Patents

Literature

35results about How to "Excellent adhesion between layers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

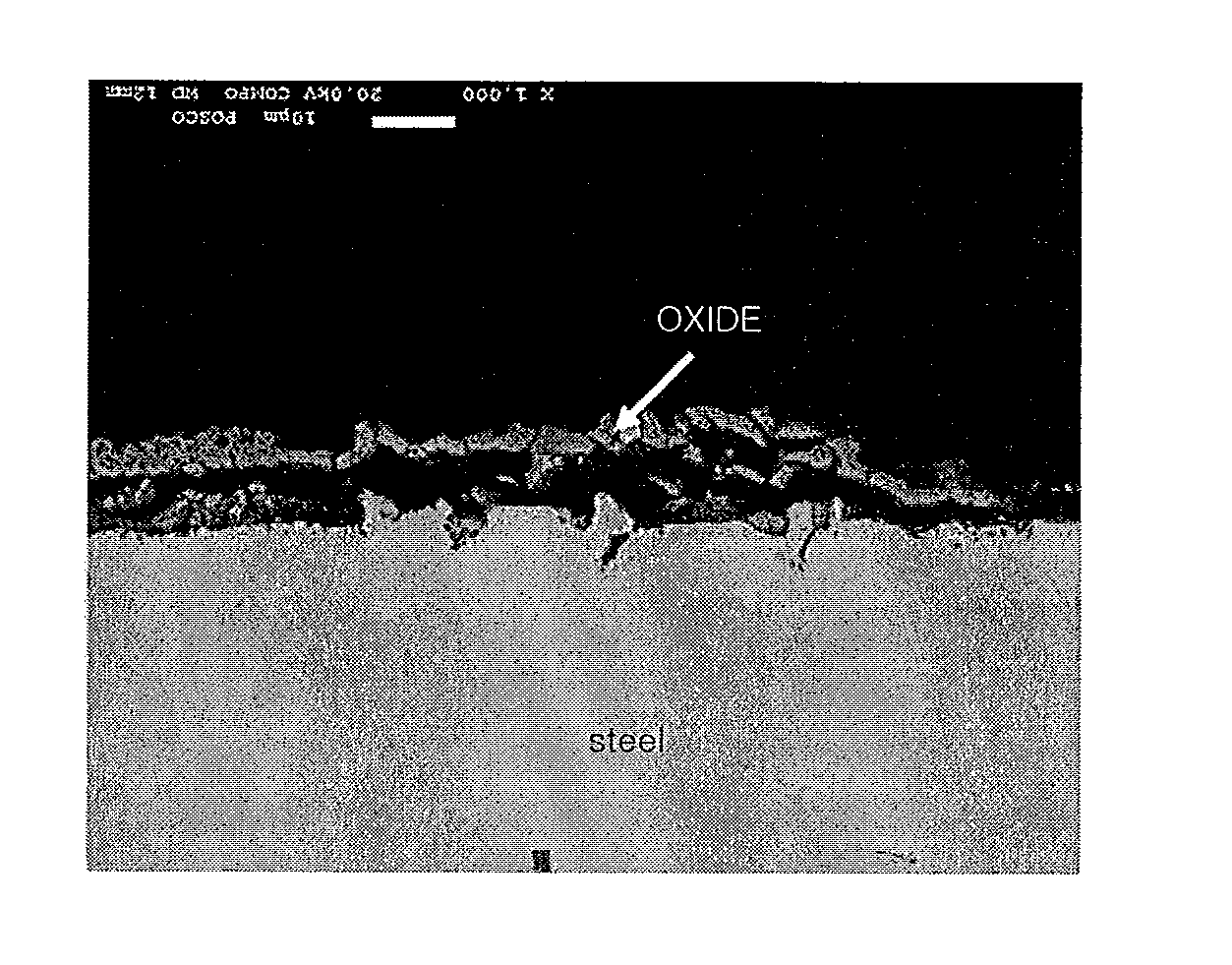

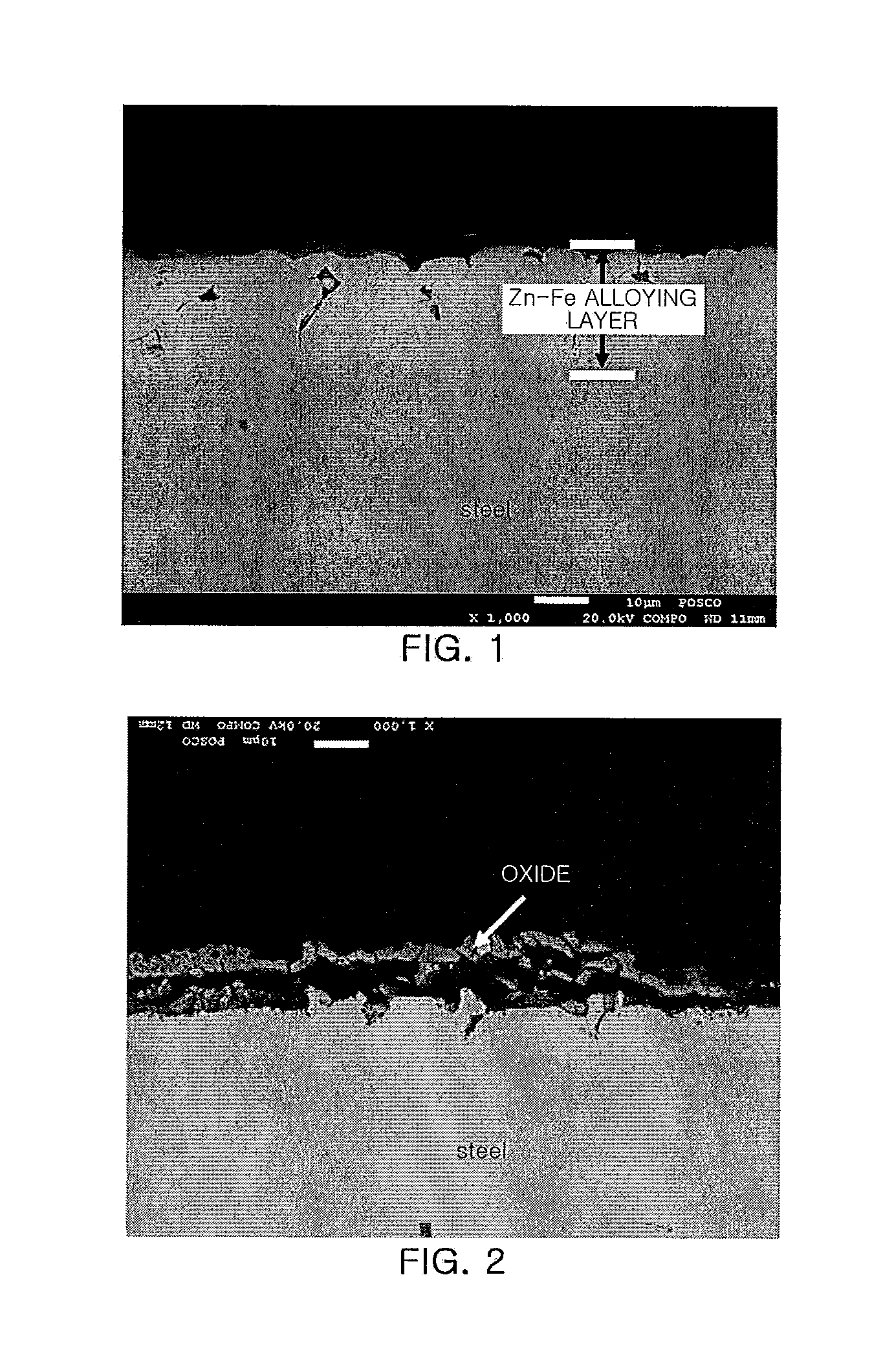

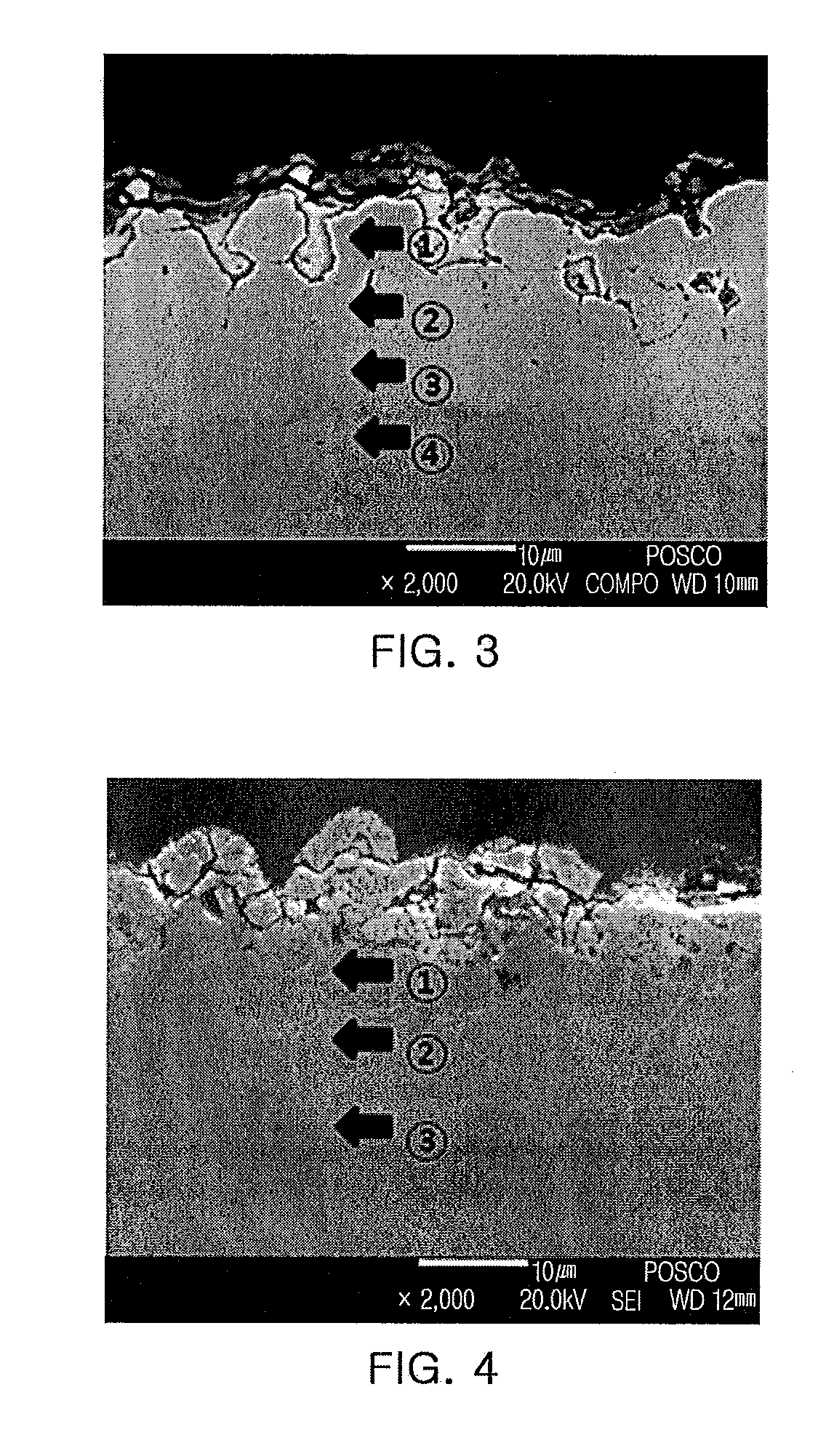

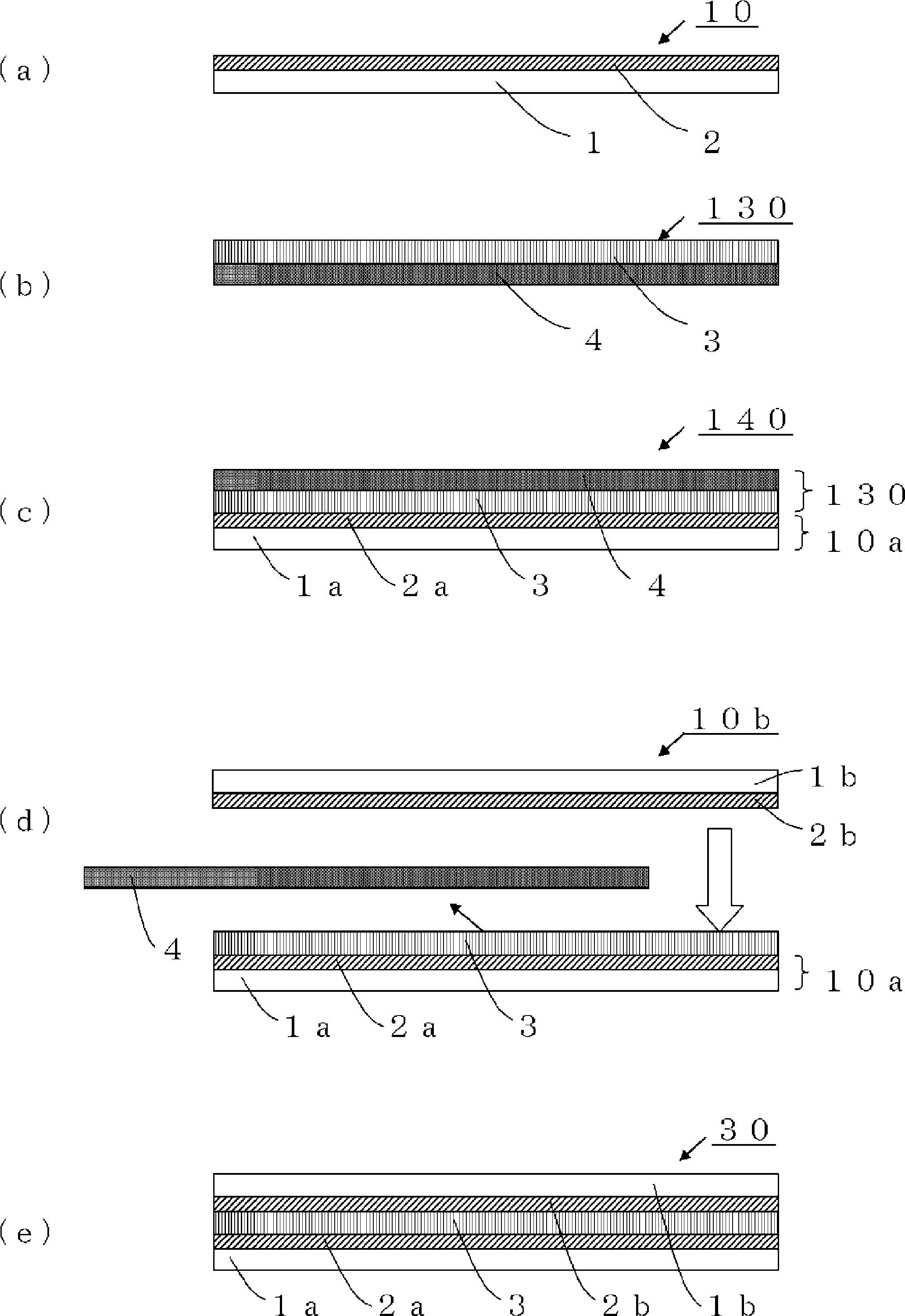

Zinc-plated steel sheet for hot pressing having outstanding surface characteristics, hot-pressed moulded parts obtained using the same, and a production method for the same

ActiveUS20120267012A1High melting temperatureDeterioration of layer be preventedHot-dipping/immersion processesSolid state diffusion coatingGibbs free energyOxygen

Provided is a zinc-plated steel sheet for hot pressing having outstanding surface characteristics, comprising: a steel foundation plate comprising a metal surface diffusion layer of which the Gibbs free energy reduction per mole of oxygen during oxidation is less than that of Cr; an aluminum-rich layer containing at least 30 wt. % of aluminium formed on the surface diffusion layer, and a zinc plating layer formed on the aluminum-rich layer. In this way, a metal having a low affinity for oxygen is coated to an effective thickness prior to annealing and thus the creation of annealing oxides at the surface of the steel sheet is suppressed and a uniform zinc plating layer is formed, and alloying of the zinc plating layer is promoted during press-processing heat treatment. Cracking in the steel foundation plate during hot press molding is prevented.

Owner:POHANG IRON & STEEL CO LTD

Gas barrier film, method for producing same, gas barrier film laminate, member for electronic devices, and electronic device

InactiveCN104066576AImprove heat resistanceGood solvent resistanceElectroluminescent light sourcesSynthetic resin layered productsPolymer scienceGlass transition

The present invention provides: a gas barrier film comprising a cured resin layer and a gas barrier layer, the gas barrier layer being provided on at least one side of the cured resin layer, the cured resin layer being a layer formed of a cured product of a curable resin composition that includes (A) a thermoplastic resin having a glass transition temperature (Tg) of 140°C or more, and (B) a curable monomer, the gas barrier film having a water vapor transmission rate of 1 g / m 2 / day or less at a temperature of 40°C and a relative humidity of 90%; a method for producing the gas barrier film; a gas barrier film laminate comprising the gas barrier film; an electronic device member comprising the gas barrier film; an electronic device member comprising the gas barrier film laminate; an electronic device comprising the electronic device member. Since the gas barrier film and the gas barrier film laminate of the present invention exhibits excellent heat resistance, excellent solvent resistance, excellent interlayer adhesion, and an excellent gas barrier capability, has a low birefringence, and exhibits excellent optical isotropy, the gas barrier film and the gas barrier film laminate may suitably be used as an electronic device member.

