Patents

Literature

373results about How to "Absorb in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymeric conjugates for tissue activated drug delivery

InactiveUS20040228831A1Simple methodAbsorption bioactivityPeptide/protein ingredientsPharmaceutical non-active ingredientsChemical MoietyActive agent

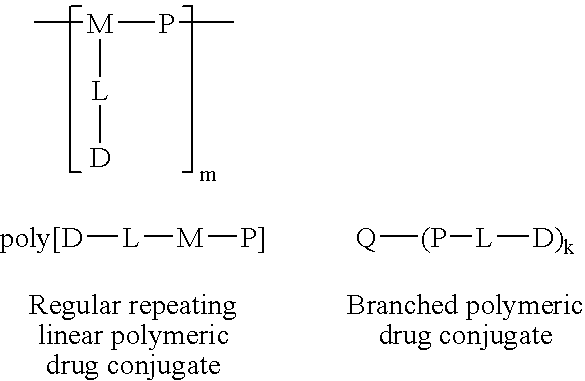

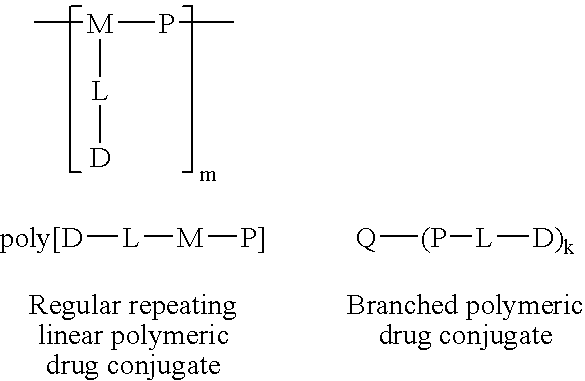

The present invention relates to a polymeric drug conjugate with one or more biologically active agents conjugated via an enzymatically cleavable linker to either a regular repeating linear unit comprising a water soluble polymer segment and a multifunctional chemical moiety, or a branched polymer comprising two or more water soluble polymer segments each bound to a common multifunctional chemical moiety, as well as to methods of making such conjugates. The present invention is also directed to pharmaceutical compositions comprising such conjugates and to the use of such conjugates to treat pathological conditions.

