Low-pressure paste additive

An additive and paste technology, applied in the directions of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of corrugated cardboard fiber damage, high steam heat energy consumption, and poor dough bonding. , to achieve the effect of reducing waste, increasing production speed, and good initial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

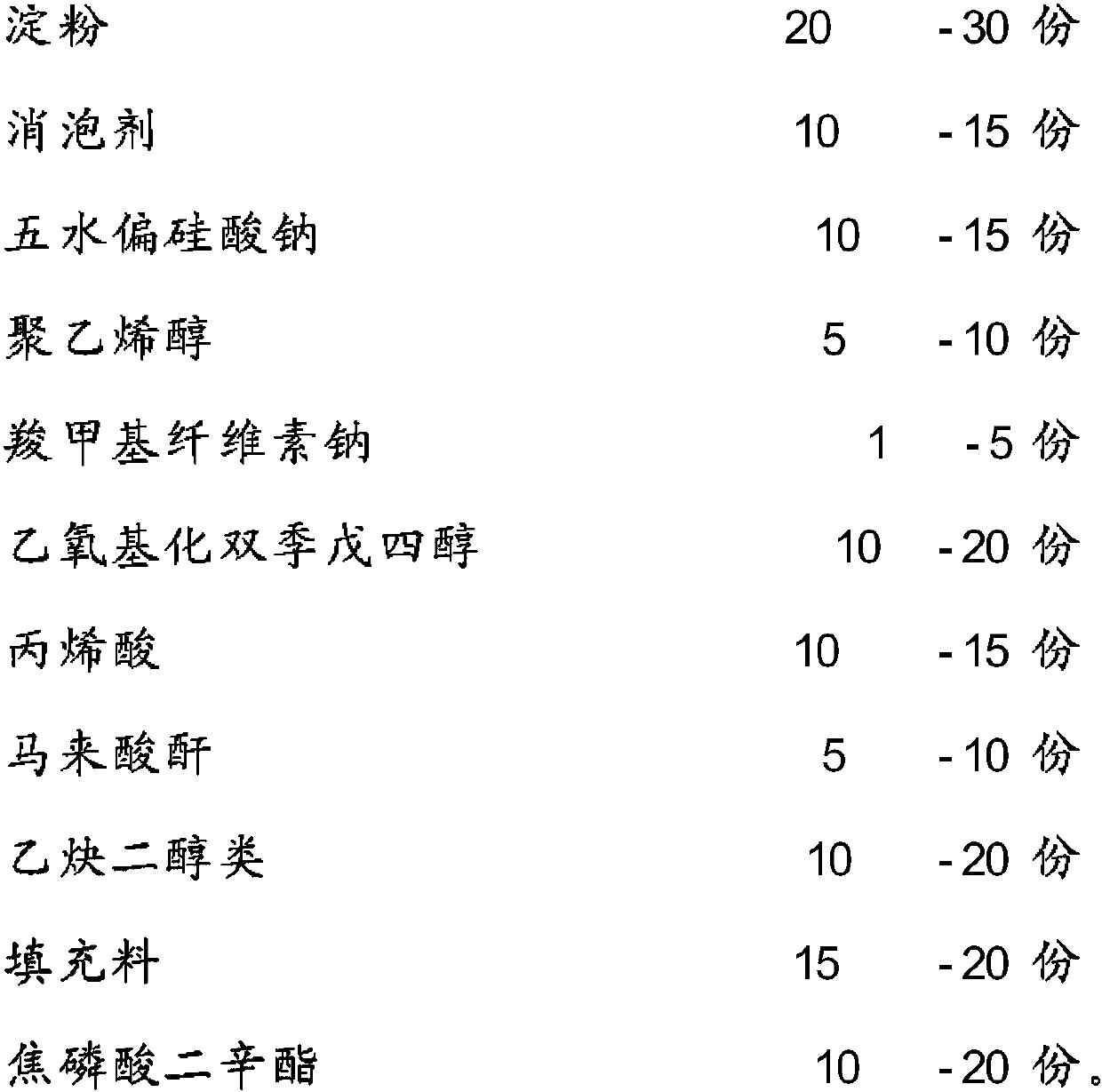

[0016] The main raw materials of a low-pressure paste additive include starch, defoamer, sodium metasilicate pentahydrate, polyvinyl alcohol, sodium carboxymethylcellulose, ethoxylated dipentaerythritol, acrylic acid, maleic anhydride, acetylene glycol Classes, fillers, dioctyl pyrophosphate.

[0017]

[0018] The defoaming agent is hydrocarbon oil and methacrylic acid polymer; the filler includes high calcium powder and kaolin.

