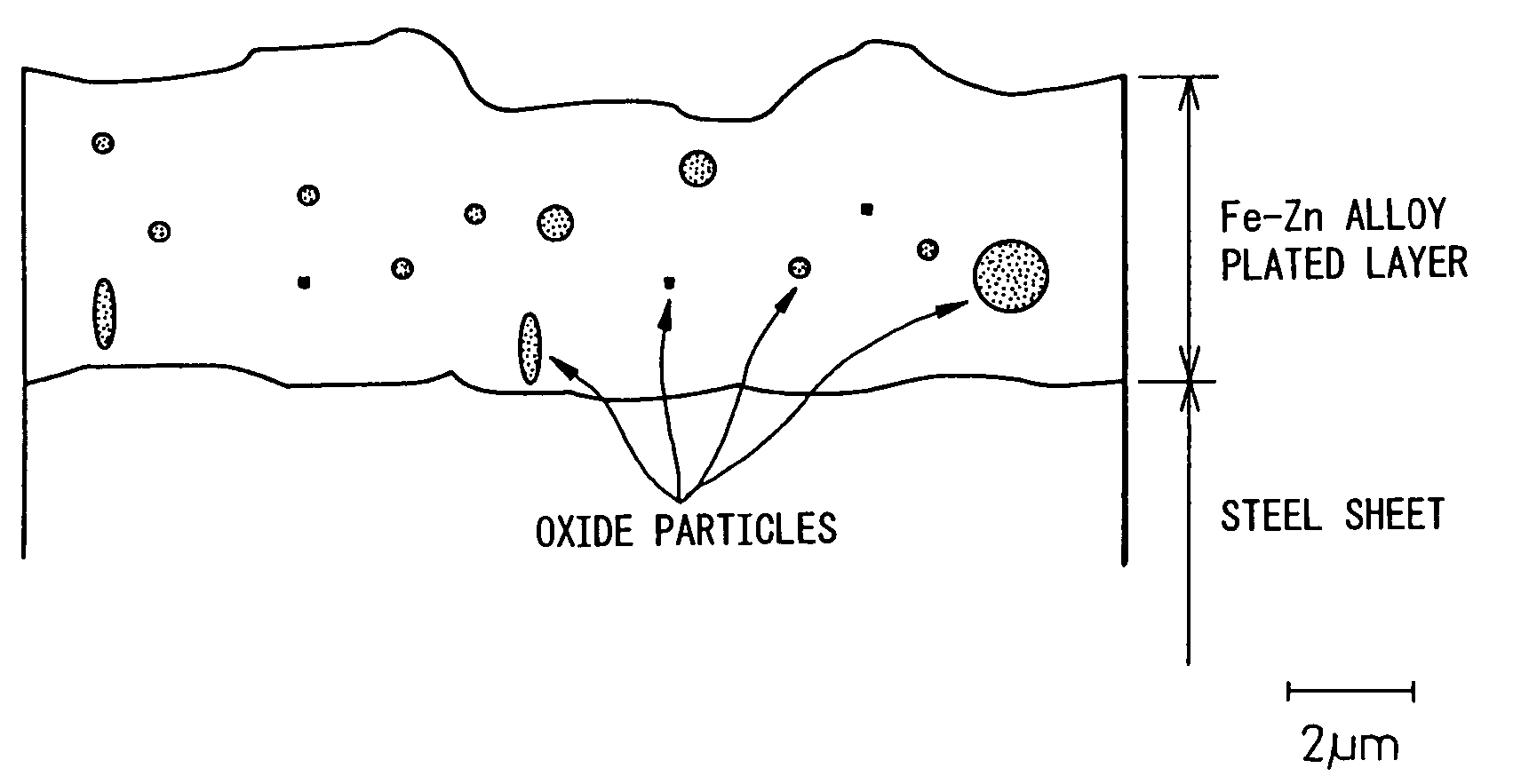

The present invention provides an alloyed molten zinc plated steel sheet having an area of the Fe and Zn alloy phase in the unformed parts in the plating layer of less than 10% of the area of the steel sheet as a whole and superior in strength and shapeability and a method of producing this alloyed molten zinc plating steel sheet by a continuous zinc plating production system which enables production at a low cost without modification of the system or addition of steps, said alloyed molten zinc plated steel sheet characterized by comprising a steel sheet including C: 0.05 to 0.40%, Si: 0.2 to 3.0%, and Mn: 0.1 to 2.5%, the balance comprised of Fe and unavoidable impurities, having on its surface a Zn alloy plating layer comprised of Fe in a concentration of 7 to 15 wt %, Al in a concentration of 0.01 to 1 wt %, and the balance of Zn and unavoidable impurities, said plating layer containing oxide particles of at least one type of oxide selected from an Al oxide, Si oxide, Mn oxide, and complex oxides of the same alone or in combination.

Owner:NIPPON STEEL CORP +1

High-performance copper-diamond electrical contact material and preparation process thereof

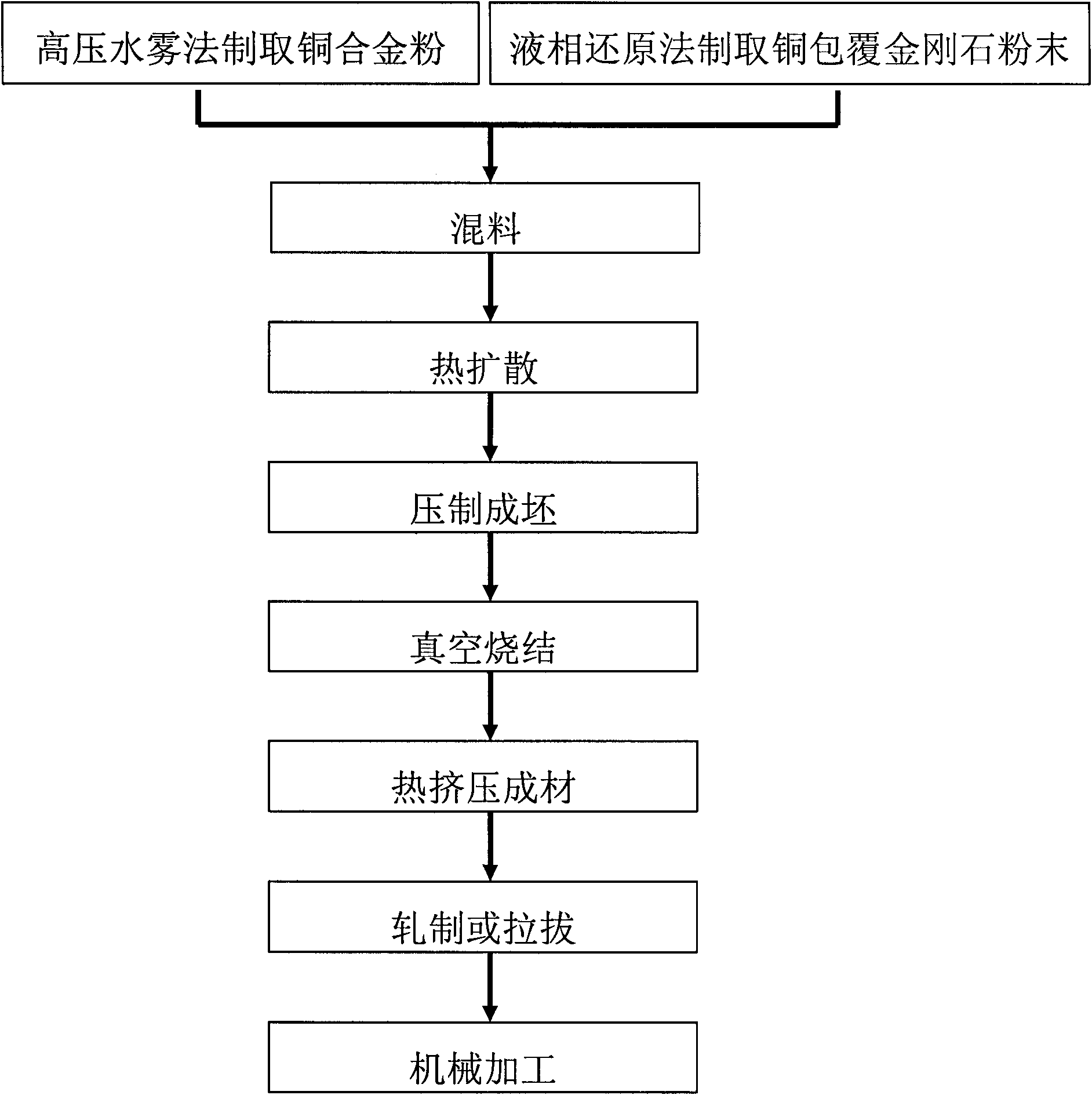

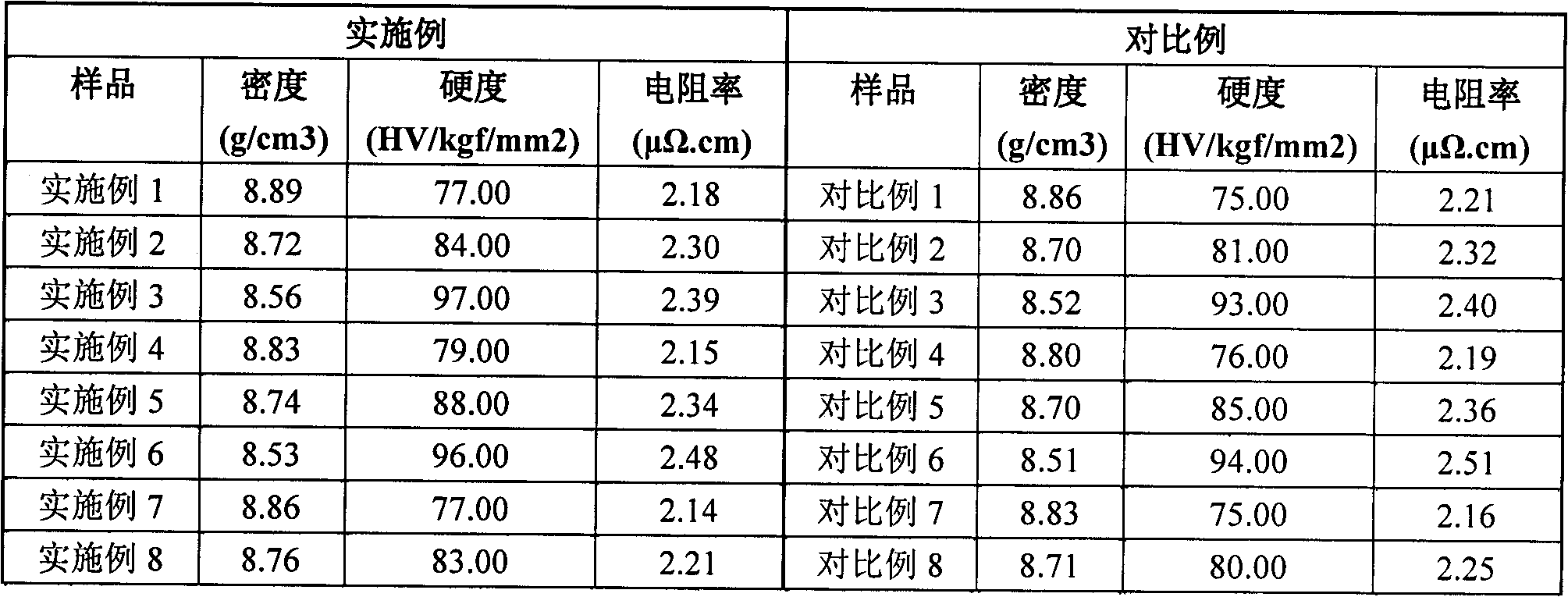

The invention relates to a preparation process of powder metallurgy material, in particular to high-performance copper-diamond electrical contact material and a preparation process thereof. The high-performance copper-diamond electrical contact material comprises the following raw materials by weight percentage: 0.001%-5.0% of diamond powder and 95%-99.999% of copper alloy powder, wherein the grain size of the diamond powder is 0.1-15 mum, and the surface of the diamond powder is coated with copper. The preparation process of the high-performance copper-diamond electrical contact material comprises the following steps: (1) preparing the raw materials: preparing the copper alloy powder by using a high-pressure spray method, preparing the copper-coated diamond powder by using a liquid-phase reduction method and mixing the copper alloy powder and the copper-coated diamond powder; (2) preparing the electrical contact material: firstly, carrying out thermal diffusion treatment to the mixture of the copper alloy powder and the copper-coated diamond powder, sintering the compressed and moulded mixture in vacuum, and thermally extruding and moulding the mixture; and (3) preparing electrical contact sectional material: rolling or drawing and machining the copper-diamond electric contact into the required-size sectional material.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