Owner:VECSTREETCARED

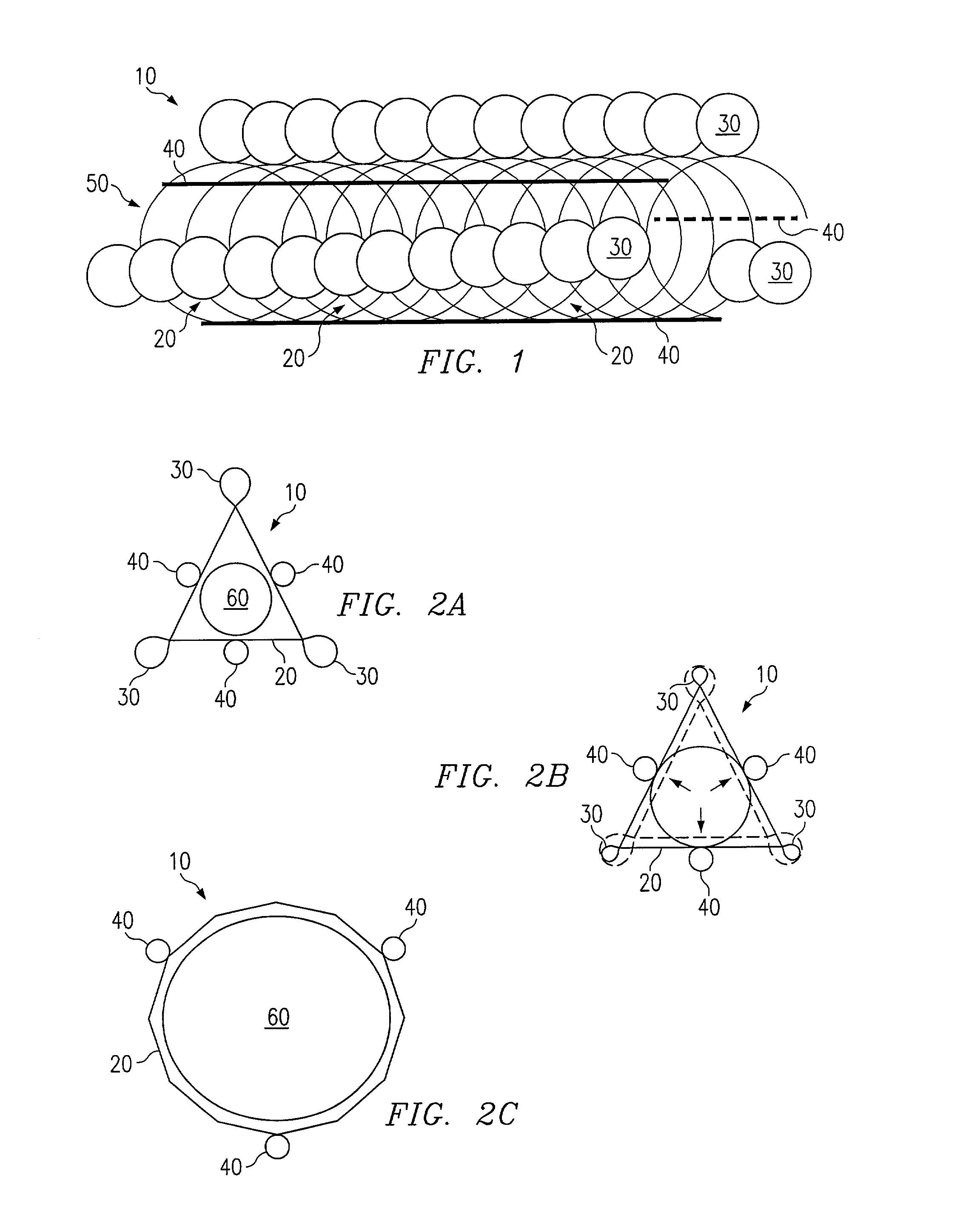

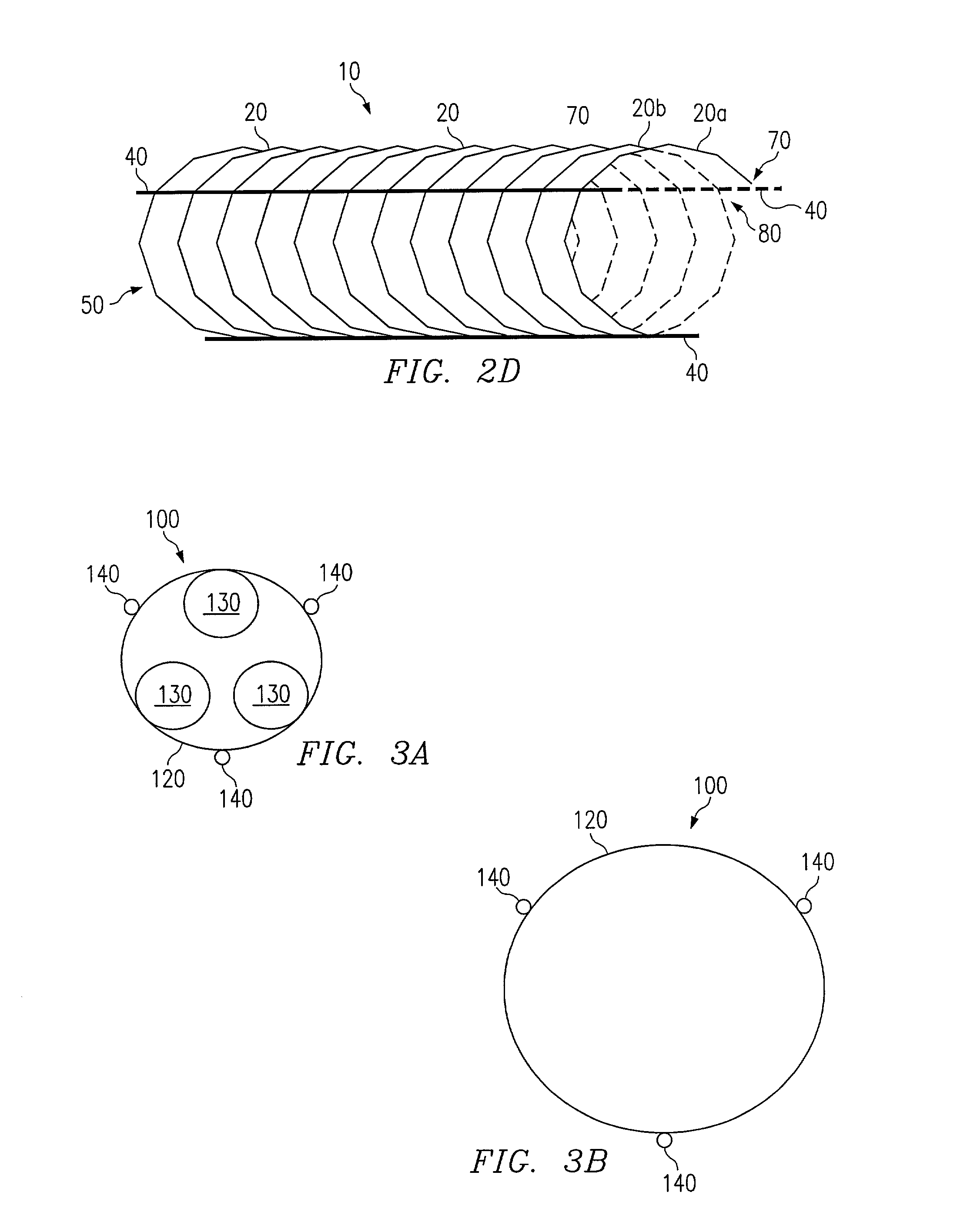

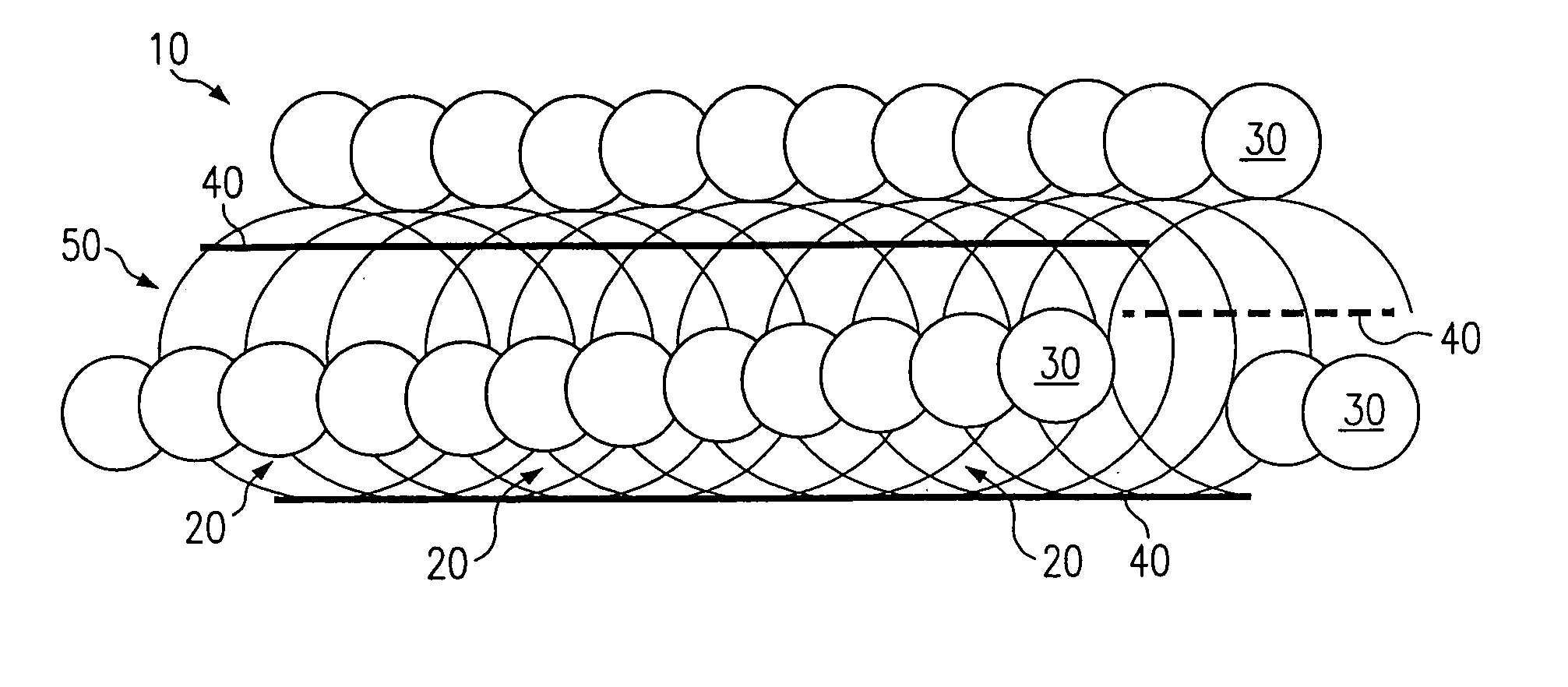