Owner:LINTEC CORP

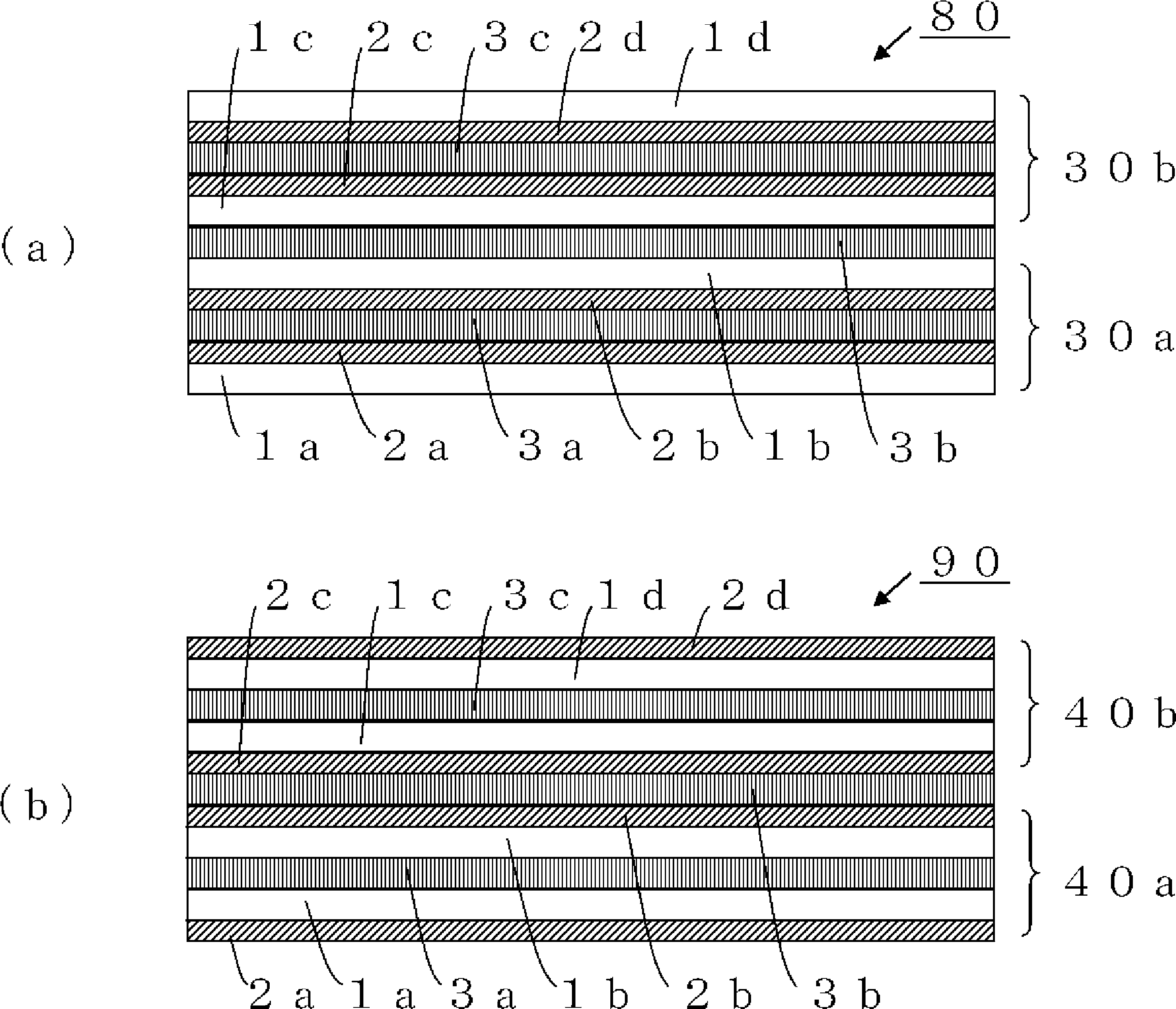

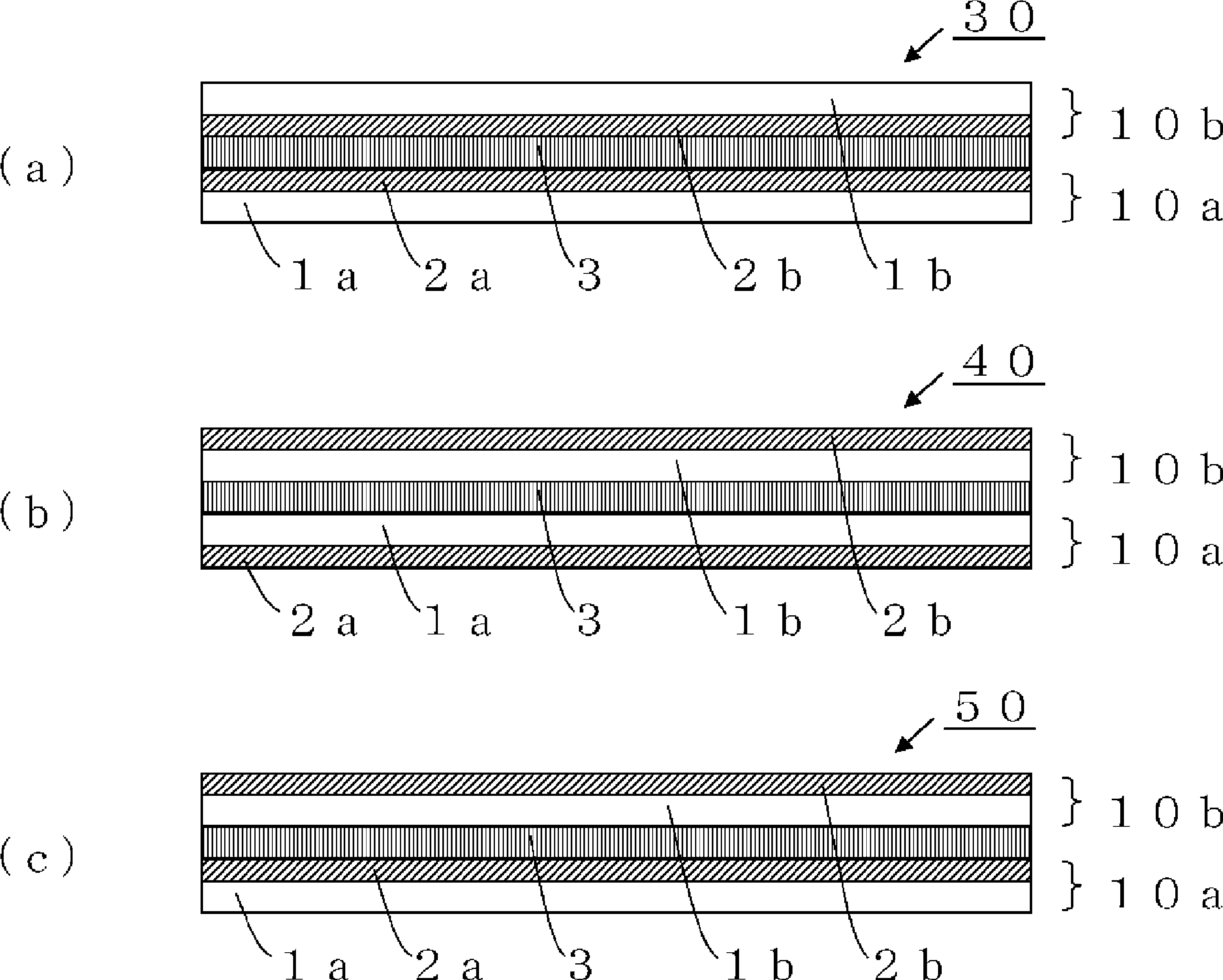

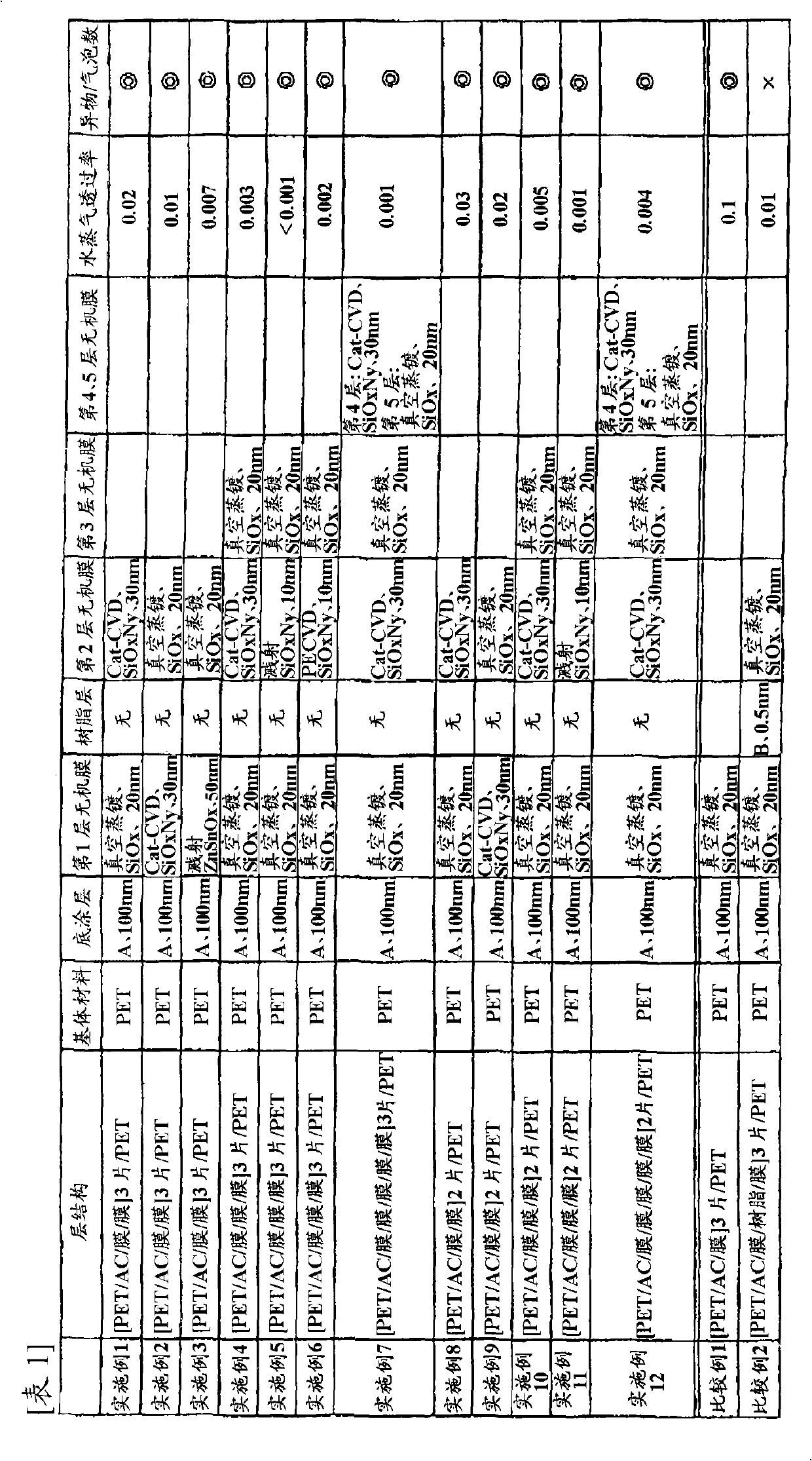

Gas barrier laminated film for organic devices

InactiveCN102026805AExcellent gas barrier performanceExcellent adhesion between layersElectroluminescent light sourcesSynthetic resin layered productsOrganic devicesM-xylylenediamine

A gas barrier laminated film which has extremely excellent gas barrier properties and exerts excellent performance as an organic device, more specifically, a gas barrier laminated film obtained by laminating plural gas barrier laminates through one or more adhesive layers, wherein the gas barrier laminates each comprise a substrate film and at least two inorganic thin film layers lying on one side of the substrate film. The at least two inorganic thin film layers contain two or more inorganic thin film layers formed in contact with each other, while the laminating of the gas barrier laminates is conducted with the face of one gas barrier laminate on the substrate film side being opposite to the face of another gas barrier laminate on the inorganic thin film side. Further, each adhesive layer consists of an epoxy adhesive having at least one of m-xylenediamine skeleton, p-xylenediamine skeleton and bisphenol skeleton.

Owner:MITSUBISHI PLASTICS INC

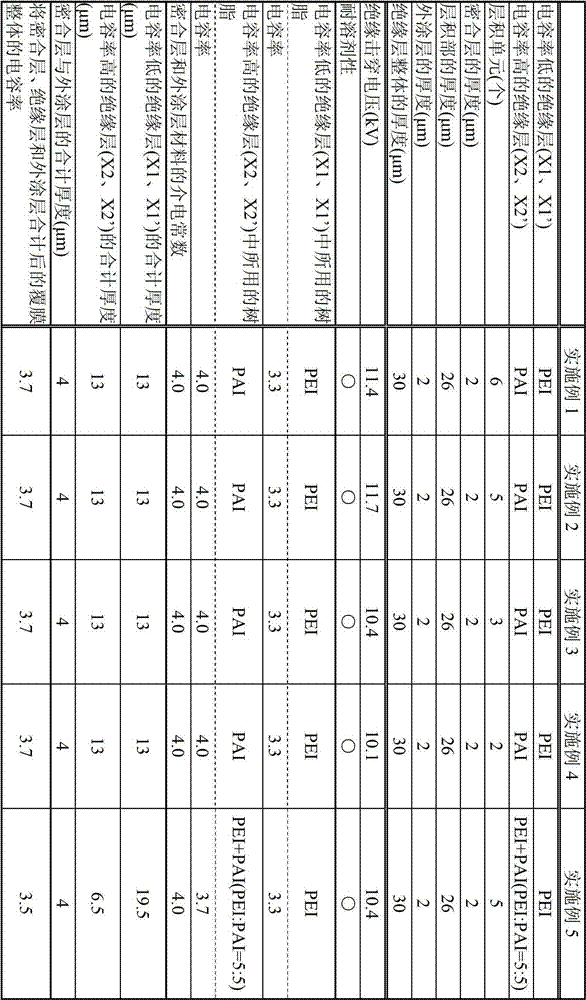

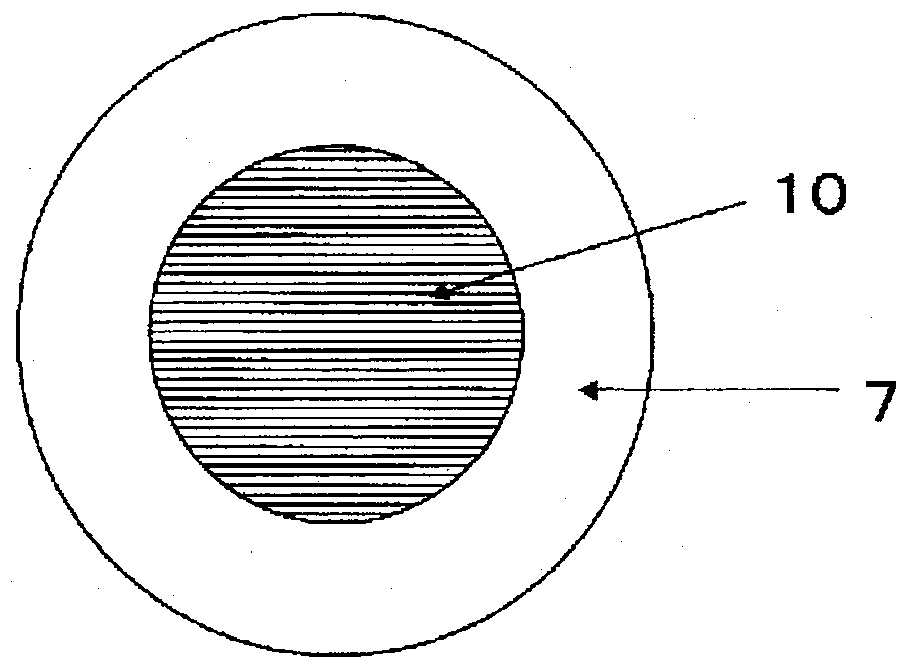

Aqueous dispersion composition for primer

ActiveCN101405358AExcellent adhesion between layersHigh hardnessLiquid surface applicatorsSynthetic resin layered productsSpecific gravityFilm structure

Disclosed is an aqueous dispersion composition which enables to form a primer layer that is excellent in interlayer adhesion with a top coat layer containing a fluororesin and capable of improving hardness and wear resistance of a coating film as a whole. Also disclosed is a coating film structure using such an aqueous dispersion composition. Specifically disclosed is an aqueous dispersion composition for primers for fluororesin coating film layers, which contains (A) a water-soluble, curable polyamideimide and / or polyimide binder polymer, (B) ceramic spherical particles, (C) modified PTFE particles and (D) an aqueous medium. This aqueous dispersion composition for primers is characterized in that the modified PTFE particles (C) have a melt creep viscosity at 380 DEG C within the range from 2*10<9> to 1*10<11> Pas, and a standard relative density of not more than 2.170. A primer layer is formed by using such an aqueous dispersion composition for primers, and a top coat layer containing a fluororesin is formed thereon.