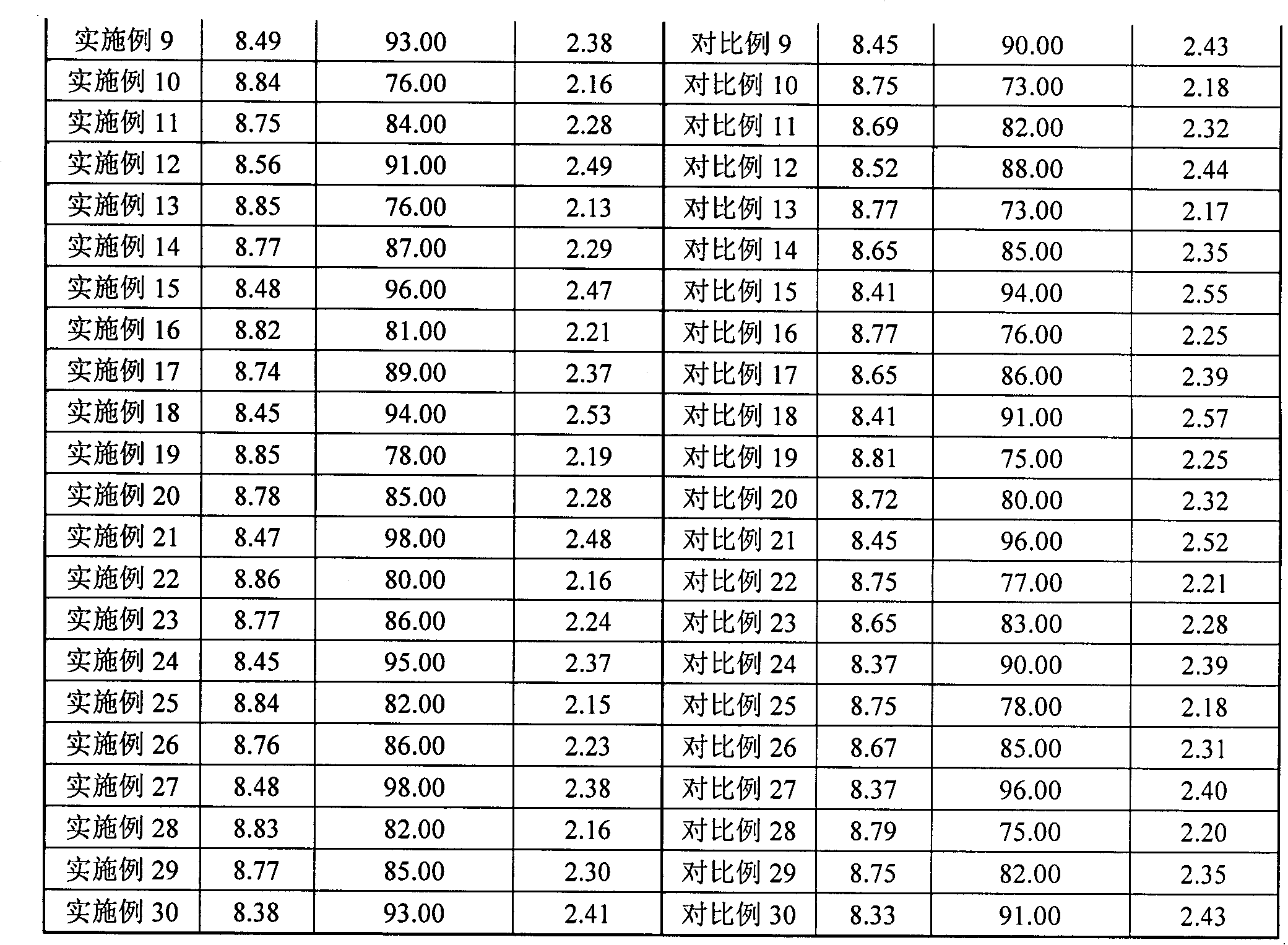

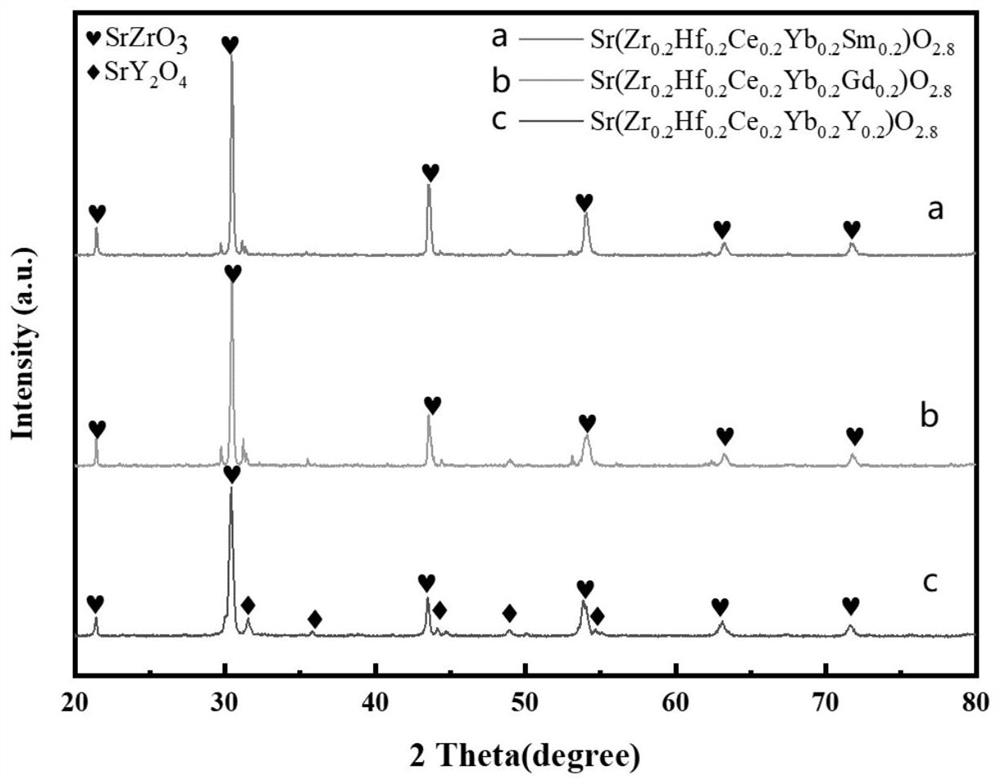

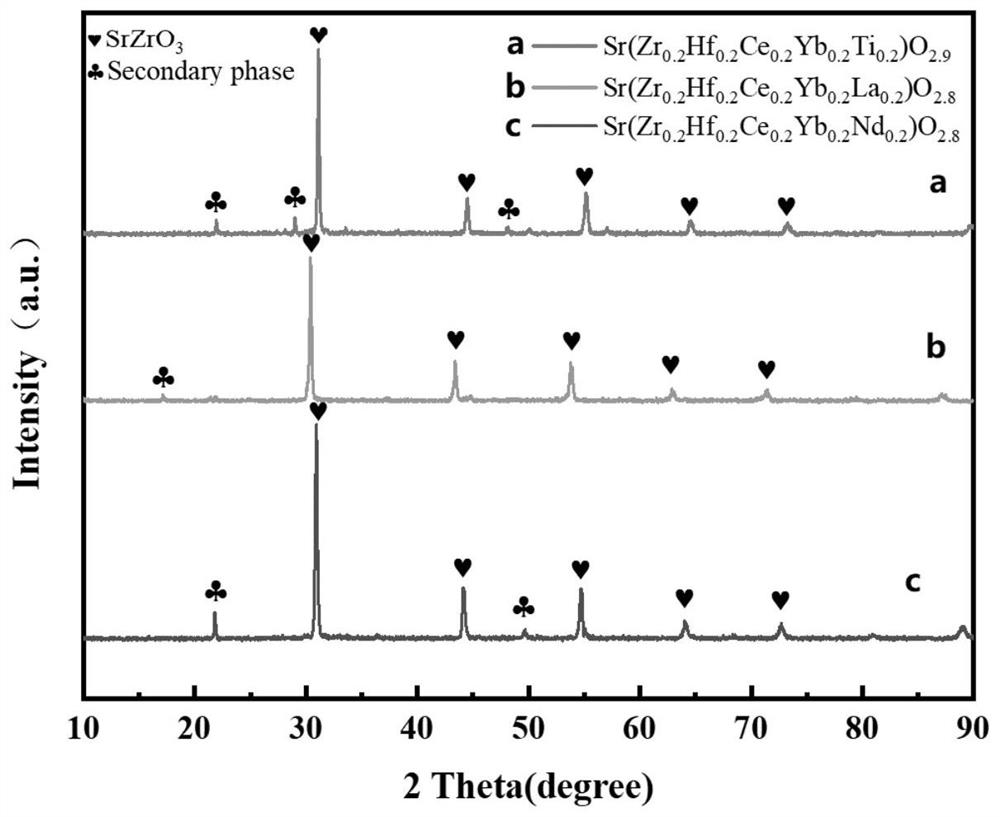

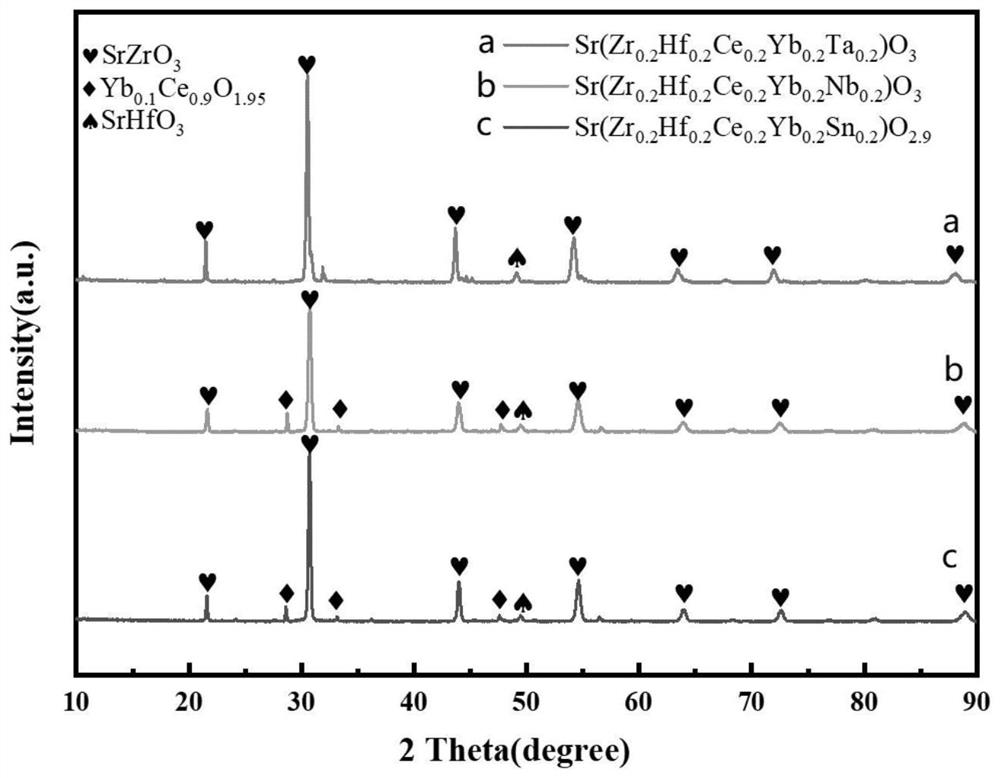

Novel perovskite structure high-entropy ceramic and preparation method thereof

ActiveCN112919908AGood phase stability at high temperatureLow thermal conductivityAlcoholPolyvinyl alcohol

The invention discloses a novel perovskite structure high-entropy ceramic and a preparation method thereof. The structure of the ceramic is an ABO3 type perovskite structure, the A-site element is Sr, and the B-site element is Zr, Hf, Ce, Yb and Me which are in an equal molar ratio. The preparation method comprises the following steps: putting the components into a mortar, adding absolute ethyl alcohol, and performing grinding; performing drying in a drying oven after the grinding, then transferring dried material into a muffle furnace for pre-calcining, and naturally cooling obtained material to room temperature to obtain a ceramic powder; putting the ceramic powder into the mortar, adding a polyvinyl alcohol aqueous solution and absolute ethyl alcohol, performing grinding again, and performing drying and sieving after the grinding is sufficient, adding the sieved ceramic powder into a steel mold of a table type powder tablet press, pre-pressing into a disc-shaped or strip-shaped block material, and then putting the block material into a cold isostatic press for cold isostatic pressing treatment to obtain a ceramic green body; and finally, calcining the ceramic green body in a muffle furnace, and performing cooling in the furnace to obtain the novel perovskite structure high-entropy ceramic. The high-entropy ceramic has the advantages of high stability, low thermal conductivity and relatively high hardness and density.

