Production method of Zn/Cu-Ag/Cu-Au composite coating steel band for photoelectric material

A technology of composite coating and production method, which is applied in the direction of metal material coating technology, coating, superimposed layer coating, etc., can solve the problems of insufficient processing and forming performance and welding performance, poor coating stability, etc., and achieve welding and processing forming Good performance, strong adhesion, and the effect of promoting the alloying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below:

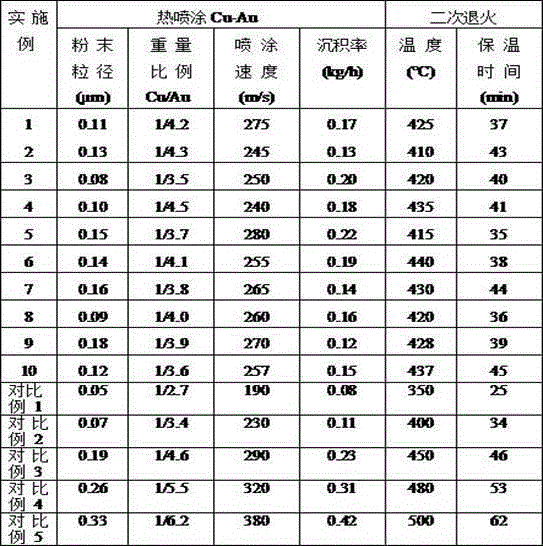

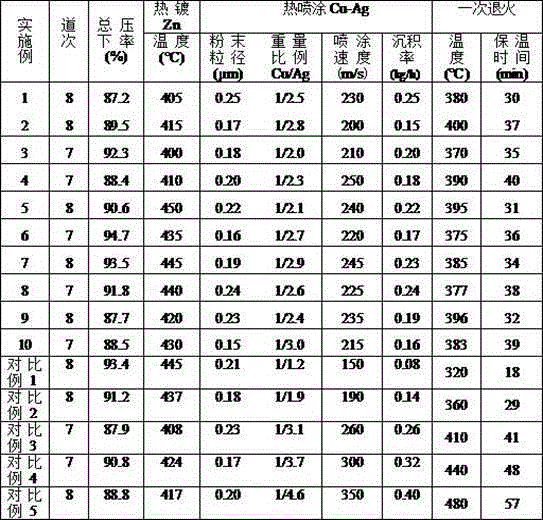

[0026] Table 1 is the cold rolling and strip-making process parameter of each embodiment of the present invention and comparative example;

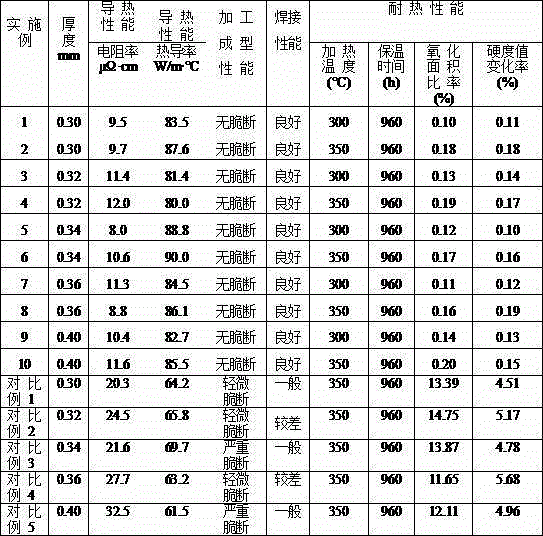

[0027] Table 2 is a product performance list of each embodiment of the present invention and comparative examples.

[0028] Each embodiment of the present invention is produced according to the following processes:

[0029] A kind of production method of Zn / Cu-Ag / Cu-Au composite coating steel strip for photoelectric material, its step:

[0030] 1) Using 08Al cold-rolled steel plate as raw material, carry out 7 or 8 passes of cold-rolled rolling, and the total cold-rolled reduction rate is 87-95%;

[0031] 2) The cold-rolled raw materials are uncoiled, slitting, and deburred after conventional degreasing;

[0032] 3) Carry out hot-dip Zn, galvanizing temperature is 400~450 ℃;

[0033] 4) Conduct thermal spraying of Cu-Ag, the weight ratio of Cu and Ag is 1:2~3; the particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com