Metal powder atomization device and method for the device to prepare FeCoTaZr alloy powder

An atomization device and metal powder technology, applied in the field of alloy powder preparation, can solve the problems of large target grain size, difficult alloying, and poor composition uniformity, and achieve low impurity content, good alloying, and low oxygen content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

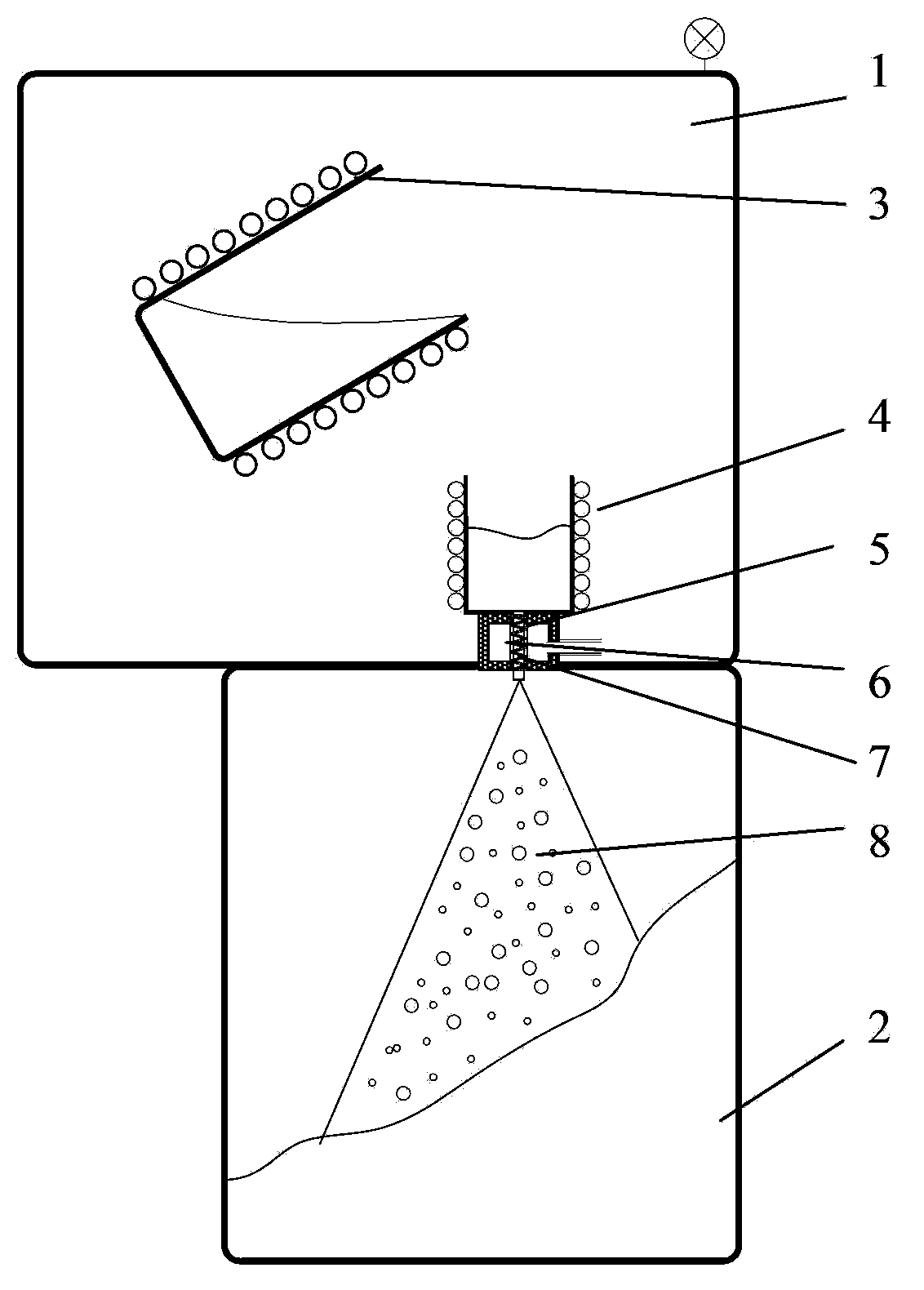

Method used

Image

Examples

Embodiment 1

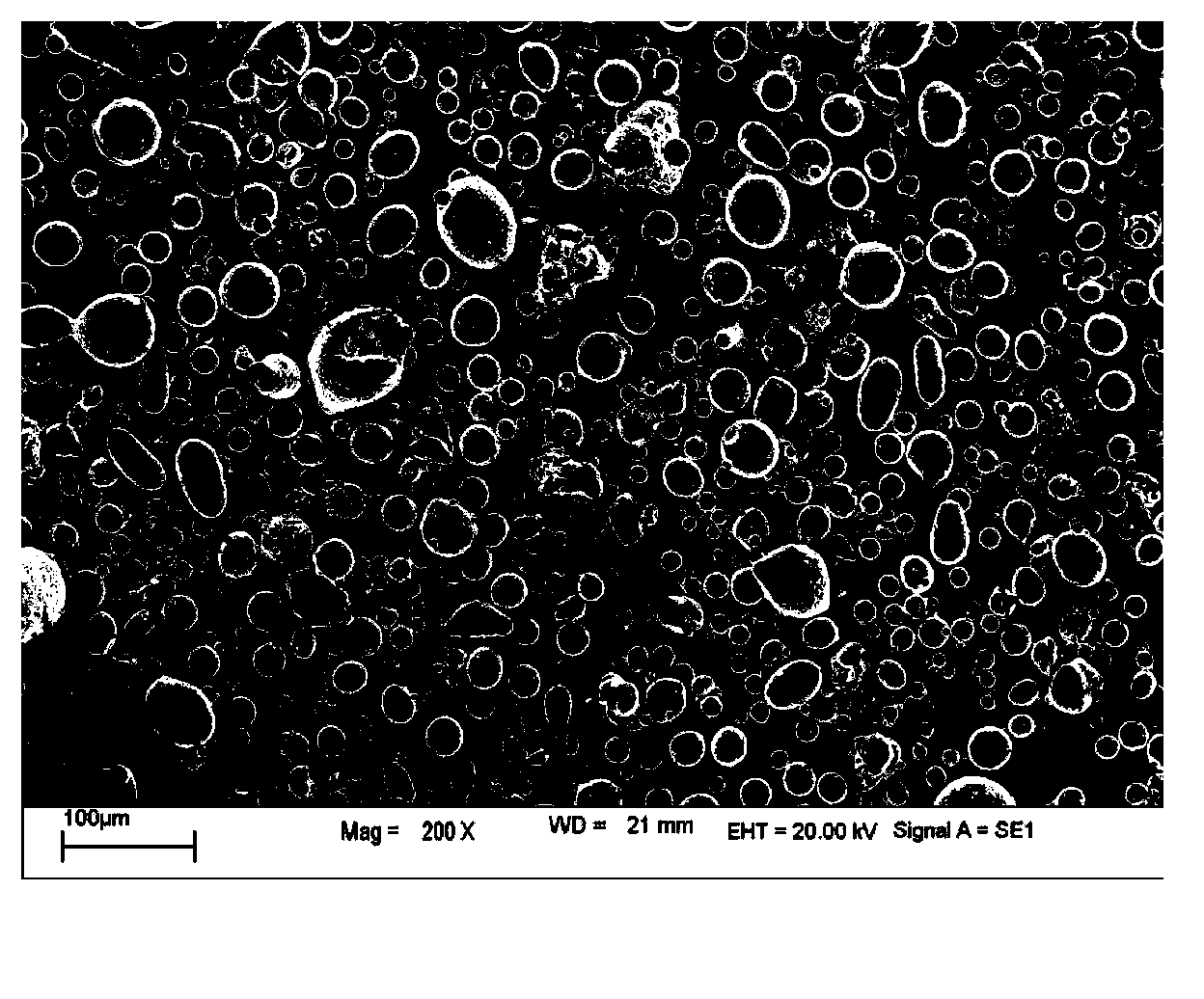

[0025] In the alloy powder in this example, the contents (percentage by weight) of the four elements Fe, Co, Ta and Zr are 35%, 32%, 24% and 9%, respectively. The ingredients are prepared according to the designed alloy composition, and the purity of the four elements is ≥99.95%. Under the protection of high-purity nitrogen, put the prepared raw materials into the yttrium oxide crucible of the melting furnace, raise the temperature to 1550°C to completely melt the raw materials, and cast them into prefabricated ingots. Put the prefabricated ingot into the intermediate frequency induction melting furnace of the atomization device, under the protection of high-purity nitrogen, raise the temperature to 1650 ° C, keep it for 12 minutes, and then pour the melt into the zirconia tundish, the temperature of the tundish is 1000 ° C, After the melt flows out through a zirconia guide tube with an inner diameter of 4.5 mm, it is atomized with high-purity argon in the atomization chamber,...

Embodiment 2