Owner:DAIKIN IND LTD

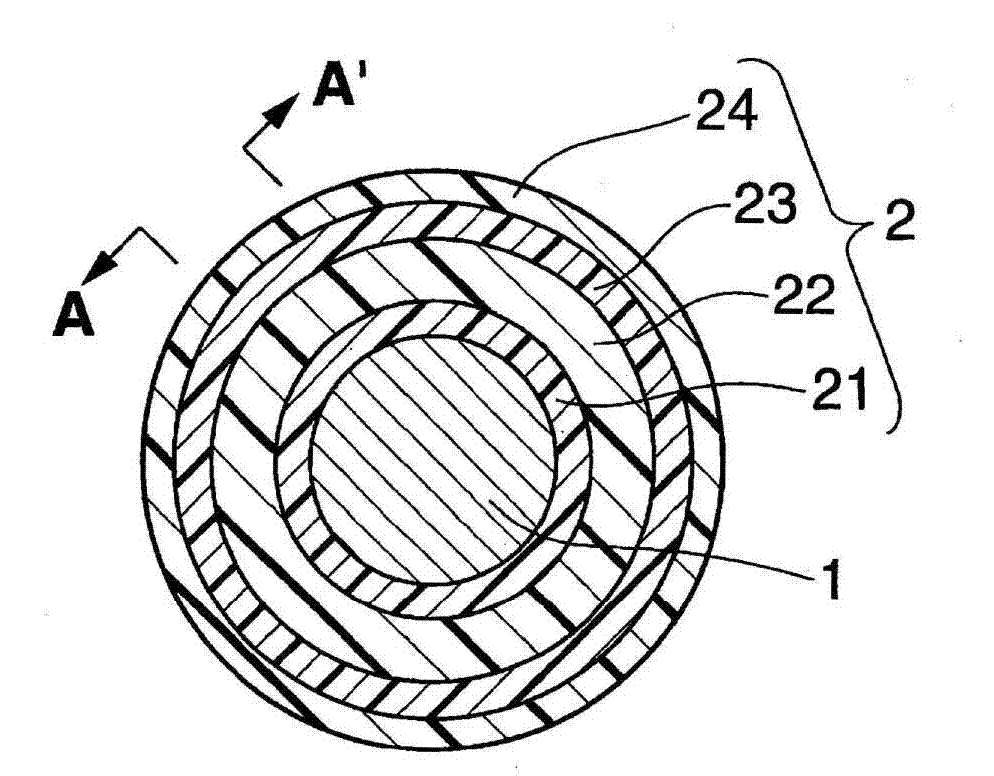

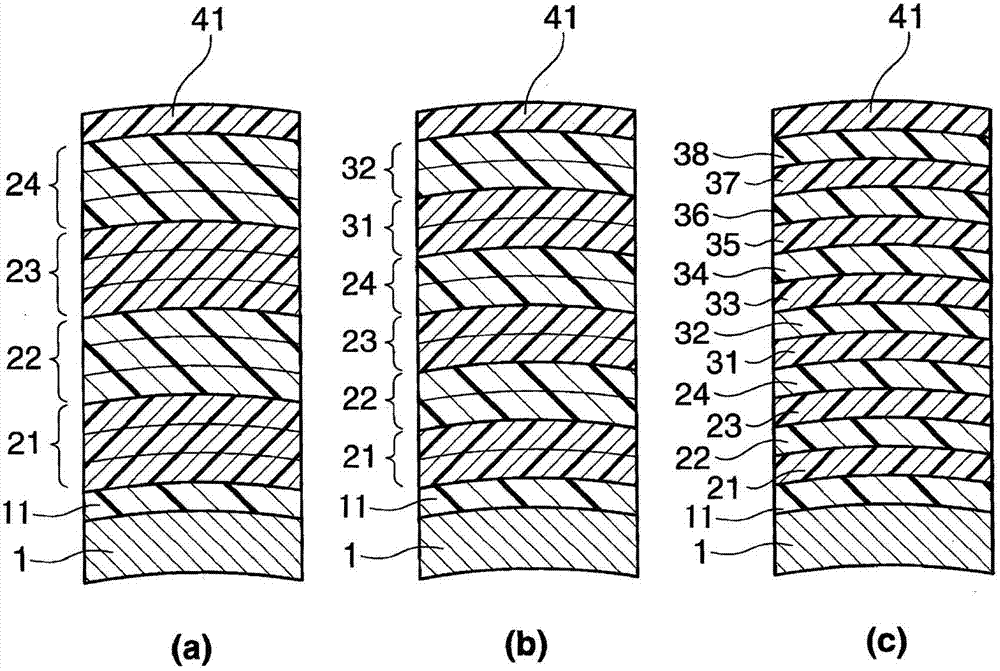

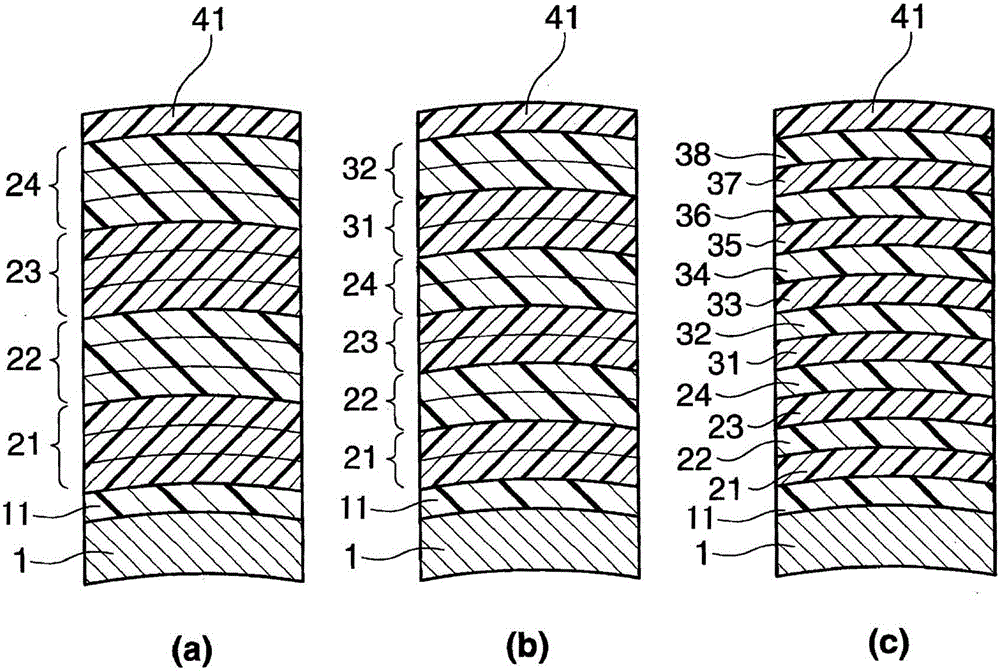

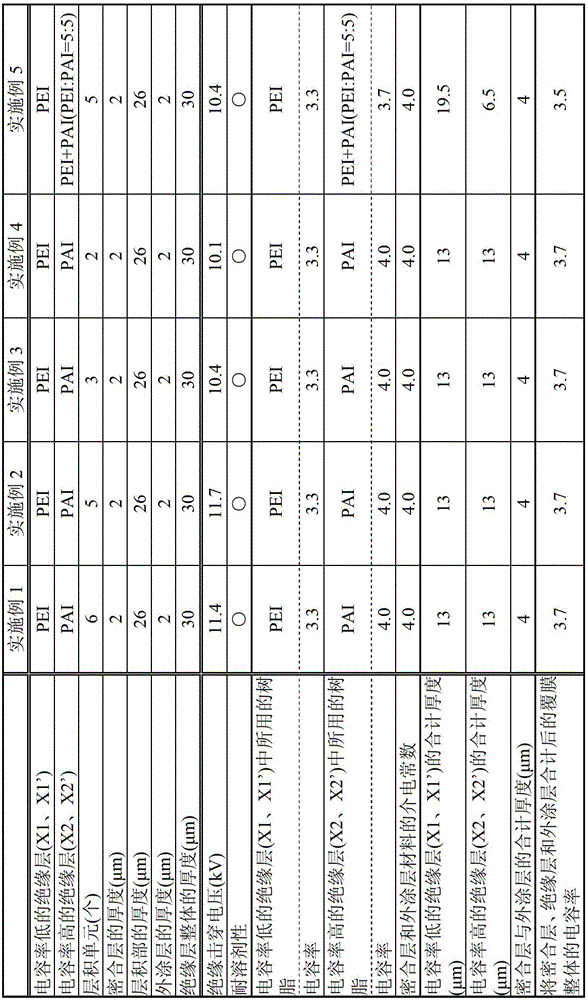

Insulated wire

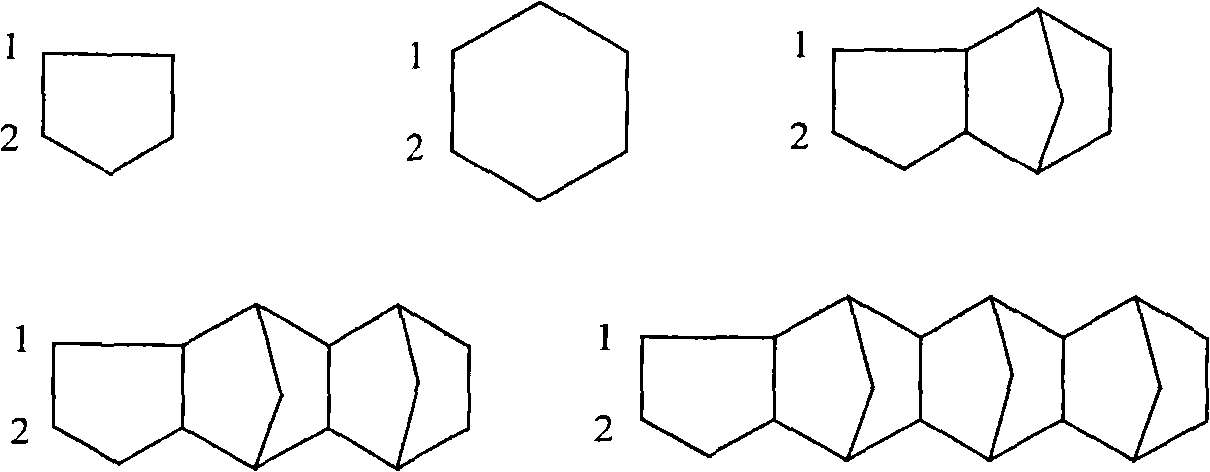

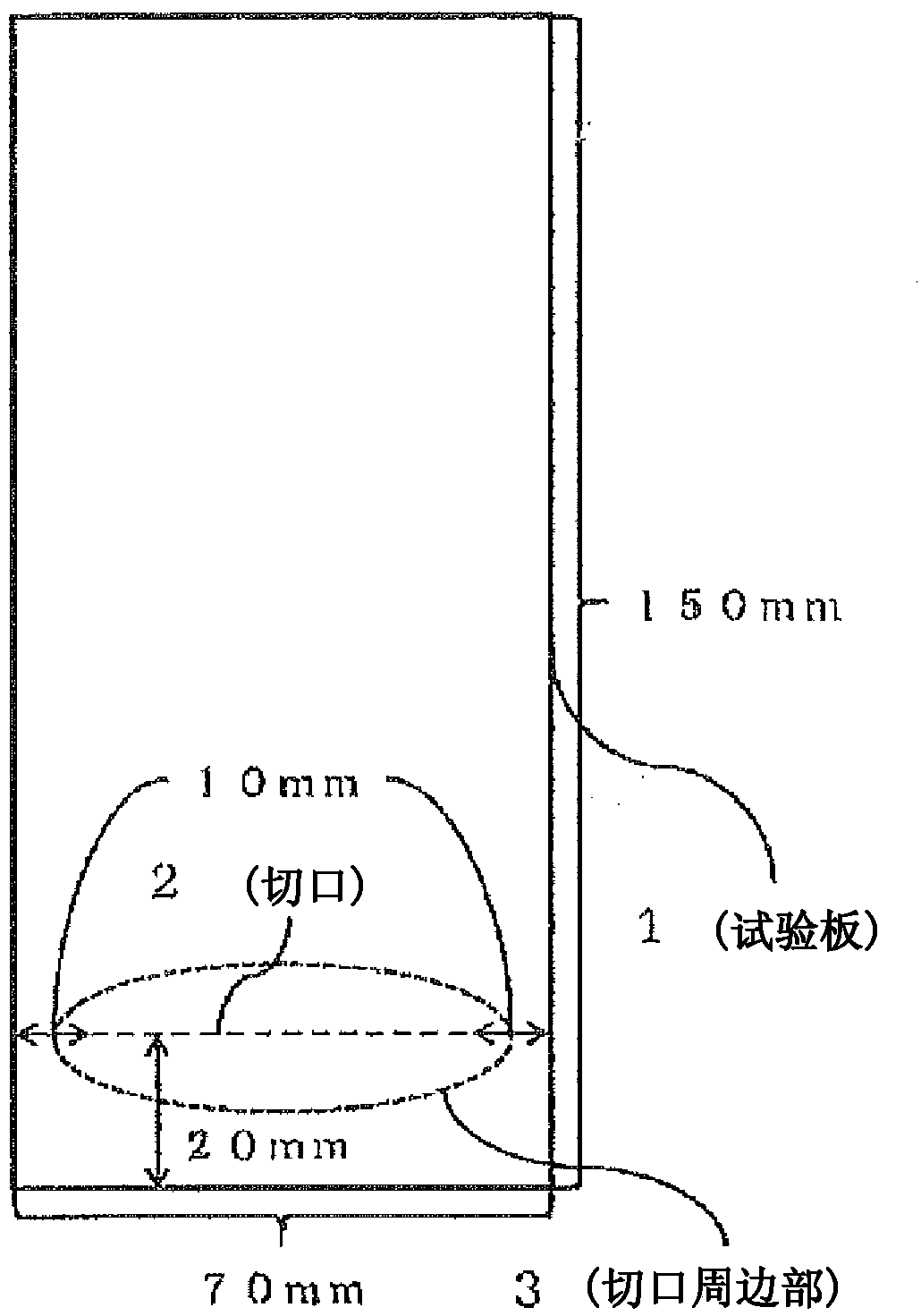

ActiveCN102782773AExcellent adhesion between layersExcellent partial discharge resistanceWindings insulation shape/form/constructionInsulated cablesCapacitanceElectrical conductor

[Problems] To provide an insulated wire, which is high in a dielectric breakdown resistance even if insulating resin coatings are laminated, because the interlayer adhesiveness is excellent, and which is excellent in a partial discharge resistance, because the dielectric constant is low. [Means to solve] An insulated wire, having directly or indirectly on a conductor (1), at least two laminate units each formed by laminating an insulating layer (21, 23) and an insulating layer (22, 24) higher in a dielectric constant than the insulating layer (21, 23), in this order from the conductor side.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

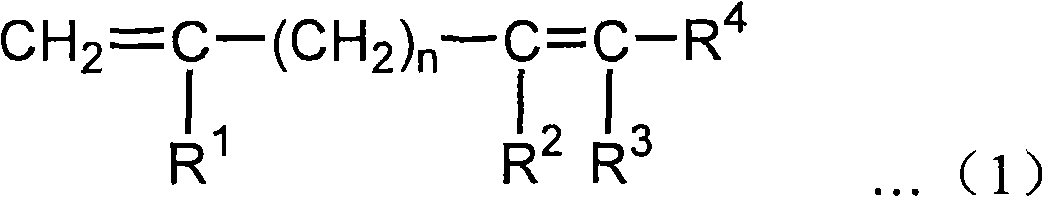

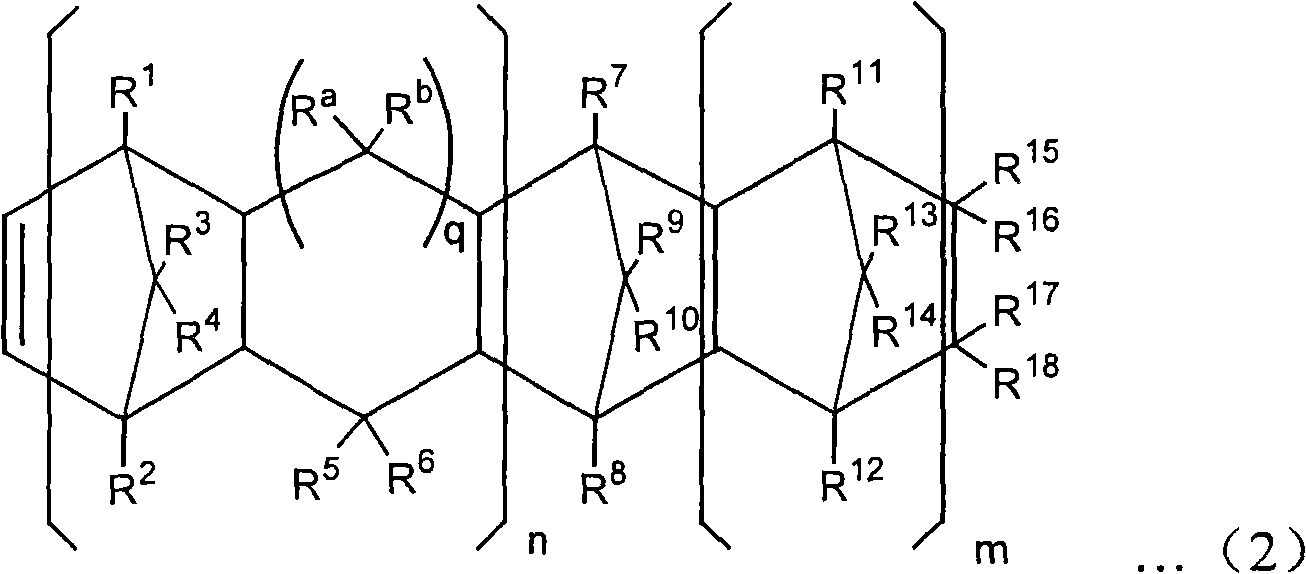

Resin composition containing olefin block polymer and use of the same

The present invention is to provide a resin composition excellent in mechanical properties and solvent resistance, and the resin composition (C) of the present invention comprises an polyolefin (A1) and an olefinic block polymer (A2), wherein the olefinic block polymer (A2) comprises, as a constitutional unit, a block (a) which is a polyolefin component and a block (b) which is a polymer unit composed of a vinyl monomer having a solubility parameter of from 18 to 25 J / m and the block (a) and the block (b) are bonded each other by a covalent bond. Moreover, another invention of the present invention is to provide a laminated structure having a laminated configuration in which a layer comprising an olefinic polymer layer and a layer comprising other synthetic resins, a metal and the like are strongly bonded through an adhesive layer, wherein the adhesive layer comprises the resin composition (C).

Owner:MITSUI CHEM INC

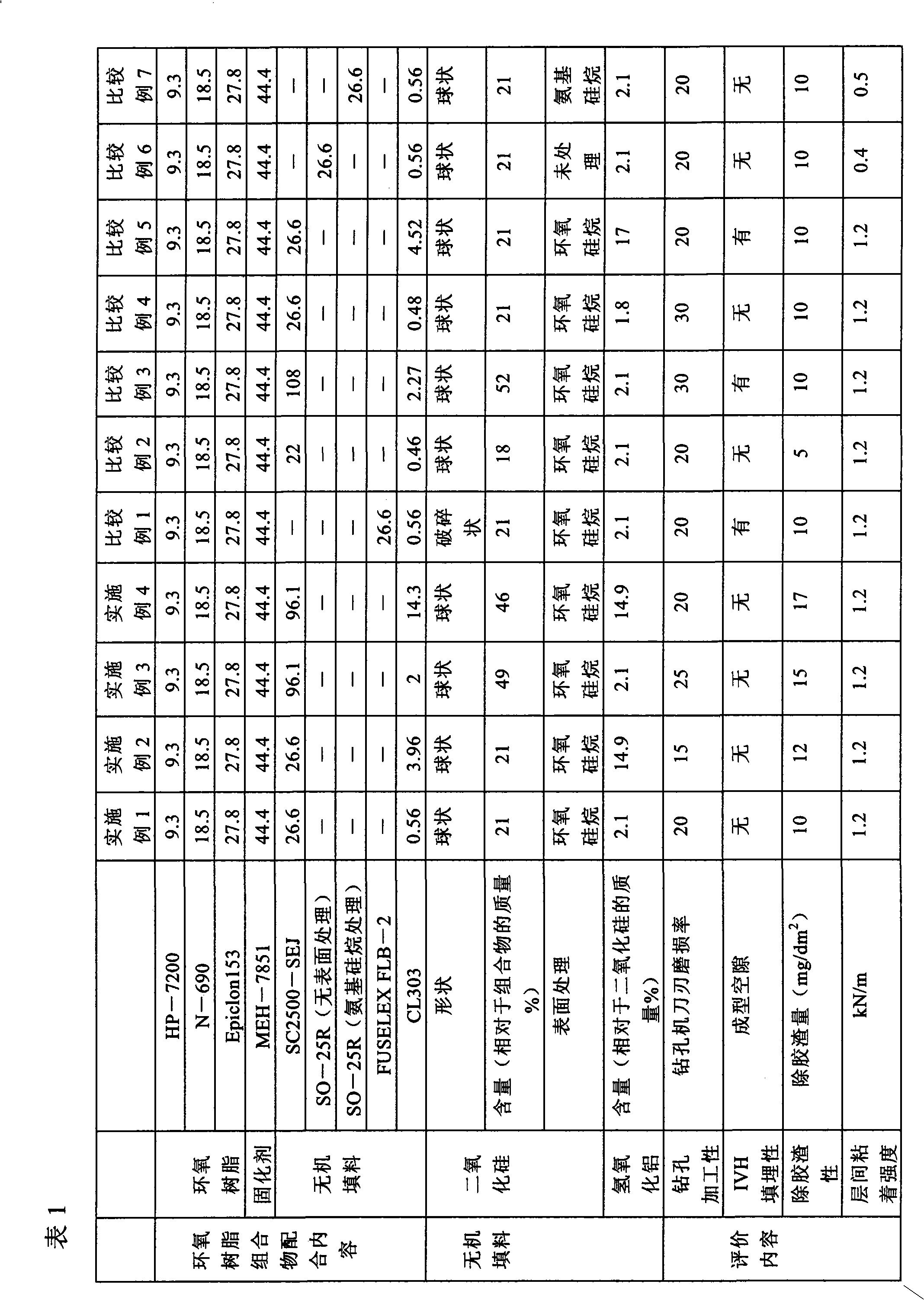

Epoxy resin composition, prepreg, metal clad laminate and multilayer printed wiring board

InactiveCN101910237AImprove drilling processabilityGood formabilityPrinted circuit aspectsSynthetic resin layered productsSilicon dioxidePhenolic aldehyde

An epoxy resin composition that excels in drillability, moldability and interlayer adhesion, ensuring favorably performing of desmear treatment. The epoxy resin composition comprises an epoxy resin, a hardening agent and an inorganic filler. As the epoxy resin, use is made of an epoxy resin with dicyclopentadiene skeleton or an epoxy resin with novolac skeleton. As the hardening agent, use is made of a phenolic resin hardening agent with biphenyl skeleton. As the inorganic filler, use is made of aluminum hydroxide and spherical silica surface-treated with epoxysilane. The content of spherical silica based on the total amount of the epoxy resin composition is in the range of 20 to 50 mass%. The content of aluminum hydroxide based on the total amount of spherical silica is in the range of 2 to 15 mass%.

Owner:PANASONIC CORP

Process for producing metal wiring board

InactiveUS20090266589A1Adhesion of substrate surfaceExcellent adhesion between layersInsulating substrate metal adhesion improvementPrinted circuit aspectsSurface finishingAdhesive

Is disclosed a process for producing a metal wiring substrate comprising a heat resistant resin substrate and a metal wiring which is laminated on the substrate and in which a surface laminated with the substrate is surface-treated with at least one metal selected from Ni, Cr, Co, Zn, Sn and Mo or an alloy comprising at least one of these metals (hereafter, the metal used for the surface-treatment is referred to as a surface-treatment metal). This process comprises the steps of forming the metal wiring on the resin substrate, and washing at least a surface of the resin substrate with an etching solution capable of removing the surface-treatment metal to increase adhesion of the surface of the resin substrate. The produced metal wiring substrate has excellent adhesion with adhesives for affixing anisotropic conductive films and IC chips to films.

Owner:UBE IND LTD

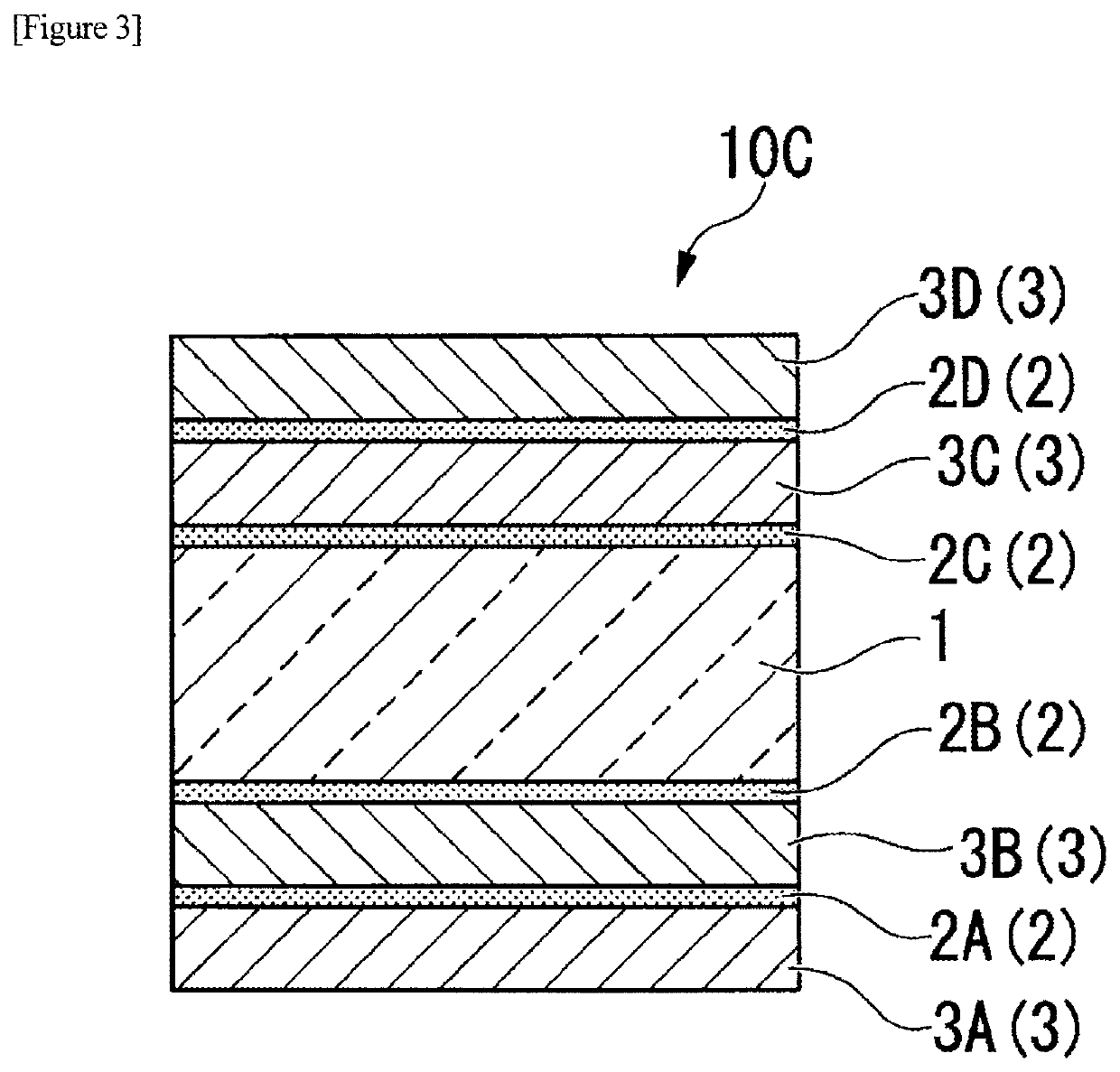

Laminate

ActiveUS20180264788A1Excellent adhesion between layersSpecial paperPolyureas/polyurethane adhesivesCellulose fiber

It is an object of the present invention to provide a laminate excellent in interlayer adhesion properties. The present invention relates to a laminate comprising: a fiber layer formed of cellulose fibers having a fiber width of 1000 nm or less; a resin layer; and an adhesive layer provided between the fiber layer and the resin layer.

Owner:OJI HLDG CORP

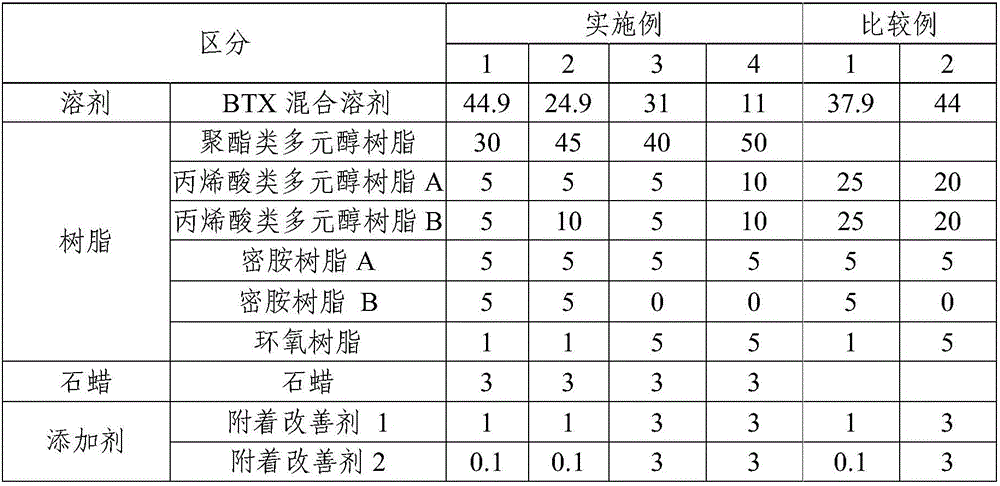

Base coating composition for non-ferrous metal

ActiveCN106280913AExcellent initial adhesionExcellent adhesion between layersPolyester coatingsPolyesterEpoxy

The invention relates to a base coating composition for non-ferrous metal, which can exhibit excellent initial stage adhesion, interlayer adhesion, recoating performance and scratch resistance in the coating of non-ferrous metal by containing polyester polyhydric alcohol resin, acrylic acid polyhydric alcohol resin, melamine resin, epoxy resin and the balance of a solvent, and a coating object.