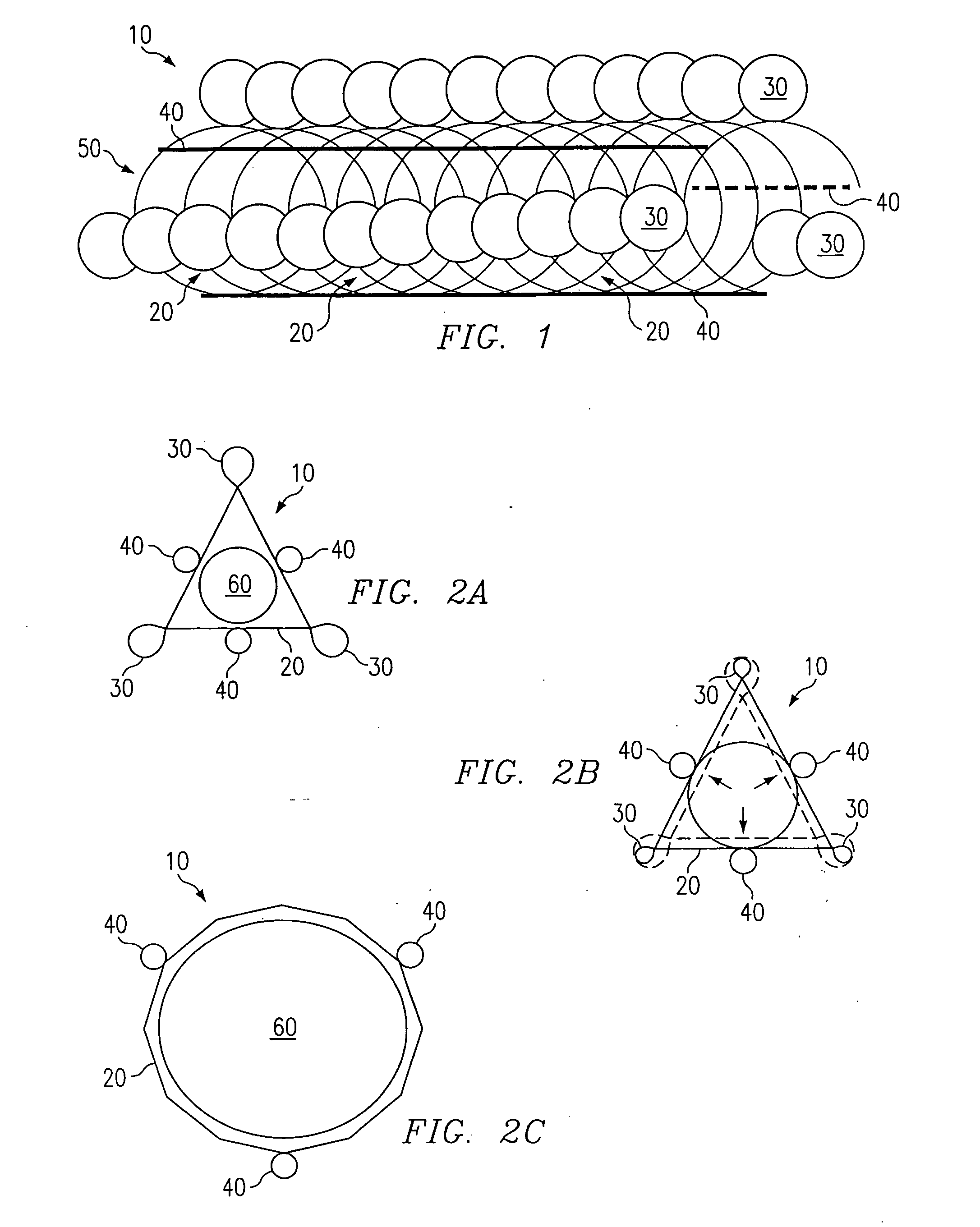

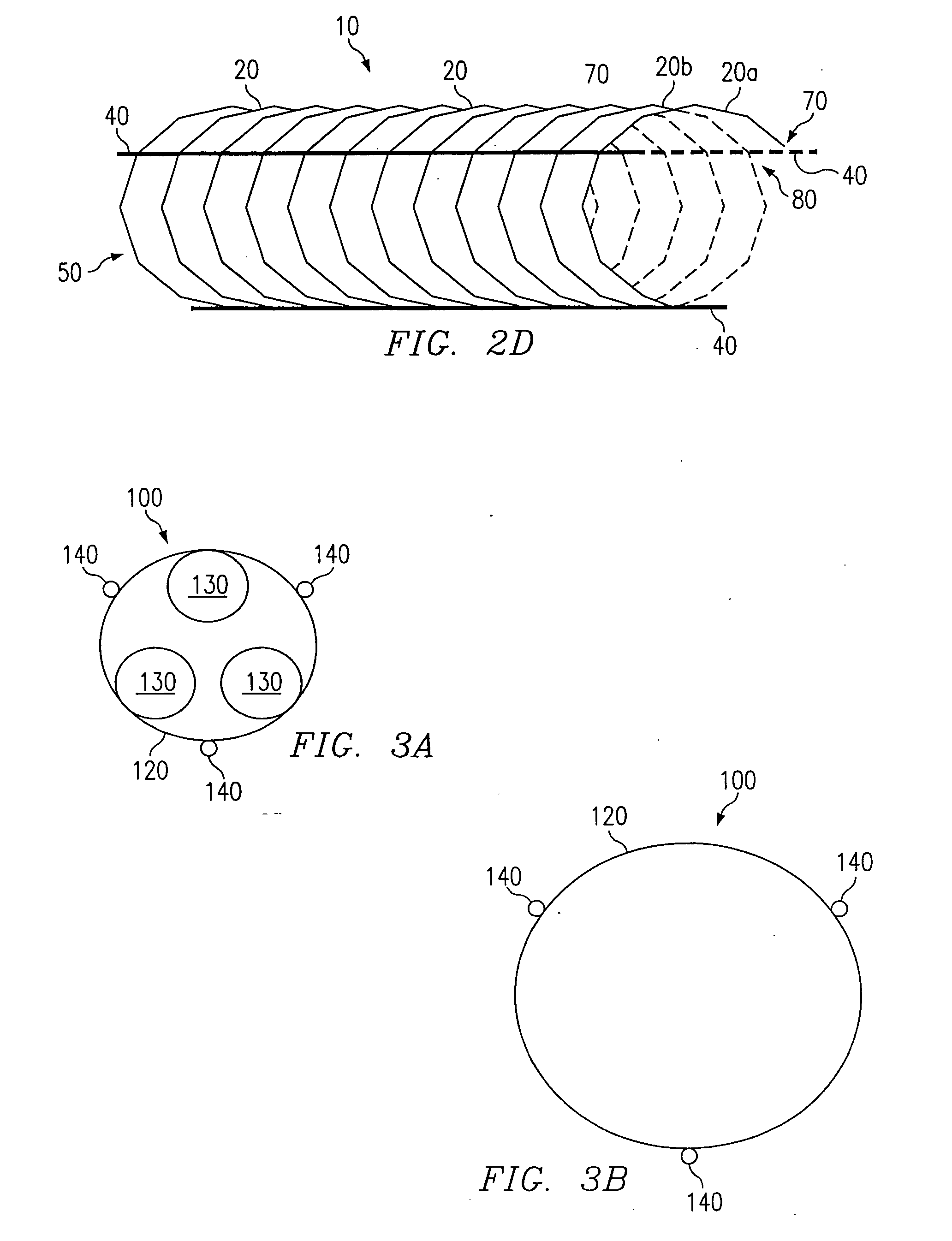

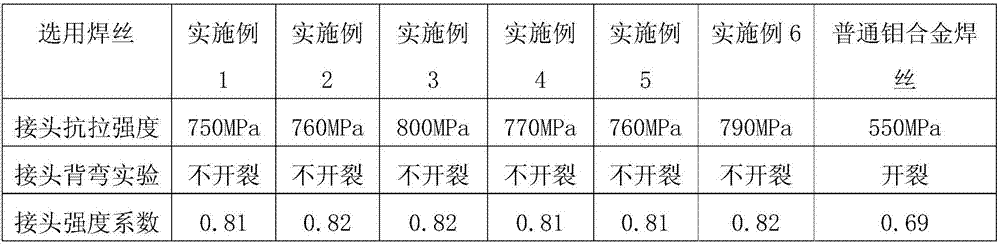

Expandable biodegradable polymeric stents for combined mechanical support and pharmacological or radiation therapy

