Novel perovskite structure high-entropy ceramic and preparation method thereof

A perovskite structure, high-entropy technology, applied in the field of high-entropy ceramic materials, can solve the problems of poor high-temperature thermal stability, low density of high-entropy ceramic materials, and poor matching degree between thermal expansion coefficient and superalloy matrix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

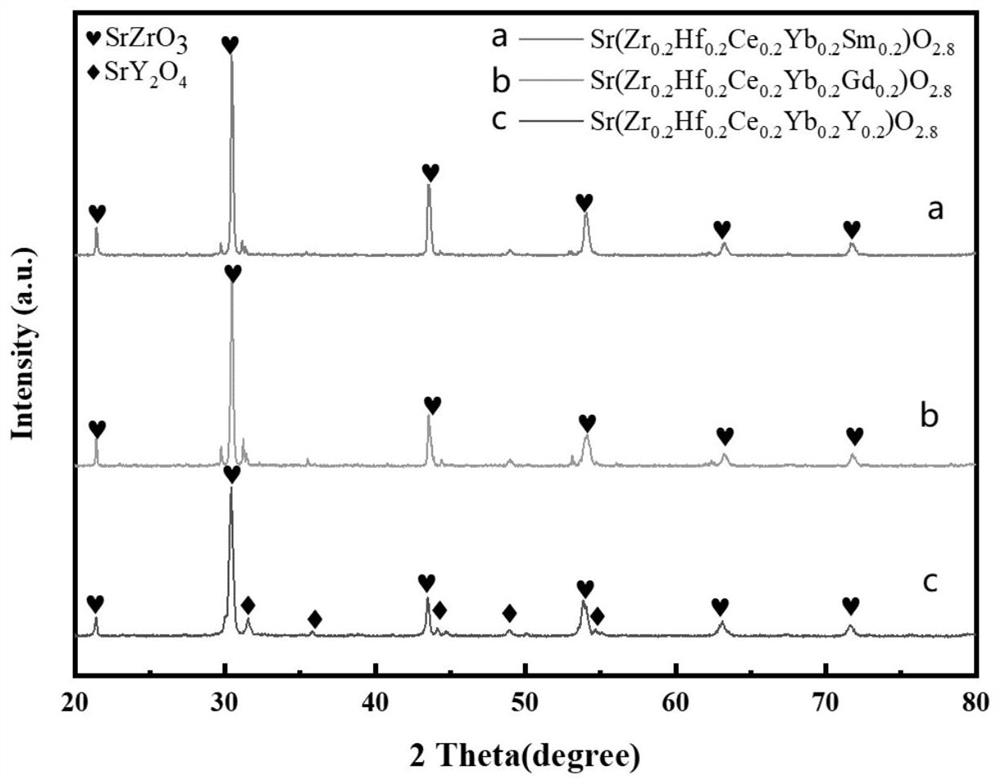

Embodiment 1

[0034] According to Sr(Zr 0.2 Hf 0.2 Ce 0.2 Yb 0.2 Me 0.2 )O 3-x The stoichiometric ratio of (Me=Y, Gd, Sm), that is, the molar ratio of Sr, Zr, Hf, Ce, Yb, and Me elements is 5:1:1:1:1:1, and three different 20g each of the mixed powder. Before weighing, the ZrO 2 , HfO 2 , CeO 2 , Yb 2 o 3 , Y 2 o 3 、Gd 2 o 3 and Sm 2 o 3 Drying treatment at 1000°C for 2h; and SrCO 3 Put it in a drying oven and keep it warm at 120°C for 12h. The specific addition of each component is:

[0035] (1) 9.52g of SrCO 3 , 1.58g of ZrO 2 , 2.70g of HfO 2 , 2.21g of CeO 2 , 2.53g of Yb 2 o 3 , 1.45g of Y 2 o 3 .

[0036] (2) 9.12g of SrCO 3 , 1.52g of ZrO 2 , 2.59g of HfO 2 , 2.12g of CeO 2 , 2.43g of Yb 2 o 3 , 2.23g of Gd 2 o 3 .

[0037] (3) 9.16 SrCO 3 , 1.52g of ZrO 2 , 2.60g of HfO 2 , 2.13g of CeO 2 , 2.44g of Yb 2 o 3 , 2.15g of Sm 2 o 3 .

