Powder metallurgy high-speed steel valve seat for clean fuel engine and production process of powder metallurgy high-speed steel valve seat

A technology of powder metallurgy and high-speed steel, applied in the field of clean fuel engine powder metallurgy high-speed steel valve seat and its preparation, can solve the problems of clean fuel engine powder metallurgy valve seat wear and other problems, achieve reasonable composition ratio, stable performance, and material source simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

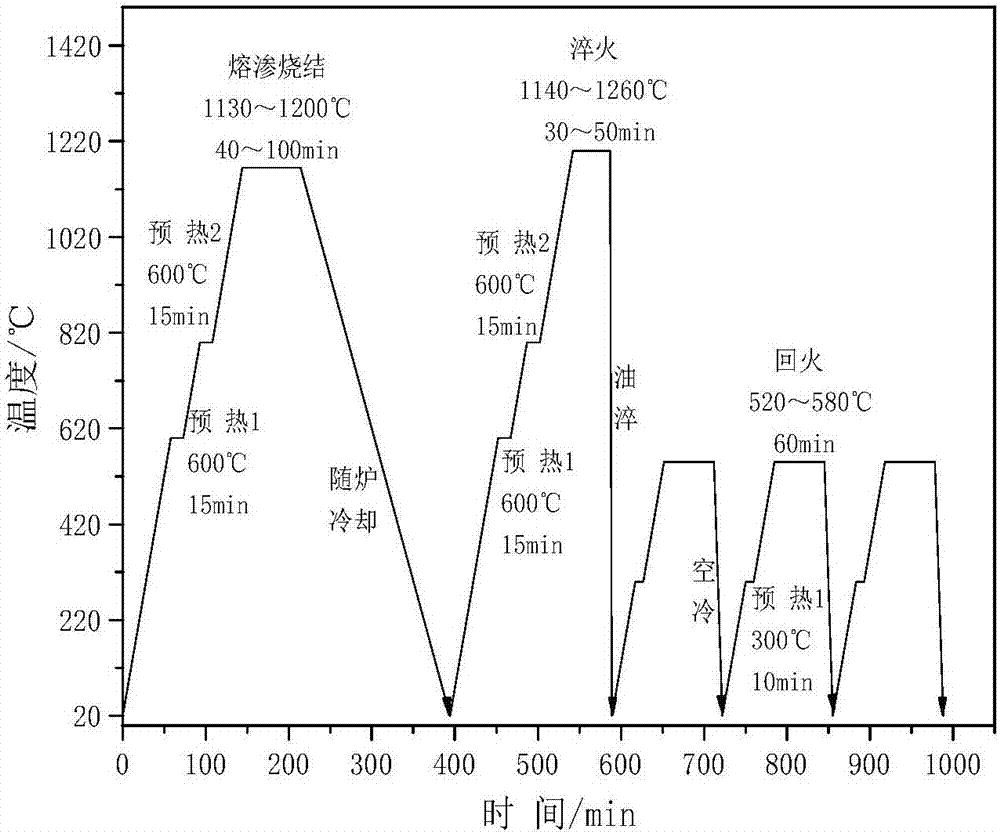

[0036] (1) Carry out direct infiltration sintering in a vacuum sintering furnace, heat preservation at 600°C and 800°C for 15 minutes, heat preservation at 1165°C for 40-100 minutes, and a heating rate of 10°C / min, and cool with the furnace after infiltration sintering is completed.

[0037] (2) Heat to 1140°C in a vacuum quenching furnace, keep it warm for 30-50 minutes, and the heating rate is 10°C / min, quench in warm oil (about 50°C), then heat to 300°C and keep it for 10 minutes, and keep it at 520°C for 60 minutes, Tempering treatment 3 times.

[0038] (3) Machining into finished products

Embodiment 2

[0040] (1) Carry out direct infiltration sintering in a vacuum sintering furnace, heat preservation at 600°C and 800°C for 15 minutes, heat preservation at 1165°C for 40-100 minutes, and a heating rate of 10°C / min, and cool with the furnace after infiltration sintering is completed.

[0041] (2) Heat to 1180°C in a vacuum quenching furnace, keep it warm for 30-50min, and the heating rate is 10°C / min, quench it in warm oil (about 50°C), then heat it to 300°C and keep it for 10min, and keep it at 580°C for 60min, Tempering treatment 3 times.

[0042] (3) Machining into finished products

Embodiment 3

[0044] (1) Carry out direct infiltration sintering in a vacuum sintering furnace, heat preservation at 600°C and 800°C for 15 minutes, heat preservation at 1165°C for 40-100 minutes, and a heating rate of 10°C / min, and cool with the furnace after infiltration sintering is completed.

[0045] (2) Heat to 1220°C in a vacuum quenching furnace, keep it warm for 30-50 minutes, and the heating rate is 10°C / min, quench in warm oil (about 50°C), then heat to 300°C and keep it for 10 minutes, and keep it at 520°C for 60 minutes, Tempering treatment 3 times.

[0046] (3) Machining into finished products

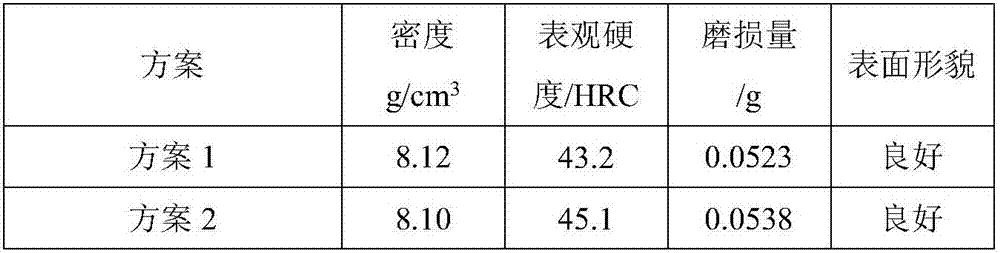

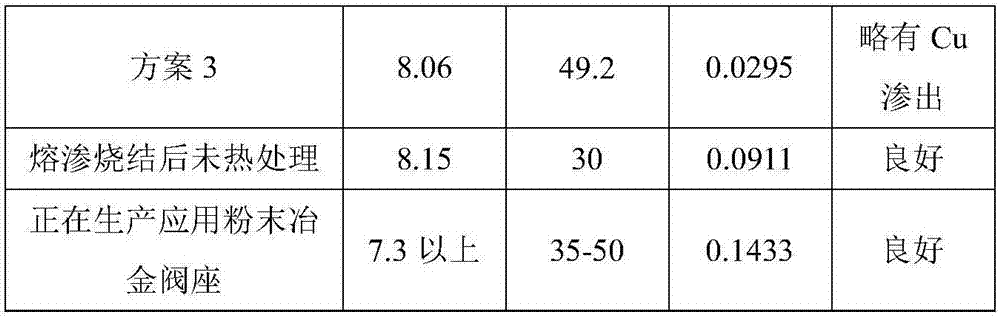

[0047] Abrasion resistance test. Test conditions: The wear test is carried out on the M-2000 friction and wear testing machine, using disc-pin wear, resin alumina material as the abrasive, the load is 120N, the friction speed is 200r / min, and the wear time is 30min.

[0048] The specific index of the powder metallurgy high-speed steel valve seat prepared by the technical solution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com