Waterproof and breathable operating gown material, preparation method thereof and operating gown

A technology of waterproof and breathable surgical gowns, which is applied in the field of surgical gowns, can solve the problems of poor air permeability and comfort of surgical gowns, poor air permeability of the rubber substrate layer, and affect the quality of surgery for surgical personnel, and achieve good waterproof and breathable performance, good touch and Soft and comfortable performance, good initial bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

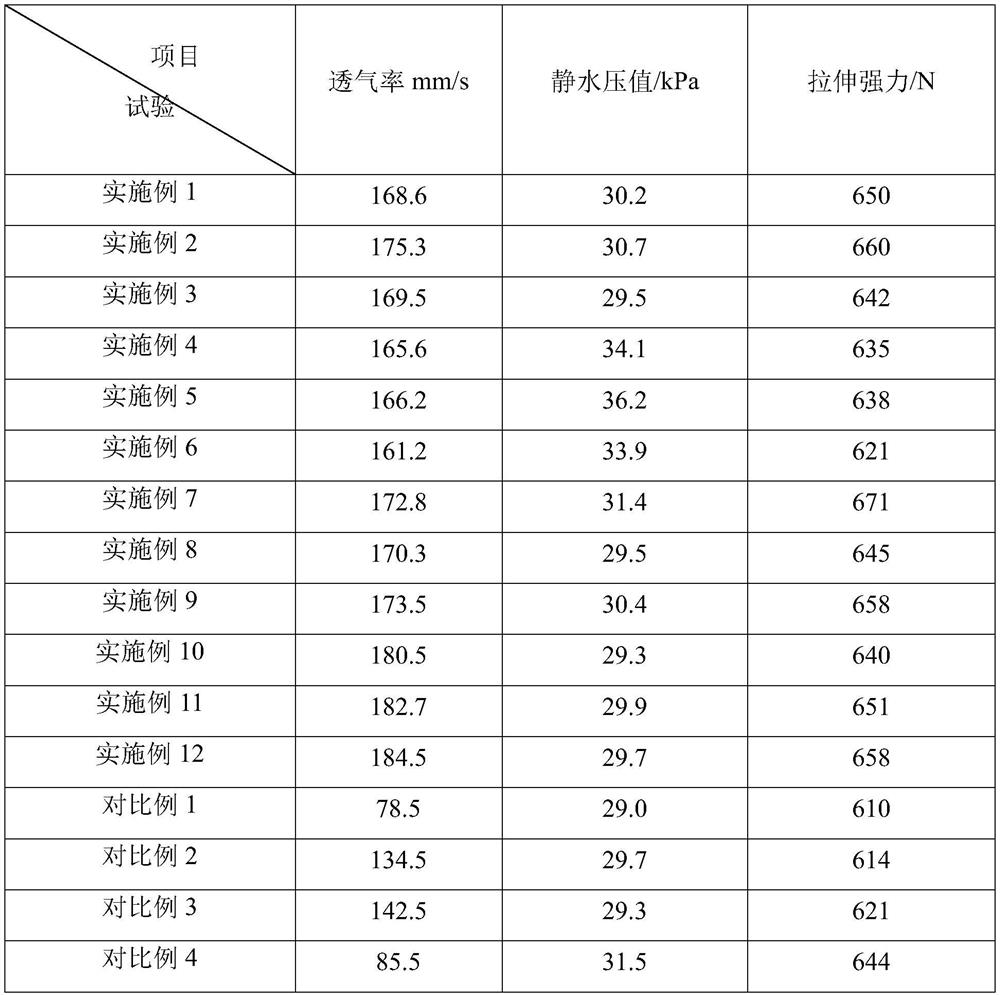

Examples

Embodiment 1

[0048] A waterproof and breathable surgical gown material, the preparation steps are as follows:

[0049] S1: Preparation of base layer: blend soybean protein fiber and flax fiber, and use Meyer-4-11.6QC double-sided knitting circular knitting machine, machine size 26#, 18G gauge, and cylinder diameter of 34 inches. Floor;

[0050] Preparation of functional layer: First, add microporous lignocellulose powder and antibacterial agent to the coating agent and mix and stir to obtain a coating. The plain film is calendered, and then the coating material is evenly coated on the surface of the calendered cellulose acetate film, and the functional layer is obtained after drying at 80 °C;

[0051] S2: Coat the mesh-like adhesive evenly on the surface of the base layer, and use the mesh-like adhesive to hot-press the functional layer on one side of the base layer. The pressure is 5Mpa, the temperature is 180°C, and the time is 120min for pressing to obtain a waterproof and breathable ...

Embodiment 2-3

[0054] A preparation method of a waterproof and breathable surgical gown material is different from Example 1 in that the components of the raw materials and their corresponding weights are shown in Table 2.

[0055] Each raw material and its weight (kg) in the embodiment 1-3 of table 2

[0056] component Example 1 Example 2 Example 3 soy protein fiber 40 45 50 flax fiber 60 55 50 Cellulose acetate film 25 35 45 coating agent 30 35 40 Microporous lignocellulose powder 15 13 10 omentum adhesive 20 17 15 Antibacterial agents 5 4 3

Embodiment 4

[0058] A preparation method of a waterproof and breathable surgical gown material, the difference from Example 1 is that the raw material of the waterproof and breathable material also includes 10kg trifluoropropyl methyl silicone oil, and in the preparation of the functional layer: the microporous lignocellulose powder , antibacterial agent and trifluoropropyl methyl silicone oil are added to the coating agent, mixed and stirred evenly to obtain the coating. At the same time, the cellulose acetate film is calendered with a pendulum calender at a rolling temperature of 60 °C. , and then the coating material is evenly coated on the surface of the calendered cellulose acetate film, and dried at 80° C. to obtain a functional layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com