[0038] The above three mixed powders were placed in a mortar, and 20 g of absolute ethanol was added to grin...

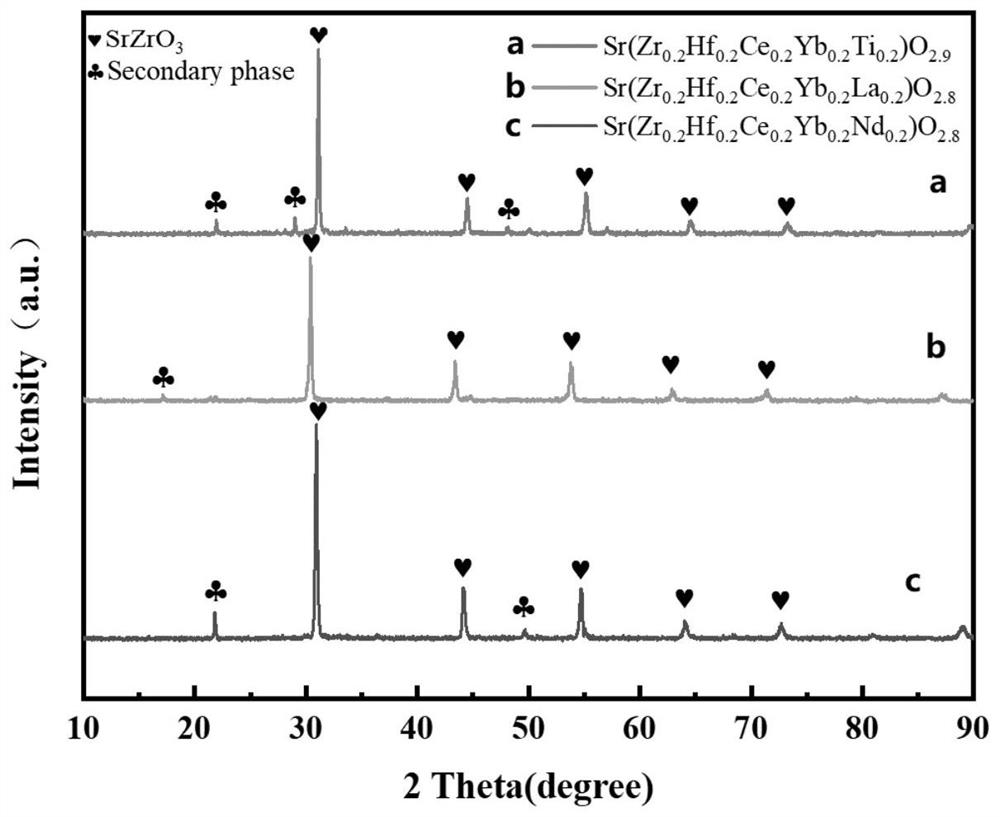

Embodiment 2

[0042] According to Sr(Zr 0.2 Hf 0.2 Ce 0.2 Yb 0.2 Me 0.2 )O 3-x The stoichiometric ratio of (Me=Nd, La, Ti), that is, the molar ratio of Sr, Zr, Hf, Ce, Yb and Me elements is 5:1:1:1:1:1, and three different 20g each of the mixed powder. Before weighing, the ZrO 2 , HfO 2 , CeO 2 , Yb 2 o 3 、Nd 2 o 3 , La 2 o 3 and TiO 2 Drying treatment at 1000°C for 2h; and SrCO 3 Put it in a drying oven and keep it warm at 120°C for 12h. The specific addition of each component is:

[0043] (4) 9.19 SrCO 3 , 1.53g of ZrO 2 , 2.61g of HfO 2 , 2.14g of CeO 2 , 2.45g of Yb 2 o 3 , 2.09g of Nd 2 o 3 .

[0044] (5) 9.22 SrCO 3 , 1.53g of ZrO 2 , 2.62g of HfO 2 , 2.14g of CeO 2 , 2.45g of Yb 2 o 3, 2.03g of La 2 o 3 .

[0045] (6) 9.72 SrCO 3 , 1.62g of ZrO 2 , 2.76g of HfO 2 , 2.26g of CeO 2 , 2.59g of Yb 2 o 3 , 1.05g of TiO 2 .

