High-performance copper alloy

A copper alloy, high-performance technology, applied in the field of high-performance copper alloys, can solve the problems that the alloy cannot meet high strength and high conductivity at the same time, the coarse primary second phase has no obvious improvement effect, and affects the conductivity of the alloy. The effect of preparing large-sized products, improving the success rate of milling, and inhibiting formation and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: Alloy powder preparation

[0057] Alloy raw materials are formulated according to the nominal composition of alloy A in Table 1, and pure metal Cu (purity is greater than or equal to 99.99%), Cr (purity is greater than or equal to 99.95%), Zr (purity is greater than or equal to 99.95%) and M (M is a mixture of RE (La: Ce: Yb = 1:3:1), Mg, Ag, B, the specific ratio is RE: Mg: Ag: B = 3:1:2:1) and other alloy raw materials Carry out vacuum melting, the vacuum degree is 5.0×10 -1 Pa, using argon protection; after the raw materials are melted and completely alloyed, adjust the melt temperature to about 1600°C, and then use argon to atomize to prepare powder, and the atomization pressure is 3.5MPa~3.6MPa.

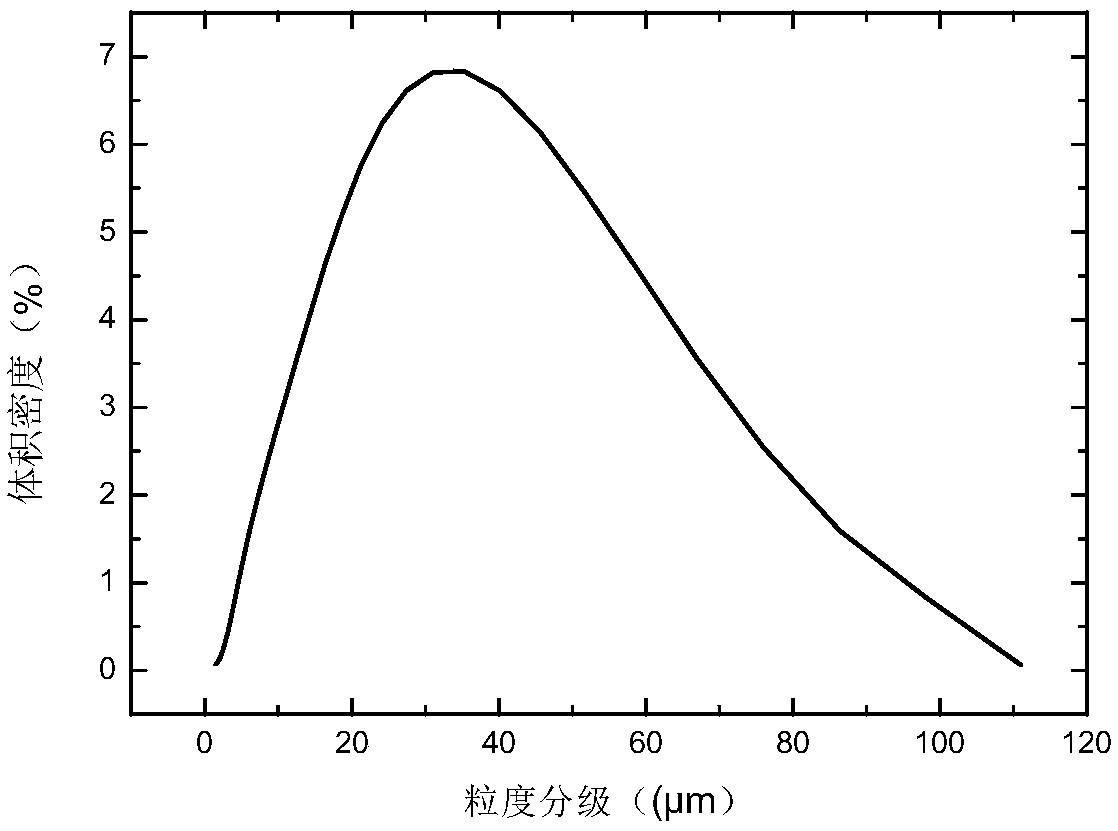

[0058] The prepared powder chemical composition analysis results are shown in Table 1, and its particle size distribution is shown in Table 1. figure 1 , The median diameter of the powder is 28.2 μm (wherein the powder yield of the fine powder with a parti...

Embodiment 2

[0059] Embodiment 2: Alloy A1 and its preparation

[0060] The alloy powder prepared in Example 1 was subjected to sheath extrusion molding and post-treatment to prepare copper alloy material A1. The specific steps are as follows: (1) Put the powder into the copper sheath and vacuumize to 4×10 -1 Pa, and evacuate for 45 minutes in an environment of 80°C, and seal and weld; (2) Carry out hot extrusion molding of the enveloped powder, the extrusion temperature is 750°C, the extrusion ratio is 15:1, and the extrusion rate is 5mm / s; (3) Carry out forging deformation on the extruded sample, and the deformation amount is 10%; (4) Carry out aging heat treatment on the alloy ingot, the aging temperature is 450 ℃, and the aging time is 100 min; (5) The pre-deformed sample is subjected to 5 passes The second rolling, the rolling temperature is room temperature, and the total reduction is 70%; (6) The alloy ingot is subjected to aging heat treatment, the aging temperature is 300° C., an...

Embodiment 3

[0061] Embodiment 3: Alloy A2 and its preparation

[0062] The alloy powder prepared in Example 1 was subjected to sheath extrusion molding and post-treatment to prepare copper alloy material A2. The specific steps are as follows: (1) Put the powder into the copper sheath and vacuumize to 5×10 -1 Pa, and evacuated for 60 minutes in an environment of 70°C, and sealed and welded; (2) Hot-extruded the sheathed powder, the extrusion temperature was 850°C, the extrusion ratio was 20:1, and the extrusion rate was 10mm / s; (3) Carry out forging deformation on the extruded sample, and the deformation amount is 10%; (4) Carry out aging heat treatment on the alloy ingot, the aging temperature is 450 ℃, and the aging time is 100 min; (5) The pre-deformed sample is subjected to 5 passes The first rolling, the rolling temperature is room temperature, and the total reduction is 80%; (6) The alloy ingot is subjected to aging heat treatment, the aging temperature is 300 ° C, and the aging tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com