Preparation method of coconut powder

A technology of coconut flour and coconut milk powder, applied in the field of food processing, can solve the problems of poor quality, loss of nutrients, influence on drinking taste, etc., and achieve the effects of high powder yield, maximizing raw material cost, and good instant dissolving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

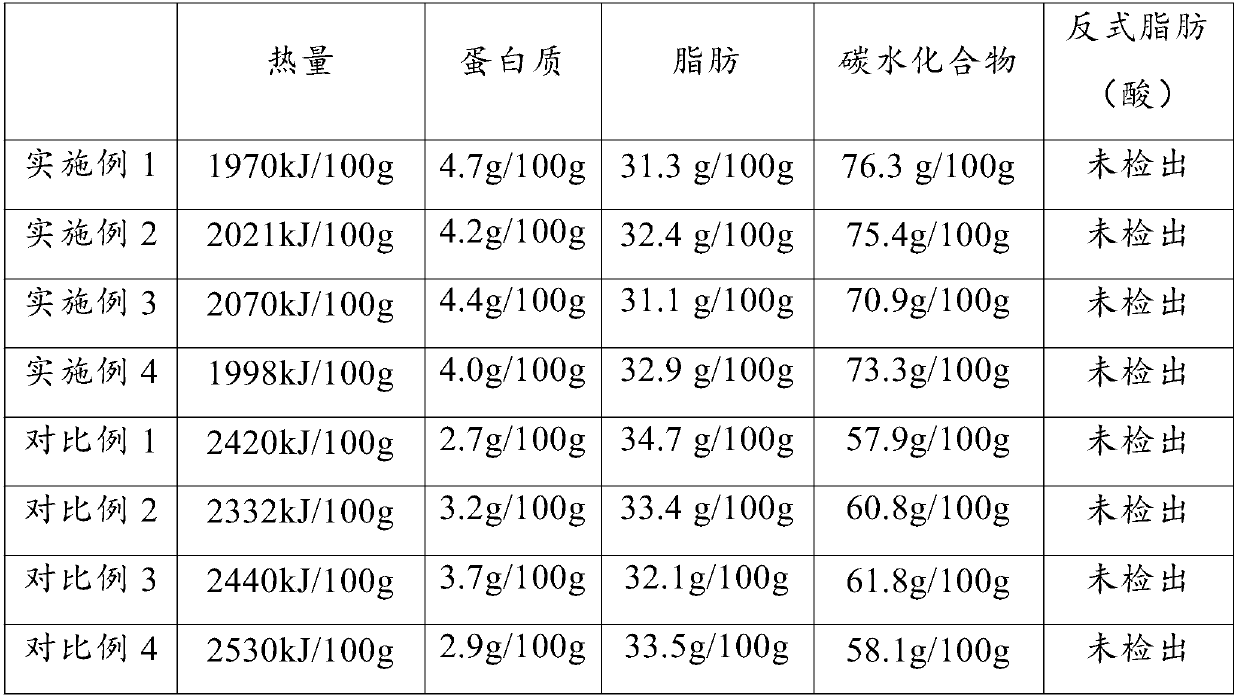

Embodiment 1

[0024] A kind of coconut powder preparation method, comprises the following steps:

[0025] S1: Wash the coconut meat and soak it in the mixed aqueous solution of 0.15% sodium chloride and 0.05% vitamin C for 0.5h, take out the coconut meat and wash it, add water and squeeze it according to the material-to-liquid ratio of 1:4 to make coconut milk, and the pressing temperature is 65°C;

[0026] S2: Coconut milk is filtered through a filter to remove coarse residue;

[0027] S3: Mix the emulsifier and thickener in the coconut milk, adjust the temperature of the coconut milk to 50°C, add citric acid or tricalcium phosphate to adjust the pH to 7, add soybean protein isolate, spirulina and β-cyclodextrin, Adjust the temperature of the coconut milk to 60°C, add citric acid or tricalcium phosphate to adjust the pH to 8.5, and mix well;

[0028] S4: Grinding the coconut milk treated in step S3 with a colloid mill, adjusting the temperature of the coconut milk to 15° C., and keeping ...

Embodiment 2

[0035] A kind of coconut powder preparation method, comprises the following steps:

[0036] S1: Wash the coconut meat and soak it in a mixed aqueous solution of 0.15% sodium chloride and 0.05% vitamin C for 1 hour, take out the coconut meat and wash it, add water and squeeze it according to the material-to-liquid ratio of 1:5 to make coconut milk, and the pressing temperature is 65 ℃;

[0037] S2: Coconut milk is filtered through a filter to remove coarse residue;

[0038] S3: Mix the emulsifier and thickener in the coconut milk, adjust the temperature of the coconut milk to 50°C, add citric acid or tricalcium phosphate to adjust the pH to 6.0, add soybean protein isolate, spirulina and β-cyclopaste Essence, adjust the temperature of coconut milk to 55°C, add citric acid or tricalcium phosphate to adjust the pH to 8.5, and mix well;

[0039] S4: Grinding the coconut milk treated in step S3 with a colloid mill, adjusting the temperature of the coconut milk to 20°C and keeping...

Embodiment 3

[0046] A kind of coconut powder preparation method, comprises the following steps:

[0047] S1: Wash the coconut meat and soak it in a mixed aqueous solution of 0.15% sodium chloride and 0.05% vitamin C for 0.5 hours, take out the coconut meat and wash it, add water and squeeze it according to the material-to-liquid ratio of 1:5 to make coconut milk, and the pressing temperature is 55°C;

[0048] S2: Coconut milk is filtered through a filter to remove coarse residue;

[0049] S3: Mix the emulsifier and thickener in the coconut milk, adjust the temperature of the coconut milk to 40°C, add citric acid or tricalcium phosphate to adjust the pH to 6, add soybean protein isolate, spirulina and β-cyclodextrin, Adjust the temperature of the coconut milk to 55°C, add citric acid or tricalcium phosphate to adjust the pH to 8, and mix well;

[0050] S4: Grinding the coconut milk treated in step S3 with a colloid mill, adjusting the temperature of the coconut milk to 15° C., and keeping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com