Owner:INNER MONGOLIA UNIV OF TECH

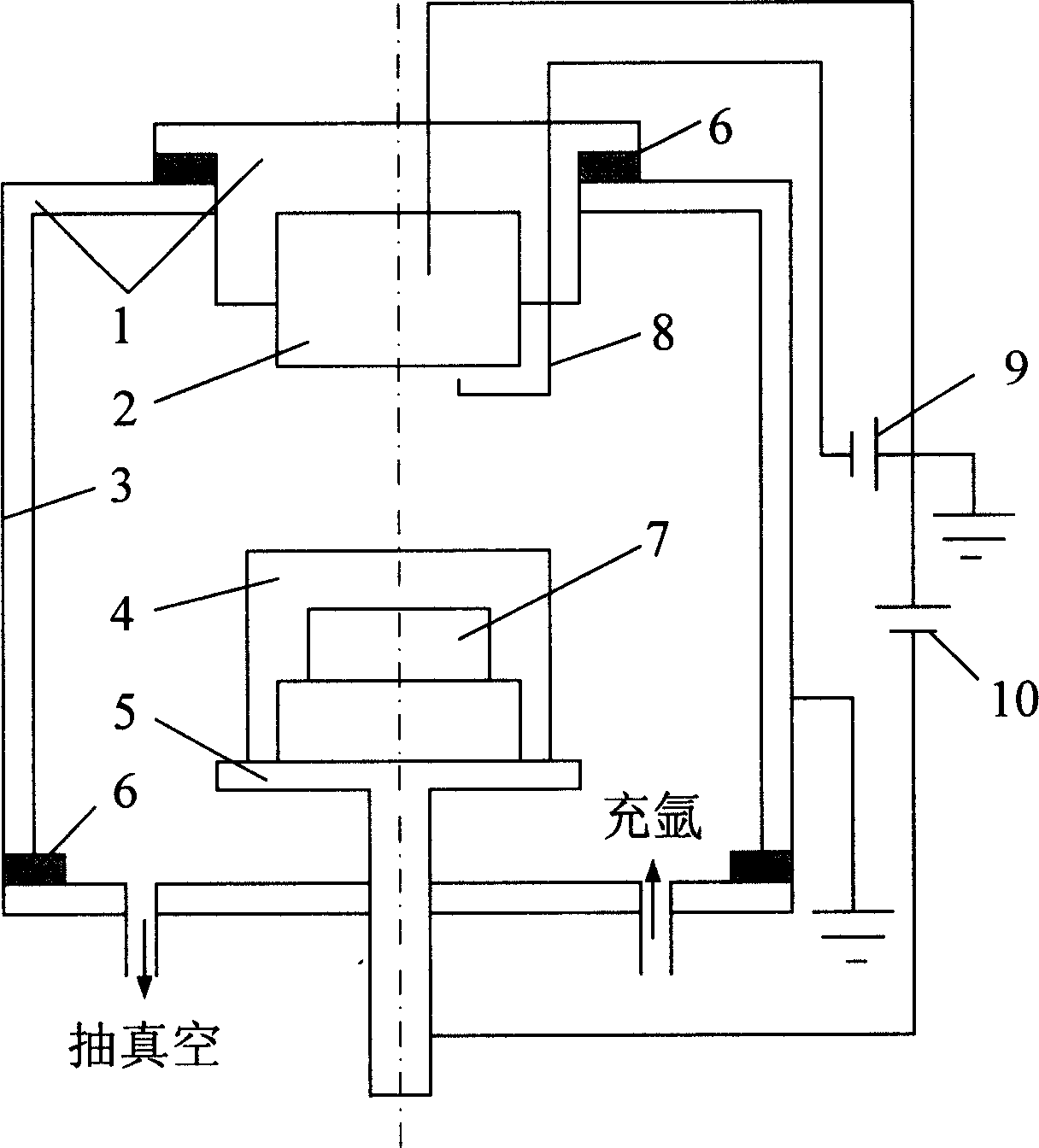

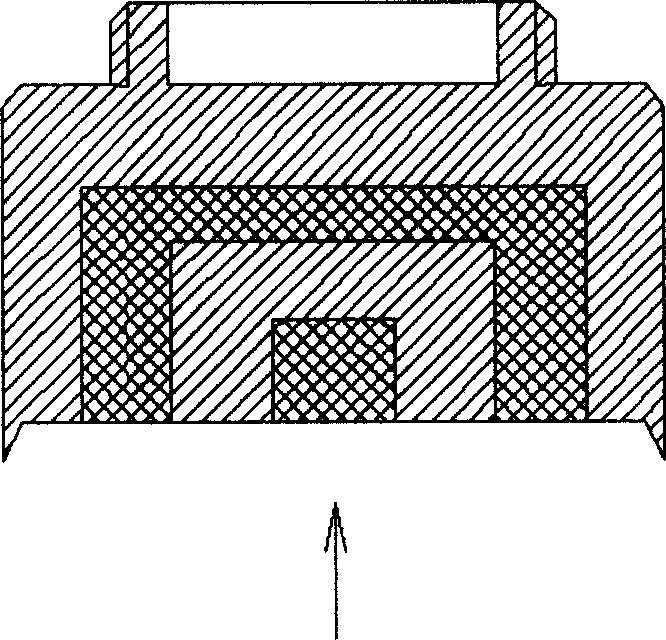

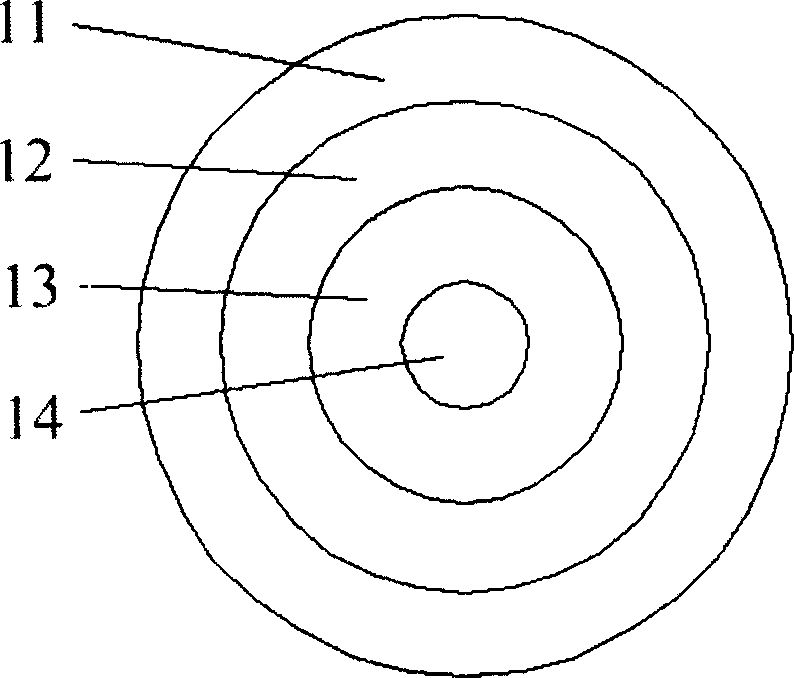

Surface alloying ceramic and its preparing process

This invention discloses a surface alloying ceramics and its preparation method. It relates to fields of improving technology of ceramics surface and composite material preparation. The features are that common ceramics are surface alloyed in arc glowing furnace by using composite target designed by this invention method. The target is pro rate mechanic consisted by one kind or several kinds of titanium (or zirconium, hafnium) and other metal materials (such as iron, chromium, nickel, manganese, molybdenum, copper, aluminum, argentums). The target evaporates or melts under the action of the arc heat and the ceramics surface is impacted by metal ions in high speed under the action of high electric field. The advantage is that the cementation speed is fast, the bond strength is high, and the thickness of alloy layer can reach more than 100 mu m. The preparations of several kinds of surface alloying ceramics and sill like composite material can be realized by this method.

Owner:TAIYUAN UNIV OF TECH

High-performance copper alloy prepared by casting method

The invention relates to a high-performance copper alloy prepared by a casting method, and belongs to the field of copper alloys. The copper alloy comprises Cu, Cr, Zr and M, wherein the mass percentof the Cr is 0.1-5.0%, and the mass percent of the Zr is 0.1-5.0%; the M is composed of RE and at least two of Mg, Ag, B, Ga, Si, Li, Ti, Fe and Mn; the RE is selected from at least three of Ce, La, Yb, Pr, Nd and Sm; and the mass ratio of the M in the high-performance copper alloy is 0.05-0.5%. The high-performance copper alloy is subjected to casting to obtain an as-cast alloy ingot, and the as-cast alloy ingot is subjected to heat treatment and deformation treatment to obtain a finished product with excellent mechanical properties and electrical conductivity.

Owner:CENT SOUTH UNIV

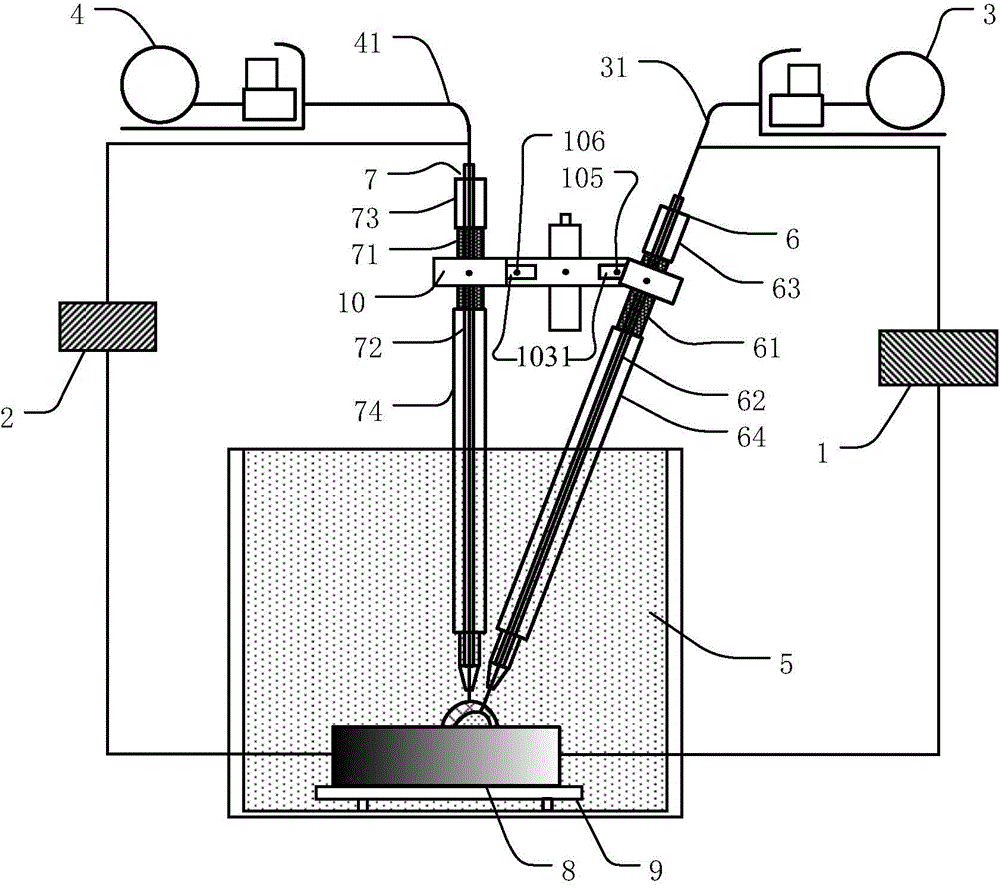

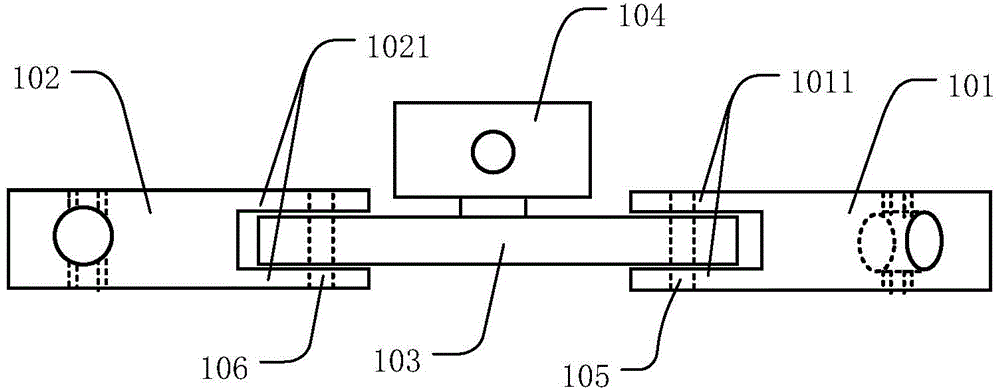

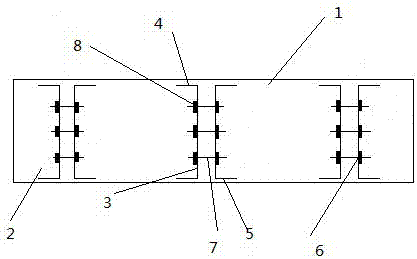

Double-wire underwater wet welding device and method

InactiveCN104400181AStable combustionIndependently adjustable welding parametersElectrode supporting devicesElectric arcBase metal

The invention relates to a double-wire underwater wet welding device and a double-wire underwater wet welding method. The welding device comprises a master welding gun power supply, a slave welding gun power supply, a master wire conveyor, a slave wire conveyor, a master welding gun and a slave welding gun, wherein the master welding gun and the slave welding gun are respectively connected to the master welding gun power supply and a slave welding gun power supply, a master welding wire and a slave welding wire are respectively conveyed to the end parts of the master and slave welding guns through the master and slave wire conveyors, the master welding gun and the slave welding gun are respectively arranged to form a certain angle with a workpiece to be welded, and a certain distance is kept between the front end of the master welding gun and the front end of the slave welding gun. According to the double-wire underwater wet welding device and method, the two welding wires in the master and slave welding guns are heated mutually, and the energy of electric arc is fully used, so that the deposition rate is greatly improved, and the problem that the underwater wet welding molten bath and the base metal cannot be fully fused is overcome.

Owner:HARBIN INST OF TECH AT WEIHAI

Lanthanum cerium-magnesium intermediate alloy and production method thereof

The invention discloses a lanthanum cerium-magnesium intermediate alloy and a production method thereof, relating to the technical field of preparation of a rare earth-magnesium intermediate alloy product. According to the production method, a coelectrodeposition method is adopted, a graphite crucible is used as an electrolytic tank and an anode, a molybdenum bar is used as a cathode, a magnesium oxide crucible is used as an alloy supporting device, an electrolyte is formed by mixing KCl, anhydrous MgCl2 and RECl3 together. By adopting the preparation method disclosed by the invention, the lanthanum cerium-magnesium intermediate alloy high in quality and low in cost can be produced through one step by adopting magnesium and rare earth compounds through the coelectrodeposition method. The process indicators of the whole production process are relatively high, wherein the average electric efficiency reaches 65-75% and more than 85% at the maximum, the rare earth direct yield is more than 85%, and the magnesium direct yield is more than 95%. The lanthanum cerium-magnesium intermediate alloy prepared by the invention is lowest in price, and resources can be continuously supplied to promote sustainable development of rare earth-magnesium alloys.