[0046] The above three mixed powders were placed in a mortar, and 20 g of absolute ethanol was added to grind them thorough...

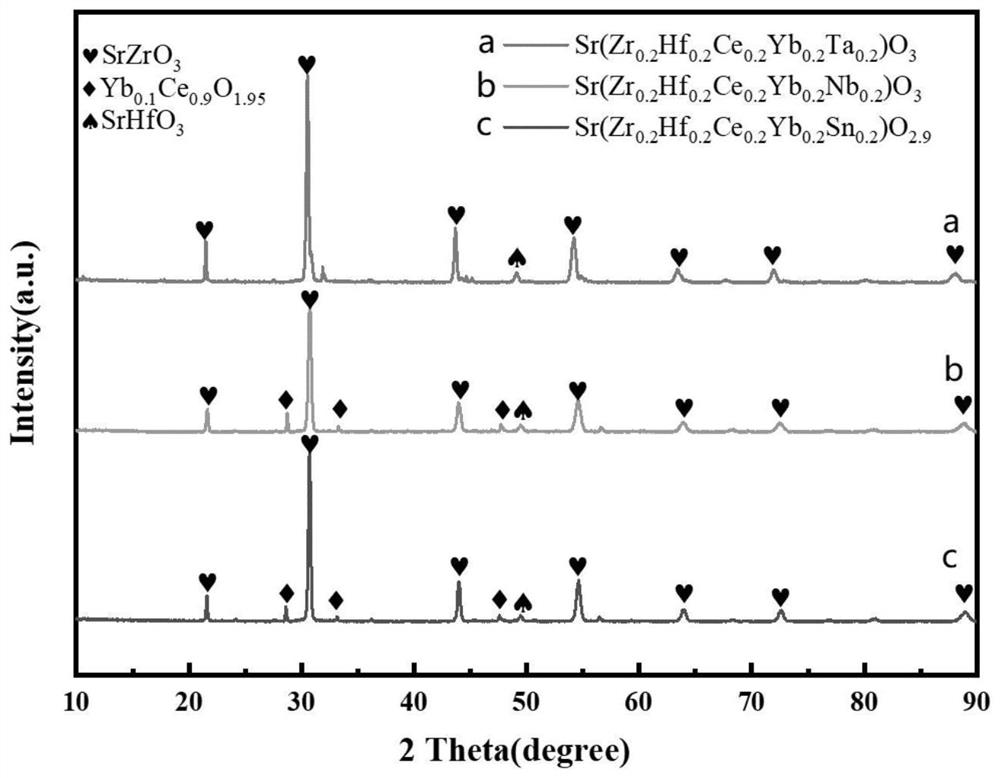

Embodiment 3

[0049] According to Sr(Zr 0.2 f 0.2 Ce 0.2 Yb 0.2 Me 0.2 )O 3-x The stoichiometric ratio of (Me=Sn, Nb, Ta), that is, the molar ratio of Sr, Zr, Hf, Ce, Yb, and Me elements is 5:1:1:1:1:1, and three different 20g each of the mixed powder. Before weighing, the ZrO 2 , HfO 2 , CeO 2 , Yb 2 o 3 , SnO 2 , Nb 2 o 5 and Ta 2 o 5 Drying treatment at 1000°C for 2h; and SrCO 3 Put it in a drying oven and keep it warm at 120°C for 12h. The specific addition of each component is:

[0050] (7) 9.29 SrCO 3 , 1.54g of ZrO 2 , 2.64g of HfO 2 , 2.15g of CeO 2 , 2.47g of Yb 2 o 3 , 1.90g of SnO 2 .

[0051] (8) 9.40 SrCO 3 , 1.56g of ZrO 2 , 2.67g of HfO 2 , 2.18g of CeO 2 , 2.50g of Yb 2 o 3 , 1.69g of Nb 2 o 5 .

[0052] (9) 8.90 SrCO 3 , 1.48g of ZrO 2 , 2.53g of HfO 2 , 2.07g of CeO 2 , 2.37g of Yb 2 o 3 , 2.66g Ta 2 o 5 .

[0053] The above three mixed powders were placed in a mortar, and 20 g of absolute ethanol was added to grind them thoroughl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com