Composite coating, preparation method thereof and thermal barrier coating

A composite coating and thermal barrier coating technology, which is applied in the coating, metal material coating process, vacuum evaporation coating, etc., can solve the problems of inability to completely remove the thermal barrier coating surface, slow reaction rate, poor high temperature stability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In some embodiments, the method for preparing the thermal barrier coating can be any known method for preparing a coating. In a specific embodiment, the preparation method of thermal barrier coating comprises the following steps:

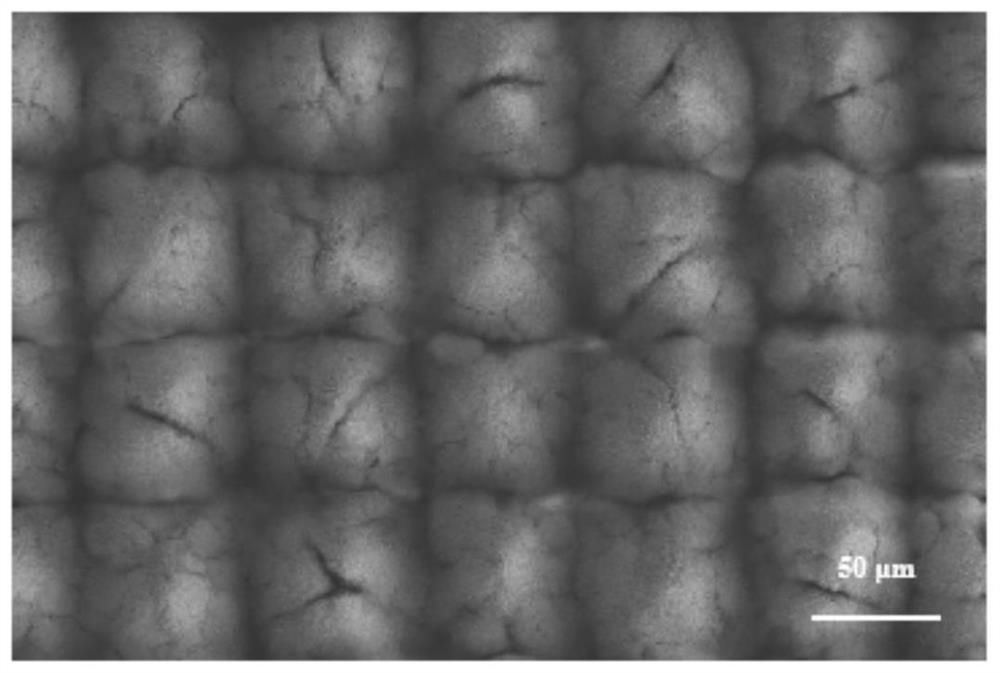

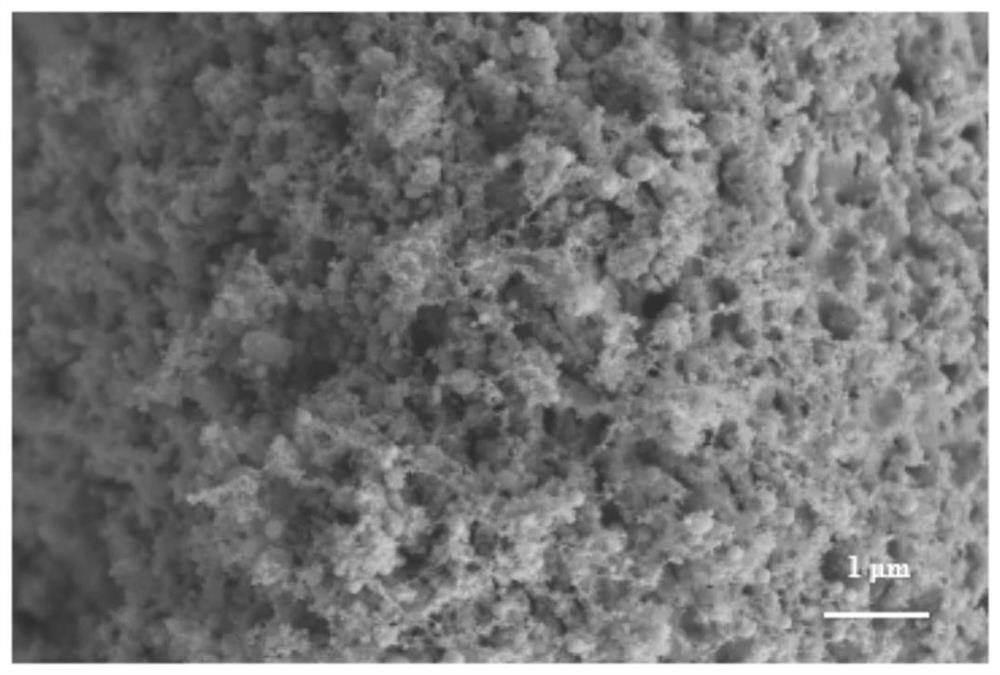

[0050] A clean superalloy substrate is provided, and a bonding layer, a first ceramic layer, a second ceramic layer and a composite coating are sequentially formed on the superalloy substrate, and a micro-nano composite structure is formed on the surface of the composite coating.