Owner:扬州宏福铝业有限公司 +1

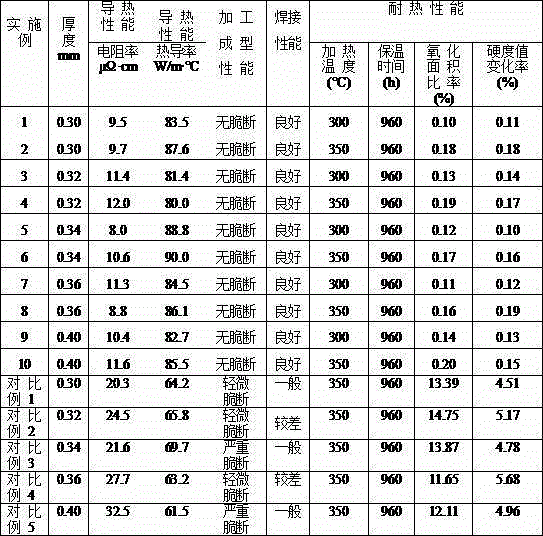

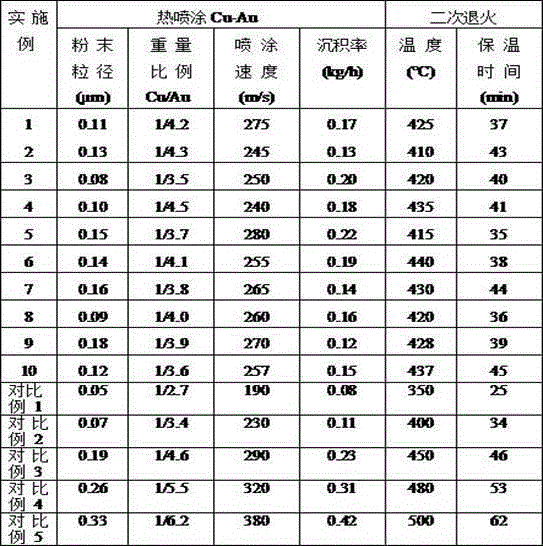

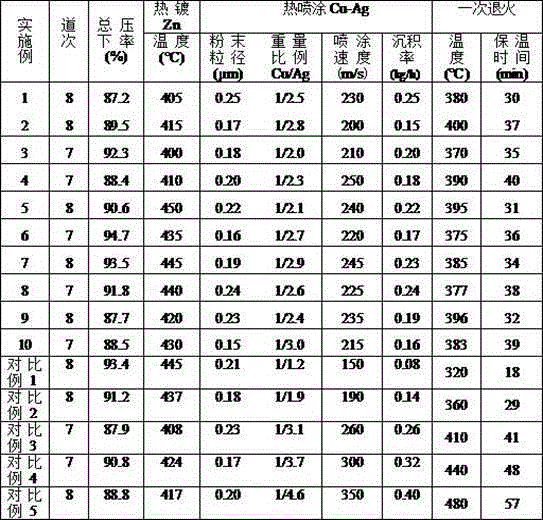

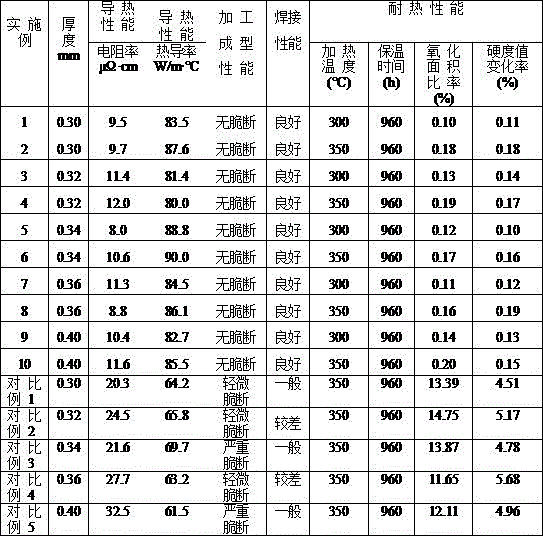

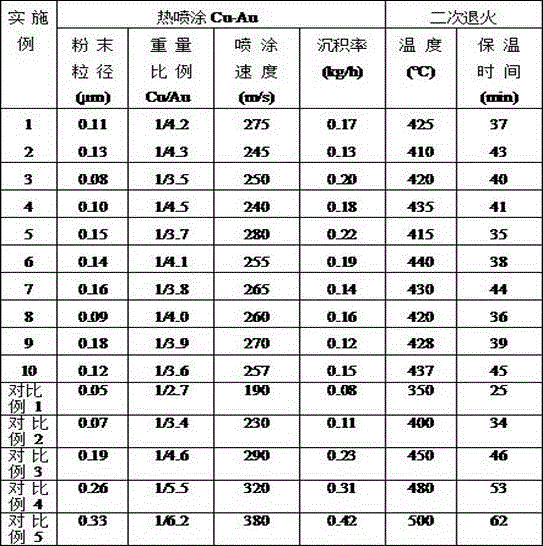

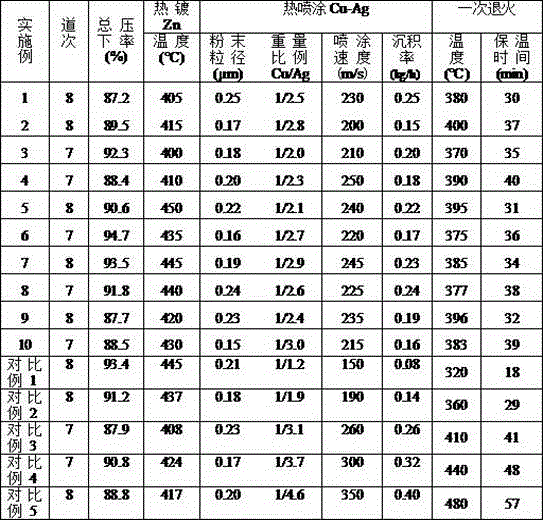

Production method of Zn/Cu-Ag/Cu-Au composite coating steel band for photoelectric material

ActiveCN105063620AReduce internal stressGuaranteed surface finishSuperimposed coating processLoss rateHydrogen

A production method of a Zn / Cu-Ag / Cu-Au composite coating steel band for a photoelectric material comprises the following steps: using a 08Al cold-rolled steel sheet as a raw material and carrying out cold rolling; after conventional degreasing, carrying out uncoiling, splitting and deburring; hot-dipping Zn; thermally spraying Cu-Ag; carrying out primary annealing at a pure nitrogen protective atmosphere; thermally spraying Cu-Au; carrying out secondary annealing at a pure nitrogen protective atmosphere; and air-cooling to a room temperature and coiling. The tensile strength is 250-300MPa, and the elongation percent is 42-48%. One Zn / Cu-Ag / Cu-Au composite coating is generated on the surface. After the Zn / Cu-Ag / Cu-Au composite coating steel band is placed under an indoor conventional atmospheric condition for 960 days, the gloss loss rate of the coating is not larger than 0.3%, and the surface corroded area is not larger than 0.3%. The product has excellent electricity and heat conductivity. After the Zn / Cu-Ag / Cu-Au composite coating steel band is kept at 300-350 DEG C for 960 days, the surface oxidized area is not larger than 0.2%, and the hardness variation rate is not larger than 0.2%. The product also has excellent welding and machining performance.

Owner:武汉钢铁有限公司

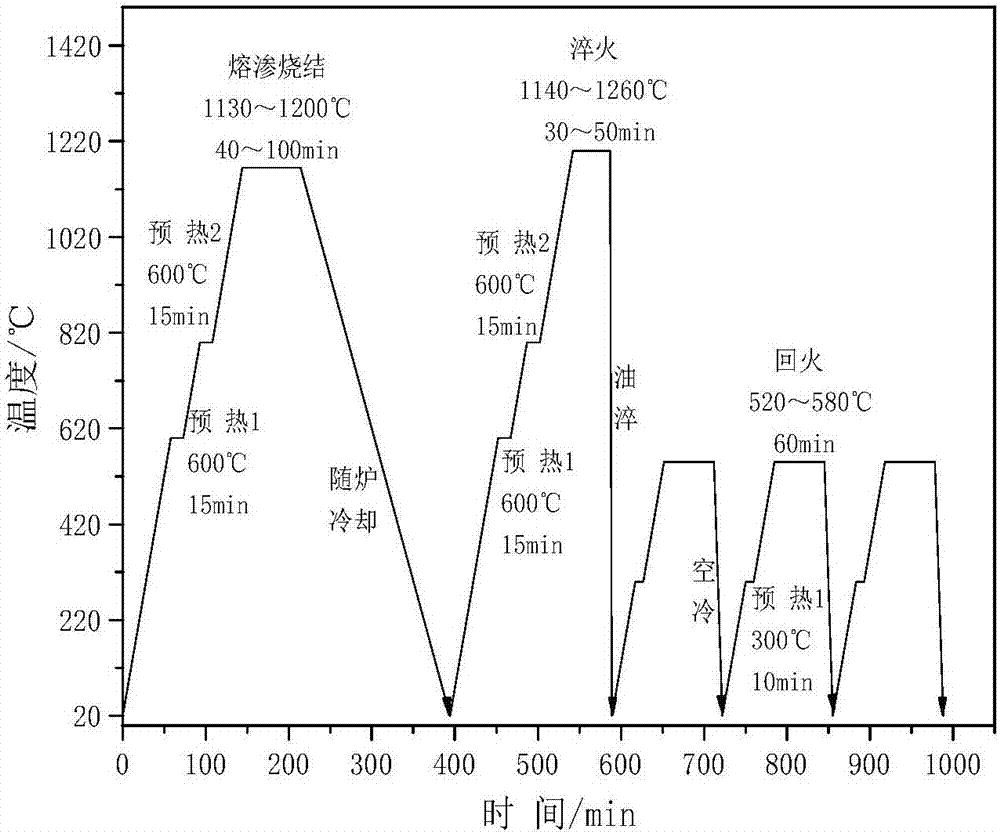

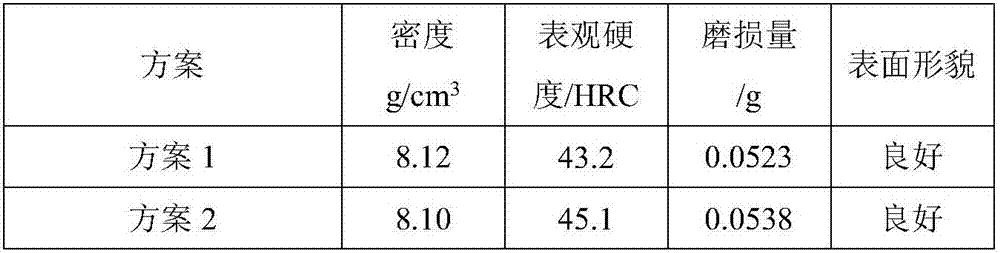

Powder metallurgy high-speed steel valve seat for clean fuel engine and production process of powder metallurgy high-speed steel valve seat

ActiveCN107267877AConvenient sourceReasonable ratio of ingredientsTransportation and packagingMetal-working apparatusCarbideAlloy

The invention discloses a powder metallurgy high-speed steel valve seat for a clean fuel engine and a production process of the powder metallurgy high-speed steel valve seat. With W6Mo5Cr4V2 high-speed steel powder as a base body material, Cu, Co-Cr-Mo and Fe-Mo hard particles are added, and the hard particles comprise, by mass percentage, 45%-57% of W6Mo5Cr4V2, 13%-17% of Co-Cr-Mo, 4%-7% of Fe-Mo, 17%-22% of Cu and 2%-3% of a solid lubricant and easy-to-cut components. According to the powder metallurgy high-speed steel valve seat, by the adoption of an infiltration sintering and heat treatment technology, the density of the powder metallurgy high-speed steel valve seat is increased, the hardness, wear resistance and the like of the powder metallurgy high-speed steel valve seat are improved; and on the one hand, stable alloy tempered martensite and fine dispersed secondary alloy carbide can be obtained, and on the other hand, the bonding of a base body and the hard particles is firmer, and the hard particles are not likely to be peeled off from the base body during frictional wear. By the adoption of the infiltration sintering and heat treatment technology, the density of the material is increased, and the hardness, wear resistance and the like of the material are improved.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