Owner:KCC CORP CO LTD

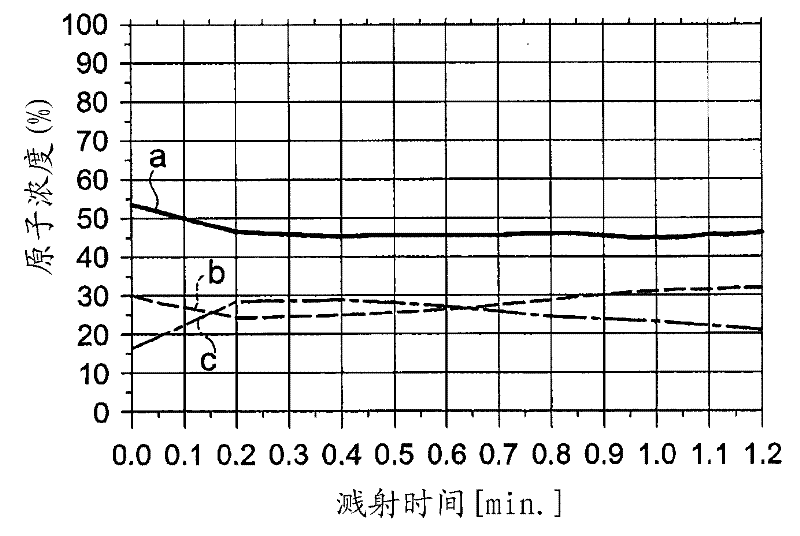

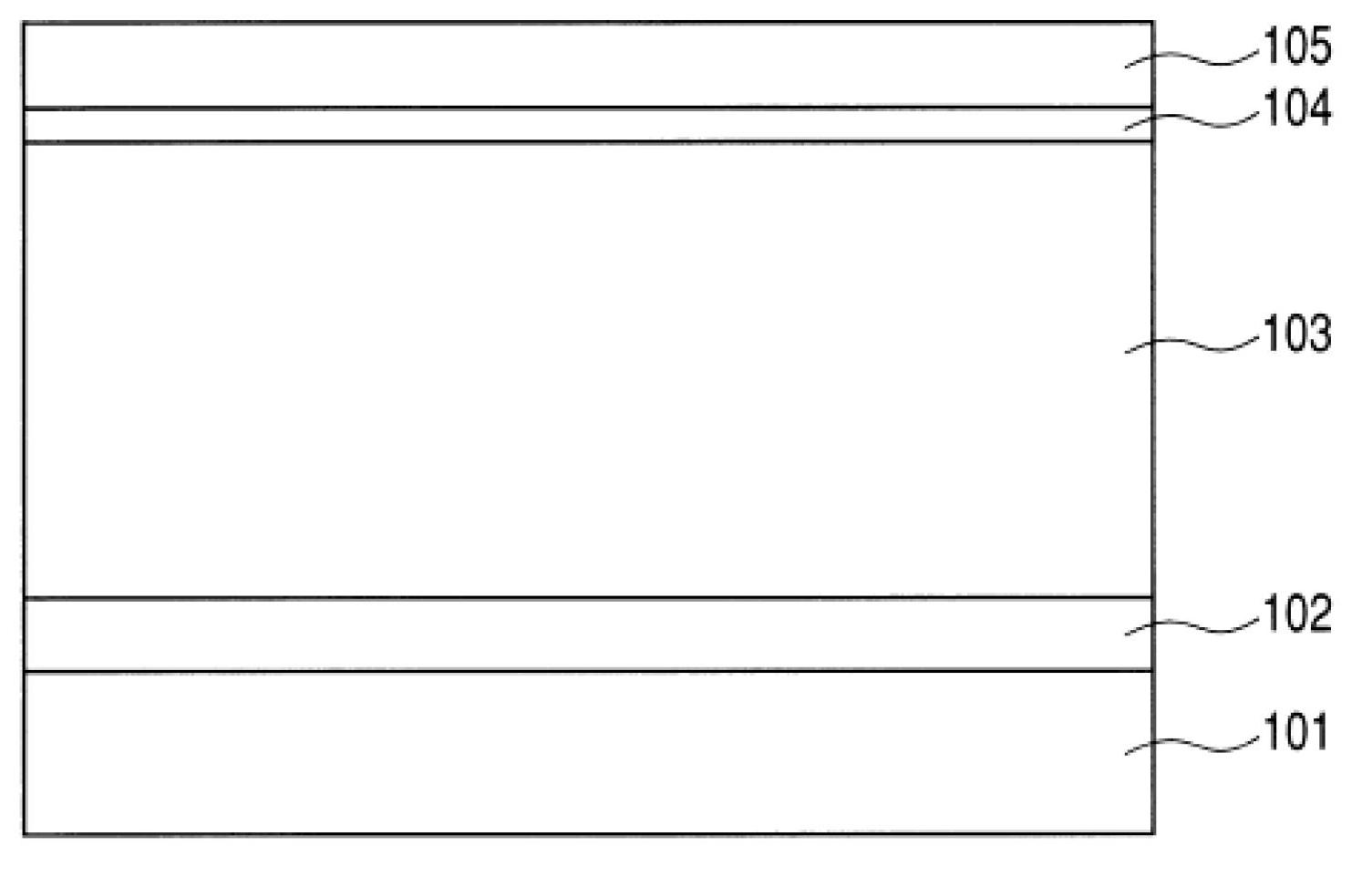

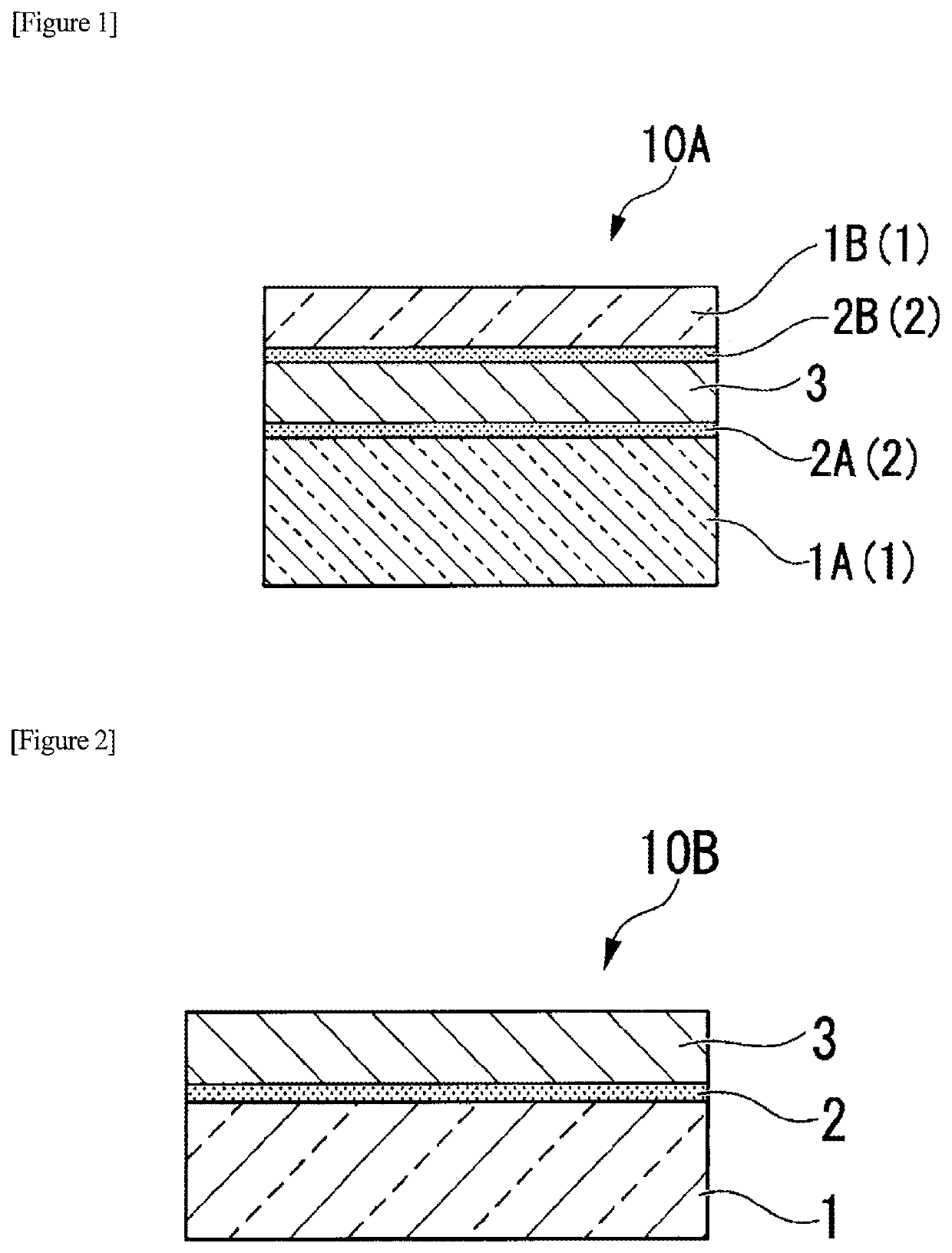

Multilayer body, method for producing same, electronic device member, and electronic device

ActiveCN102317070AExcellent gas barrier performanceExcellent adhesion between layersSynthetic resin layered productsSolid-state devicesDisplay deviceHigh surface

Disclosed is a multilayer body which comprises at least a conductor layer and a gas barrier layer that is configured from a material containing oxygen atoms, carbon atoms and silicon atoms. The multilayer body is characterized in that the present ratio of oxygen atoms in the gas barrier layer gradually decreases from the surface of the gas barrier layer to the depth direction, while the present ratio of carbon atoms gradually increases. Also disclosed are a method for producing the multilayer body, an electronic device member which is composed of the multilayer body, and an electronic device which comprises the electronic device member. The multilayer body exhibits excellent gas barrier properties and excellent interlayer adhesion, while comprising a conductor layer with high surface smoothness. Since the multilayer body can be flexible and light-weighted, the multilayer body is suitable for use as an electronic device member for an organic EL display, a solar cell and the like. In addition, since the multilayer body can be produced by a roll-to-roll mass production process, the multilayer body can be produced at low cost.