Embodiment 2

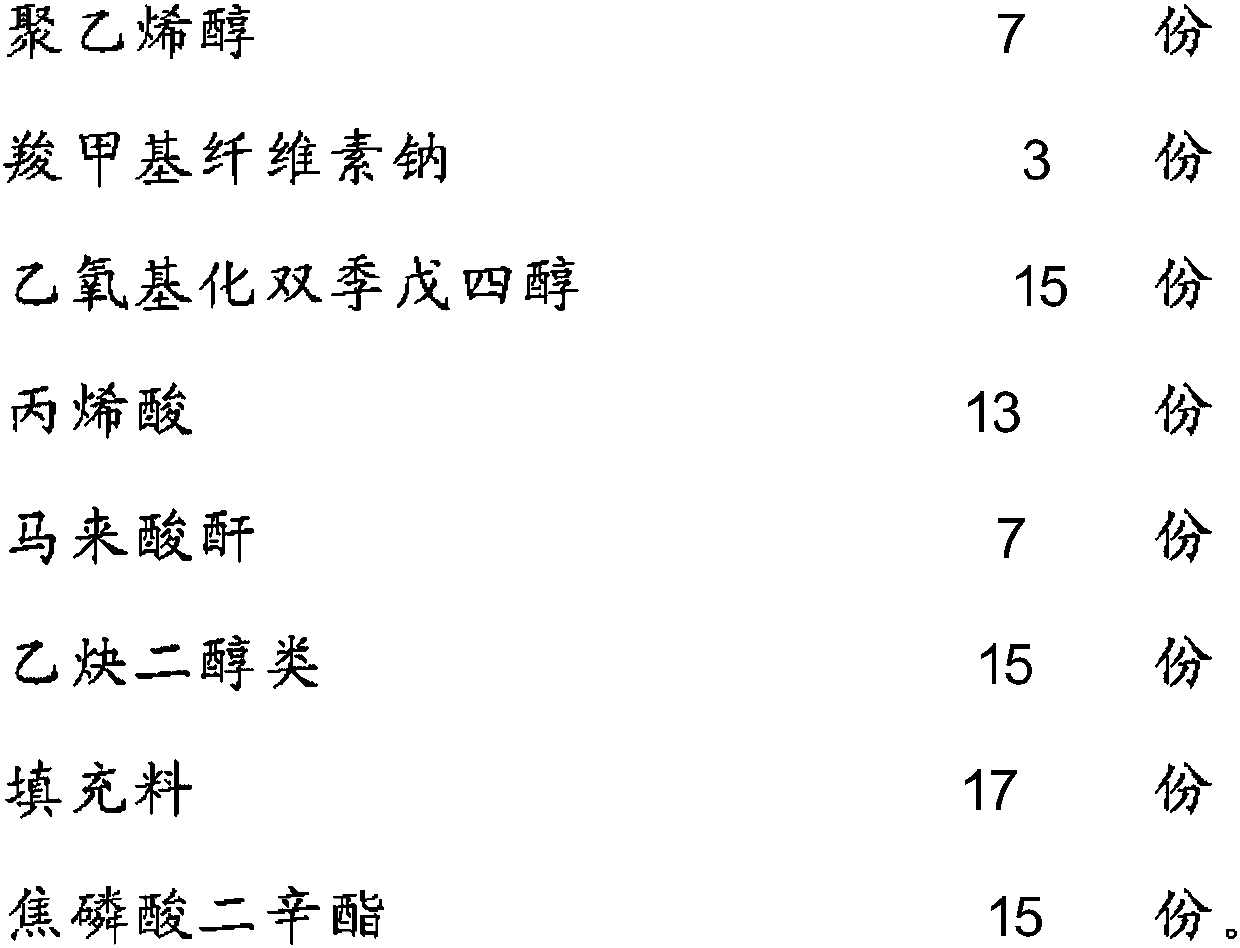

[0020] The main raw materials of a low-pressure paste additive include starch, defoamer, sodium metasilicate pentahydrate, polyvinyl alcohol, sodium carboxymethylcellulose, ethoxylated dipentaerythritol, acrylic acid, maleic anhydride, acetylene glycol Classes, fillers, dioctyl pyrophosphate.

[0021]

[0022] The defoaming agent is hydrocarbon oil and methacrylic acid polymer; the filler includes high calcium powder and kaolin.

Embodiment 3

[0024] The main raw materials of a low-pressure paste additive include starch, defoamer, sodium metasilicate pentahydrate, polyvinyl alcohol, sodium carboxymethylcellulose, ethoxylated dipentaerythritol, acrylic acid, maleic anhydride, acetylene glycol Classes, fillers, dioctyl pyrophosphate.

[0025]

[0026]

[0027] The defoaming agent is hydrocarbon oil and methacrylic acid polymer; the filler includes high calcium powder and kaolin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com