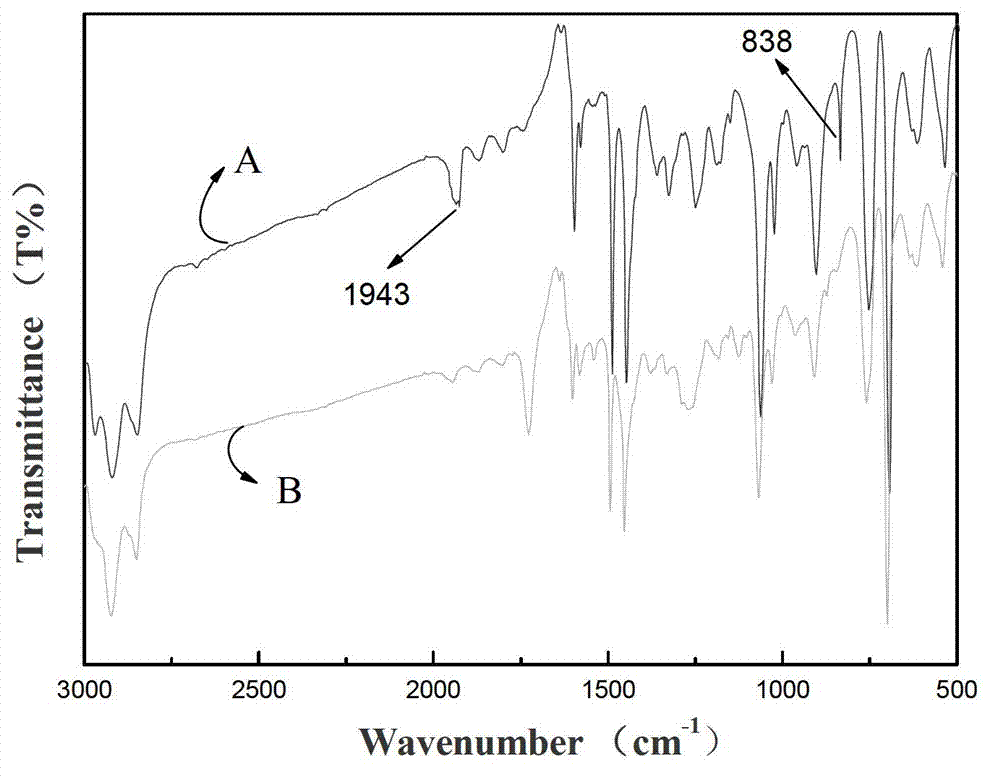

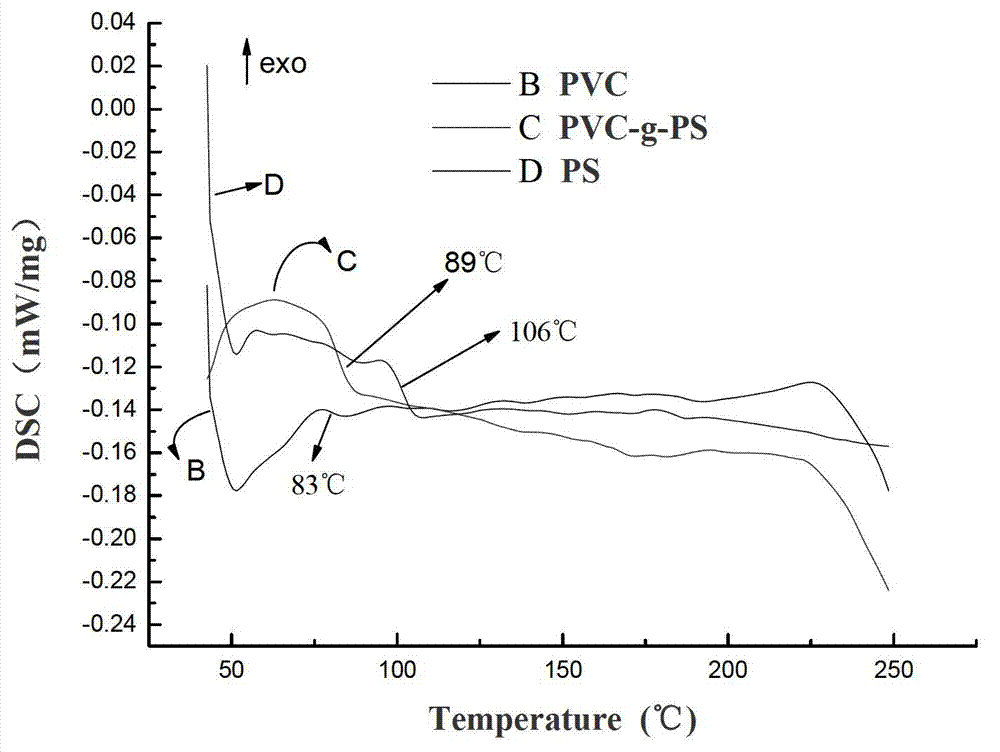

PVC (polyvinyl chloride)/styrene polymer alloy and preparation method thereof

ActiveCN102731936AAlloying is simpleImprove flame retardancyAluminum chloride anhydrousCompatibilization

The invention discloses a PVC (polyvinyl chloride) / styrene polymer alloy. The alloy is characterized by being prepared from the following raw materials in percentage by weight: 50-95% of PVC resin, 3-30% of styrene polymer, 0.2-6% of catalyst, 0-10% of addition agent and 1.5-4% of heat stabilizer. Besides, the invention also discloses a preparation method of the PVC / styrene polymer alloy. The PVC / styrene polymer alloy material has the following advantages: not only are the defects of the existing extra compatilizer overcome, but also the alloying of PVC and styrene polymer is simpler and more convenient; anhydrous aluminium chloride, anhydrous ferric chloride or anhydrous stannic tetrachloride is taken as the catalyst; the reaction mixing / extrusion in-situ compatibilization technology is adopted, thus realizing the blending of PVC and styrene polymer; and the polymer alloy material can improve the flame retardance of the styrene polymer while reinforcing and toughening the PVC, and has industrial application prospects.

Owner:XIAN UNIV OF SCI & TECH

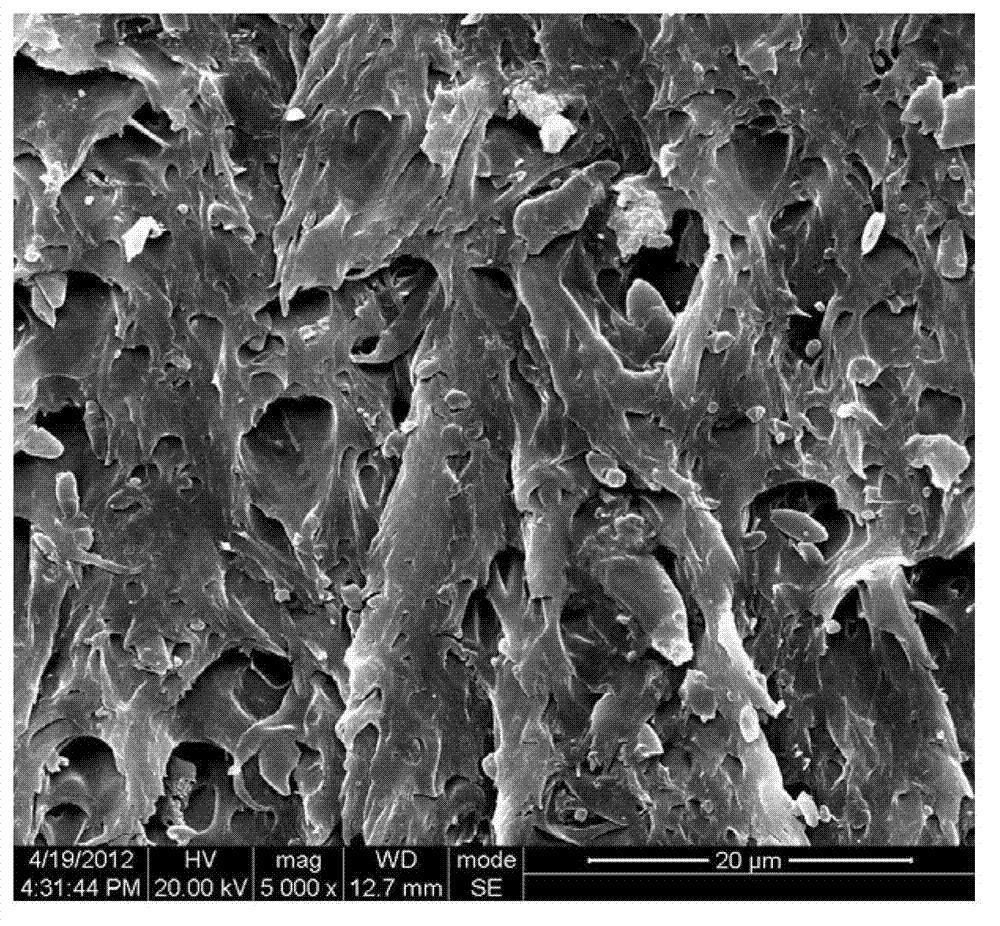

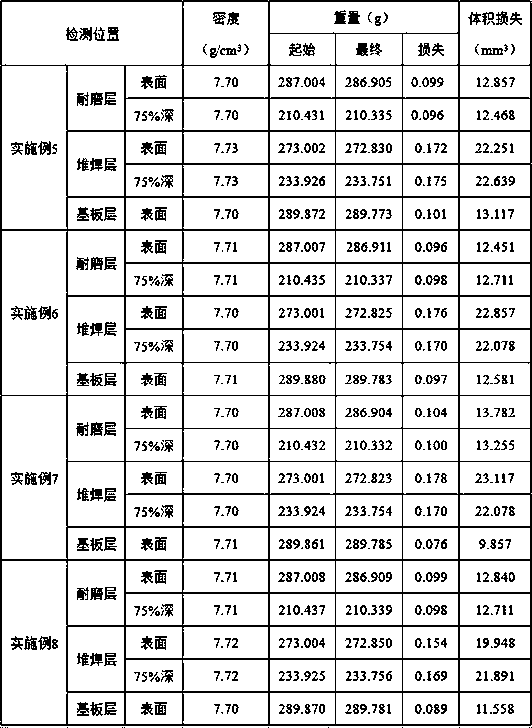

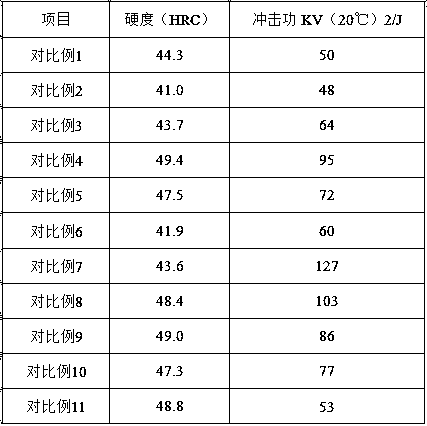

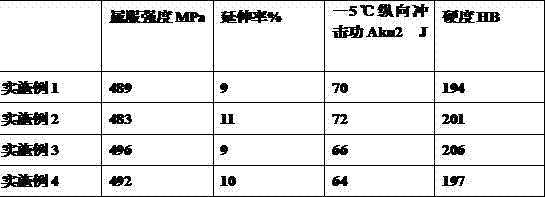

Impact-resistant abrasion-resistant composite steel plate

ActiveCN109082579APromote alloyingImprove wear resistanceWelding/cutting media/materialsSoldering mediaManganeseAlloy composite

The invention relates to the technical field of metal welding materials, in particular to an impact-resistant abrasion-resistant composite steel plate. The impact-resistant abrasion-resistant composite steel plate comprises a base plate layer and an abrasion-resistant layer, wherein the base plate layer is a common steel plate, and the abrasion-resistant layer is a high-strength alloy composite layer. The abrasion-resistant layer comprises, by weight, 25.00%-55.00% of chromium, 3.00%-8.00% of carbon, 0.50%-4.00% of manganese, 0.10%-3.00% of silicon, 0.25%-3.00% of nickel, 0.25%-3.00% of molybdenum, 0.10%-1.50% of vanadium, and the balance iron and inevitable impurities. The impact-resistant abrasion-resistant composite steel plate overcomes the defects that precious metal adding in a traditional abrasion-resistant layer is high and the abrasion resistance is low caused by low C content. By adding a small amount of vanadium with lower cost, the abrasion resistance of the abrasion-resistant layer is improved. According to the impact-resistant abrasion-resistant composite steel plate, the C content is increased within the range of components and proportions, but the abrasion-resistantlayer still has better toughness, so that the composite steel plate has better abrasion-resistant strength and toughness.

Owner:江苏沃盾耐磨新材料有限公司

Powder metallurgy method of titanium alloy for preparing golf club head

A metallurgy method for producing titanium alloy powder for producing golf bar heads is disclosed, pertaining to preparing method of titanium alloy for golf bar heads. The method uses Ti powder and additive powder containing Al, V, Fe, and Mo elements as raw materials, mixes the Ti powder with a certain granularity proportion and the additive powder with a certain component range evenly, prepares slice blank by using a die forming mode, uses a multi-stage heating technique giving priority to middle-low temperature quick heating and high temperature slow heating during sinter process, performs quenching immediately after the heating process is completed, thereby prepares the Ti alloy sintering blank, and the titanium alloy material for producing golf bar head is finally produced by forge work and subsequent anneal process. Since the powder metallurgy technique has the characteristics of near net shape and easily control components, alloying is realized easily. At the same time, the high-usage of raw material is provided, the raw material cost and processing cost are saved, and the production energy consumption is reduced greatly. The method is suitable for producing titanium alloy material for producing golf bar heads.

Owner:GUIZHOU TAIYI TECH DEV

Method for preparing single crystal blades based on double-induction directional recrystallization of ultrafine nickel powder area

ActiveCN107159896ALower crystallization temperatureGrain refinementTurbinesZone meltingSingle crystal

The invention relates to a method for preparing single crystal blades based on double-induction directional recrystallization of an ultrafine nickel powder area. Ultrafine single crystal nickel powder serves as a main raw material; other ultrafine metal powder is added according to the high-temperature alloy material prescription requirement; and the nickel-based high-temperature alloy single crystal turbine blades of an airplane engine are prepared through the method of smelting, directional solidification and recrystallization of the double-constraint induction area of an electromagnetic field after forming. Compared with the prior art, the method for preparing the single crystal blades based on double-induction directional recrystallization of the ultrafine nickel powder area has the advantages that alloying and recrystallization are completed at a time, the recrystallization process is easy to control, the single crystal finished product rate is high, mechanical performance of products is high, the production cost is high, a mould shell and a mold core are not needed, and waste is not generated in crystal guiding and selecting sections.

Owner:SHANGHAI JIAO TONG UNIV

Alloyed molten zinc plated steel sheet and process of production of same

ActiveUS7695826B2Good shapeabilityHigh strengthHot-dipping/immersion processesLiquid surface applicatorsAlloyZinc

The present invention provides an alloyed molten zinc plated steel sheet having an area of the Fe and Zn alloy phase in the unformed parts in the plating layer of less than 10% of the area of the steel sheet as a whole and superior in strength and shapeability and a method of producing this alloyed molten zinc plating steel sheet by a continuous zinc plating production system which enables production at a low cost without modification of the system or addition of steps, said alloyed molten zinc plated steel sheet characterized by comprising a steel sheet including C: 0.05 to 0.40%, Si: 0.2 to 3.0%, and Mn: 0.1 to 2.5%, the balance comprised of Fe and unavoidable impurities, having on its surface a Zn alloy plating layer comprised of Fe in a concentration of 7 to 15 wt %, Al in a concentration of 0.01 to 1 wt %, and the balance of Zn and unavoidable impurities, said plating layer containing oxide particles of at least one type of oxide selected from an Al oxide, Si oxide, Mn oxide, and complex oxides of the same alone or in combination.

Owner:NIPPON STEEL CORP +1

High-performance copper alloy

The invention relates to a high-performance copper alloy, and belongs to the field of copper alloy materials and powder metallurgy. The copper alloy comprises Cu, Cr, Zr and M according to the mass percentages of 0.1% to 5.0% of Cr, 0.1% to 5.0% of Zr, and 0.05% to 0.5% of M. M is composed of Re and at least two elements of Mg, Ag, B, Ga, Si, Li, Ti, Fe and Mn. RE is composed of at least three elements of Ce, La, Yb, Pr, Nd and Sm. According to the high-performance copper alloy, the Cu-Cr-Zr-M copper powder is prepared by adopting a gas atomization technology, a supersaturated solid solution with uniform ingredients and fine microstructures is obtained, then the powder is subjected to extrusion molding with a powder sheath and heat treatment, and the Cu-Cr-Zr-M copper powder with excellentperformance is prepared. The high-performance copper alloy is reasonable in component designing, and simple and controllable in preparation technology, a product is good in performance, and large-scale industrial application is facilitated.