[0051] In some embodiments, the superalloy substrate can be a second-generation single crystal alloy, such as DD6, N5, etc., or a directional superalloy, such as DZ125, etc.

[0052] In some embodiments, the method of forming the NiCoCrAlY bonding layer may be electron beam physical vapor deposition, multi-arc ion plating, and the like.

[0053] The specific steps of the electron beam physical vapor deposition can be: prepare the superalloy substrate and the evapo...

Embodiment 1

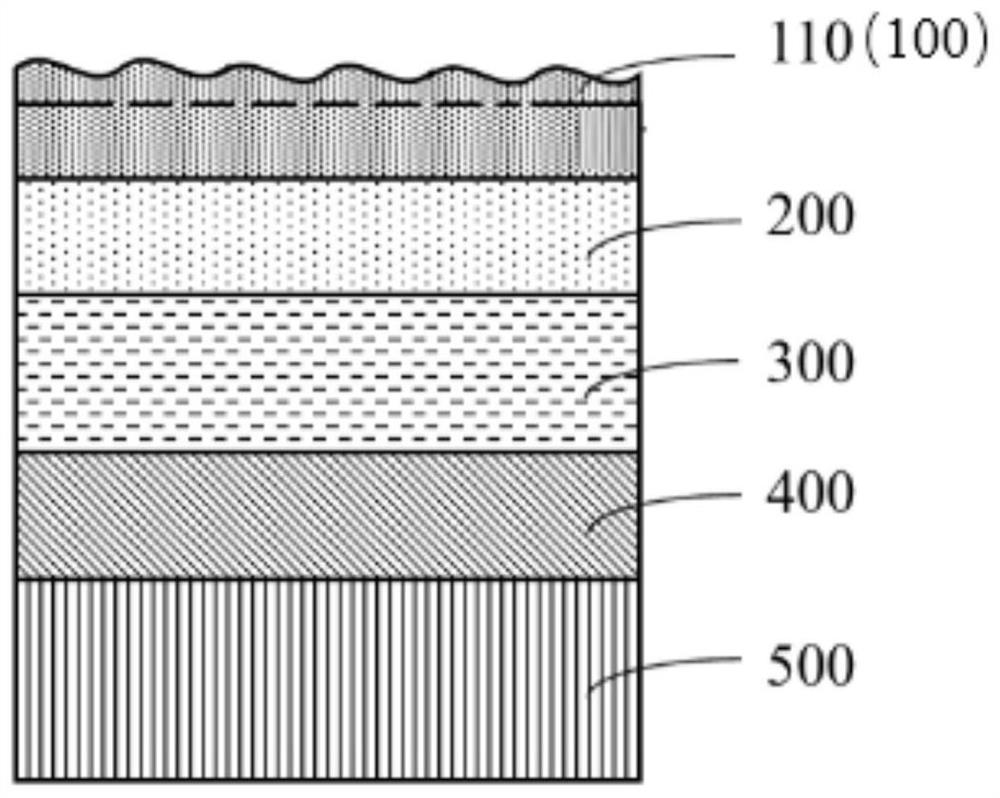

[0063] Such as figure 1 As shown, a PtNiAl bonding layer 400 (electroplating Pt aluminized)+YSZ first ceramic layer 300 (PS-PVD)+GYbZ second ceramic layer 200 (PS-PVD)+doped Al is prepared on the surface of a superalloy substrate 500 2 o 3 The composite structural thermal barrier coating of the GYbZ composite coating 100 (PS-PVD), the specific steps are as follows:

[0064] In the first step, the superalloy substrate 500 is ground, polished, and sandblasted on the surface. The superalloy is the second generation single crystal alloy (DD6 or N5) or directional superalloy DZ125;

[0065] In the second step, a PtNiAl bonding layer is prepared on the superalloy substrate 500 by means of electroplating and embedding infiltration, and the steps are as follows:

[0066] Diammonium platinum nitrite (Pt(NH 3 ) 2 (NO 2 ) 2 ), ammonium nitrate (NH 4 NO 3 ), sodium nitrite (NaNO 2 ), ammonia water (NH 3 ·H 2 O) mixing and preparing the Pt electroplating solution. Put the supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com