Preparation method of dual-element or multi-element noble metal catalyst for fuel cell

A precious metal catalyst, fuel cell technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high price, reduce catalyst utilization, limited, etc., and achieve the beneficial effect of improving utilization, activity and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

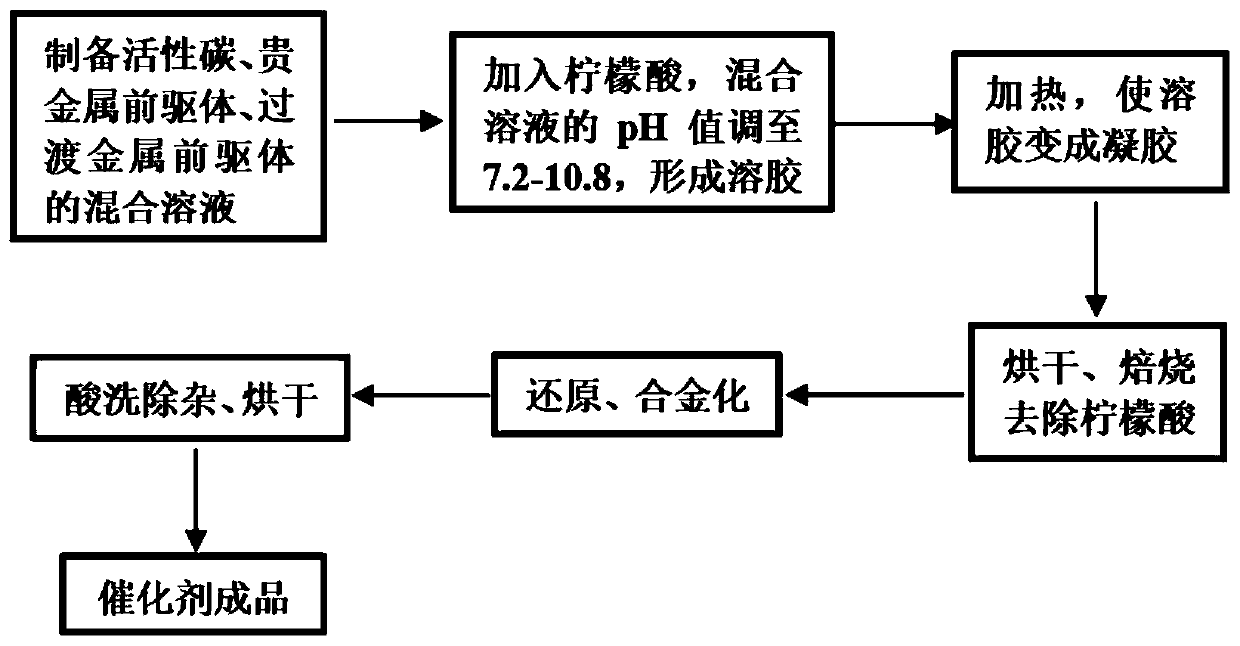

Method used

Image

Examples

Embodiment 1

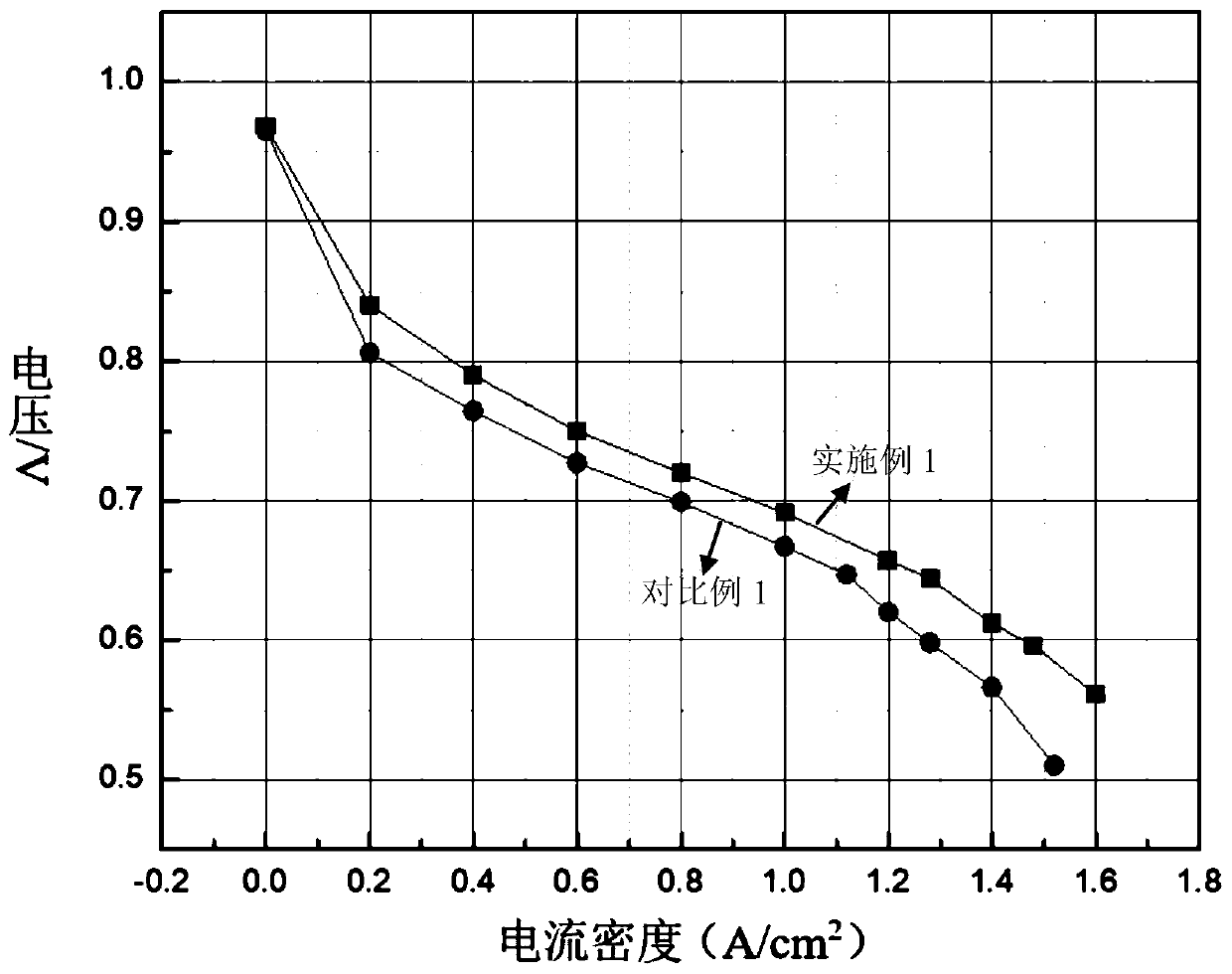

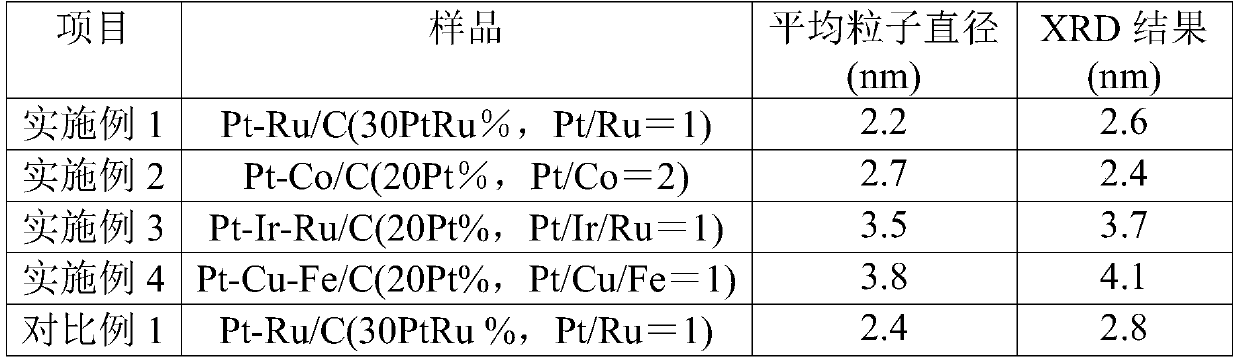

[0033] The preparation of binary catalyst Pt-Ru / C (Pt-Ru:30%, Pt / Ru=1 (atomic ratio)) for fuel cell comprises the following steps:

[0034] (1) Activated carbon XC-72R (particle size 30nm) was pre-treated with 5mol / L nitric acid solution, dried at 200°C for 4 hours, weighed 5g and dispersed with 400mL ultrapure water for 30 minutes to obtain carbon slurry;

[0035] (2) Dissolve 3.9g chloroplatinic acid (containing 1.44g Pt) and 1.94g ruthenium trichloride (containing 0.72g Ru) into 50mL ultrapure water to prepare a platinum-ruthenium mixed solution, and transfer it to the carbon slurry after ultrasonic oscillation for 20 minutes After fully stirring for 4 hours, add 