Owner:CENT SOUTH UNIV

Gold deposition process on surface of metal palladium and preparation of palladium alloy membrane

ActiveCN106381484AImprove conversion rateIncrease profitLiquid/solution decomposition chemical coatingPotassiumAlloy

The invention relates to a method of preparing a Pd-Au alloy membrane by means of chemical plating on the surface of a porous ceramic or a porous metal matrix and belongs to the field of application of chemical plating. The method is characterized in that a gold plating solution used in a gold plating process for preparing the Pd-Au alloy membrane is composed of four agents: A, B, C and D, wherein A is one or more of chloroauric acid, gold chloride, sodium chloroaurate, potassium chloroaurate and ammonium chloraurate powder; B is a complexing agent EDTA, for example, Na2EDTA and (NH4)2EDTA; C is ammonia water; and D is NaOH or KOH. Compared with an existing gold plating method, the chemical plating process provided by the invention is mild in reaction condition and can be totally performed at normal temperature, and the gold plate is more uniform and compact, so that unordered gold precipitates are avoided and hollowness in a gold layer is avoided. As the gold chemical plating solution does not contain highly toxic cyanides, the process is an environmental-friendly green process. The gold plating process can improve the conversion rate and the utilization ratio of gold, and no impurities will be introduced into the gold plate.

Owner:RISON HI TECH MATERIALS CO LTD

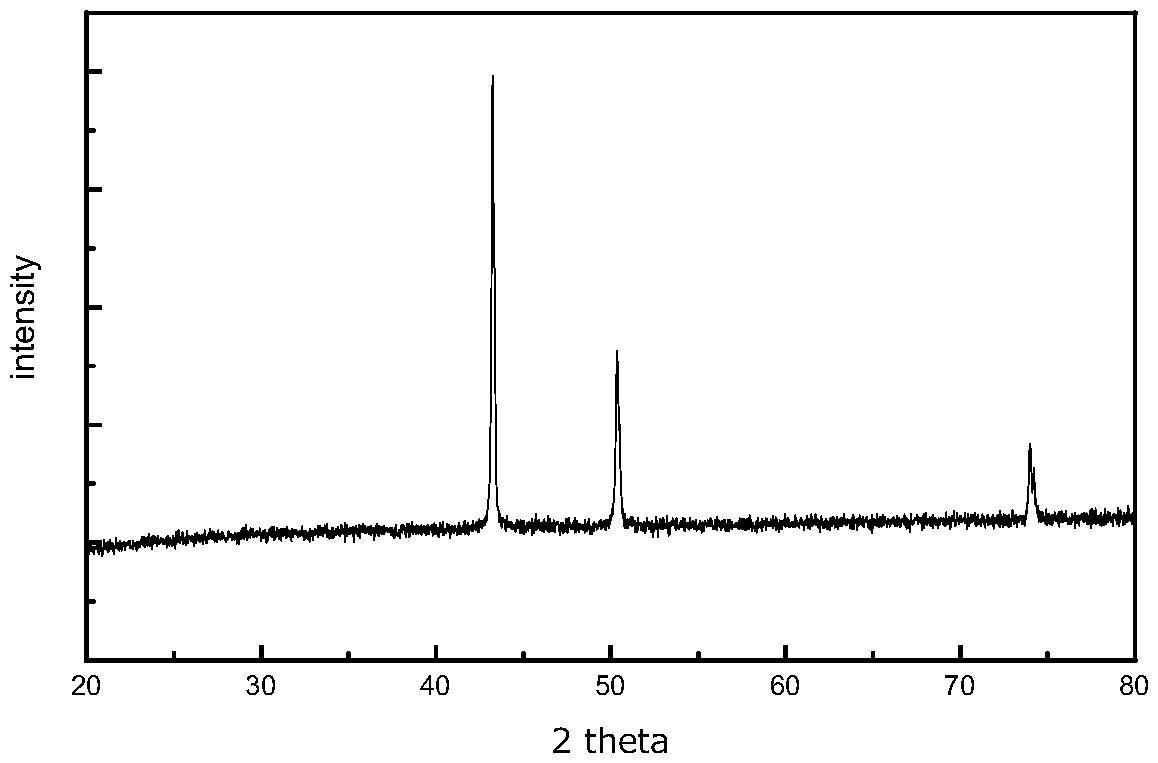

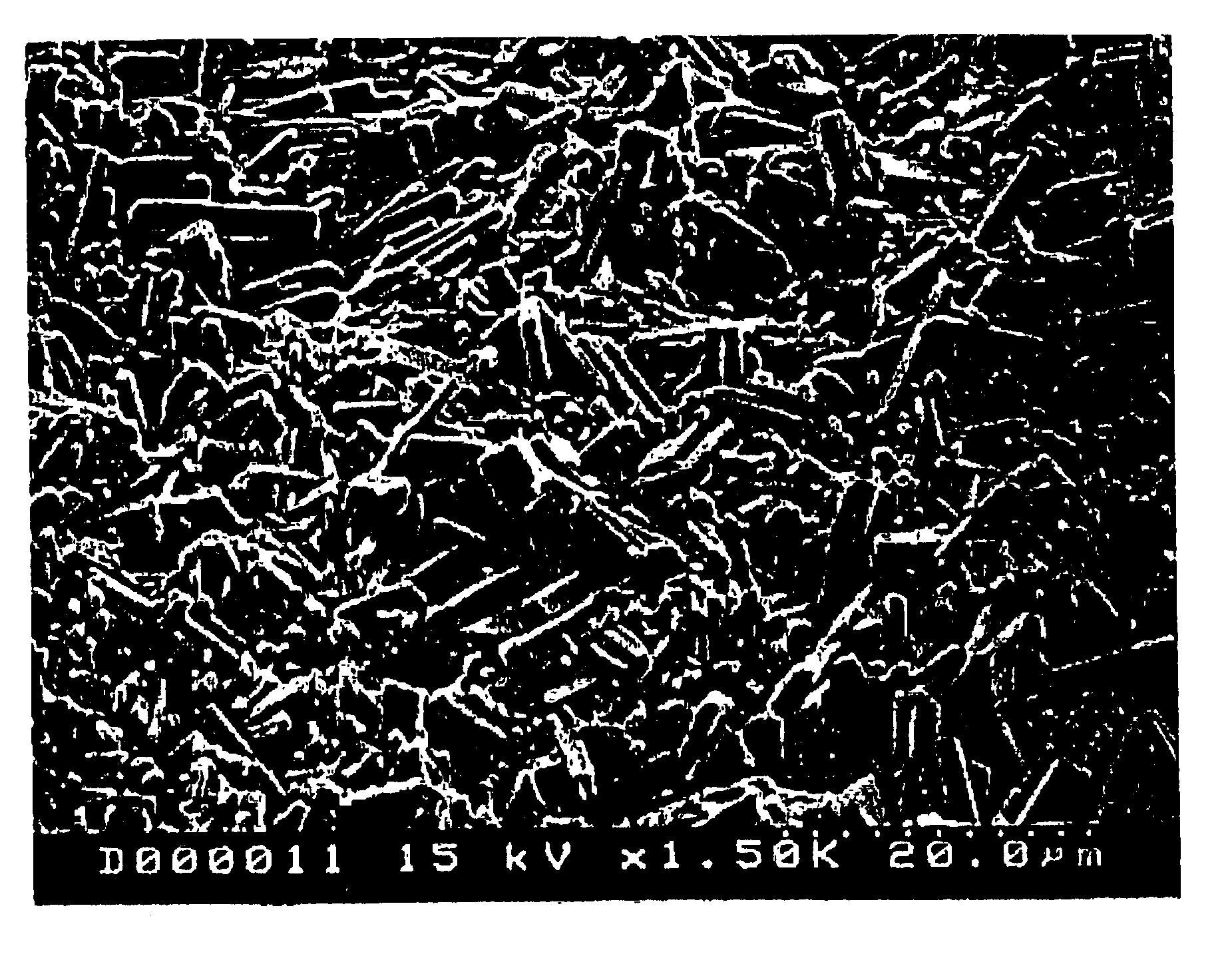

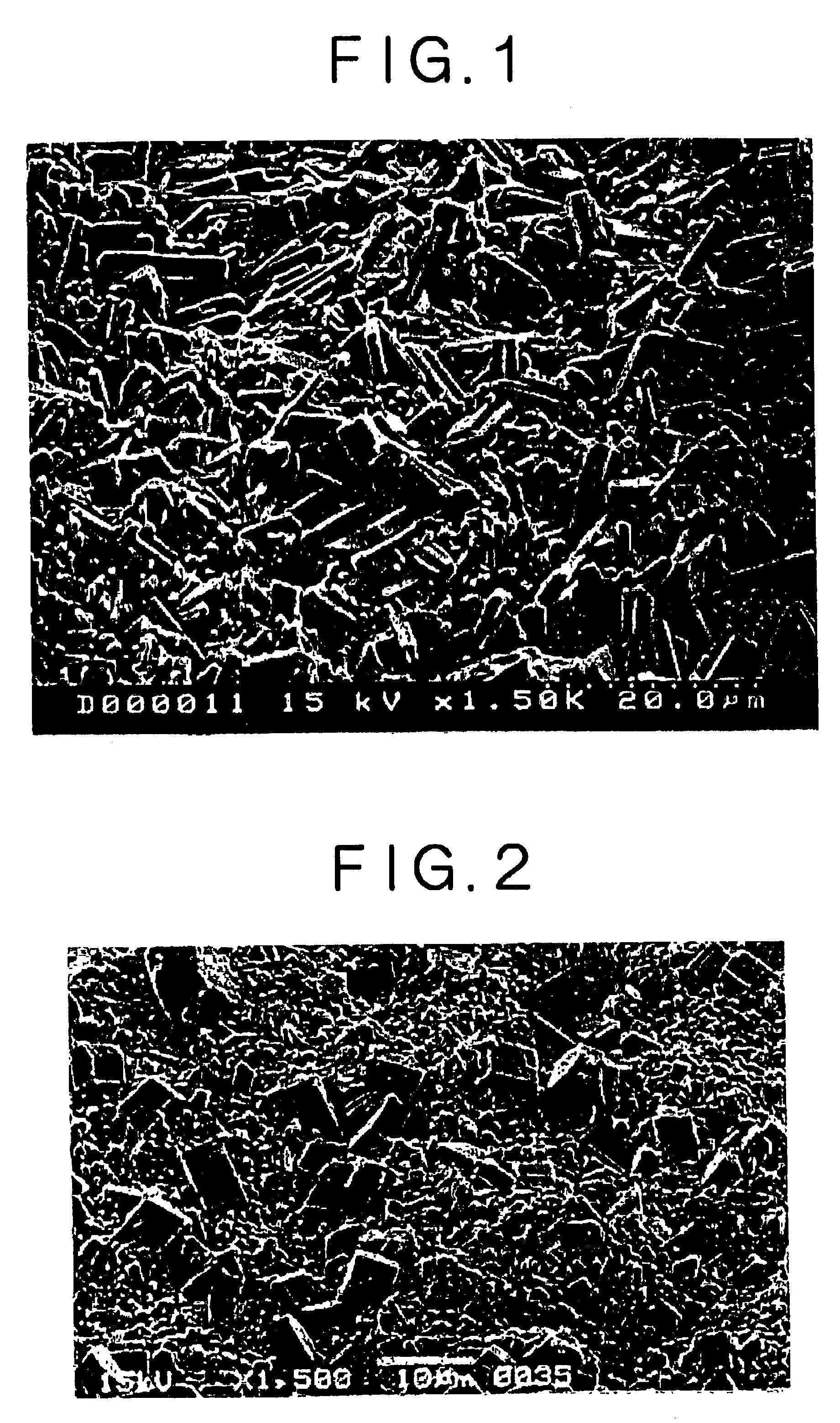

Galvannealed steel sheet superior in workability

InactiveUS6767652B2Improve mechanical propertiesElongationHot-dipping/immersion processesLiquid surface applicatorsSurface layerAlloy

A galvannealed steel sheet superior in workability wherein the steel sheet is characterized by containing silicon in an amount no less than 0.8 mass % and retained austenite in an amount no less than 3% (in terms of packing factor) and the alloy zinc plating is characterized by containing Zn-Fe alloy crystal grains which exist in its surface layer and have a specific crystal grain size such that the longer side of a crystal grain is no larger than twice the shorter side of a crystal grain and the number of crystal grains with an average particle size no smaller than 4 mum is no more than 5 per 70x50 mum.The steel sheet with alloy zinc coating has good mechanical properties (such as total elongation) and good plating surface slidability.

Owner:KOBE STEEL LTD

A kind of production method of zn/cu-ag/cu-au composite coated steel strip for photoelectric material

ActiveCN105063620BReduce glossPrecise and controllable thicknessSuperimposed coating processLoss rateHydrogen

A production method of a Zn / Cu-Ag / Cu-Au composite coating steel band for a photoelectric material comprises the following steps: using a 08Al cold-rolled steel sheet as a raw material and carrying out cold rolling; after conventional degreasing, carrying out uncoiling, splitting and deburring; hot-dipping Zn; thermally spraying Cu-Ag; carrying out primary annealing at a pure nitrogen protective atmosphere; thermally spraying Cu-Au; carrying out secondary annealing at a pure nitrogen protective atmosphere; and air-cooling to a room temperature and coiling. The tensile strength is 250-300MPa, and the elongation percent is 42-48%. One Zn / Cu-Ag / Cu-Au composite coating is generated on the surface. After the Zn / Cu-Ag / Cu-Au composite coating steel band is placed under an indoor conventional atmospheric condition for 960 days, the gloss loss rate of the coating is not larger than 0.3%, and the surface corroded area is not larger than 0.3%. The product has excellent electricity and heat conductivity. After the Zn / Cu-Ag / Cu-Au composite coating steel band is kept at 300-350 DEG C for 960 days, the surface oxidized area is not larger than 0.2%, and the hardness variation rate is not larger than 0.2%. The product also has excellent welding and machining performance.

