Method for welding molybdenum alloy

A welding method and technology of molybdenum alloy, applied in welding equipment, welding medium, welding equipment, etc., can solve the problems of molybdenum alloy becoming brittle, molybdenum intergranular brittle fracture, reducing molybdenum bonding strength, etc., to reduce moisture and refine grain Granules, the effect of reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

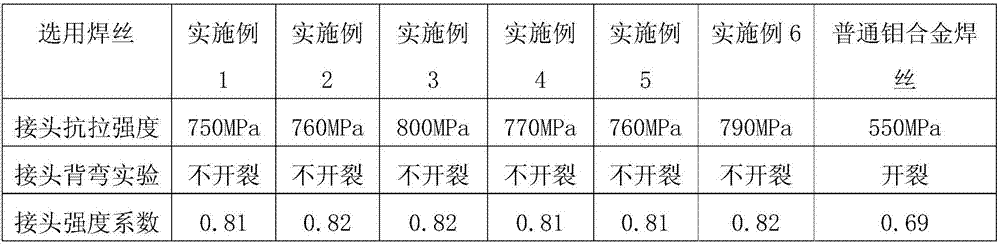

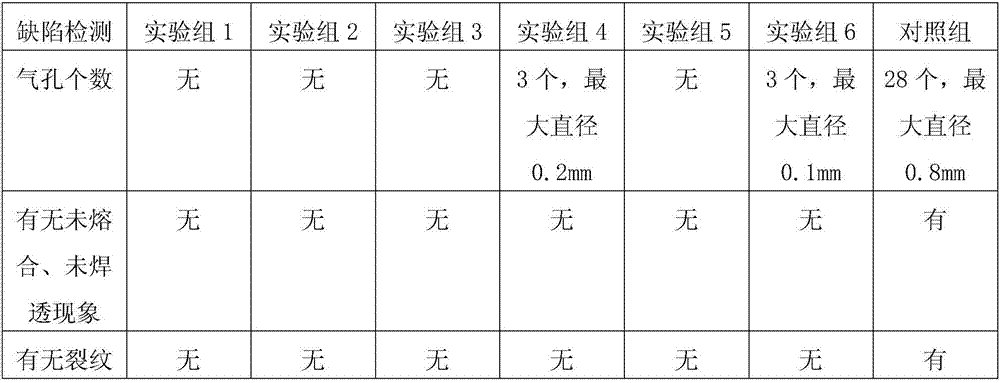

Examples

Embodiment 1

[0025] A welding method for molybdenum alloys, comprising the steps of:

[0026] (1) Clean the molybdenum alloy welding area to remove the oxide film and oil stains on the surface of the molybdenum alloy. Wash in water and remove acetone residues on the surface of the workpiece; soak the cleaned workpiece in a mixed solution consisting of 2% hydrofluoric acid alcohol solution and 8% nitric acid solution for 7 minutes, then take out the parts and put them in water Clean and remove the residue of the mixed solution on the surface of the workpiece, and then put the molybdenum alloy workpiece into a vacuum drying oven for drying. The drying temperature is controlled at 80°C for 10 minutes;

[0027] (2) Making special welding wire for molybdenum alloy, which is mainly made of the following raw materials in weight percentage: 20% nickel, 12% chromium, 0.5% aluminum, 2.5% manganese, 0.03% niobium, 0.03% carbon, silicon 0.2%, titanium 0.6%, phosphorus 0.005% and the rest of molybdenu...

Embodiment 2

[0033]A welding method for molybdenum alloys, comprising the steps of:

[0034] (1) Clean the molybdenum alloy welding area to remove the oxide film and oil stains on the surface of the molybdenum alloy. Wash in water and remove acetone residues on the surface of the workpiece; soak the cleaned workpiece in a mixed solution consisting of 5% hydrofluoric acid alcohol solution and 15% nitric acid solution for 10 minutes, then take out the parts and put them in water Clean and remove the residue of the mixed solution on the surface of the workpiece, and then put the molybdenum alloy workpiece into a vacuum drying oven for drying. The drying temperature is controlled at 150°C for 25 minutes;

[0035] (2) Making special welding wire for molybdenum alloy, which is mainly made of the following raw materials in weight percentage: 32% nickel, 19% chromium, 1.2% aluminum, 9.5% manganese, 0.09% niobium, 0.1% carbon, silicon 1.1%, titanium 1.3%, phosphorus 0.015% and the rest of molybden...

Embodiment 3

[0041] A welding method for molybdenum alloys, comprising the steps of:

[0042] (1) Clean the molybdenum alloy welding area to remove the oxide film and oil stains on the surface of the molybdenum alloy. Wash in water and remove acetone residues on the surface of the workpiece; soak the cleaned workpiece in a mixed solution consisting of 2% hydrofluoric acid alcohol solution and 8% nitric acid solution for 7 minutes, then take out the parts and put them in water Clean and remove the residue of the mixed solution on the surface of the workpiece, and then put the molybdenum alloy workpiece into a vacuum drying oven for drying. The drying temperature is controlled at 80°C for 10 minutes;

[0043] (2) Making special welding wire for molybdenum alloy, which is mainly made of the following raw materials in weight percentage: 30% nickel, 18% chromium, 1.1% aluminum, 8.5% manganese, 0.04% niobium, 0.04% carbon, silicon 0.3%, titanium 0.7%, phosphorus 0.006% and the rest of molybdenu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com