50 mL of 1 mol / L citric acid solution, continue stirring for 4 hours, add ammonia water to adjust the pH of the mixed solution to 7.2, and form a sol. Put the sol into a metal bath heating device, and the temperature of the metal bath is 120°C, heat while stirring, the heating time is 30min, the sol turns into a vi...

Embodiment 2

[0039] The preparation of binary catalyst Pt-Co / C (Pt:20%, Pt / Co=2) for fuel cell comprises the following steps:

[0040] (1) Activated carbon XC-72R (particle size 30nm) was pre-dried at 200°C for 4 hours, weighed 2g and dispersed with 75mL ultrapure water for 30 minutes to obtain a carbon slurry;

[0041] (2) Measure 15 mL of chloroplatinic acid / water solution (Pt: 38.5 mg / mL), measure 10.0 mL of cobalt nitrate water solution (Co: 30 mg / mL) and mix, transfer to carbon slurry after ultrasonic oscillation for 40 minutes, and stir thoroughly for 4 After one hour, add 200 mL of 1 mol / L citric acid solution, continue to stir for 4 hours, add ammonia water to adjust the pH value of the mixed solution to 10.8, and form a sol, put the sol in a metal bath heating device, the temperature of the metal bath is 100 ° C, Heating while stirring, the heating time is 2h, the sol turns into a viscous gel, and then cool down to 25°C;

[0042] (3) Use a porcelain boat to take a certain amount ...

Embodiment 3

[0045] The preparation of the fuel cell three-way catalyst Pt-Ir-Ru / C (Pt: 20%, Pt / Ir / Ru=1) comprises the following steps:

[0046] (1) Activated carbon XC-72R (particle size 30nm) was pre-dried at 200°C for 4 hours, weighed 2g and dispersed with 75mL ultrapure water for 30 minutes to obtain a carbon slurry;

[0047] (2) Measure 8 mL of chloroplatinic acid aqueous solution (Pt: 50 mg / mL), measure 10 mL of ruthenium trichloride / water (Ru: 10.4 mg / mL) and mix, measure chloroiridic acid aqueous solution (Ir: 20 mg / mL) 10mL, mixed with ultrasonic vibration for 30 minutes, then transferred to carbon slurry, after 40 minutes of ultrasonic vibration, transferred to carbon slurry, after fully stirring for 4 hours, add 100mL of 1mol / L citric acid solution, continue stirring for 2 hours, add ammonia water to adjust the mixed solution When the pH reaches 9.0, a sol is formed. Put the sol into a metal bath heating device. The temperature of the metal bath is 90°C, and heat while stirring....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com