Surface alloying ceramic and its preparing process

A technology of surface alloying and ceramics, which is applied in the field of surface alloying ceramics and its preparation, can solve the problems of easy cracking, decline of ceramic surface finish, and poor adaptability, so as to reduce the concentration of interface stress and avoid the influence of obstruction and embrittlement , Improve the effect of interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

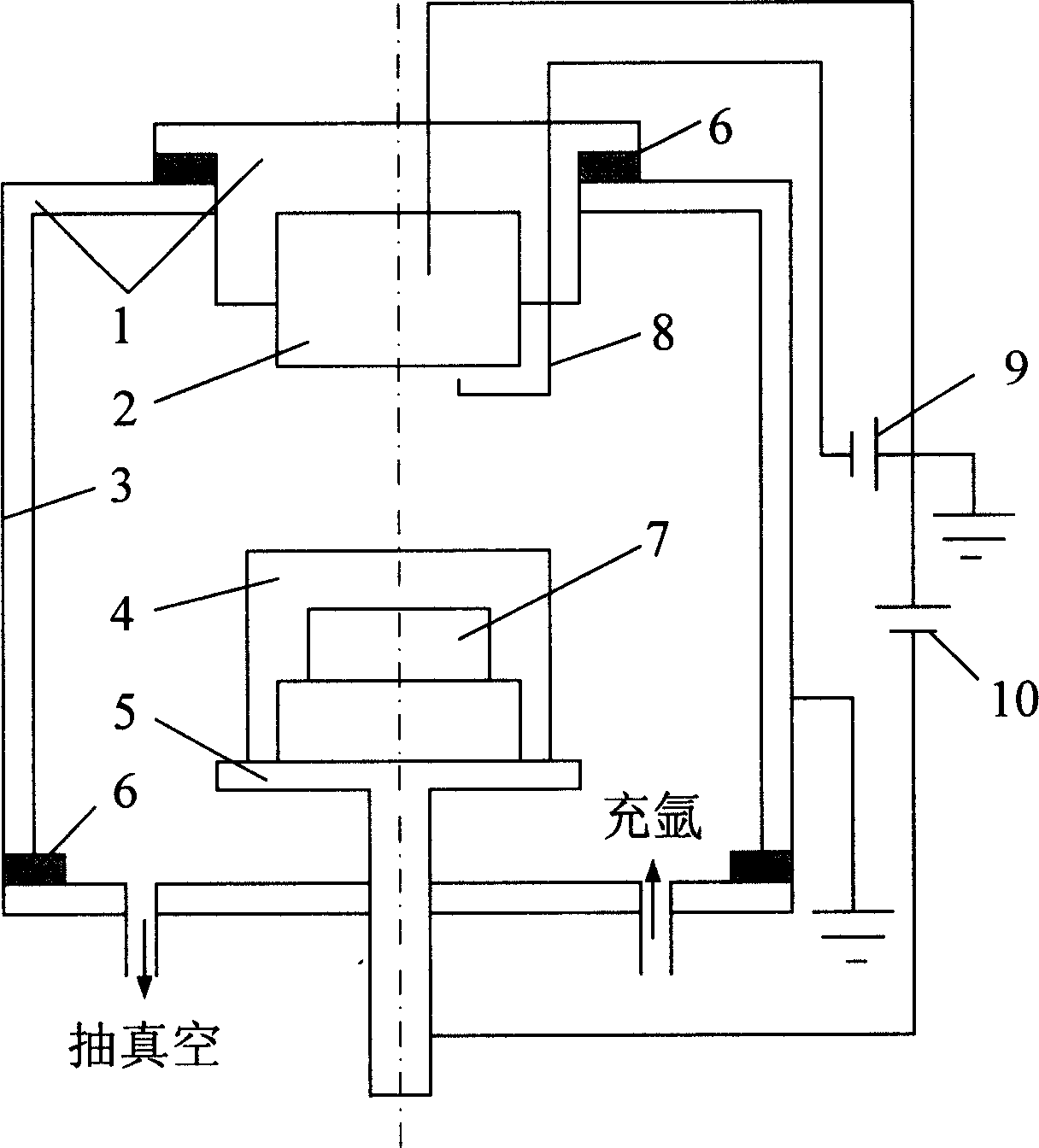

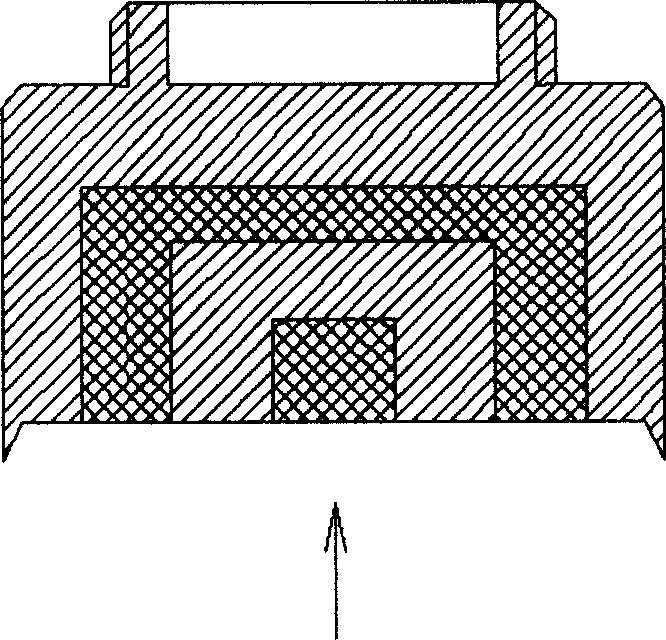

[0027] Surface alloyed Al 2 o 3 Preparation of ceramics for the purpose of conducting surfaces.