Owner:LINTEC CORP

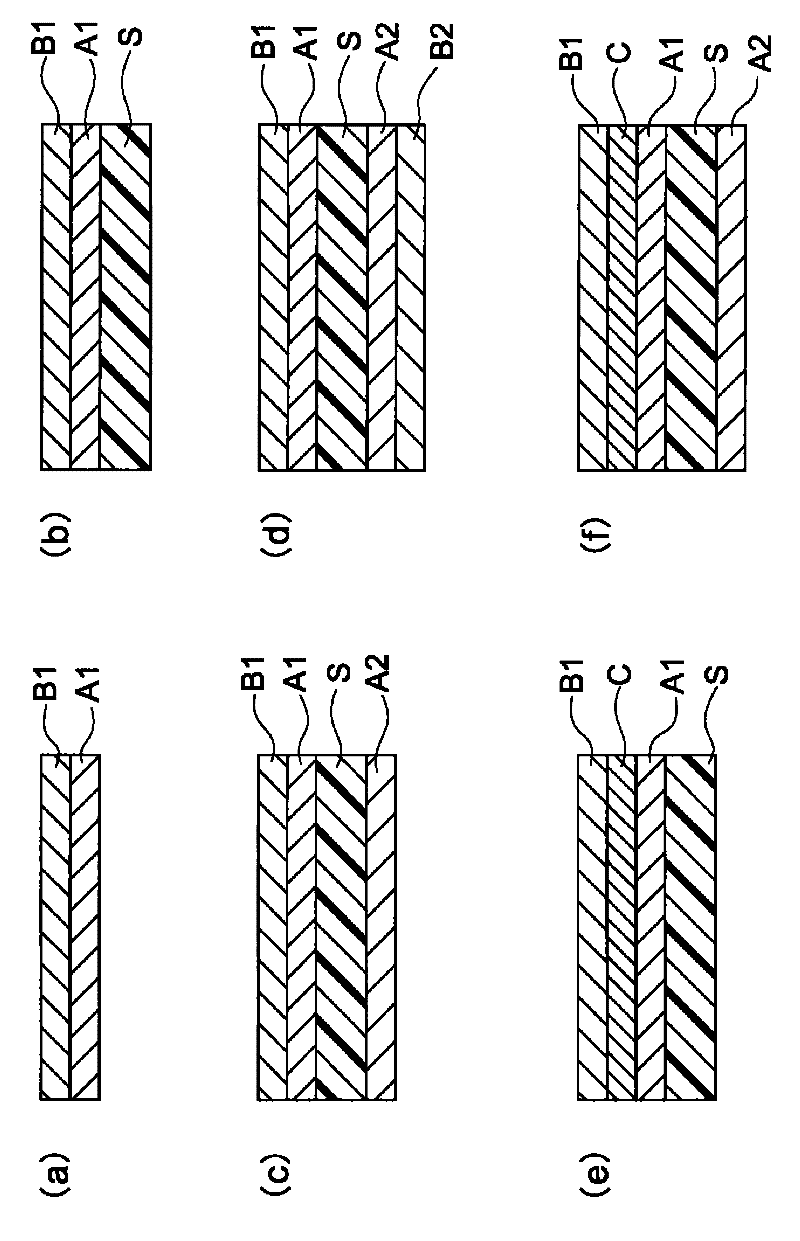

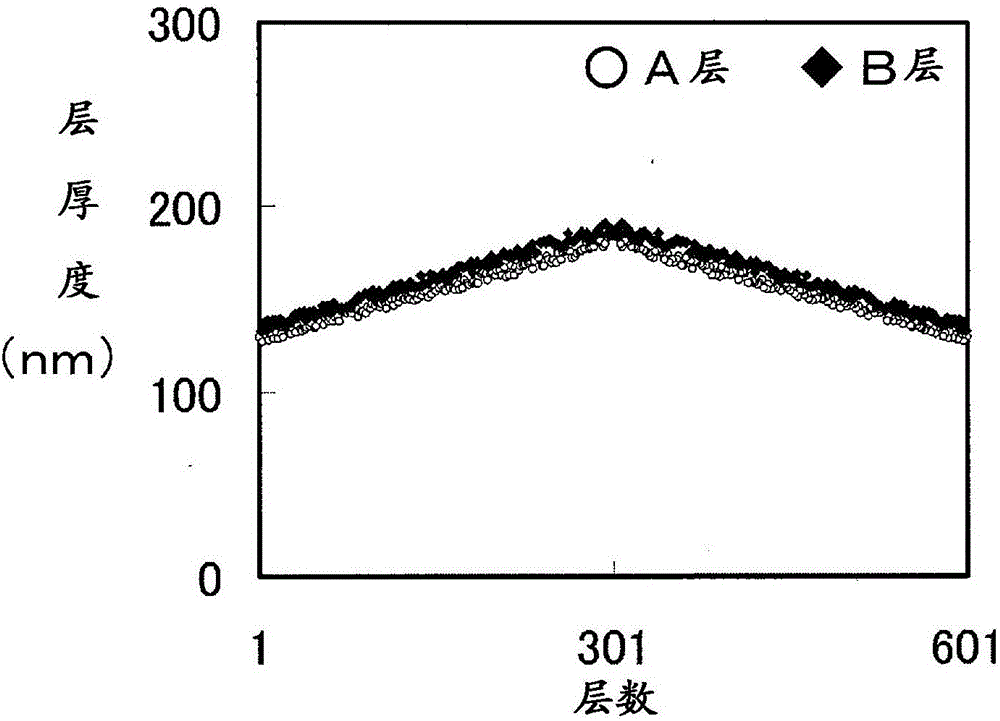

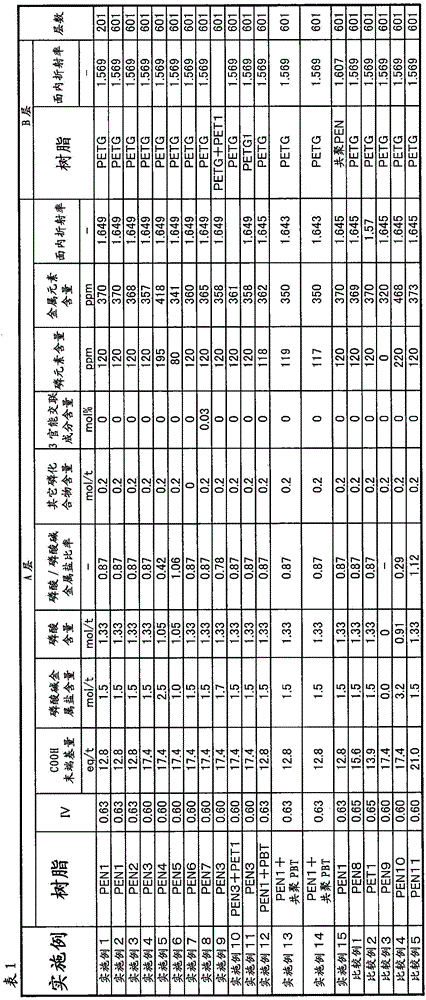

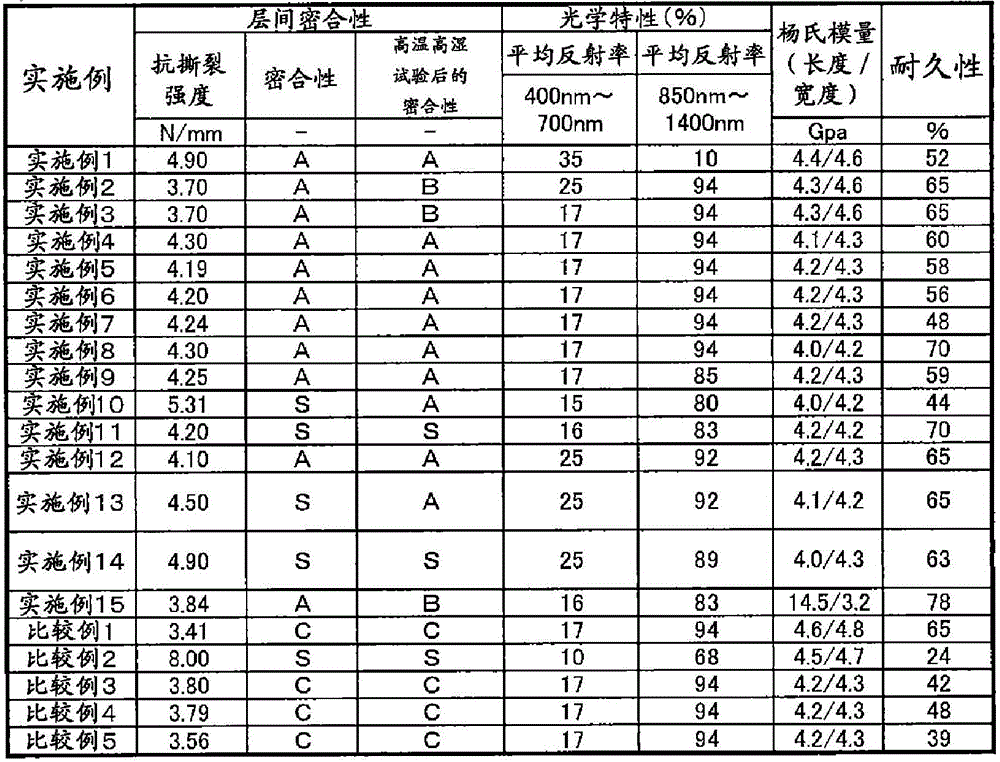

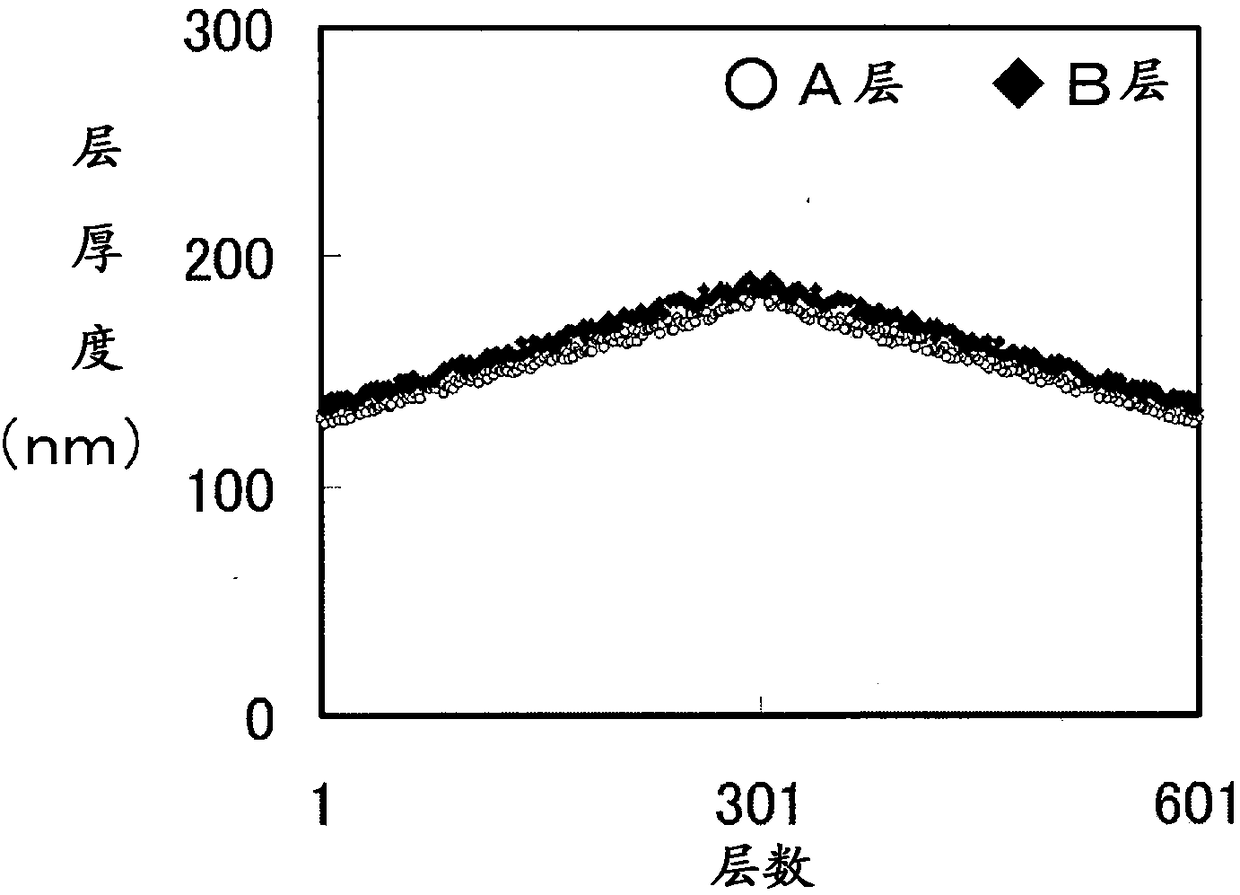

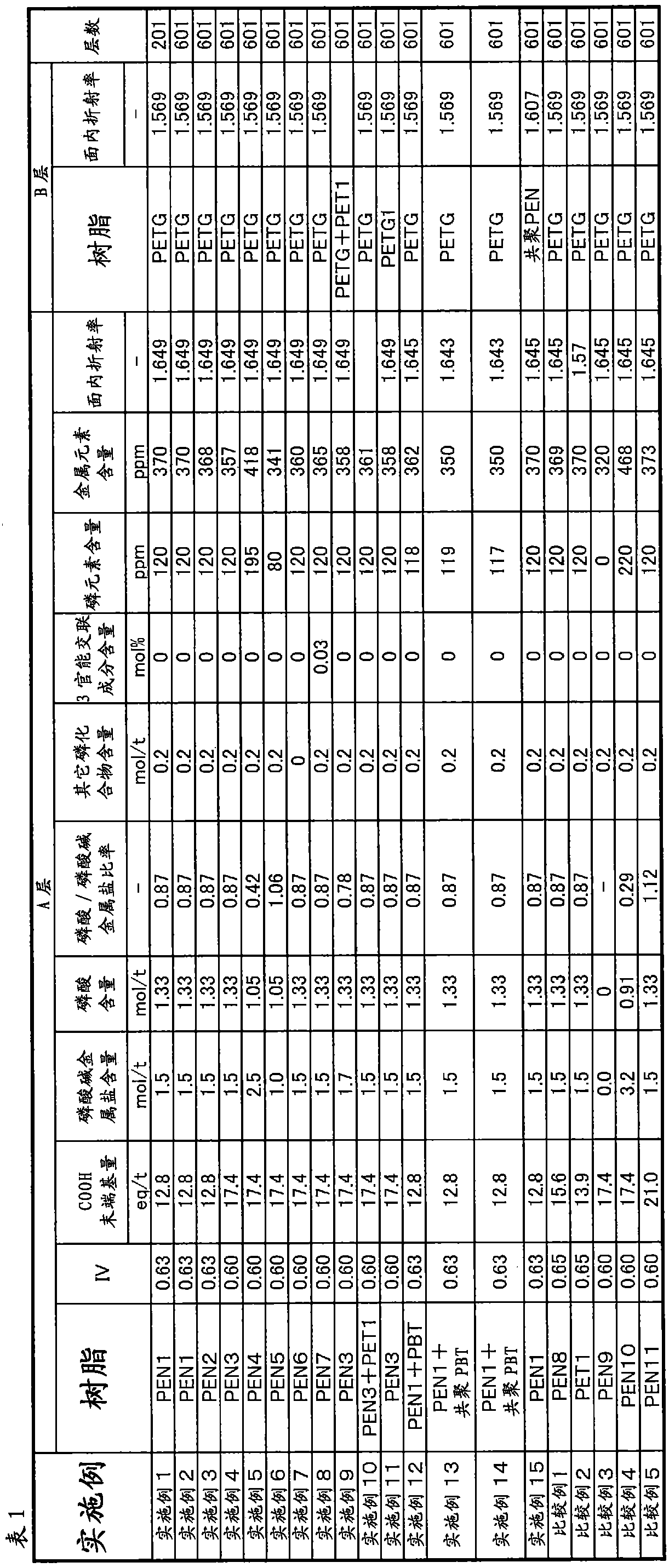

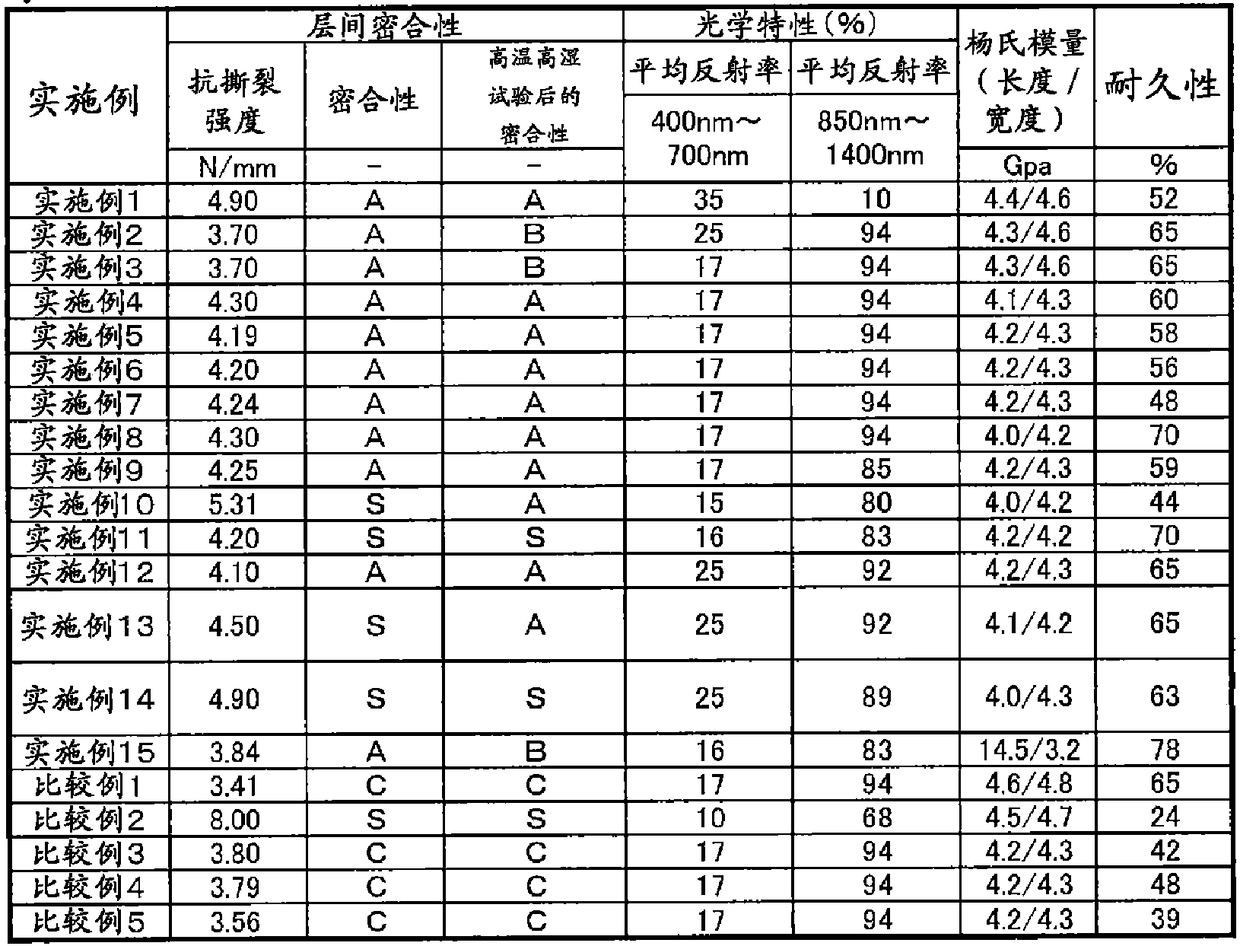

Multilayer film

ActiveCN106457810AWith transparencyExcellent adhesion between layersSynthetic resin layered productsOptical elementsPolyesterO-Phosphoric Acid

The present invention provides a multilayer film which reflects light within a specific band, and which is free from the problem of delamination that occurs in cases where a polyethylene naphthalate resin is used therefor. A multilayer film which has 201 or more layers obtained by alternately laminating layers A that are formed of a polyester A containing ethylene-2,6-naphthalate as a main repeating unit and layers B that are formed of a polyester B containing ethylene terephthalate as a main repeating unit and having a refractive index lower than that of the polyester constituting the layers A. This multilayer film is characterized in that the polyester A satisfies the following requirements. (1) The amount of terminal carboxylic acid groups is from 5 eq / t to 20 eq / t (inclusive). (2) An alkali metal phosphate salt is contained in an amount of from 1.3 mol / ton to 3.0 mol / ton (inclusive), and phosphoric acid is contained at a molar ratio of from 0.4 times to 1.5 times (inclusive) relative to the alkali metal phosphate salt. (3) The intrinsic viscosity is from 0.55 to 0.63 (inclusive).

Owner:TORAY IND INC

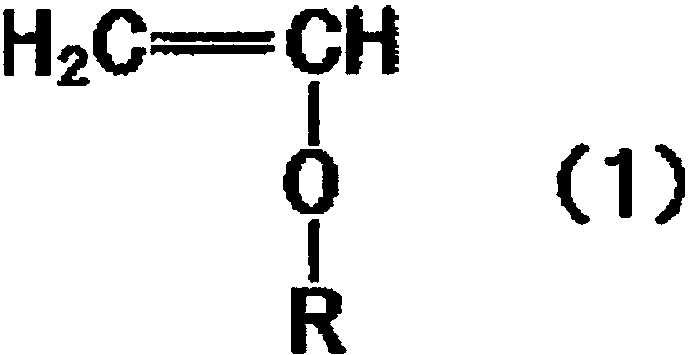

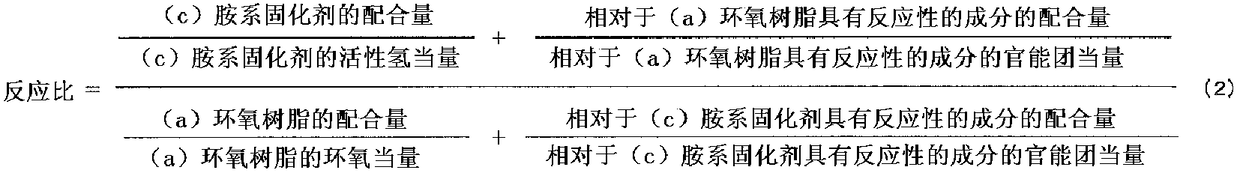

Anticorrosion coating composition, anticorrosion coating film, substrate with anticorrosion coating film, and method of manufacturing same

ActiveCN108699382AImprove corrosion resistanceImprove suitabilityLiquid surface applicatorsSynthetic resin layered productsPolymer scienceFirming agent

The present invention relates to an anticorrosion coating composition, an anticorrosion coating film, a substrate with an anticorrosion coating film, and a method of manufacturing a substrate with ananticorrosion coating film. The anticorrosion coating composition contains (a) an epoxy resin, (b) a polyvinyl alkyl ether (co)polymer, and (c) an amine-based curing agent.

Owner:CHUGOKU MARINE PAINTS

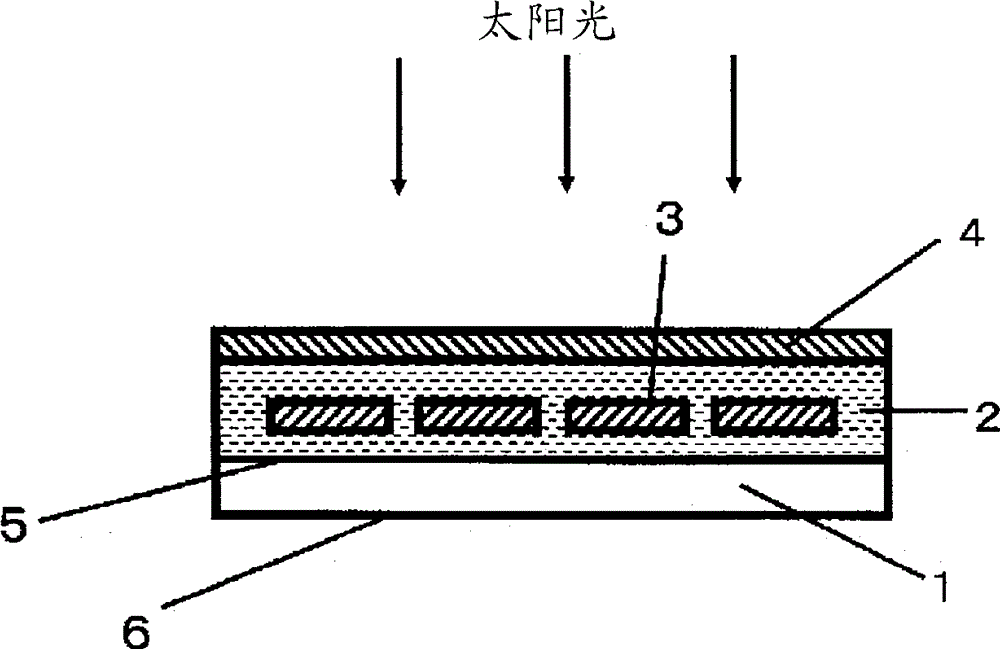

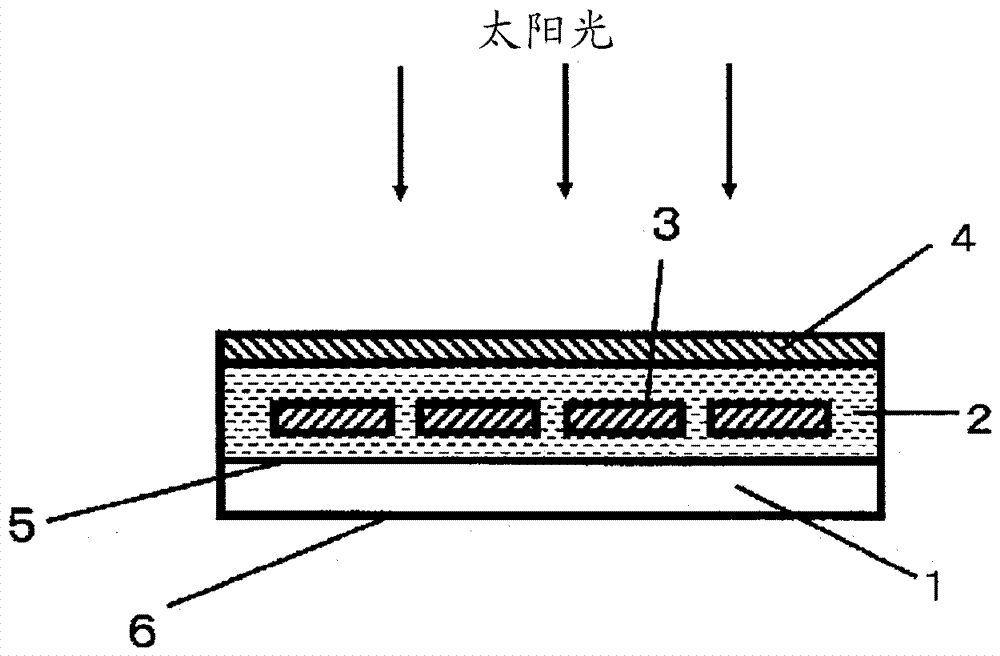

Laminated sheet and method for manufacturing same, solar cell back sheet, solar cell module, and method for manufacturing solar cell back sheet

InactiveCN104822528AImprove performanceExcellent adhesionSynthetic resin layered productsElectrical equipmentPolytetramethylene terephthalatePolyolefin

A laminated sheet having: a layer having a polybutylene terephthalate resin as a principal component (P1 layer); and a layer having a polyolefin resin as a principal component (P3 layer). A solar cell back sheet, characterized in that the acetic acid permeability (Pa) (g / m2 / day) at 85°C and water vapor permeability (Pw) (g / m2 / day) at 40°C 90% RH satisfy relationships (1) 200 ≤ Pa and (2) Pw ≤ 2.5. Provided are a laminated sheet having a better moist heat resistance and an improved capacity to obtain both heat resistance and adhesion performance with respect to a sealing member compared with a conventional laminated sheet in which a polybutylene terephthalate resin is used, and a method for manufacturing the laminated sheet. Also provided are a solar cell module back sheet that is inexpensive and that is capable of preventing discoloration of the collector electrode of a solar cell while maintaining the power generation characteristics of the solar cell module over a long period, and a method for manufacturing the solar cell module back sheet.

Owner:TORAY IND INC

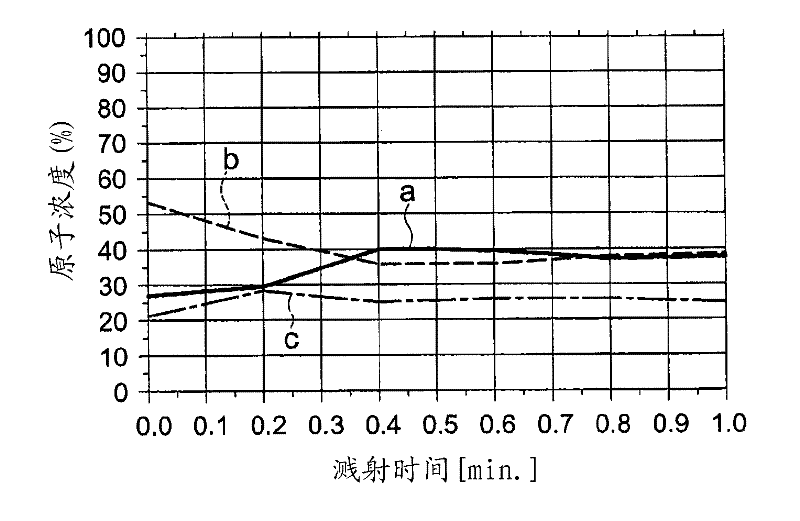

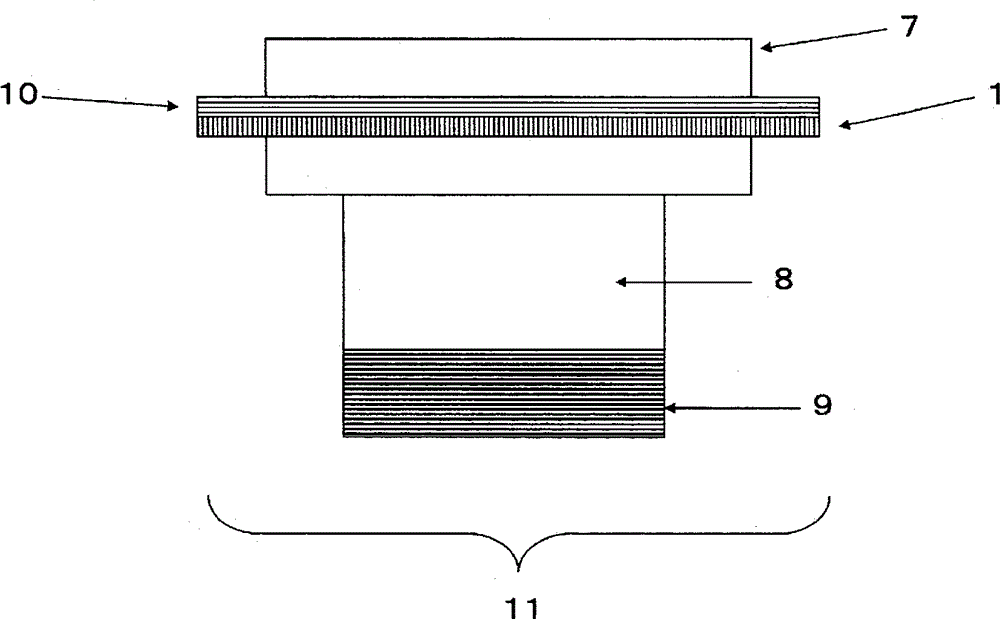

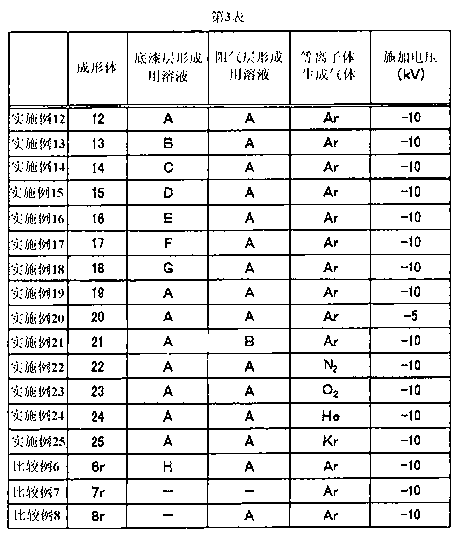

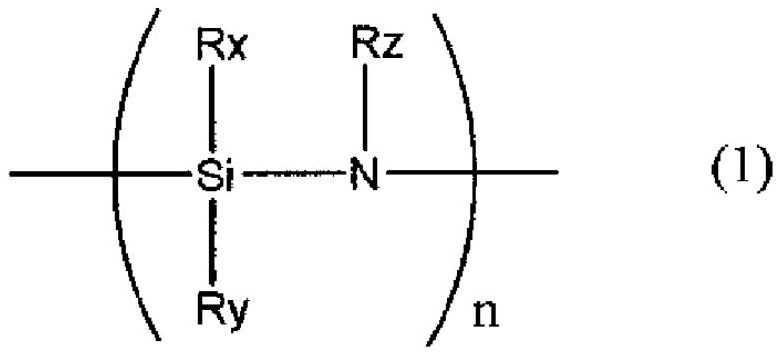

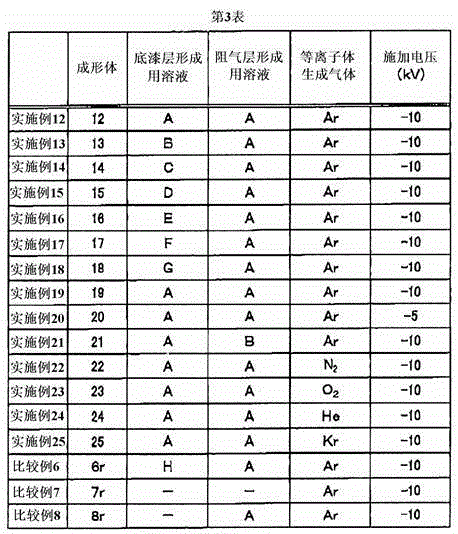

Formed body, production method thereof, electronic device member and electronic device

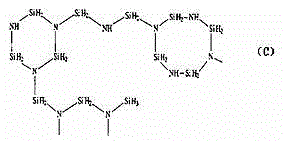

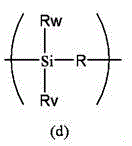

ActiveCN103209834AExcellent adhesion between layersExcellent gas barrier performanceSynthetic resin layered productsVacuum evaporation coatingSilanesEngineering

The present invention is a formed body, a production method thereof, an electronic device member comprising the formed body, and an electronic device comprising the electronic device member, the formed body being formed by sequentially layering a base layer, a primer layer and a gas barrier layer, characterized in that: the primer layer is configured from a material containing at least carbon atoms, oxygen atoms and silicon atoms, and in which the binding energy peak position of the 2p electron orbital in the silicon atom is 101.5 to 104 eV in the X-ray photoelectron spectroscopy (XPS) measurement; and the gas barrier layer is configured from a material containing (I) a layer obtained by implanting an ion in a polymer layer containing at least one type selected from a group comprising a polysilazane-based compound, a polyorganosiloxane-based compound, a polycarbosilane-based compound and a polysilane-based compound, or (II) at least oxygen atoms and silicon atoms, the proportion of oxygen atoms present being 60 to 75%, the proportion of nitrogen atoms present being 0 to 10%, and the proportion of silicon atoms present being 25 to 35%, with respect to the entire amount of oxygen atoms, nitrogen atoms and silicon atoms in the surface portion, and the film density in the surface layer portion being 2.4 to 4.0 g / cm3.

