Gas barrier laminated film for organic devices

A technology of organic devices and gas barrier properties, applied in the direction of electrical solid devices, applications, coatings, etc., can solve problems such as insufficiency, and achieve the effects of reducing the generation of bubbles and foreign matter, excellent adhesion strength, and excellent gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

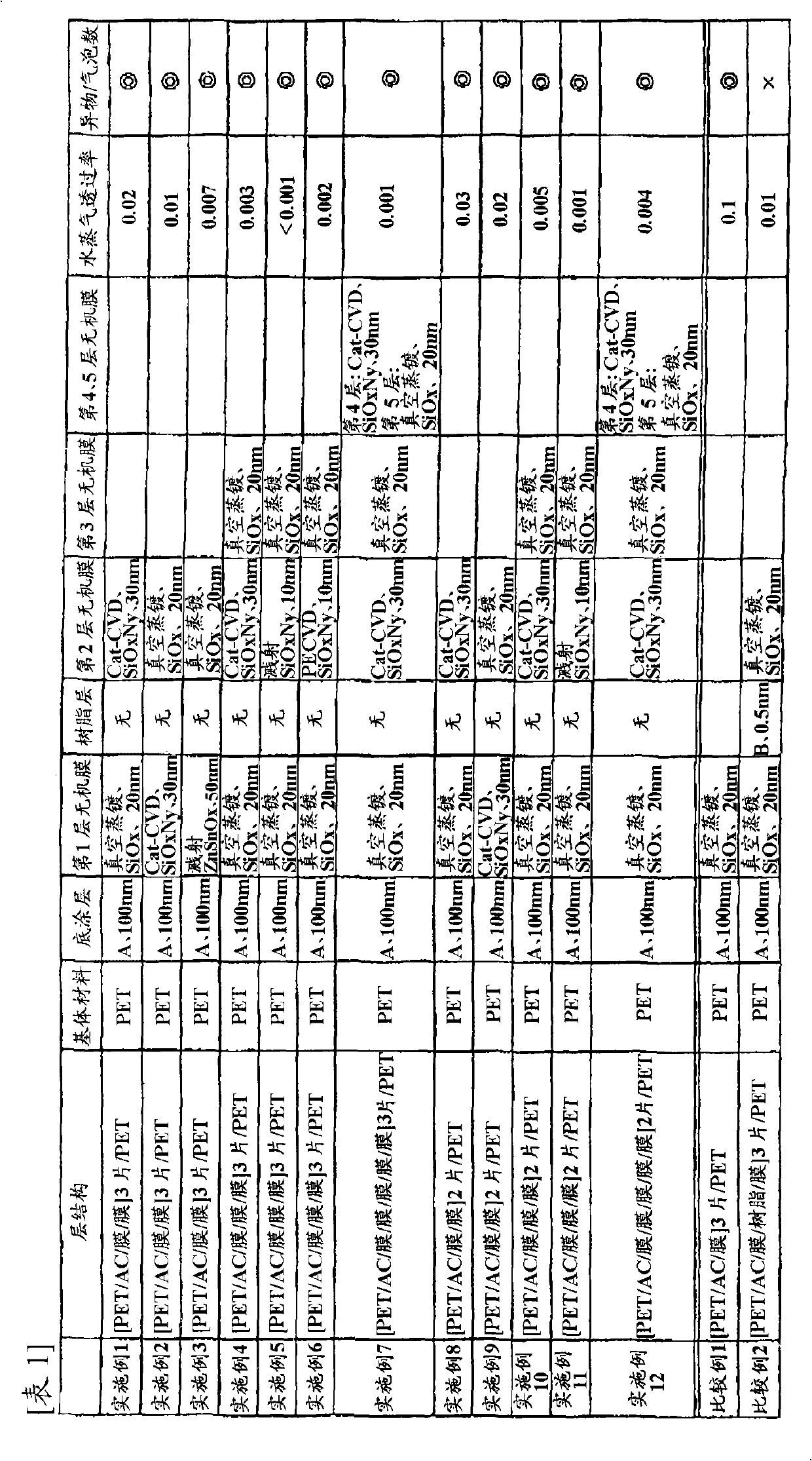

Examples

preparation example Construction

[0086] The preparation method of the gas barrier laminated film for organic devices of the present invention has the following steps:

[0087] (1) The step of obtaining a gas barrier laminate having at least two inorganic thin film layers on at least one surface of the base material film, and the at least two inorganic thin film layers include a layer formed in contact with each other. more than two layers of inorganic thin film layers;

[0088] (2) A step of laminating a plurality of gas barrier laminates obtained above to obtain a gas barrier laminate film, wherein the surface of the base material film side of the gas barrier laminate to be laminated is It is opposite to the surface of the inorganic thin film layer of another gas barrier laminate, and an adhesive layer having a m-xylylenediamine skeleton is sandwiched between the gas barrier laminates. , p-xylylenediamine skeleton, and at least one epoxy-based adhesive in the bisphenol skeleton; and

[0089] (3) A step of ...

Embodiment 1

[0122] Polyethylene terephthalate resin (hereinafter referred to as "PET"; "NOVAPEX" manufactured by Mitsubishi Chemical Co., Ltd.) was melt-extruded to form a sheet. direction, and then stretched in the width direction at a stretching temperature of 110° C. and a stretch ratio of 3.3 to obtain a biaxially oriented PET film with a thickness of 12 μm. On one side of the film, an isocyanate compound ("CORONET L" manufactured by Nippon Polyurethane Industry Co., Ltd.) and a saturated polyester ("Vylon 300" manufactured by Toyobo Co., Ltd., number average molecular weight 23000) were coated at a ratio of 1:1 by mass. The resulting mixture was mixed and dried to form an undercoat (AC) layer having a thickness of 100 nm.

[0123] Next, using a vacuum evaporation device, at 1.33 x 10 -3 Pa(1×10 -5 Under the vacuum of Torr), SiO is evaporated by high-frequency heating, and an inorganic thin film with a thickness of about 20 nm is formed on the undercoat layer.

[0124] Using a cata...

Embodiment 2

[0128] A gas barrier film laminate was obtained and evaluated in the same manner as in Example 1, except that the order of producing the first and second inorganic thin films was reversed. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com