CA scanning assisted preparation method and applications of Pd-Cu/Ti electrode

An electrode, cuso4·5h2o technology, which is applied in the field of pentachlorophenol (PCP) dechlorination, can solve the problems such as the preparation of Pd-Cu/Ti electrodes that are not assisted by CV scanning, and the different purposes of use, etc., to increase the electrode surface area and Electrocatalytic active sites, fast dechlorination, and high dechlorination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) palladium chloride (PdCl 2 ) powder was dissolved in 3M hydrochloric acid (the concentration of palladium chloride is 1g palladium chloride / 100ml hydrochloric acid), diluted with deionized water to obtain 15mM PdCl 2 solution.

[0026] 2) Take 50mL of the palladium chloride solution in step 1), add 0.0625g CuSO to it 4 ·5H 2 O, stir evenly.

[0027] 3) Add NaOH to the mixed solution in step 2) to adjust the pH to 1.0.

[0028] 4) With the titanium mesh (2cm×2cm) as the cathode and the platinum sheet as the anode, a constant potential of -0.9V (relative to Hg / Hg 2 SO 4 Electrodes) were deposited in the solution in step 3) for 25min.

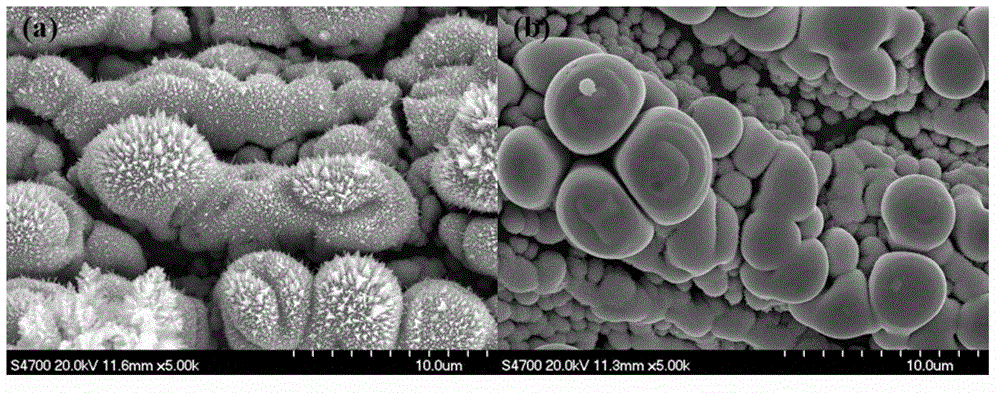

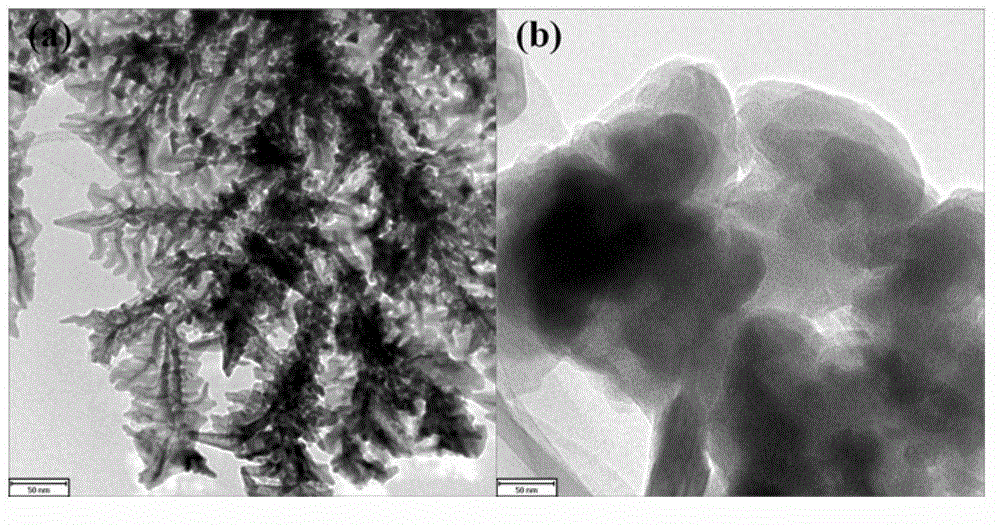

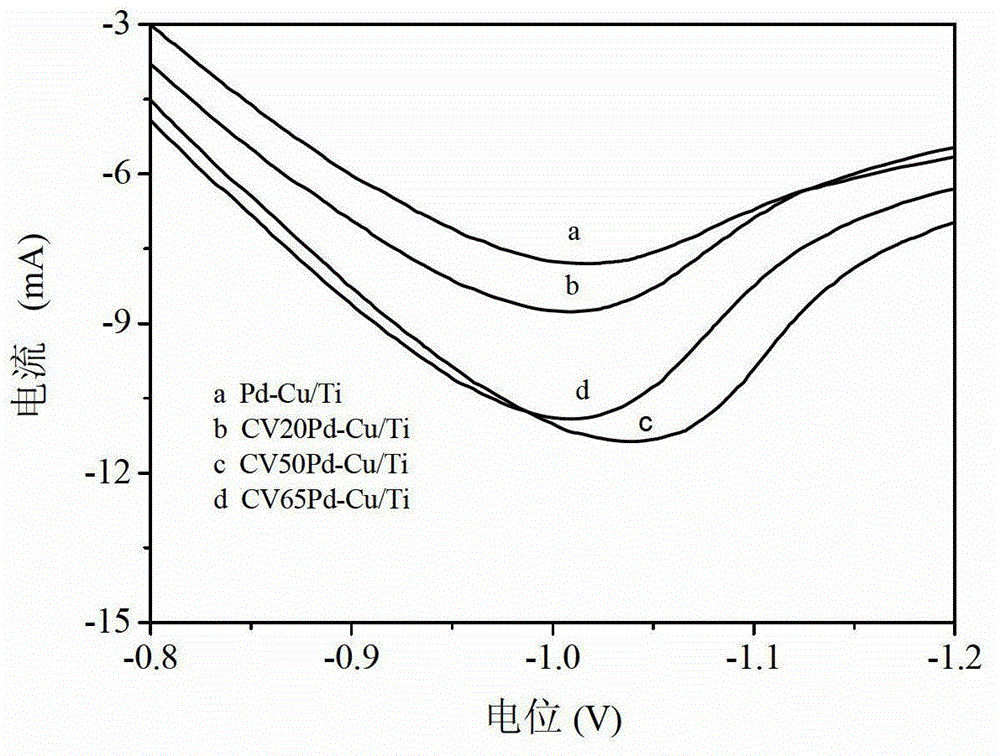

[0029] 5) The Pd-Cu / Ti electrode prepared in step (4) was heated in 0.5M H 2 SO 4 Carry out CV scanning in the medium, the potential scanning range is -800mV~700mV, the scanning speed is 50mV / s, scanning 20 circles, get CV20Pd-Cu / Ti electrode.

[0030] Add 30mL10mg / L PCP and 0.13g Na to the cathode chamber of the reactor 2 SO ...

Embodiment 2

[0033] 1) palladium chloride (PdCl 2 ) powder was dissolved in 3M hydrochloric acid (the concentration of palladium chloride is 1g palladium chloride / 100ml hydrochloric acid), diluted with deionized water to obtain 15mM PdCl 2 solution.

