A kind of production process of pressure-sensitive adhesive for waterproof membrane

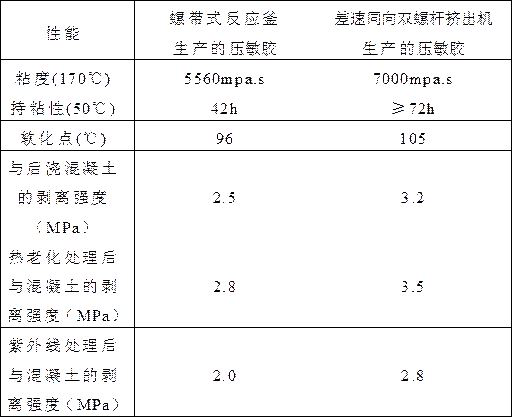

A production process and waterproof membrane technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of poor mixing effect of ribbon reactor, degradation of adhesive performance, aging of adhesive, etc. , to achieve the effects of short mixing time, preventing material aging and excellent stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the present invention will be further described below in conjunction with the examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

[0026] The present invention provides a production process of pressure-sensitive adhesive for waterproof coiled materials. The pressure-sensitive adhesive is produced through an extruder, and the extruder is a differential-speed co-rotating twin-screw extruder; the production process includes the following steps:

[0027] 30 parts by mass of styrene-isoprene-styrene block copolymer, 35 parts by mass of hydrogenated C5 petroleum resin, 15 parts by mass of hydrogenated rosin resin and 14 parts by mass of naphthenic oil are put into a premixer for premixing, premixed The mixed material is sent into the first section of the barrel in the front section of the extruder;

[0028] Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com