[0027] In the alloy powder in this example, the contents (percentage by weight) of the four elements Fe, Co, Ta and Zr are 50%, 25%, 22% and 8%, respectively. The ingredients are prepared according to the designed alloy composition, and the purity of the four elements is ≥99.95%. The protective atmosphere in the smelting furnace is high-purity argon, and the prepared raw materials are put into a calcium oxide crucible, and cast into prefabricated ingots at 1500°C. Put the prefabricated ingot into the calcium oxide intermediate frequency induction melting furnace of the atomization device, raise the temperature to 1600°C under the protection of high-purity argon, keep it for 10 minutes, and then pour the melt into the calcium oxide tundish. The temperature of the tundish is At 950°C, after the melt flows out of the calcium oxide and zirconia composite guide tube with an inner diameter of 3.5 mm, it is atomized with high-purity argon in the atomization chamber, and the atomizati...

Embodiment 3

[0029] In the alloy powder in this example, the contents (percentage by weight) of the four elements Fe, Co, Ta and Zr are 31%, 34%, 25% and 10%, respectively. The ingredients are prepared according to the designed alloy composition, and the purity of the four elements is ≥99.95%. A zirconia crucible is used in the melting furnace, the protective atmosphere is high-purity helium, and the melt temperature is 1600°C to cast into prefabricated ingots. Put the prefabricated ingot into the zirconia medium-frequency induction melting furnace of the atomization device. The protective atmosphere in the melting room is high-purity helium. The temperature is raised to 1700°C and kept for 14 minutes. Then, the melt is poured into the zirconia tundish. The tundish temperature The temperature is 1200°C. After the melt flows out of the yttrium oxide guide tube with an inner diameter of 3.0mm, it is atomized with high-purity argon in the atomization chamber, and the atomization pressure is 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com