Owner:LINTEC CORP

Paint

InactiveCN107337971AImprove cold resistanceReduced heat absorption capacityCoatingsAdjuvantPolymer science

The invention discloses a paint, which is made of the following materials in parts by weight: 100-200 parts of acrylic modified resin latex, 10-15 parts of low-molecular-weight polyethylene, 10-20 parts of high-molecular-weight polyethylene, nanoelectric 10-30 parts of stone powder, 10-20 parts of nanometer far-infrared ceramic powder, 100-200 parts of pigment, 30-40 parts of dipropylene glycol methyl ether acetate, 10-20 parts of additives; among them, the solid content of acrylic modified resin latex It is 80-90%, adding a small amount of low-molecular-weight polyethylene and high-molecular-weight polyethylene to the coating of the present invention can combine with each other to improve the cold resistance of the coating, without cracking, impact resistance, and can reduce the heat absorption of the coating.

Owner:广西点图包装有限公司

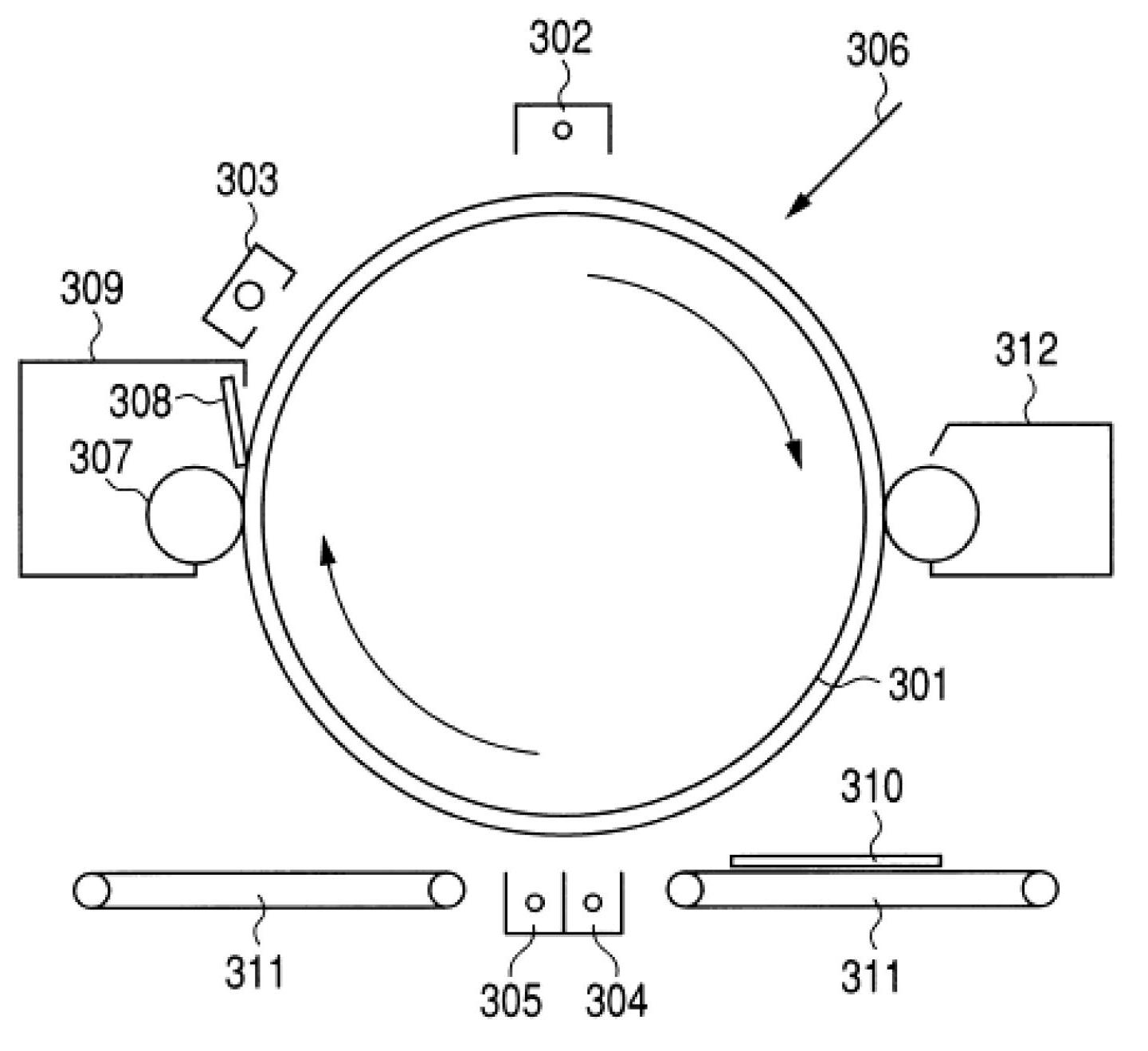

Electrophotographic photosensitive member and electrophotographic apparatus

InactiveCN102687080AExcellent adhesion between layersImprove featuresElectrography/magnetographySurface layerEngineering

The present invention provides an electrophotographic photosensitive member having an a-SiC upper charge injection inhibition layer and an a-SiC surface layer, which is superior in adhesiveness, suppresses the surface deterioration, is superior in sensitivity characteristics and charging characteristics, and can keep an adequate image-forming capability for a long period of time. The upper charge injection inhibition layer contains 10 atom ppm or more and 30,000 atom ppm or less of the Group 13 atoms or the Group 15 atoms of the Periodic Table with respect to silicon atoms in the upper charge injection inhibition layer, and the ratio (C / (Si+C)) of the number of carbon atoms in the upper charge injection inhibition layer with respect to the sum of the number of silicon atoms and the number of the carbon atoms in the upper charge injection inhibition layer is 0.10 or more and 0.60 or less; and the sum of the atom density of the silicon atoms and the atom density of the carbon atoms in the surface layer is 6.60 1022 atoms / cm3 or more, and the ratio (C / (Si+C)) of the number of carbon atoms with respect to the sum of the number of silicon atoms and the number of the carbon atoms in the surface layer is 0.61 or more and 0.75 or less.

Owner:CANON KK

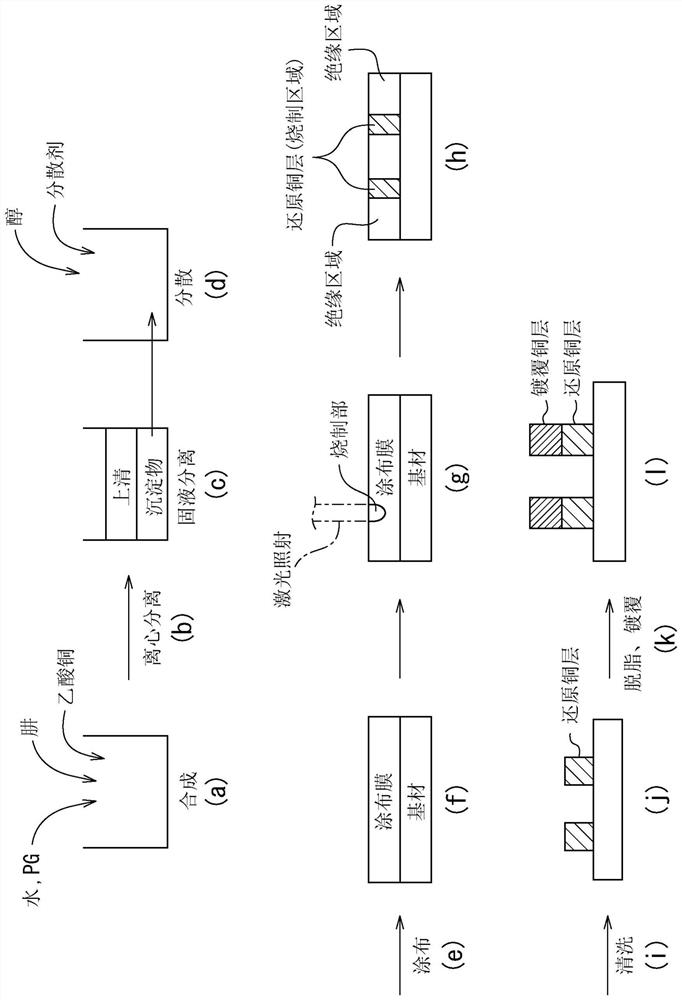

Structure with conductive pattern and method for manufacturing same

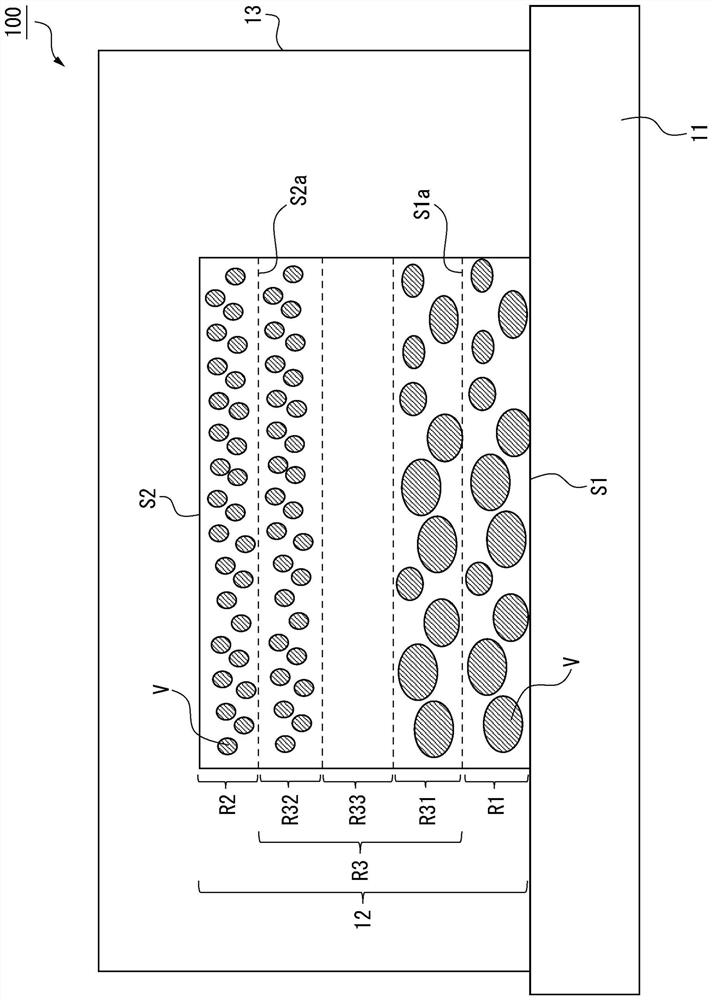

PendingCN114451071AExcellent adhesion between layersConductive layers on insulating-supportsHigh frequency circuit adaptationsPorosity

Provided are: a structure with a conductive pattern, which can be obtained by a simple manufacturing process and has good interlayer adhesion; and a method for manufacturing the structure. One embodiment of the present invention provides a structure with a conductive pattern, which is provided with a base material and a conductive layer that is arranged on the surface of the base material and contains copper, and wherein: when the main surface of the conductive layer on the side facing the base material is a first main surface and the main surface on the opposite side from the first main surface is a second main surface, the first main surface and the second main surface are opposite to each other; the conductive layer has a porosity of 0.01% by volume or more and 50% by volume or less in a first main surface-side region extending from the first main surface to a depth of 100 nm in the thickness direction of the conductive layer, and has a porosity of 10% by volume or less in a second main surface-side region extending from the second main surface to a depth of 100 nm in the thickness direction of the conductive layer.

Owner:ASAHI KASEI KK

Sheet-like adhesive, gas barrier laminated body, and sealed body

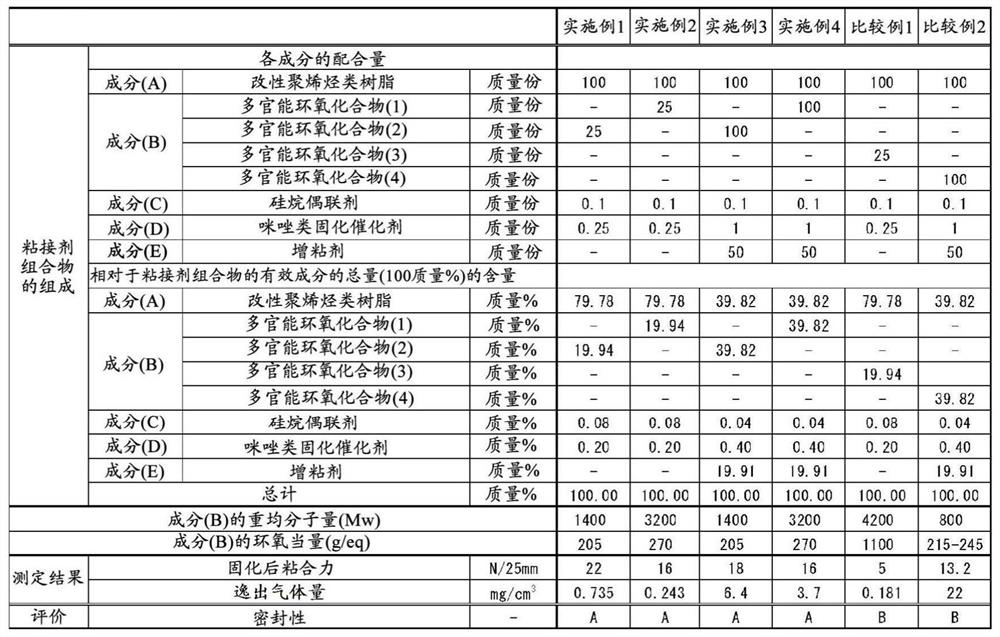

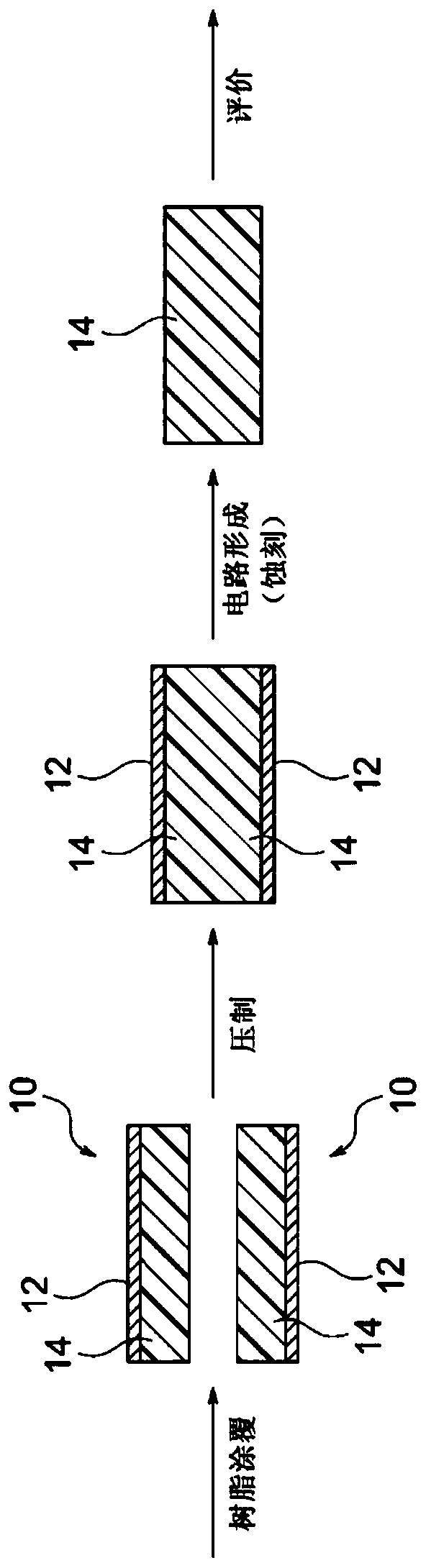

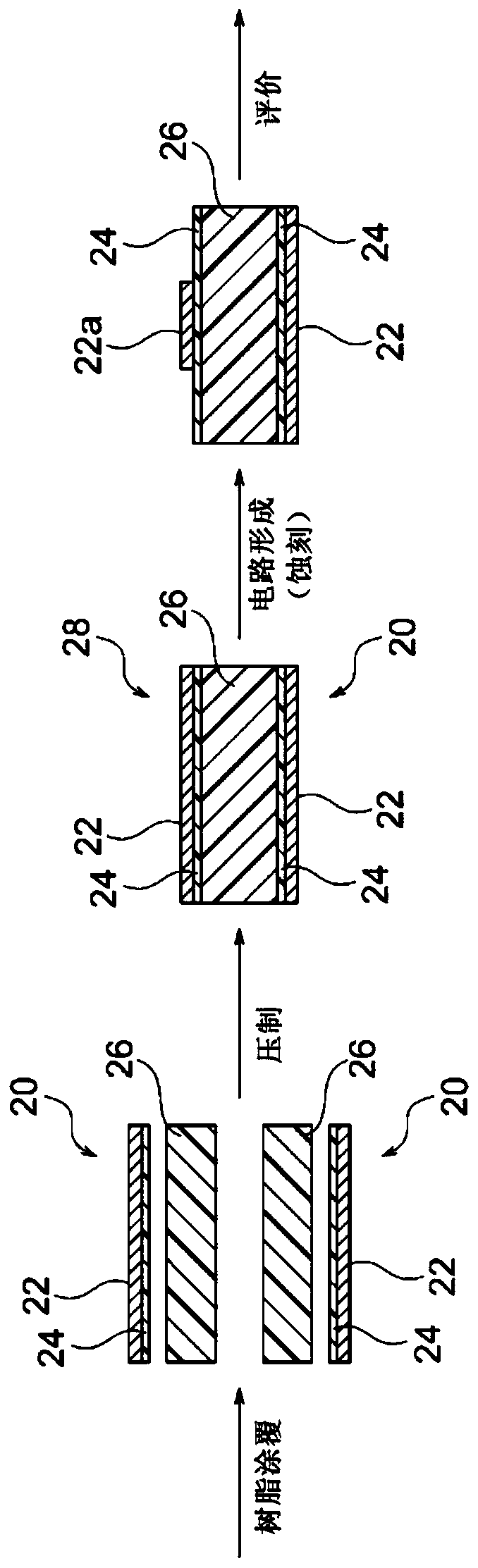

ActiveCN110709485BExcellent adhesion between layersEnhanced inhibitory effectNon-macromolecular adhesive additivesSynthetic resin layered productsPolymer sciencePolyethylene terephthalate

The sheet-like adhesive of the present invention is formed of an adhesive composition containing a modified polyolefin resin (A) and a thermosetting component (B), and satisfies the following conditions (I) and (II). ・Condition (I): When the sheet-shaped adhesive is left to stand for 20 minutes in an environment of 120°C, the 3 The amount of evolved gas produced is 20mg / cm 3 the following. ·Condition (II): Under the conditions of temperature 60°C, pressure 0.2MPa and speed 0.2m / min, use a roller to paste the sheet-like adhesive on a polyethylene terephthalate film with a thickness of 50μm. The laminated body of the adhesive is pressed against a glass plate, the surface of the laminated body on the side of the sheet-shaped adhesive is bonded to the glass plate, and the sheet-shaped adhesive is made to After curing, it was stored at 23° C. and a relative humidity of 50% for 24 hours, and then, under the conditions of a peeling speed of 300 mm / min and a peeling angle of 180°, the adhesion of the laminate to the glass plate was measured according to JIS Z0237:2000. Adhesive force, the adhesive force is 10N / 25mm or more.