InactiveUS7128755B2Avoid residual stressAbsorb in timeStentsBlood vesselsAngioplasty balloonRadiation therapy

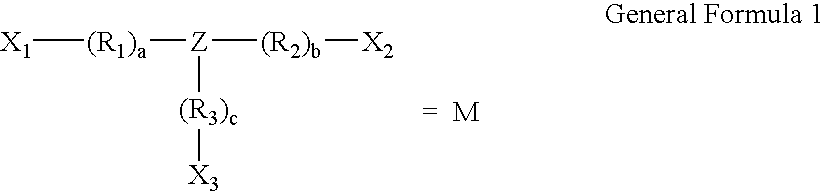

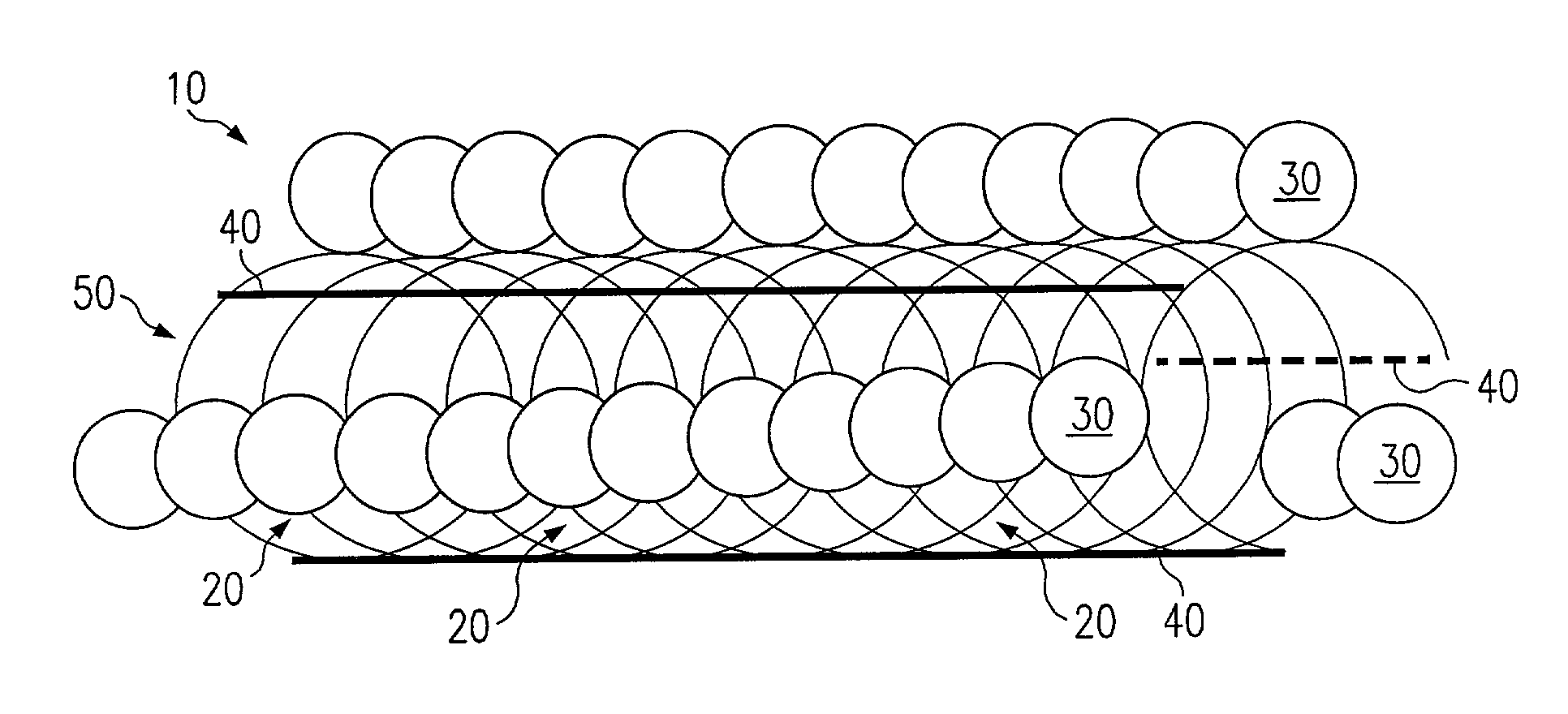

An expandable biodegradable polymeric stent is fabricated with biodegradable polymer fibers (Poly-L-lactic acid, PLLA) in a coil shape that is constructed with both central and external or internal peripheral lobes. It is delivered and expanded using a conventional angioplasty balloon system. The disclosed stent can serve as a temporary scaffold for coronary vessels after PTCA or for peripheral endovascular stenting, or it can provide mechanical palliation for strictures of ductile organs (trachea, esophagus, bile and pancreatic ducts, ureter etc.). The disclosed stent also serves as a unique device for specific local drug delivery. Therapeutic agents (chemical compounds, protein enzyme and DNA sequences) and cells can be loaded into the stent and gradually released to target tissues. Local radiation therapy can also be delivered by a specially adapted stent.

