Base coating composition for non-ferrous metal

A base paint and composition technology, applied in the direction of polyester paint, coating, etc., can solve the problems of reducing corrosion resistance, chipping resistance, hardness, repaintability, yellowing, non-softness, etc., and achieve excellent The effect of initial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

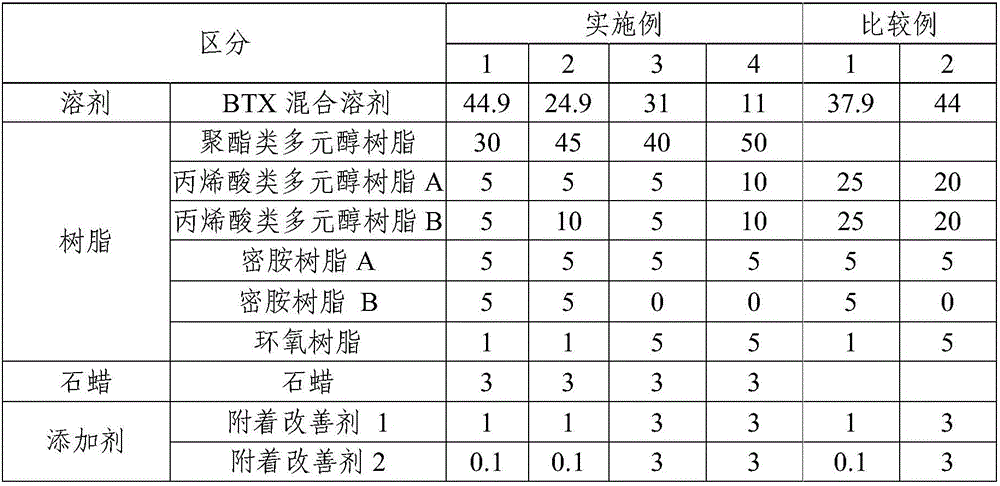

[0030] After implementing the powder primer pretreatment on the aluminum substrate, the coating compositions of Examples 1-4 and Comparative Examples 1-2 having the composition of the following Table 1 are coated as liquid varnish samples and powder varnish samples , to evaluate the physical properties of the coatings.

[0031] For the pretreatment of the powder primer, electrostatic coating is used to make the coating thickness 80-120 microns, and the curing is carried out at a curing temperature of 170°C for 10 minutes. For liquid varnish samples, apply After using air spraying or electrostatic spraying to coat 20-35 microns on the substrate, after a setting time of 10 minutes at room temperature, use the same coating method as the substrate to coat the liquid varnish, set After 10 minutes it was cured at about 140°C for 10 minutes. For the powder varnish sample, after the 20-35 micron coating is carried out by air spraying or electrostatic spraying on the substrate that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com