Owner:LINTEC CORP

Resin composition for printed wiring board, copper foil with resin, copper-clad laminate board, and printed wiring board

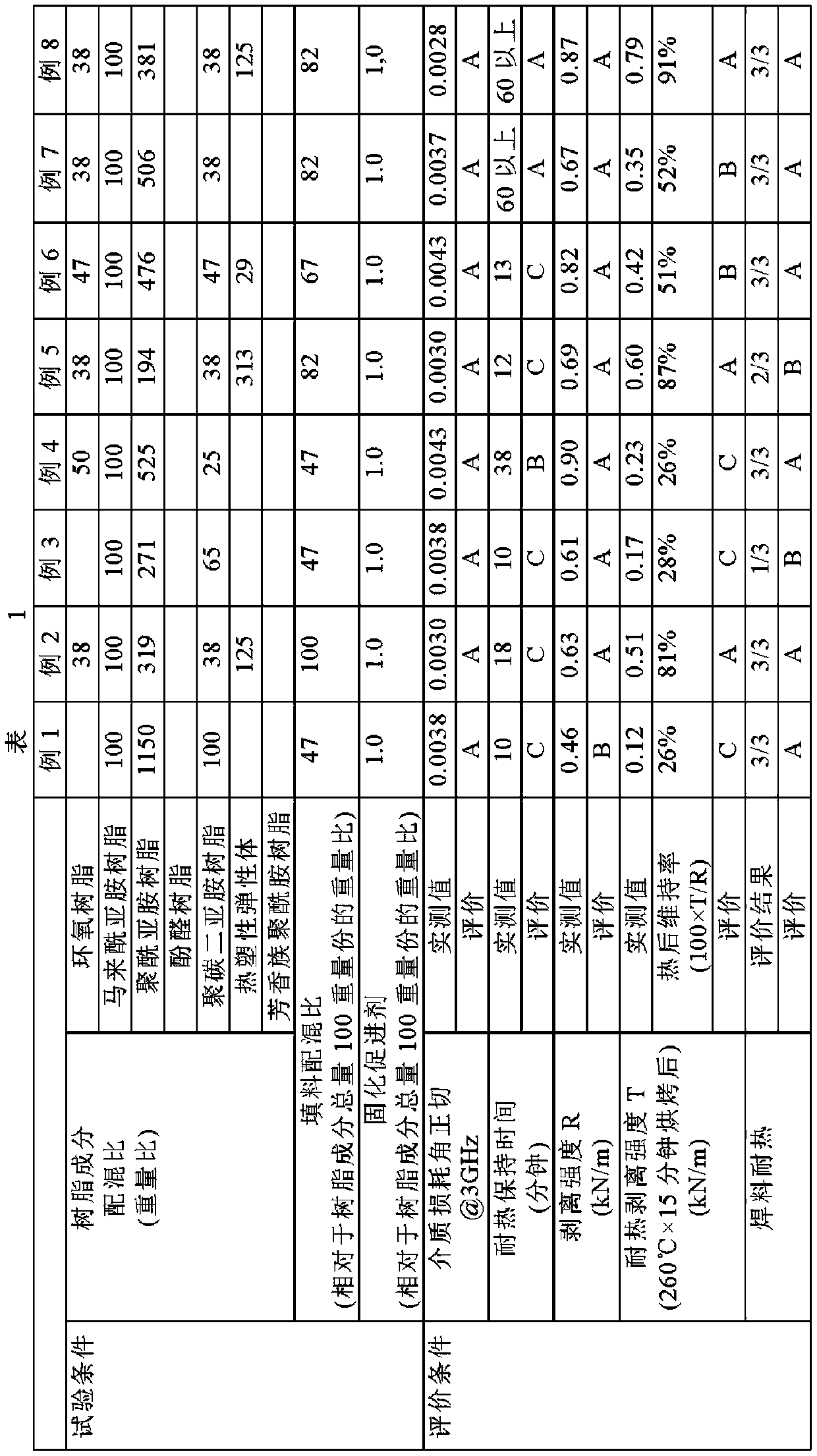

ActiveCN111201277AExcellent dielectric propertiesExcellent adhesion between layersCircuit susbtrate materialsPolymer scienceDielectric loss

Provided is a resin composition for a printed wiring board capable of exhibiting excellent dielectric properties (extremely low dissipation factor tangent) appropriate for high-frequency use, and, when used in a copper-clad laminate board or a printed wiring board, can demonstrate excellent adherence between layers, and heat resistance. This composition includes: a maleimide resin; a polyimide resin in the amount of 150-1200 parts by weight per 100 parts by weight of the maleimide resin; and a polycarbodiimide resin in the amount of 15-120 parts by weight per 100 parts by weight of the maleimide resin.

Owner:MITSUI MINING & SMELTING CO LTD

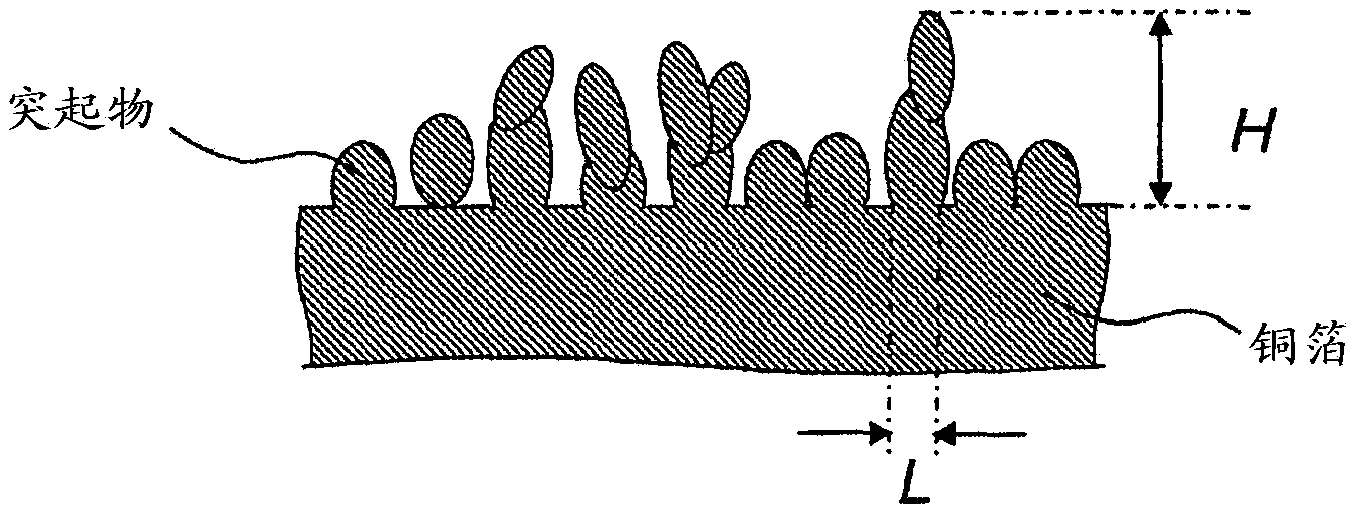

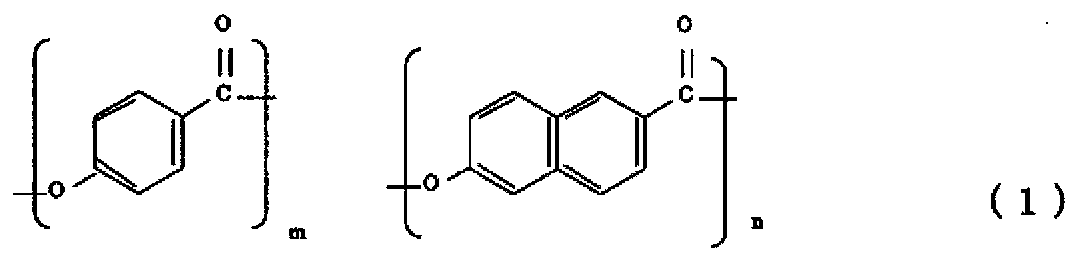

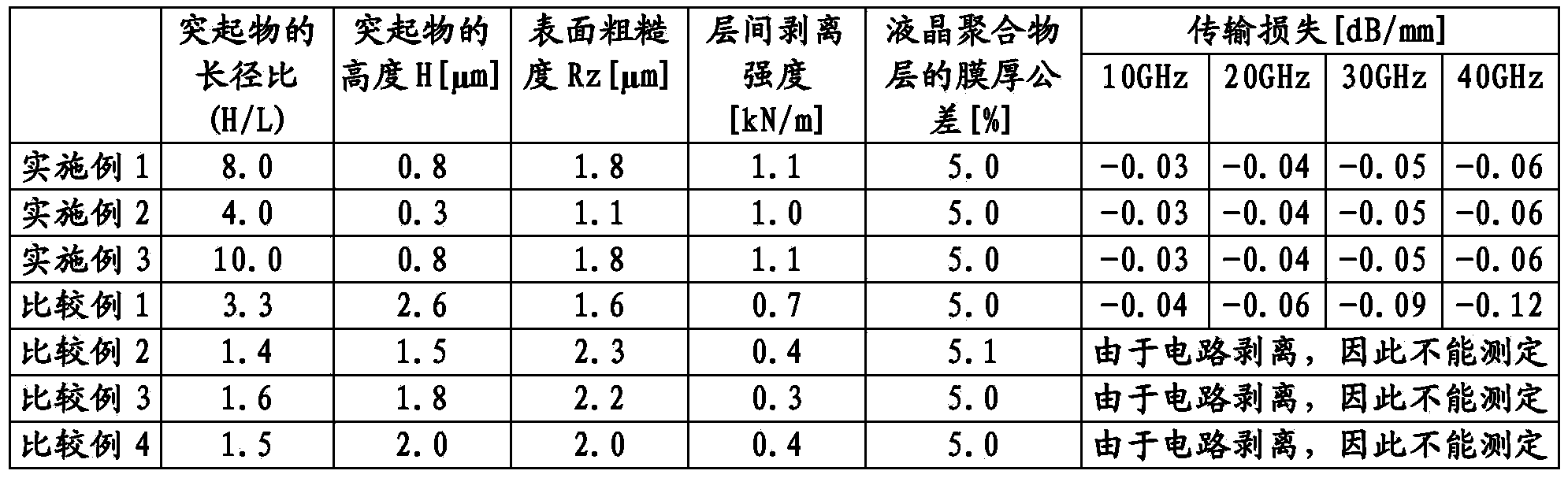

Metal-clad laminated plate

ActiveCN103069933BExcellent adhesion between layersImprove qualityInsulating substrate metal adhesion improvementSynthetic resin layered productsMetal foilCharacteristic impedance

Provided is a metal-clad laminated plate, wherein dielectric-thickness tolerance that contributes to characteristic-impedance tolerance is made to be low to deal with the tendency of transmission frequency becoming higher, and wherein transmission loss of signals at high-frequency ranges is small. The metal-clad laminated plate comprises a metal foil on one face or on both faces of a liquid crystal polymer layer, and is characterized in that the metal foil has protrusions formed on the surface layer thereof, by having a face thereof that comes in contact with the liquid crystal polymer layer roughened, and the aspect ratio (H / L) of the protrusions, indicated by the ratio of the height (H) thereof with respect to the width (L) of the base sections thereof, is within a range of 3-20. The metal-clad laminated plate is also characterized in that the height of the protrusions is within a range of 0.1-2 µm, the thickness of the liquid crystal polymer layer is 10-200 µm, and the film-thickness tolerance thereof is less than 6%.

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD

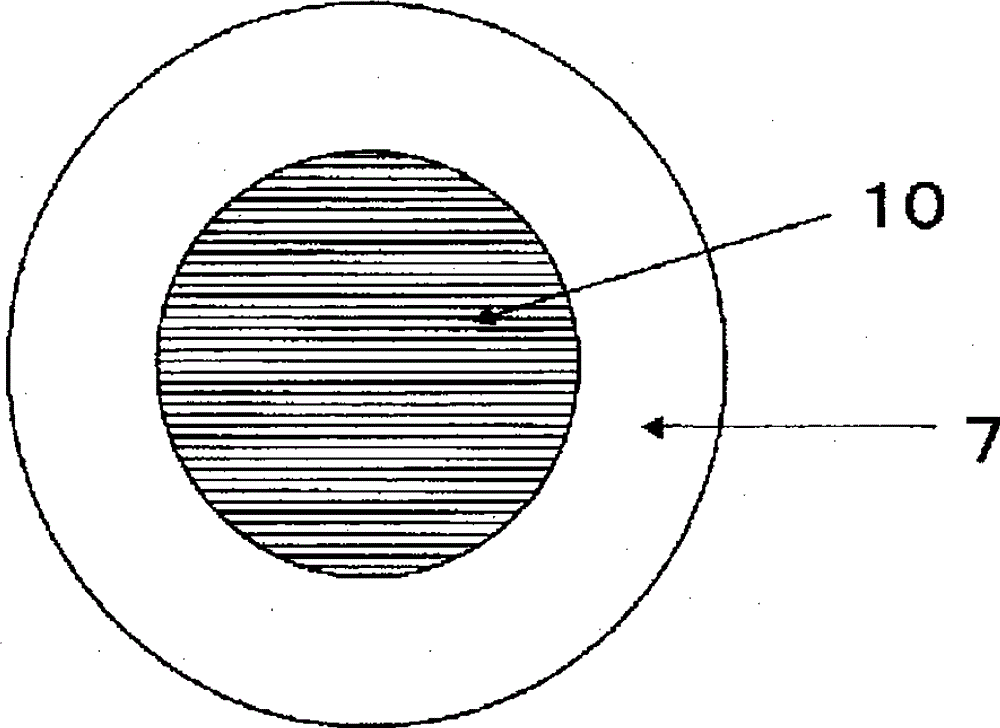

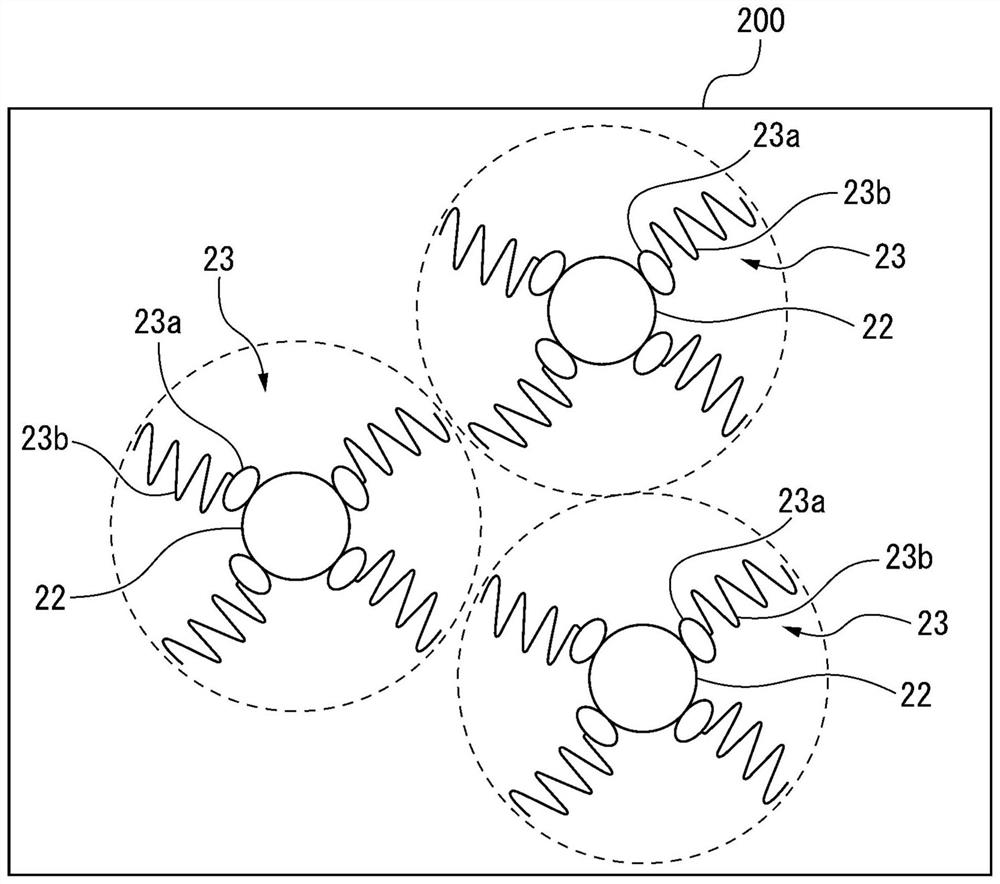

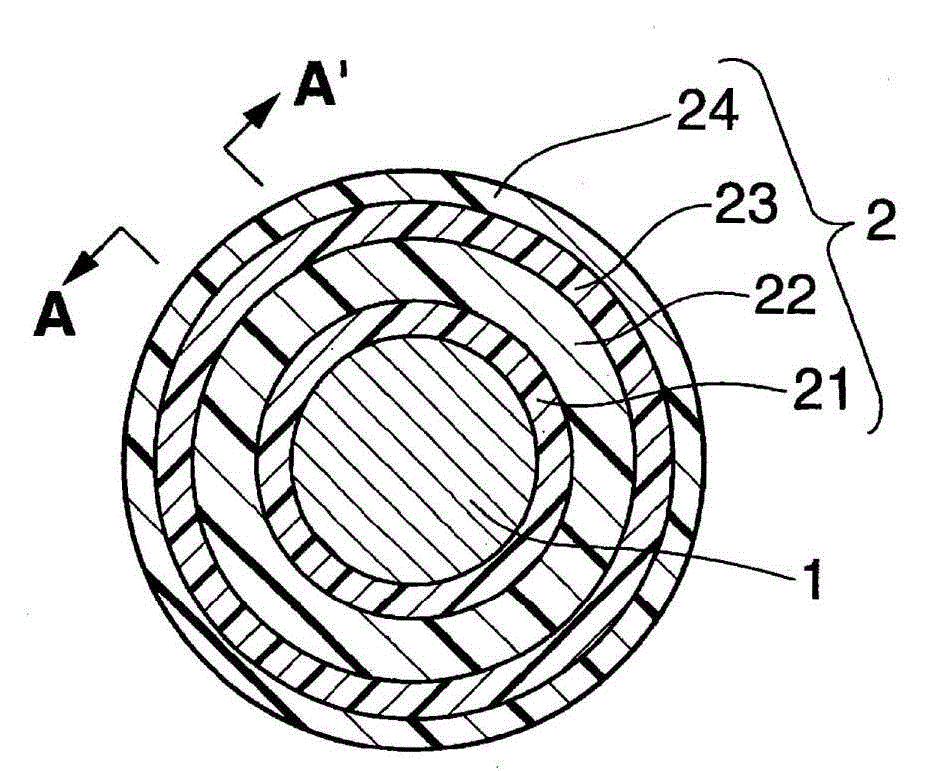

insulated wire

ActiveCN102782773BExcellent adhesion between layersExcellent partial discharge resistanceInsulated cablesInsulatorsCapacitanceElectrical conductor

{Problems} To provide an insulated wire, which is high in a dielectric breakdown resistance even if insulating resin coatings are laminated, because the interlayer adhesiveness is excellent, and which is excellent in a partial discharge resistance, because the dielectric constant is low. {Means to solve} An insulated wire, having directly or indirectly on a conductor (1), at least two laminate units each formed by laminating an insulating layer (21,23) and an insulating layer (22, 24) higher in a dielectric constant than the insulating layer (21, 23), in this order from the conductor side.

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

Laminated sheet, method for producing same, back sheet for solar cell, solar cell module, and method for manufacturing back sheet for solar cell

InactiveCN104822528BImprove performanceExcellent adhesionSynthetic resin layered productsElectrical equipmentPolytetramethylene terephthalatePolyolefin

A laminated sheet having: a layer having a polybutylene terephthalate resin as a principal component (P1 layer); and a layer having a polyolefin resin as a principal component (P3 layer). A solar cell back sheet, characterized in that the acetic acid permeability (Pa) (g / m2 / day) at 85°C and water vapor permeability (Pw) (g / m2 / day) at 40°C 90% RH satisfy relationships (1) 200 ≤ Pa and (2) Pw ≤ 2.5. Provided are a laminated sheet having a better moist heat resistance and an improved capacity to obtain both heat resistance and adhesion performance with respect to a sealing member compared with a conventional laminated sheet in which a polybutylene terephthalate resin is used, and a method for manufacturing the laminated sheet. Also provided are a solar cell module back sheet that is inexpensive and that is capable of preventing discoloration of the collector electrode of a solar cell while maintaining the power generation characteristics of the solar cell module over a long period, and a method for manufacturing the solar cell module back sheet.

Owner:TORAY IND INC

Method for manufacturing a laminate with one metal-plated side

ActiveCN102781661BImprove reliabilityImprove qualityLayered product treatmentSynthetic resin layered productsWrinkle skinMetal foil

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD

Production method for an in-mould, semi-cured transfer film

InactiveCN101952353AImproving the sex work environmentImprove cutting effectPretreated surfacesCoatingsHazardous substanceUltraviolet

The present invention relates to a production method for an in-mould, semi-cured transfer film. More specifically, it relates to a production method for an in-mould, semi-cured transfer film which has a laminated structure comprising, in sequence on a base film: a mould-release layer and a protective layer, a print layer, a vapour-deposited layer and an adhesive layer. The said transfer film doesnot produce harmful substances such as formaldehyde (HCHO) during the production process, and can endow injection moulded articles with highly outstanding physical properties when it is used.

Owner:李昌根

Formed body, production method thereof, electronic device member and electronic device

ActiveCN103209834BExcellent adhesion between layersExcellent gas barrier performanceSynthetic resin layered productsVacuum evaporation coatingEngineeringPolysilane

The present invention is a formed article sequentially including a base layer, a primer layer, and a gas barrier layer, the primer layer being formed of a material that includes at least a carbon atom, an oxygen atom, and a silicon atom, and is characterized in that a peak position of binding energy of 2p electrons of the silicon atom as determined by X-ray photoelectron spectroscopy (XPS) is 101.5 to 104 eV, and the gas barrier layer (I) being a layer obtained by implanting ions into a polymer layer that includes at least one compound selected from a group consisting of a polysilazane compound, a polyorganosiloxane compound, a polycarbosilane compound, and a polysilane compound, or (II) being formed of a material that includes at least an oxygen atom and a silicon atom, a surface layer part of the gas barrier layer having an oxygen atom content rate of 60 to 75%, a nitrogen atom content rate of 0 to 10%, and a silicon atom content rate of 25 to 35%, based on a total content rate of oxygen atoms, nitrogen atoms, and silicon atoms, and the surface layer part of the gas barrier layer having a film density of 2.4 to 4.0 g / cm 3 . Also provided are a method for forming the same, an electronic device member including the formed article, and an electronic device including the electronic device member.

