Lead-calcium alloy for positive grid, and preparation method thereof

A technology of lead-calcium alloy and positive plate, which is applied in the direction of battery electrodes, electrode carriers/current collectors, electrical components, etc., can solve the problems of unspecified influence, easy casting, and unspecified problems, so as to improve anti-corrosion performance, prevent agglomeration, Anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

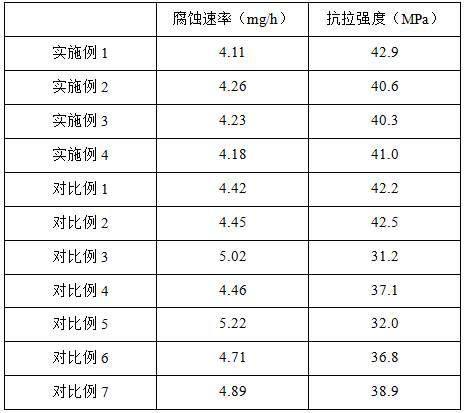

Examples

Embodiment 1

[0032] A lead-calcium alloy for a positive grid, the lead-calcium alloy is made of the following components in weight percentage: 0.094% calcium, 0.02% aluminum, 1.7% tin, 0.1% bismuth, 0.3% rare earth, and 0.12% modified graphene , and the balance is lead.

[0033] The rare earth is composed of the following components in weight percent: 32% lanthanum, 28% yttrium, 22% neodymium, and 18% cerium.

[0034] The preparation method of described modified graphene is:

[0035] Add 2 parts of carbon nanotubes to 23 parts of concentrated sulfuric acid, and stir at 150 rpm for 120 minutes to obtain a mixed solution;

[0036] Add 4 parts of graphene to 21 parts of deionized water, and evenly disperse to obtain a suspension; add the mixed solution and suspension to a planetary ball mill for ball milling to obtain a mixed slurry, ultrasonically treat the mixed slurry, and dry to obtain modified graphite alkene.

[0037] The rotational speed of the planetary ball mill is 300rpm, and the...

Embodiment 2

[0042] A lead-calcium alloy for a positive grid, the lead-calcium alloy is made of the following components in weight percent: 0.09% calcium, 0.01% aluminum, 1.5% tin, 0.08% bismuth, 0.1% rare earth, and 0.08% modified graphene , and the balance is lead.

[0043] The rare earth is composed of the following components in weight percent: 32% lanthanum, 28% yttrium, 22% neodymium, and 18% cerium.

[0044] The preparation method of described modified graphene is:

[0045] Add 2 parts of carbon nanotubes to 23 parts of concentrated sulfuric acid, and stir at 150 rpm for 120 minutes to obtain a mixed solution;

[0046] Add 4 parts of graphene to 21 parts of deionized water, and evenly disperse to obtain a suspension; add the mixed solution and suspension to a planetary ball mill for ball milling to obtain a mixed slurry, ultrasonically treat the mixed slurry, and dry to obtain modified graphite alkene.

[0047] The rotational speed of the planetary ball mill is 300rpm, and the ba...

Embodiment 3

[0052] A lead-calcium alloy for a positive grid, the lead-calcium alloy is made of the following components in weight percentage: 0.096% calcium, 0.05% aluminum, 2% tin, 0.12% bismuth, 0.4% rare earth, and 0.2% modified graphene , and the balance is lead.

[0053] The rare earth is composed of the following components in weight percent: 32% lanthanum, 28% yttrium, 22% neodymium, and 18% cerium.

[0054] The preparation method of described modified graphene is:

[0055] Add 2 parts of carbon nanotubes to 23 parts of concentrated sulfuric acid, and stir at 150 rpm for 120 minutes to obtain a mixed solution;

[0056] Add 4 parts of graphene to 21 parts of deionized water, and evenly disperse to obtain a suspension; add the mixed solution and suspension to a planetary ball mill for ball milling to obtain a mixed slurry, ultrasonically treat the mixed slurry, and dry to obtain modified graphite alkene.

[0057] The rotational speed of the planetary ball mill is 300rpm, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com