Owner:武汉钢铁有限公司

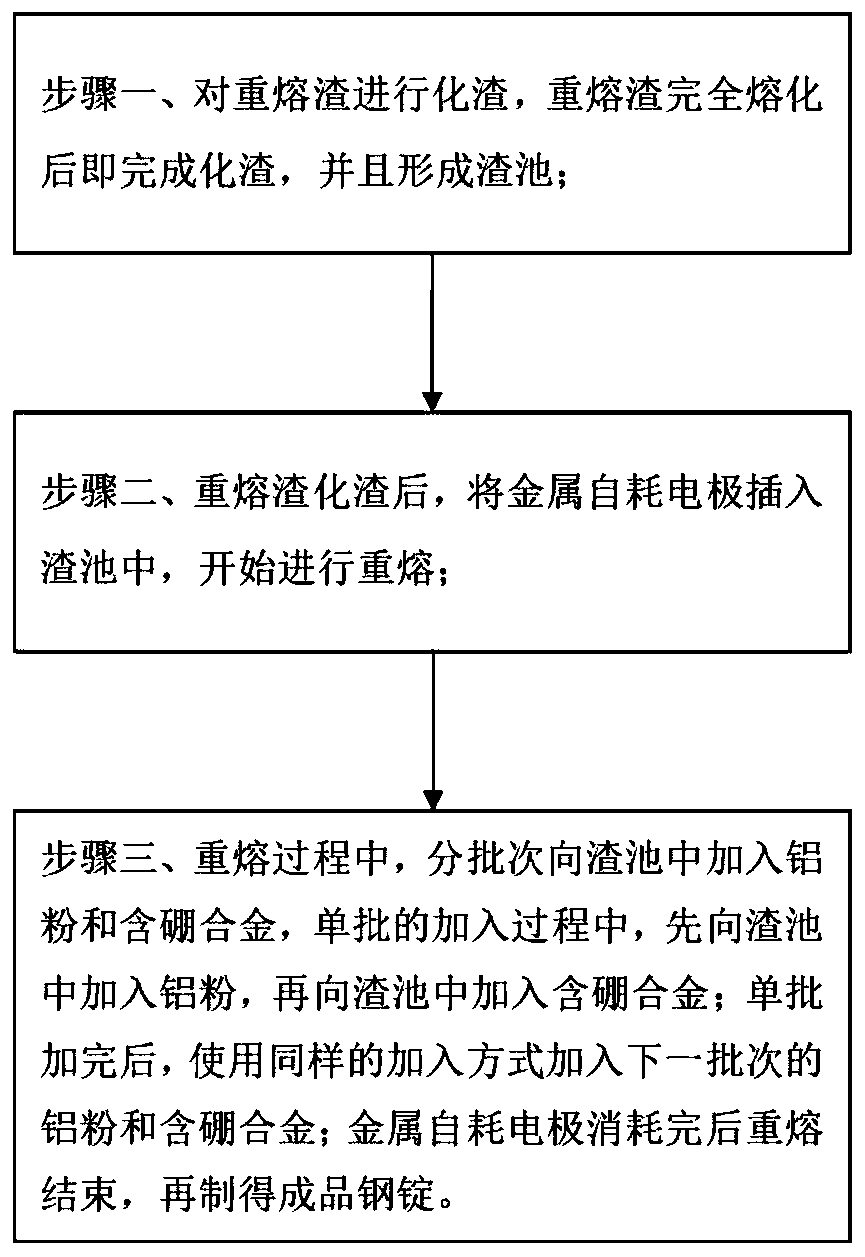

Method for conducting boron alloying in electro-slag remelting process

The invention discloses a method for conducting boron alloying in the electro-slag remelting process and relates to the technical field of electro-slag remelting. In the electro-slag remelting process, after a metal consumable electrode is inserted into a slag bath and starts remelting, boron-contained alloy composed of Al-B-Fe is added to the slag bath, and then boron alloying is conducted on steel of metal consumable electrode. The boron alloy is added into the slag bath, so that Al in the boron-contained alloy can locally conduct targeted deoxidation around the B element, it is avoided thatthe B element is oxidized in the adding process, and therefore the final yield of the B element is improved; in addition, after the boron-contained alloy composed of the Al-B-Fe is added, the boron-contained alloy can rapidly pass across the slag bath to float between interfaces of the slag bath and a melting bath, on one hand, doping can be avoided, and on the other hand, rapid alloying of molten steel is facilitated.

Owner:马鞍山市中桥金属材料有限公司

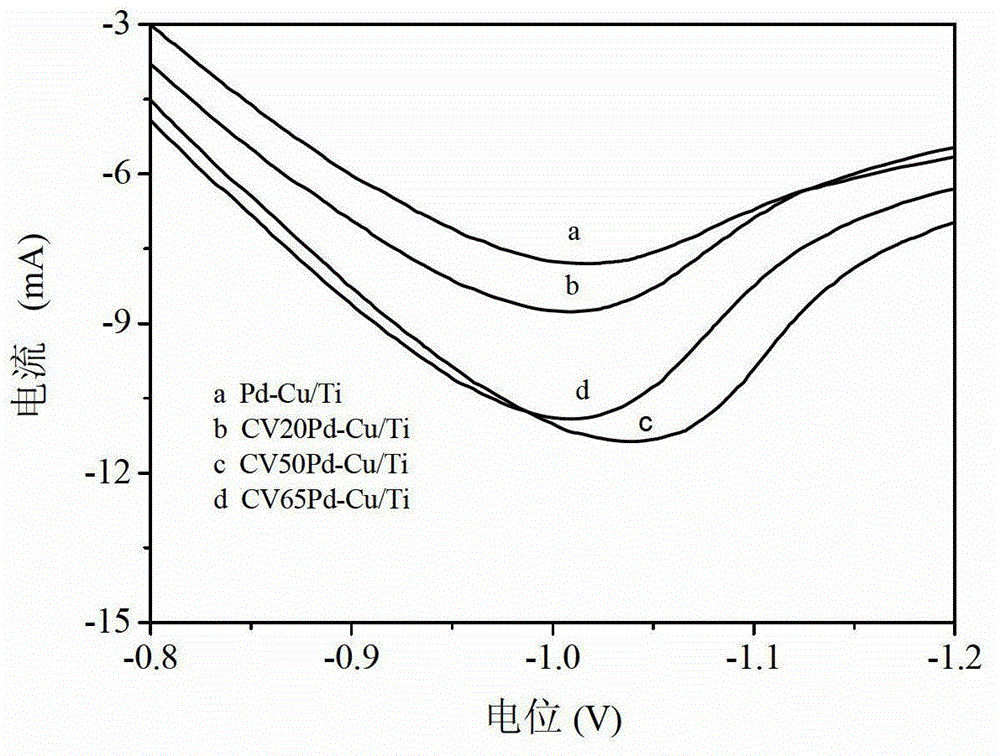

CA scanning assisted preparation method and applications of Pd-Cu/Ti electrode

ActiveCN103334121ALong electrode lifeThere will be no secondary pollution problemsWater/sewage treatmentElectrodesPlatinumElectrochemistry

The invention discloses a CA scanning assisted preparation method and applications of a Pd-Cu / Ti electrode, and belongs to the field of electrochemical water treatment technologies. The CA scanning assisted preparation method comprises following steps: firstly, preparing a PdCl2 solution containing CuSO4, and adjusting the pH value of the solution to 1.0; taking a titanium mesh as a cathode, and a platinum sheet as an anode, and performing deposition with a constant potential so as to obtain the Pd-Cu / Ti electrode, wherein the constant potential relative to the potential of a Hg / Hg2SO4 electrode is -0.9V; and then subjecting the Pd-Cu / Ti electrode to CV scanning in a H2SO4 solution of 0.5M, wherein the potential scanning range is -800mV to 700mV, the scanning speed is 50Mv / S, and the scanning circles are 1 to 65. The Pd-Cu / Ti electrode can be used for electrocatalytic reductive dechlorination of PCP, and the reaction solution is close to neutral after the reaction by controlling an initial pH value, so that it is convenient for subsequent processing.