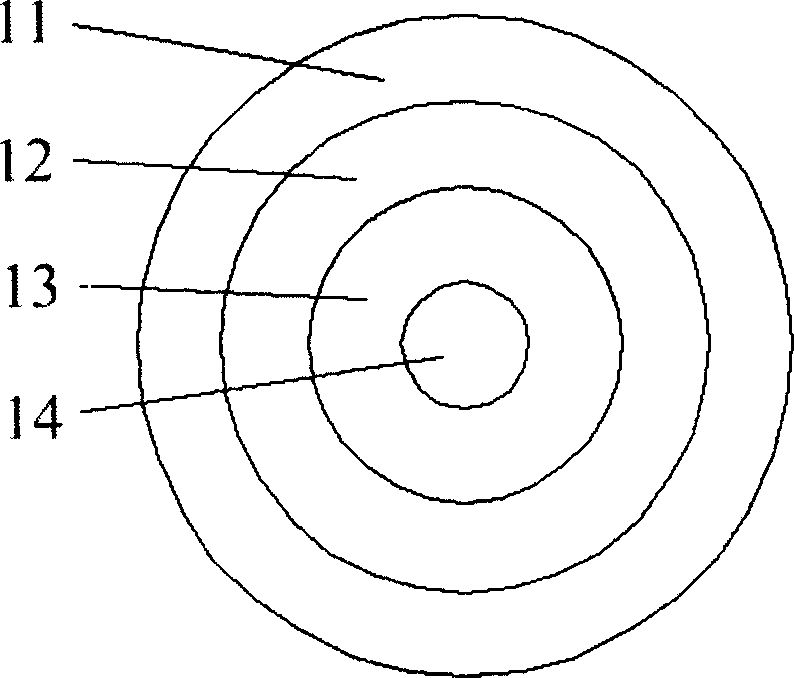

[0028] Ceramic is Al 2 o 3 , The composite target adopts three components of titanium, copper, and aluminum, and is arranged as copper, aluminum, and titanium materials from outside to inside, and the area ratio is 30-40%, 30-40%, and 20-40%. The process parameters of ceramic surface alloying are:

[0029] Ultimate vacuum 6Pa Glow voltage 600V

[0030] Arc current 60A Dipping time 30min

[0031] Working medium argon

[0032] Al 2 o 3 The thickness of the alloy layer on the ceramic surface is 20 μm, which has good electrical conductivity.

Embodiment approach 2

[0034] Surface Alloyed Ceramics for Microjoints

[0035] The ceramic material is Al 2 o 3 , the metal is aluminum foil after 15 μm, the composite target adopts two components of aluminum and titanium, aluminum is used as the outer ring, titanium is used as the inner ring, and the area ratio of aluminum and titanium in the composite target is 60-80% and 20-40%. The surface alloyed ceramics are connected with metal and solder in a vacuum furnace.

[0036] The process parameters of ceramic surface alloying and brazing with metal are:

[0037] Ultimate vacuum 6Pa Working air pressure 20Pa

[0038] Glow voltage 700V Arc current 60A

[0039] Dipping time 50min Brazing temperature 500℃

[0040] Holding time 10min Working medium Argon

[0041] al 2 o 3 The thickness of the infiltrated alloy layer on the ceramic surface is 10-20 μm, and the brazing results show that Al 2 o 3 The ceramic / metal aluminum foil joint has no cracks, and the entire joint surface has no unconnected pla...

Embodiment approach 3

[0043] Low vacuum brazing of surface alloyed ceramics to metals for ceramic / metal joints

[0044] The ceramic material is Si 3 N 4 , the metal material is carbon steel Q235, the composite target uses copper, titanium and iron three components, copper is used as the outer ring, titanium copper is used as the inner ring, and the area ratio of copper, titanium and iron is 40-60%, 20-40% , 10-40%, the surface alloyed ceramics and metals and Ag-Cu solder are placed in a vacuum furnace for brazing.

[0045] The process parameters of ceramic surface alloying and brazing with metal are:

[0046] Ultimate vacuum 6Pa Working air pressure 20Pa

[0047] Glow voltage 700V Arc current 60A

[0048] Dipping time 50min Brazing temperature 850℃

[0049] Brazing vacuum 5×10 -2 Pa holding time 10min

[0050] Working medium argon

[0051] The thickness of the alloy layer on the ceramic surface is 30μm, the quality of the brazed joint is good, Si 3 N 4 The ceramic has no cracks, and the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com