Owner:DUNING

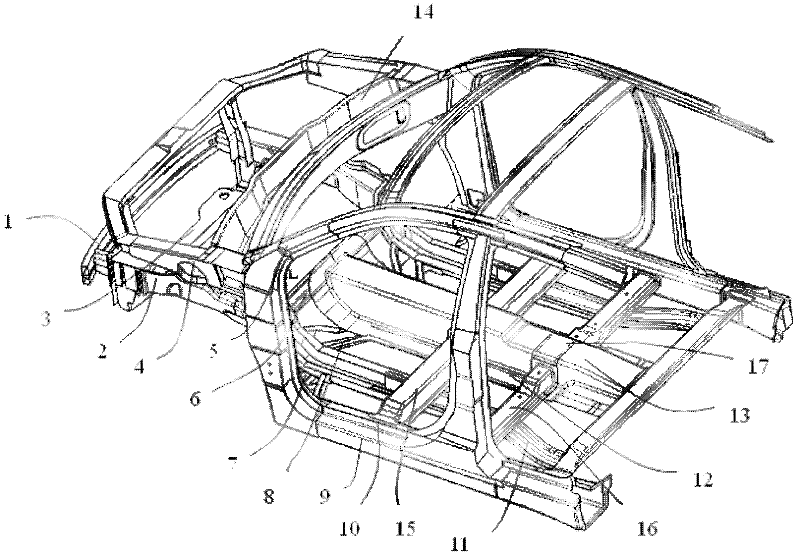

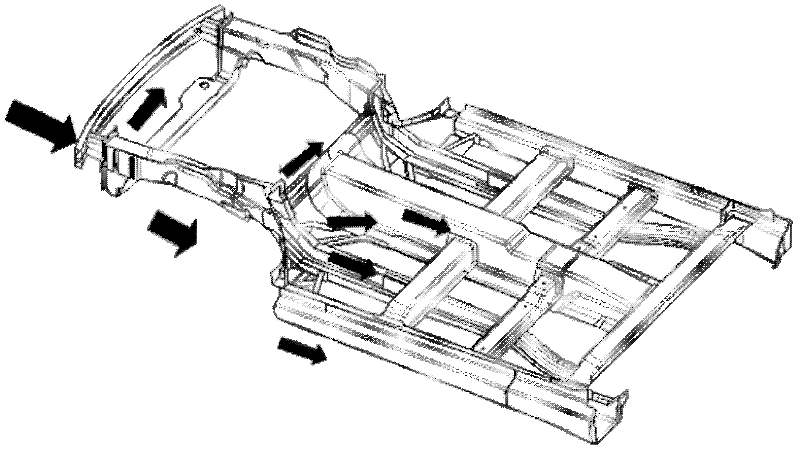

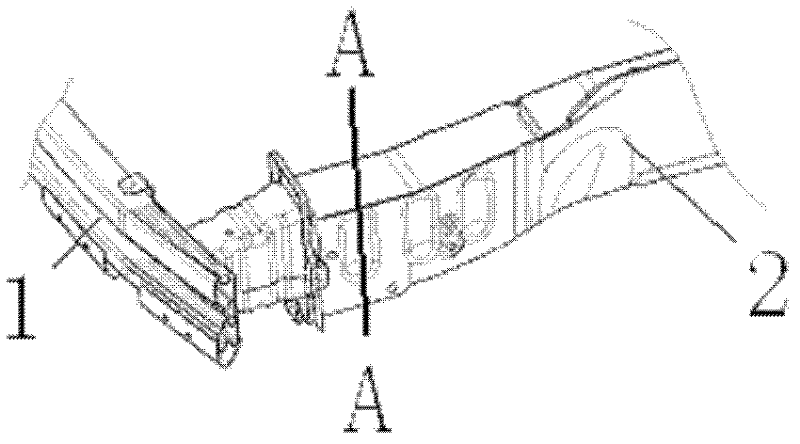

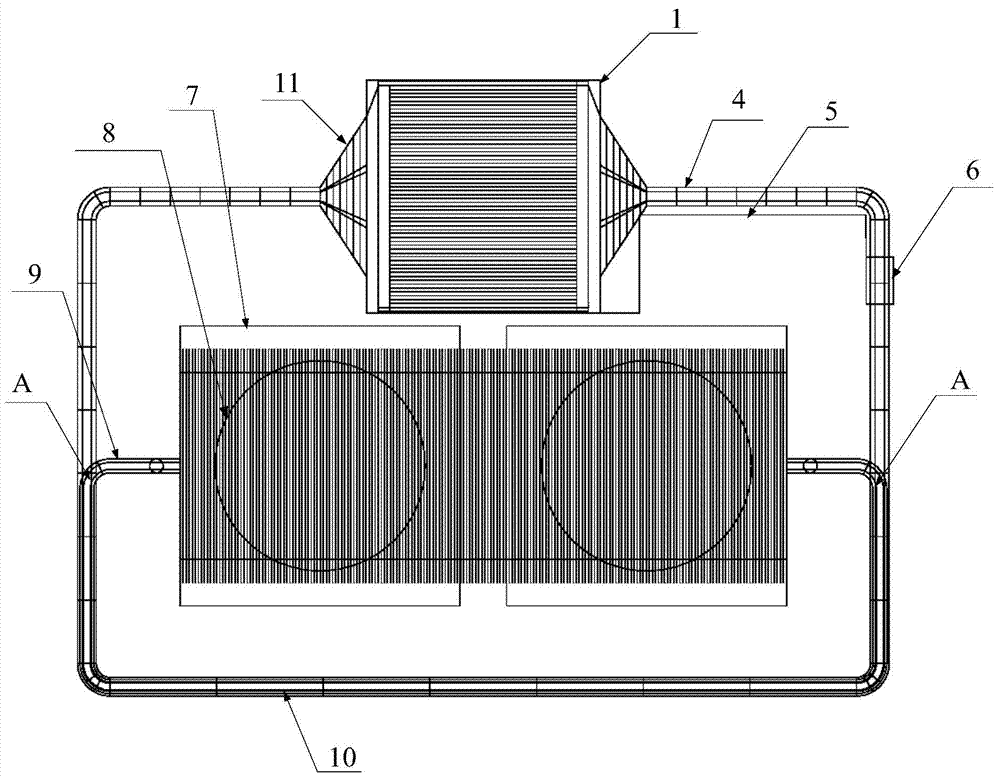

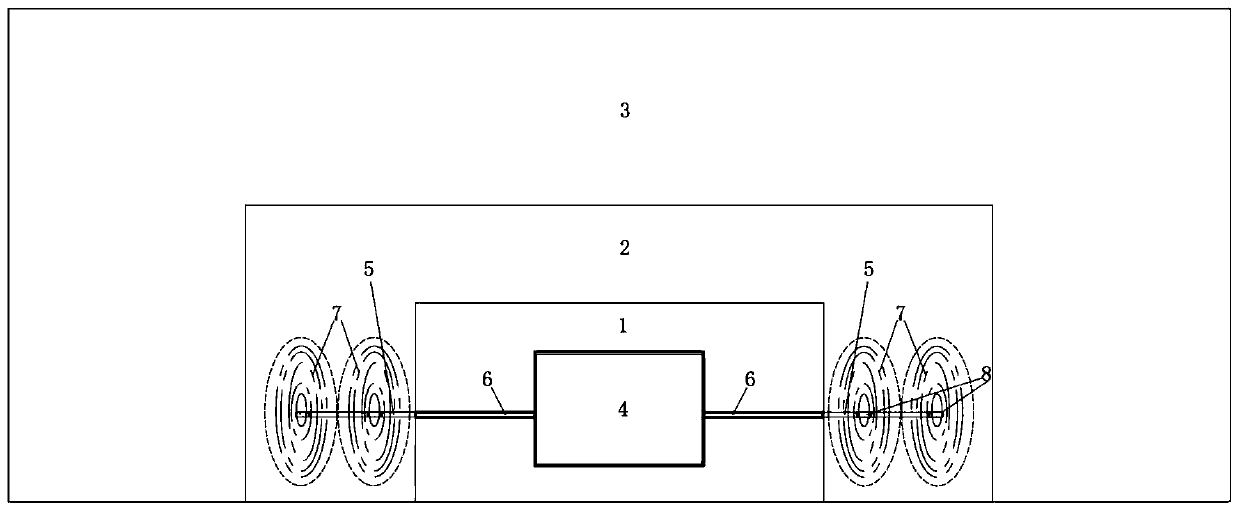

Front body framework structure of automobile

ActiveCN102358349AAbsorb in timeReasonable dispersionMonocoque constructionsAbsorbed energyEngineering

The invention discloses a front body framework structure of an automobile. The front body framework structure of the automobile comprises an automobile body A post, a front protective cross beam, a front engine room framework assembly and a front floor framework assembly, wherein the front engine room framework assembly comprises a front engine room longitudinal beam, and a plurality of longitudinal beams and cross beams, which are connected with the front engine room longitudinal beam and are used for dispersing and transferring collision energy; and the front floor framework assembly comprises a front floor longitudinal beam, a lower door sill, and a plurality of longitudinal beams and cross beams, which are connected with the front floor longitudinal beam and the lower door sill and are used for dispersing and transferring collision energy. Through the technical scheme, a plurality of structural beams are welded to form a closed annular body framework structure; the plurality of longitudinal beams and cross beams are used for absorbing and transferring the collision impact load, so that the front part is deformed and absorbs energy sufficiently; the number of impact energy transfer passages is large; the energy is reasonably dispersed; the energy is absorbed in time; the invasion amount of a front baffle plate is small; the deformation of the floor and a middle passage is small; the deformation of a cab is reduced; and thus, the damage to a passenger in the collision, and the maintenance cost of the automobile are reduced.