Owner:BEIJING UNIV OF TECH

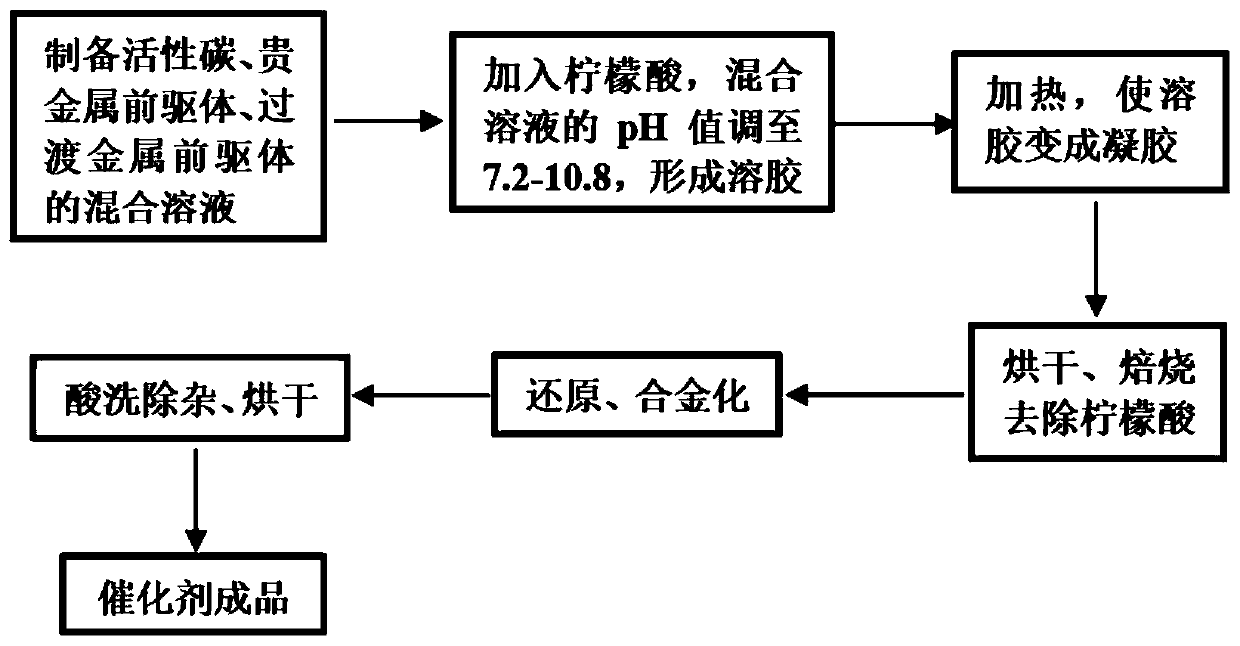

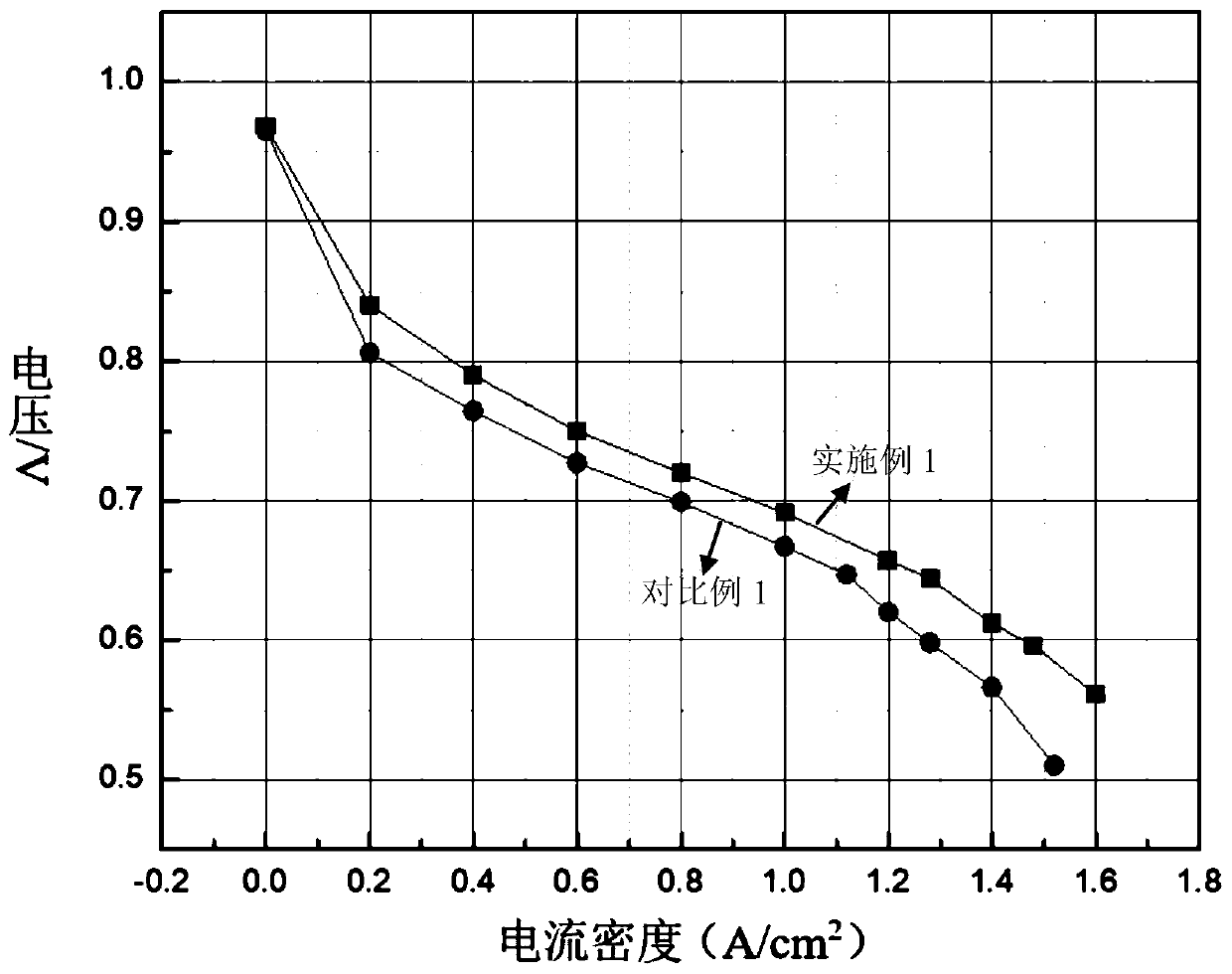

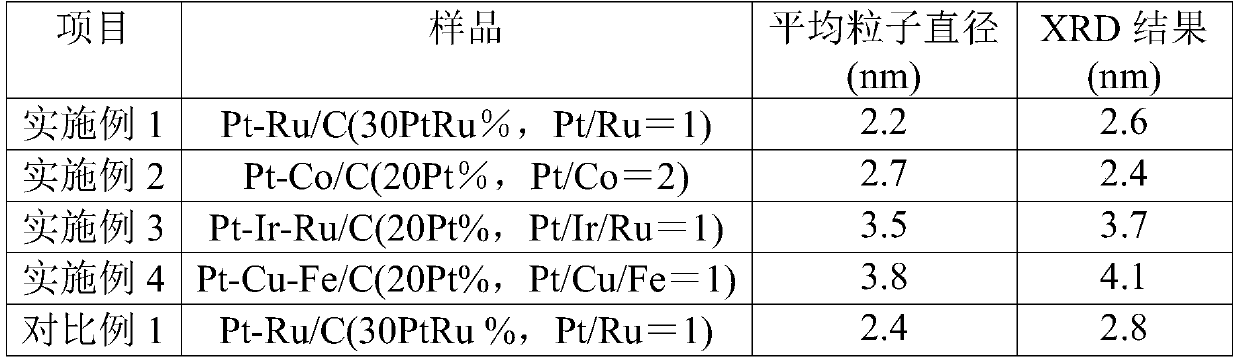

Preparation method of dual-element or multi-element noble metal catalyst for fuel cell

ActiveCN111584885AIncrease profitFavorable for activity and longevityCell electrodesActivated carbonSol-gel

The invention belongs to the technical field of fuel cells, and particularly relates to a preparation method of a dual-element or multi-element noble metal catalyst for a fuel cell. One or more transition metal components are introduced into noble metal, and the noble metal and the transition metal are alloyed, so that the oxygen reduction activity of the alloyed cathode is higher than that of single-component noble metal, and the loading capacity of the noble metal can be reduced; and the spherical porous activated carbon is adopted, more active sites can be exposed out of the catalyst due tothe large specific surface area of the spherical porous activated carbon, and the prepared nano-alloy particles are all concentrated on the surface of the carbon carrier, so that the utilization rateof the catalyst can be increased. In the preparation process, one or more precursor solutions form sol-gel, and macromolecular citric acid and metal ions are complexed to form a whole, so that nano-alloy particles can be prevented from being embedded into internal pores of activated carbon, alloying of the nano-alloy particles can be improved, and the performance of the catalyst is improved.

Owner:WUXI WEIFU HIGH TECH CO LTD

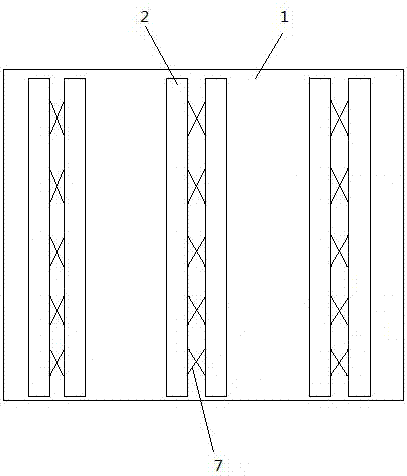

Prefabricated concrete floor

The invention provides a prefabricated concrete floor. The prefabricated concrete floor comprises a plurality of longitudinal U steel, wherein every two pieces of U steel are arranged back to back and provided with outward openings so as to form a pair of U steel; each U steel is provided with a back plate and an upper plate and a lower plate arranged in up-down symmetry; the back plates of every pair of U steel are provided with connection holes; connecting pieces pass through the connection holes so as to connect a pair of U steel, every two connecting pieces form a group and are arranged in a cross manner, and each group of the connecting pieces is parallel to the other; and concrete is casted out of the longitudinal U steel so as to form the prefabricated concrete floor. According to the invention, paired U steel is formed by connecting each pair of U steel via the parallel groups of two crossed connecting pieces, so the floor is locally reinforced, good strength is obtained in the transverse axial direction of the prefabricated concrete floor; thus, the comprehensive strength of the prefabricated concrete floor is improved, and the relative weight of the floor is reduced. The concrete used in the invention has effectively improved compressive strength and tensile strength.

Owner:绿砼(江苏)建筑科技有限公司

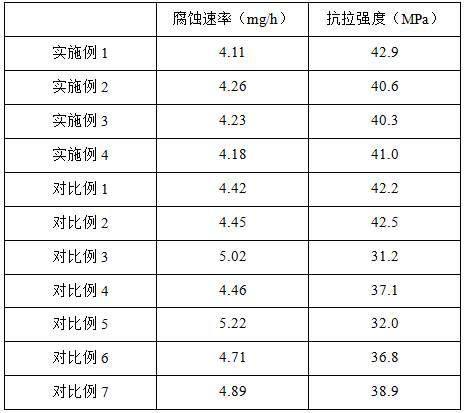

Lead-calcium alloy for positive grid, and preparation method thereof

ActiveCN112522536AAvoid reunionImprove corrosion resistanceElectrode carriers/collectorsElectrical batteryGraphite

The invention discloses a lead-calcium alloy for a positive grid, and a preparation method thereof. The lead-calcium alloy is prepared from the following components: calcium, aluminum, tin, bismuth, rare earth, modified graphene and the balance lead. The lead-calcium alloy for the positive grid is high in corrosion resistance and tensile strength, and the service life of a storage battery can be effectively prolonged; according to the lead-calcium alloy, the content of the calcium in the lead-calcium alloy is controlled to be 0.09%-0.096%, and the anti-corrosion effect can be remarkably improved; when the content of the calcium is 0.094%, the anti-corrosion effect is optimal; when the content of the calcium is higher than 0.096%, in the using process, the growth speed in the length-width direction is increased, the corrosion speed of the alloy is increased, and accordingly the service life of a battery is shortened; when the content of the calcium is lower than 0.09%, the internal crystal structure of the alloy is thickened, and the intercrystalline corrosion speed is increased; and the positive grid can be rotted and broken more quickly in the use process, and consequently the service life of the battery is shortened.

Owner:广东奥克莱集团有限公司

A kind of aluminum alloy composite material and preparation method thereof

Owner:中山市乘盟金属制品有限公司

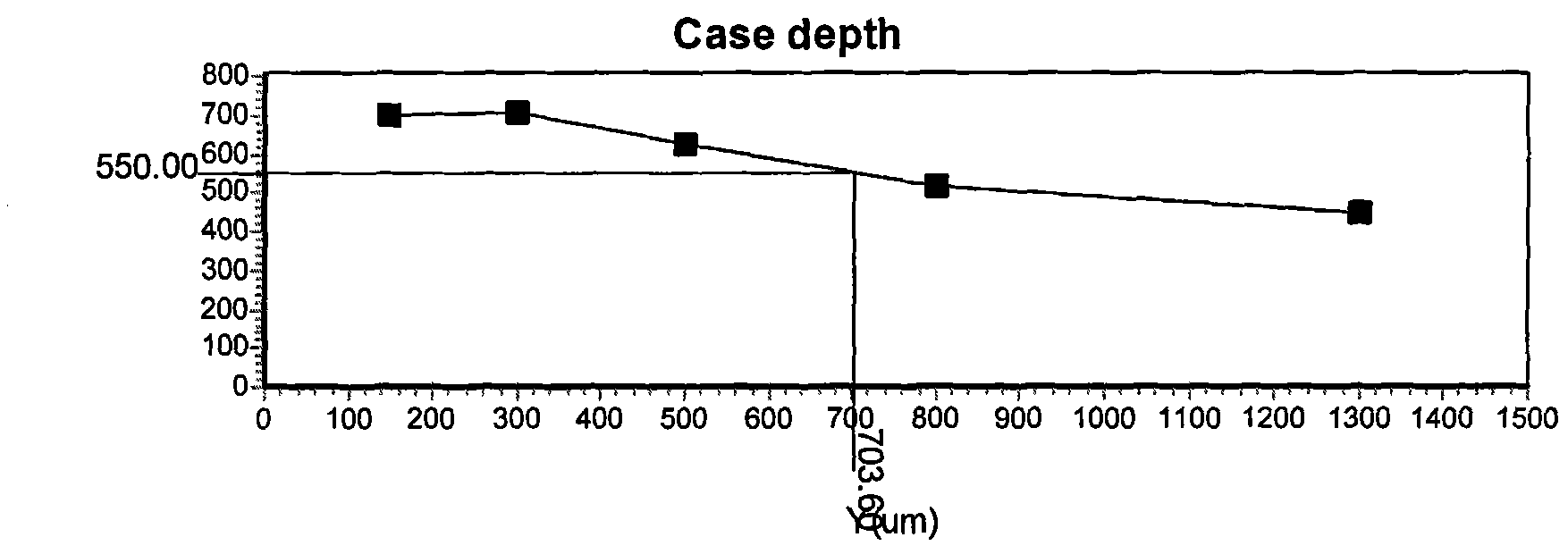

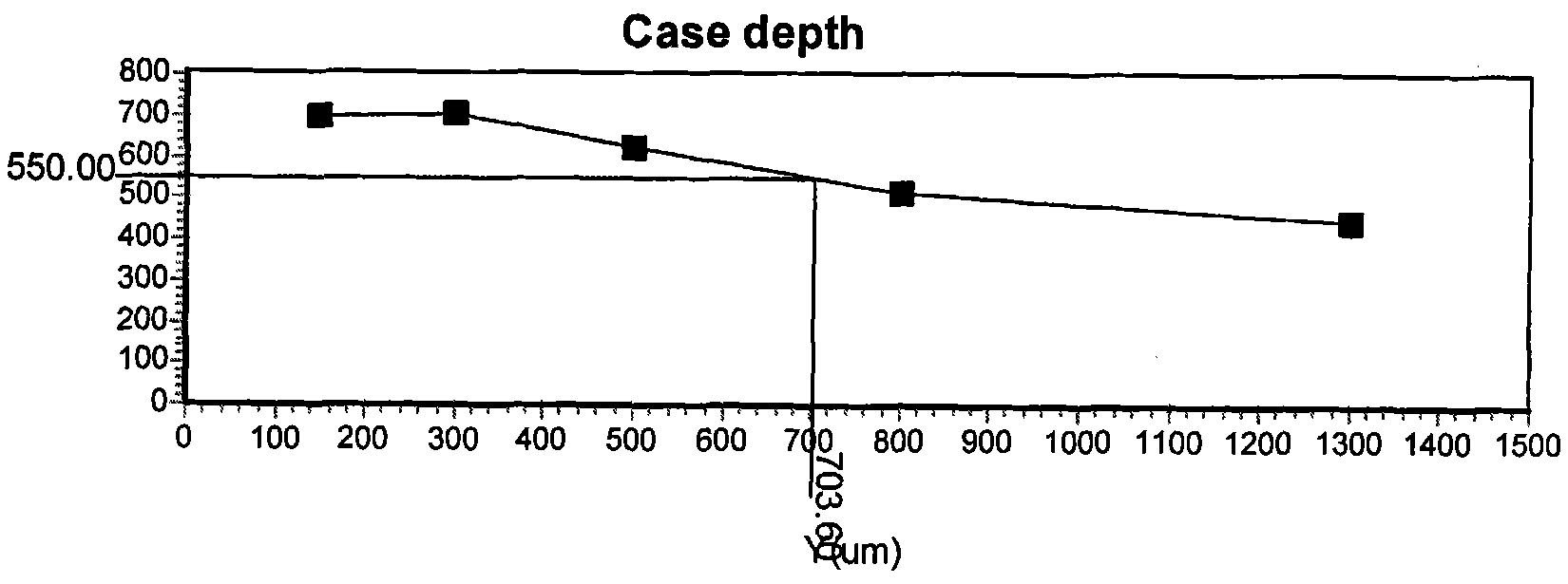

Rapid superficial layer carburizing process for prepared carbon potential of large- and medium-scale furnace body

The invention relates to the technical field of carburizing processes for steel workpieces, in particular to a rapid superficial layer carburizing process for the prepared carbon potential of a large- and medium-layer furnace body. The process comprises the following steps of: controlling the preparing carbon potential of a steel workpiece at the carburizing temperature of 800 DEG C-900 DEG C, controlling the proportion of the strong carburizing period and the spreading period of the steel workpiece, and controlling baked carbon potential retraction of the steel workpiece to obtain the expected depth and tissue of a carburizing layer, thereby effectively controlling the quality of the steel workpiece. The invention has the significance of breaking through the blind spot that the superficial layer carburizing with common carburizing depth of the large- and medium-scale equipment is controlled above 1.2mm and below 0.9mm is difficult to relate and control by using the large- and medium-scale equipment, meanwhile, the process opens up a simple and practical way for the superficial layer carburizing of the large- and medium-scale equipment.

Owner:CRRC QISHUYAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com