Multilayer film

A laminated film and laminated technology, applied to layered products, synthetic resin layered products, instruments, etc., can solve problems such as insufficient hydrolysis resistance, and achieve excellent outdoor durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

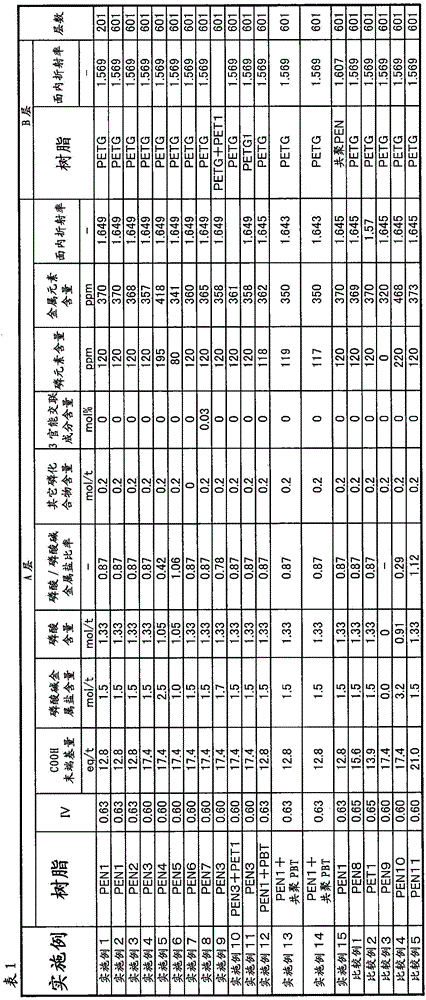

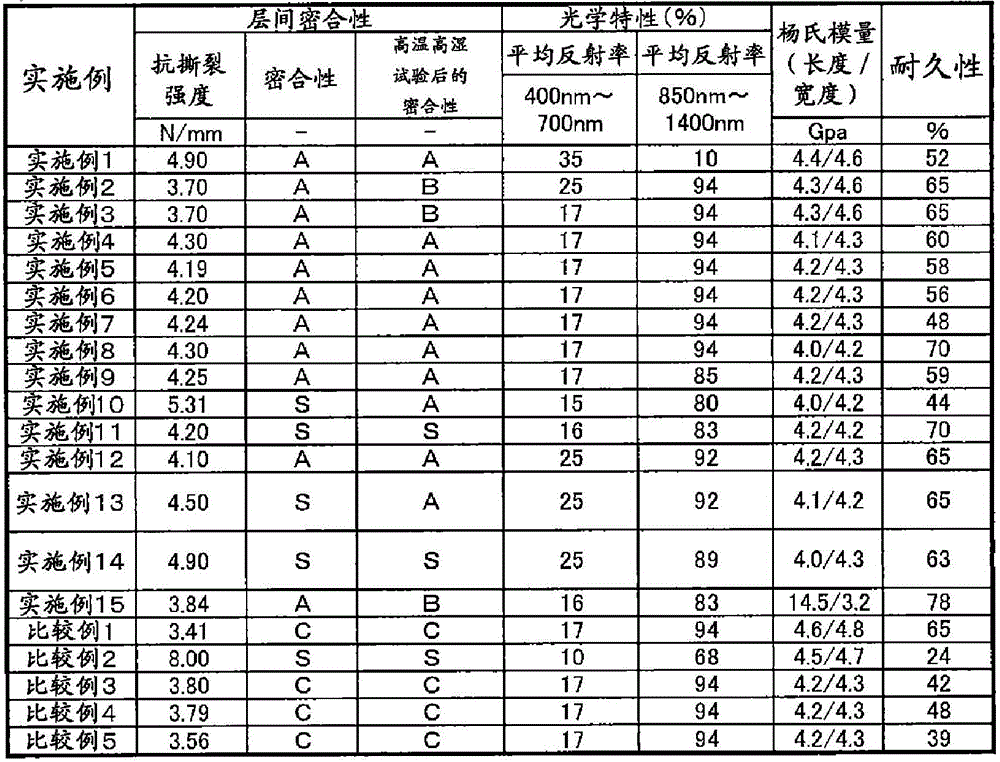

[0134] As the polyester A, PEN1 was used, and for the polyester B, PET obtained by copolymerizing 33 mol% of cyclohexanedimethanol (hereinafter referred to as PETG. Part number: GN001, manufactured by Istman Chemical Co., Ltd.) was used. As a result of measuring the heat of fusion of polyester by DSC, PEN1 was a crystalline polyester, and PETG was an amorphous polyester. Polyester A and polyester B were melted at 290°C by extruder respectively, passed through 5 pieces of FSS-type leaf disk filters, then passed through gear pumps and filters, and then made use of a 201-layer feed die set to make them confluence. The thickness of each layer of the merged polyester A and B in the feed die set is substantially constant from the surface side to the opposite surface side, forming a structure consisting of 101 layers of polyester A and 100 layers of polyester B. Alternately laminated structure along the thickness direction. The adjustment of the thickness of each layer was adjusted...

Embodiment 2

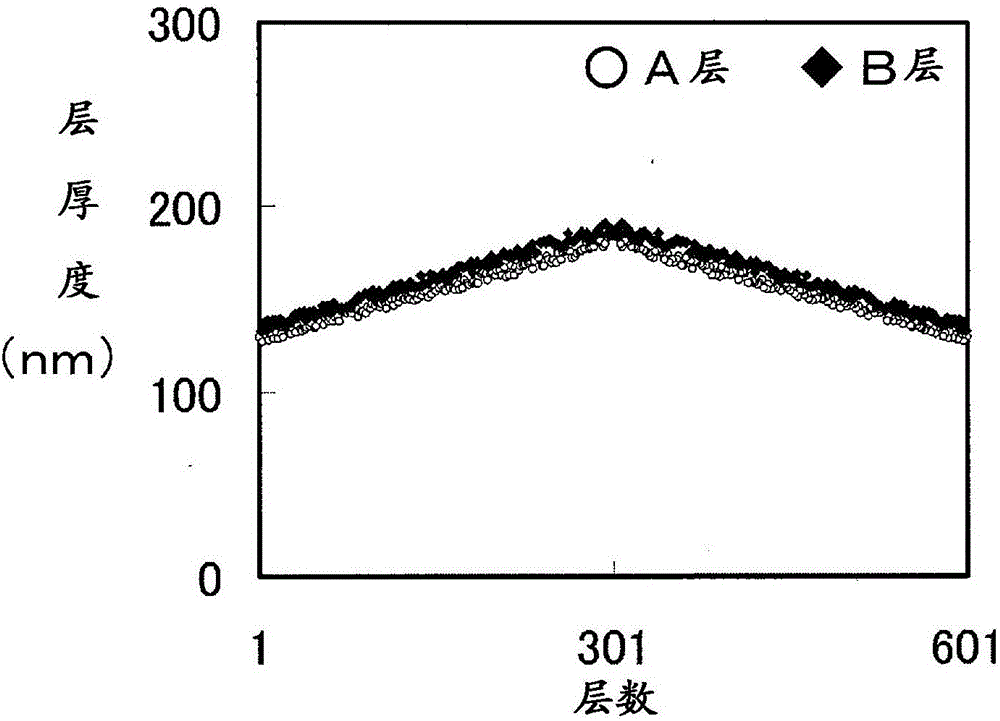

[0139]While measuring with a gear pump so that the ratio of optical thickness except for the thick film layer of the film is polyester A / polyester B = 1, a configuration using two slit plates with 301 slits The 601-layer lamination device is combined to form a laminated body in which 601 layers are alternately laminated along the thickness direction. The method of producing a laminate is carried out in accordance with the description in paragraphs [0053] to [0056] of JP-A-2007-307893. In addition, since there are layers formed by overlapping layers A, the number of gaps in the slit plate is 602. In addition, in order to make the reflection band with a wavelength of 1200nm or less be a polymer multilayer laminate, and the average reflectance of a wavelength of 850nm or more and 1200nm or less is 60% or more, the slit design is based on the layer thickness of the laminated film obtained through the following steps distributed as figure 1 Designed as shown. Then, it carried ou...

Embodiment 3

[0141] Except having changed sodium dihydrogen phosphate into potassium dihydrogen phosphate, it carried out similarly to the manufacturing method of PEN1, and produced PEN2, and carried out similarly to Example 2, and obtained the biaxially stretched film. As shown in Table 1, the resulting film exhibited substantially equivalent properties to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com