High-temperature thermal barrier coating material and preparation method thereof

A coating material and warming technology, applied in the field of materials, can solve the problems of easy grain growth, increased thermal conductivity, coating failure, etc., and achieve the effect of low material thermal conductivity and superior high temperature phase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

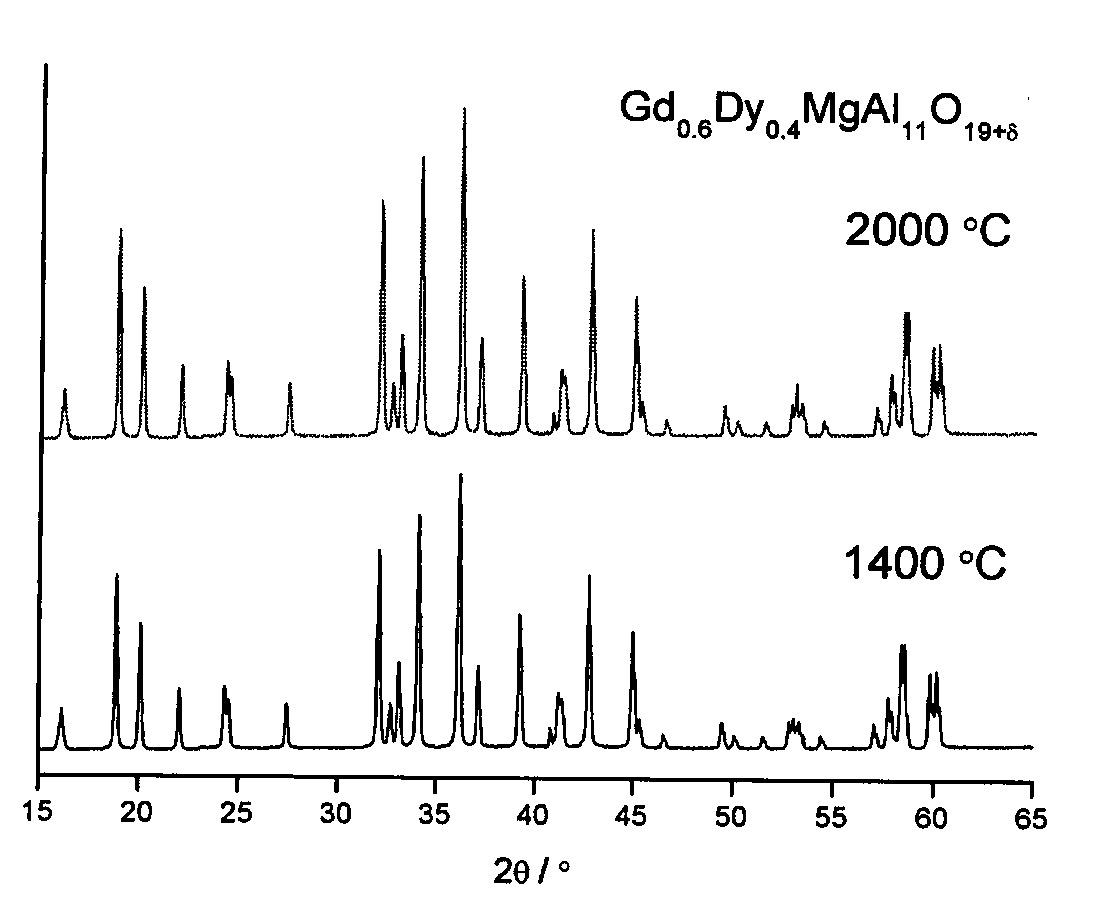

[0042] Using aluminum chloride, magnesium chloride, gadolinium chloride and dysprosium chloride as raw materials to prepare nano-Gd 0.6 Dy 0.4 MgAl 11 o 19+δ Powder material.

[0043] (1) aluminum chloride (AlCl 3 ·6H 2 O, 99wt%), magnesium chloride (MgCl 2 ·6H 2 O, 99wt%), gadolinium chloride (GdCl 3 ·6H 2 O, 99.9wt%) and dysprosium chloride (DyCl 3 ·6H 2 (2, 99.9wt%) is mixed with the actual metal ion molar ratio of 11:1:0.6:0.4, and a certain amount of deionized water is added, stirred, and fully dissolved.

[0044] (2) Weigh acetic acid equal to the molar number of the total metal ions, dissolve it in deionized water, and adjust its pH value to 3 with dilute ammonia water with a volume fraction of 5%.

[0045] (3) Use a mechanical stirrer to stir the mixed metal salt solution under the condition of heating in a water bath. The heating temperature of the water bath is 90°C. At the same time, add the acetic acid solution with adjusted pH dropwise to the mixed meta...

Embodiment 2

[0051] Nano-La 0.3 Gd 0.5 b 0.2 MnAl 11 o 19+δ Powder material.

[0052] (1) Aluminum nitrate (Al(NO 3 ) 3 9H 2 O, 99wt%), manganese nitrate (Mn(NO 3 ) 2 , 50wt% aqueous solution), lanthanum nitrate (La(NO 3 ) 3 nH 2 O, La 2 o 3 content not less than 44wt%, gadolinium nitrate (Gd(NO 3 ) 3 6H 2 O, 99wt%) and ytterbium nitrate (Yb(NO 3 ) 3 5H 2 (2, 99.9wt%) is mixed with the actual metal ion molar ratio of 11:1:0.3:0.5:0.2, and a certain amount of deionized water is added, stirred, and fully dissolved.

[0053] (2) Weigh citric acid equal to the molar number of the total metal ions, dissolve it in deionized water, and adjust its pH value to 5 with dilute ammonia water with a volume fraction of 5%.

[0054] (3) Stir the mixed metal salt solution with a mechanical stirrer under water bath heating conditions. The water bath heating temperature is 80 ° C. At the same time, the citric acid solution that has adjusted the pH is added dropwise to the mixed metal salt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com