Owner:LINTEC CORP

Laminate

ActiveUS11065850B2Excellent adhesion between layersSpecial paperPolyureas/polyurethane adhesivesPolymer scienceCellulose fiber

It is an object of the present invention to provide a laminate excellent in interlayer adhesion properties. The present invention relates to a laminate comprising: a fiber layer formed of cellulose fibers having a fiber width of 1000 nm or less; a resin layer; and an adhesive layer provided between the fiber layer and the resin layer.

Owner:OJI HLDG CORP

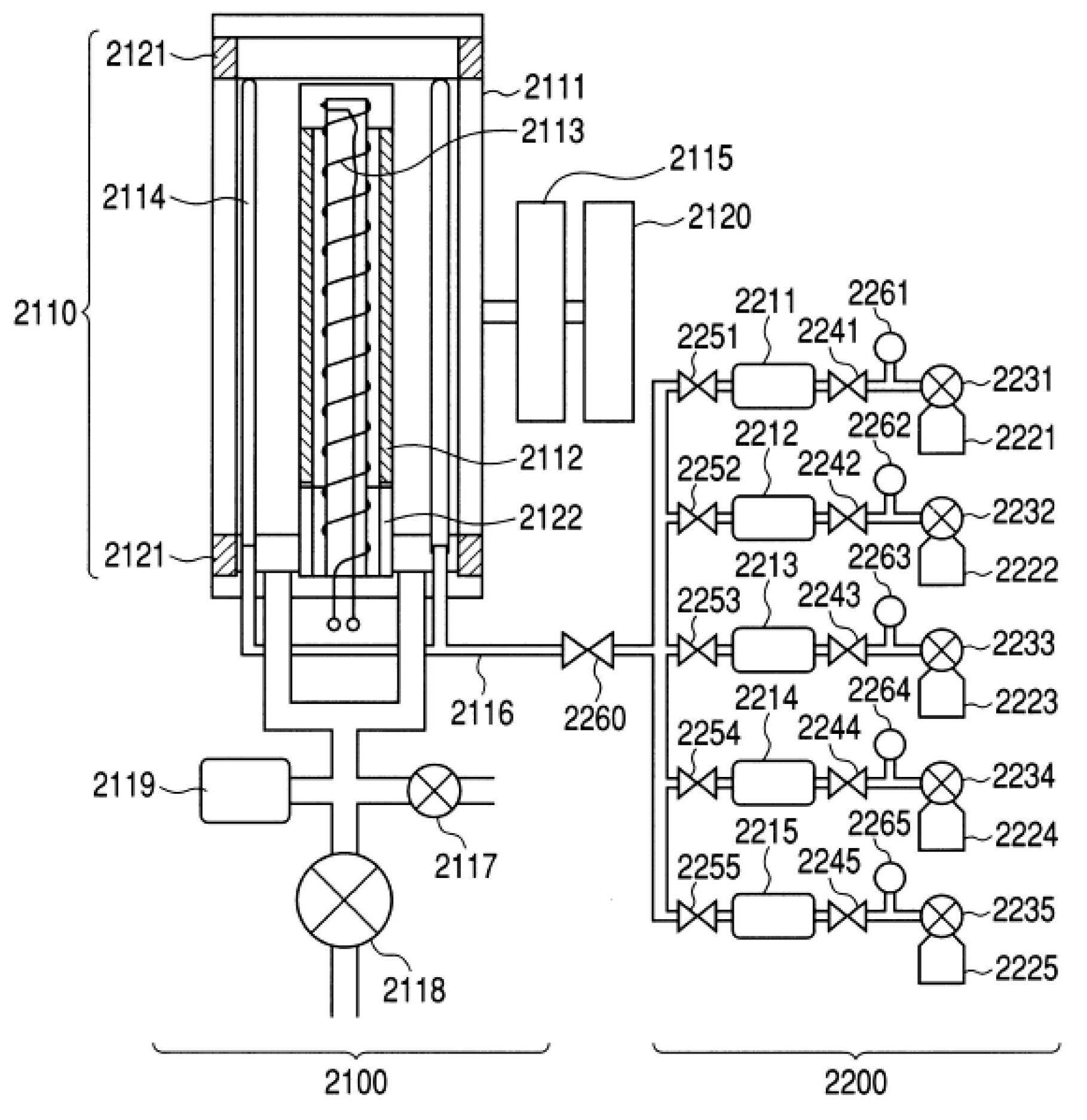

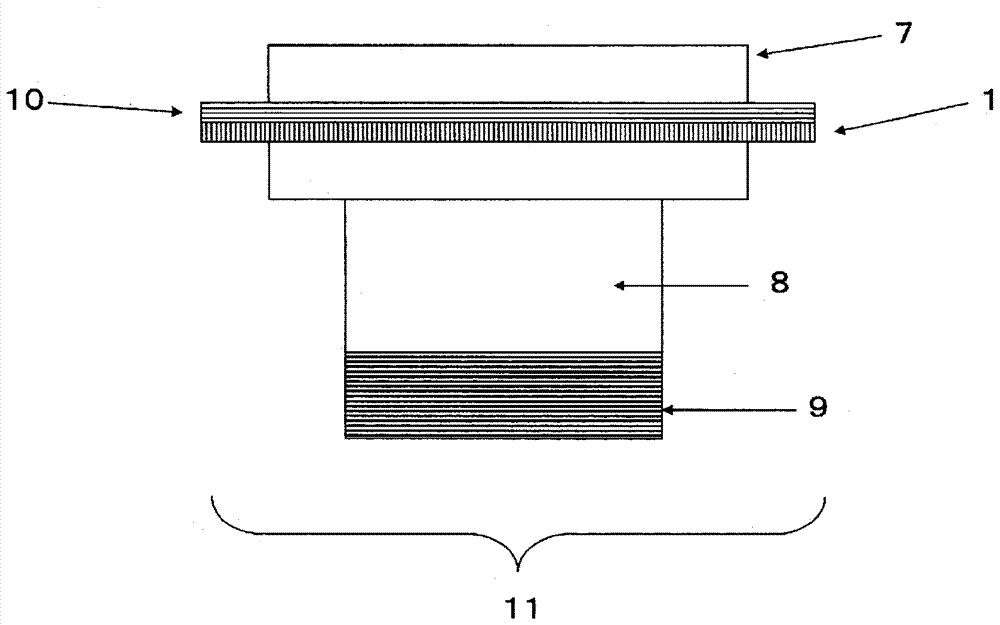

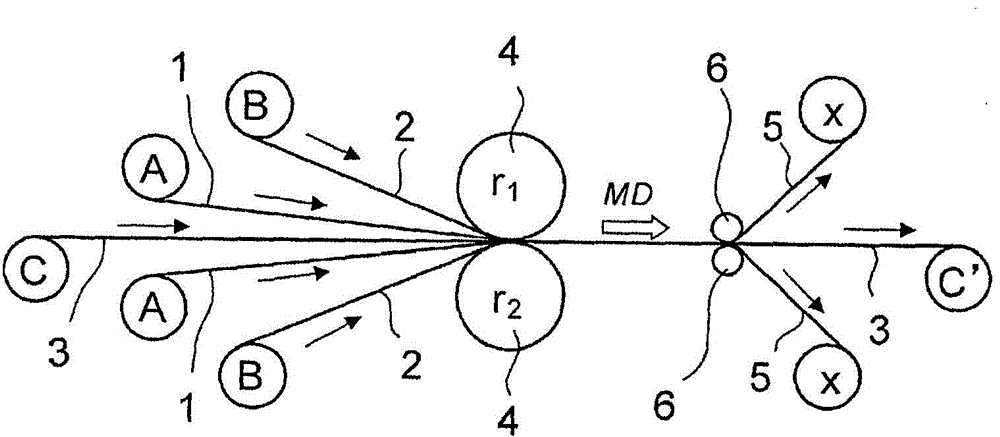

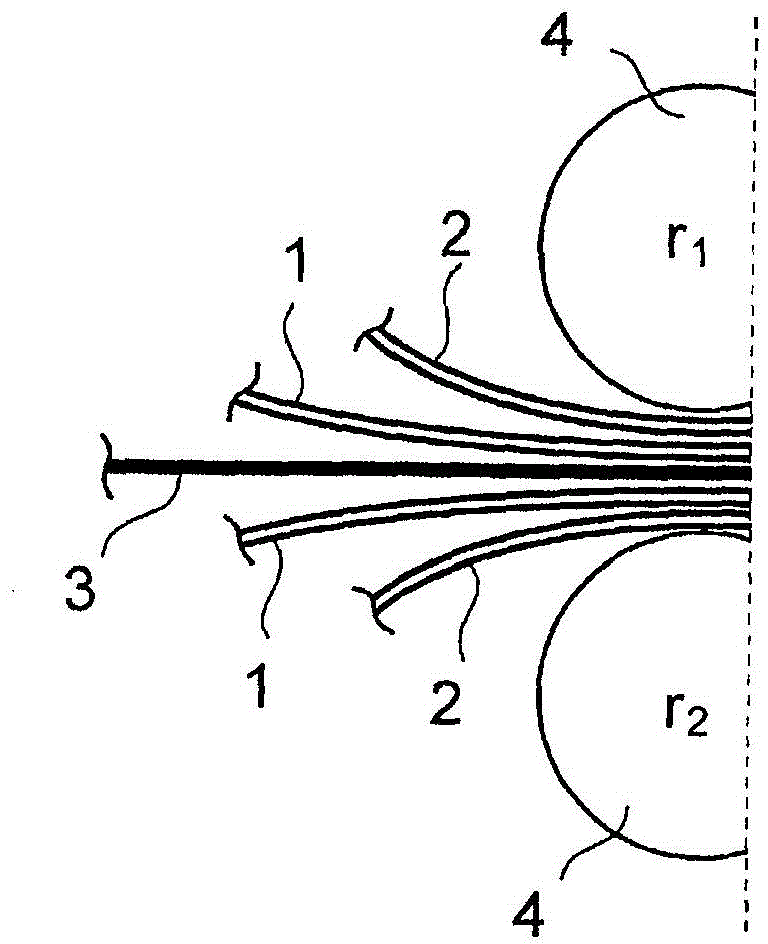

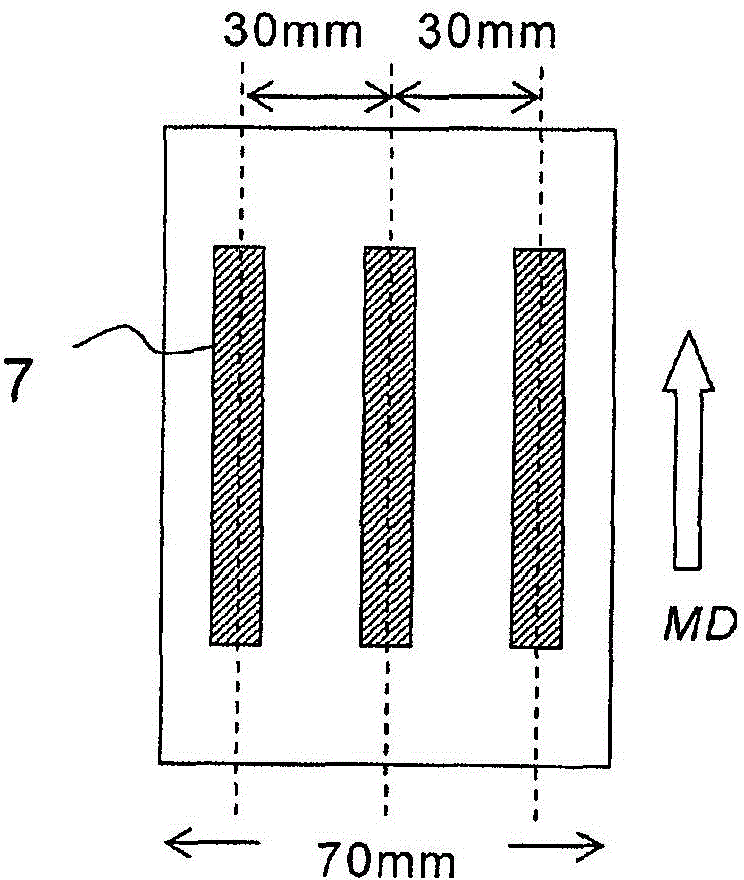

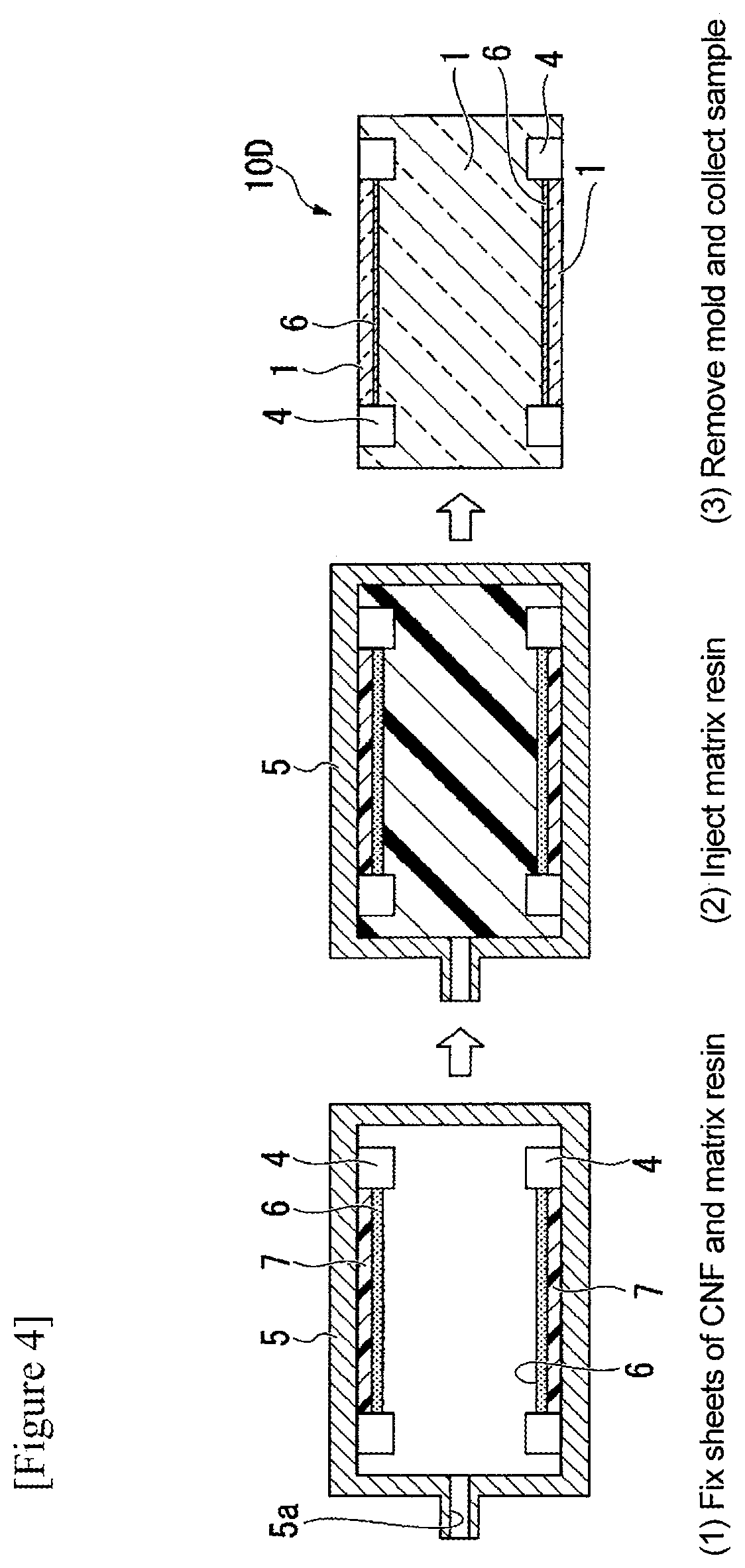

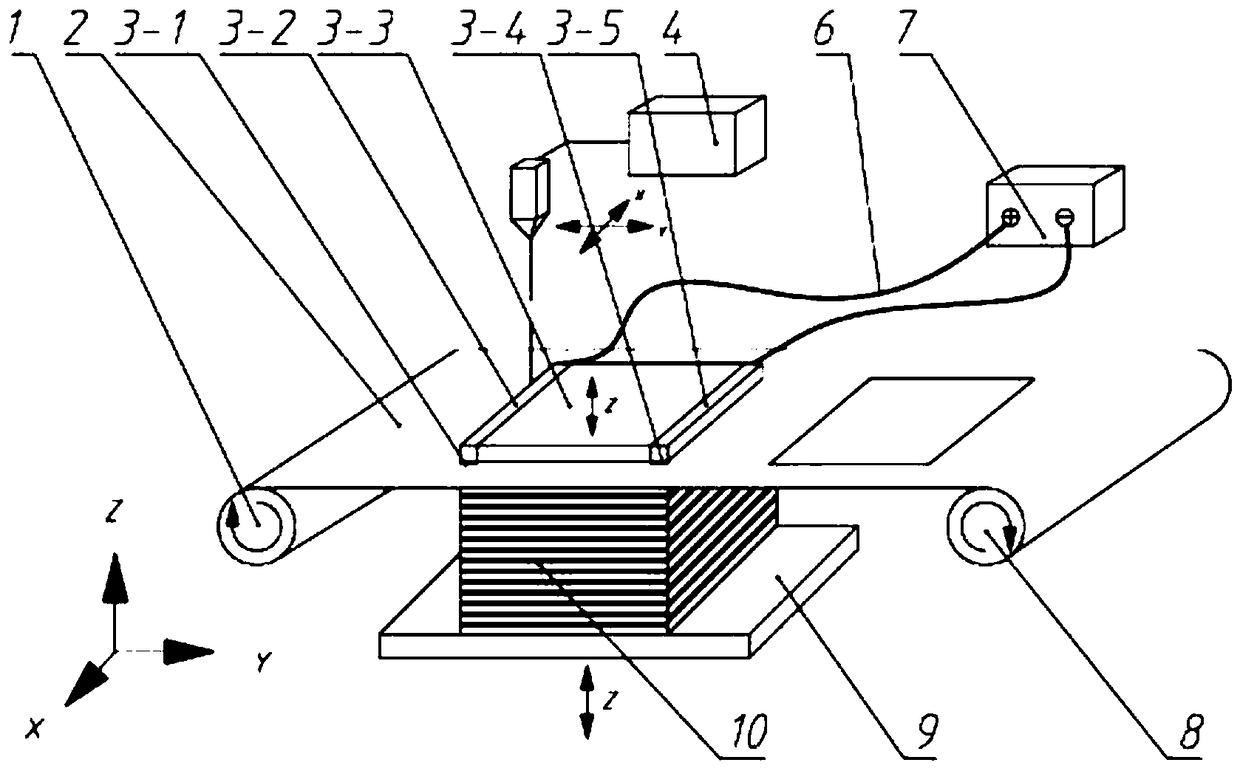

Carbon fiber reinforced resin matrix composite material current heating LOM manufacturing method and device

ActiveCN109130243AExcellent fiber wettabilityExcellent adhesion between layersThree dimensional modelResin matrix

The invention relates to a method and device for manufacturing a carbon fiber reinforced resin matrix composite material current heating LOM, wherein a prepreg tape of the carbon fiber reinforced resin-based composite material is conveyed to the upper part of a working platform, the working platform is moved upward to fit the prepreg tape, a pressing plate mechanism moves downwards to press the prepreg tape on the working platform, at the same time, the electrodes at both ends of the pressing plate are powered on the prepreg tape of a pressing area, the pressing plate mechanism is moved upwardaway from the prepreg tape after the prepreg tape is heated and solidified, a laser emitter cuts the prepreg tape along the cross-section of the three-dimensional model, the outer part of the cross-section is cut into fine pieces, and after the cutting is finished, the working platform descends off the prepreg tape, and then the whole prepreg tape is conveyed to the upper part of the working platform, the residual prepreg tape is retracted by a winding drum after being cut, that is, the single-layer forming and solidifying is completed, a process is recycled until the forming and solidifyingof the whole three-dimensional solid component is completed, that is, the required three-dimensional solid component is obtained; the forming mode is rapid and unsupported; the solidifying technologyis low in consumption and energy-saving.

Owner:XI AN JIAOTONG UNIV

Aqueous dispersion composition for primer

ActiveCN101405358BExcellent adhesion between layersHigh hardnessLiquid surface applicatorsSynthetic resin layered productsPolymer chemistryAqueous dispersion

Disclosed is an aqueous dispersion composition which enables to form a primer layer that is excellent in interlayer adhesion with a top coat layer containing a fluororesin and capable of improving hardness and wear resistance of a coating film as a whole. Also disclosed is a coating film structure using such an aqueous dispersion composition. Specifically disclosed is an aqueous dispersion composition for primers for fluororesin coating film layers, which contains (A) a water-soluble, curable polyamideimide and / or polyimide binder polymer, (B) ceramic spherical particles, (C) modified PTFE particles and (D) an aqueous medium. This aqueous dispersion composition for primers is characterized in that the modified PTFE particles (C) have a melt creep viscosity at 380 DEG C within the range from 2*10<9> to 1*10<11> Pas, and a standard relative density of not more than 2.170. A primer layer is formed by using such an aqueous dispersion composition for primers, and a top coat layer containing a fluororesin is formed thereon.

Owner:DAIKIN IND LTD

multilayer laminated film

ActiveCN106457810BWith transparencyExcellent adhesion between layersSynthetic resin layered productsOptical elementsPolyesterPolymer science

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com