[0034] 2) Take 50mL of the palladium chloride solution in step 1), add 0.0625g CuSO to it 4 ·5H 2 O, stir evenly.

[0035] 3) Add NaOH to the mixed solution in step 2) to adjust the pH to 1.0.

[0036]4) With the titanium mesh as the cathode and the platinum sheet as the anode, a constant potential of -0.9V (relative to Hg / Hg 2 SO 4 electrode) in step 3) solution, deposited for 25min.

[0037] 5) The Pd-Cu / Ti electrode prepared in step (4) was heated in 0.5M H 2 SO 4 Carry out CV scanning in the medium, the potential scanning range is -800mV~700mV, the scanning speed is 50mV / s, scan 50 circles, obtain CV50Pd-Cu / Ti electrode.

[0038] Add 30mL10mg / L PCP and 0.13g Na to the cathode chamber of the reactor 2 SO 4 , add 30mL0.03M Na to ...

Embodiment 3

[0041] 1) palladium chloride (PdCl 2 ) powder was dissolved in 3M hydrochloric acid (the concentration of palladium chloride is 1g palladium chloride / 100ml hydrochloric acid), diluted with deionized water to obtain 15mM PdCl 2 solution.

[0042] 2) Take 50mL of the palladium chloride solution in step 1), add 0.0625g CuSO to it 4 ·5H 2 O, stir evenly.

[0043] 3) Add NaOH to the mixed solution in step 2) to adjust the pH to 1.0.

[0044] 4) With the titanium mesh as the cathode and the platinum sheet as the anode, a constant potential of -0.9V (relative to Hg / Hg 2 SO 4 electrode) in step 3) solution, deposited for 25min.

[0045] 5) The Pd-Cu / Ti electrode prepared in step (4) was heated in 0.5M H 2 SO 4 Carry out CV scanning in the medium, the potential scanning range is -800mV~700mV, the scanning speed is 50mV / s, scanning 65 circles, get CV65Pd-Cu / Ti electrode.

[0046] Add 30mL10mg / L PCP and 0.13g Na to the cathode chamber of the reactor 2 SO 4 , add 30mL0.03M Na t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com