Owner:CHERY AUTOMOBILE CO LTD

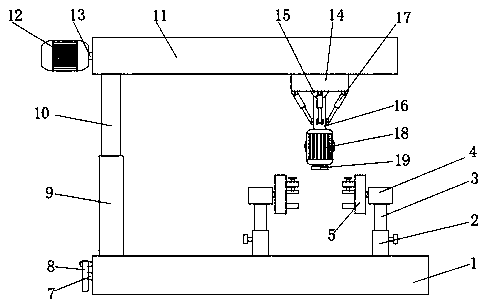

Polishing machine for building materials capable of adjusting polishing positions and polishing method thereof

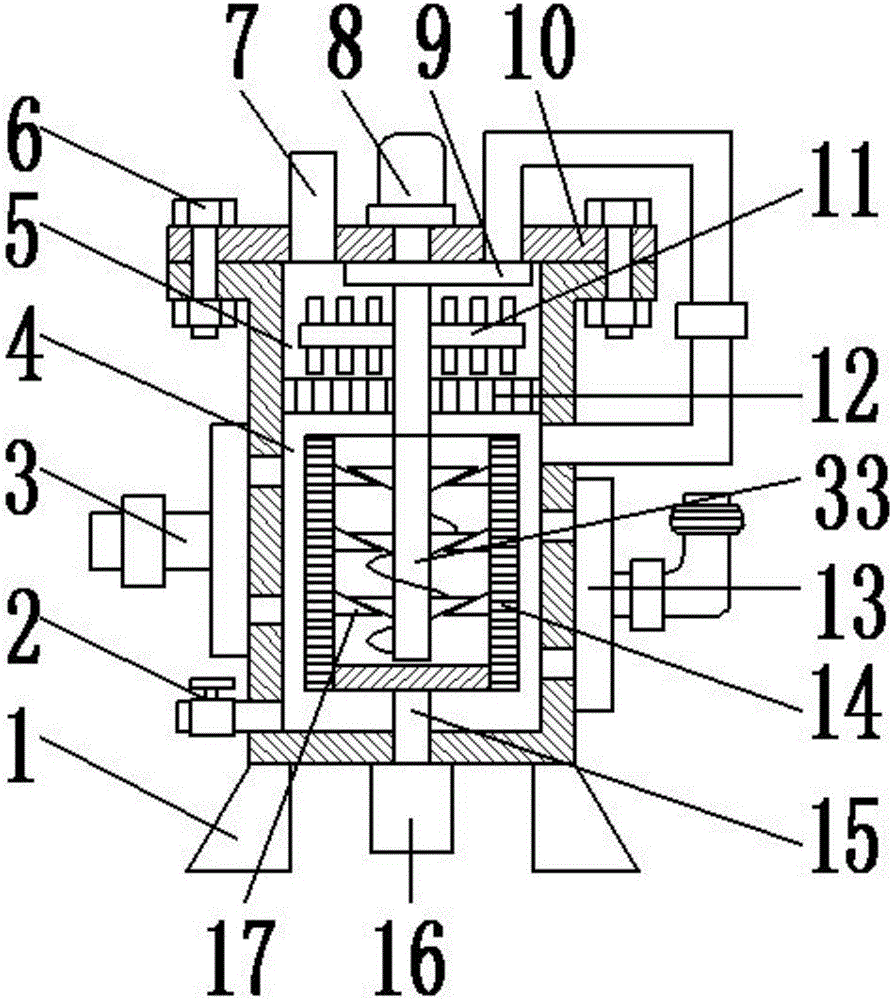

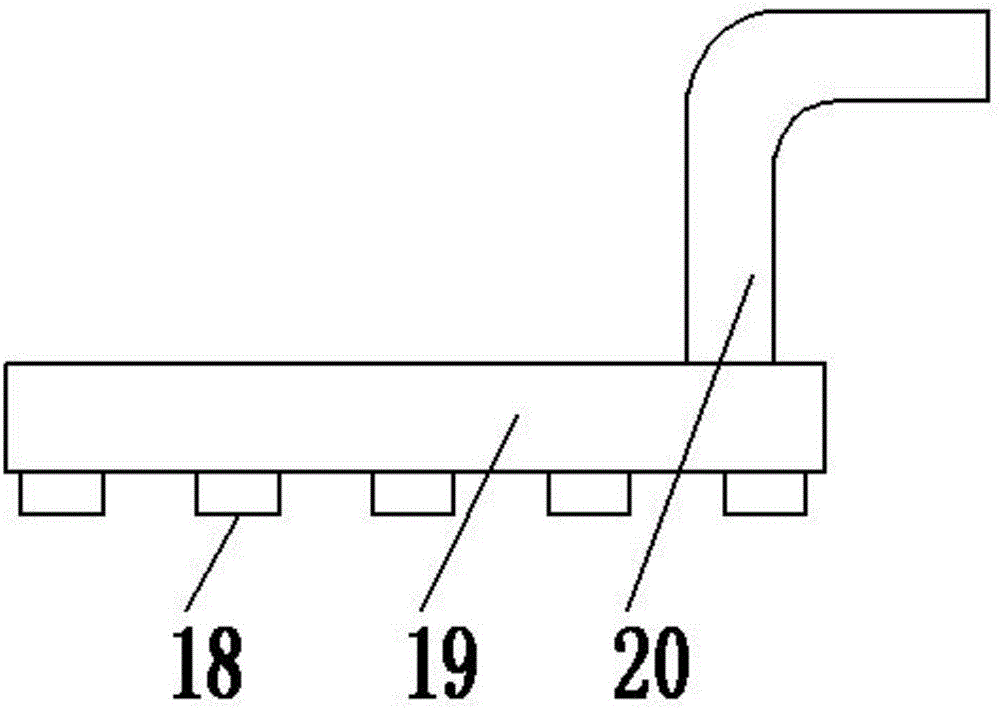

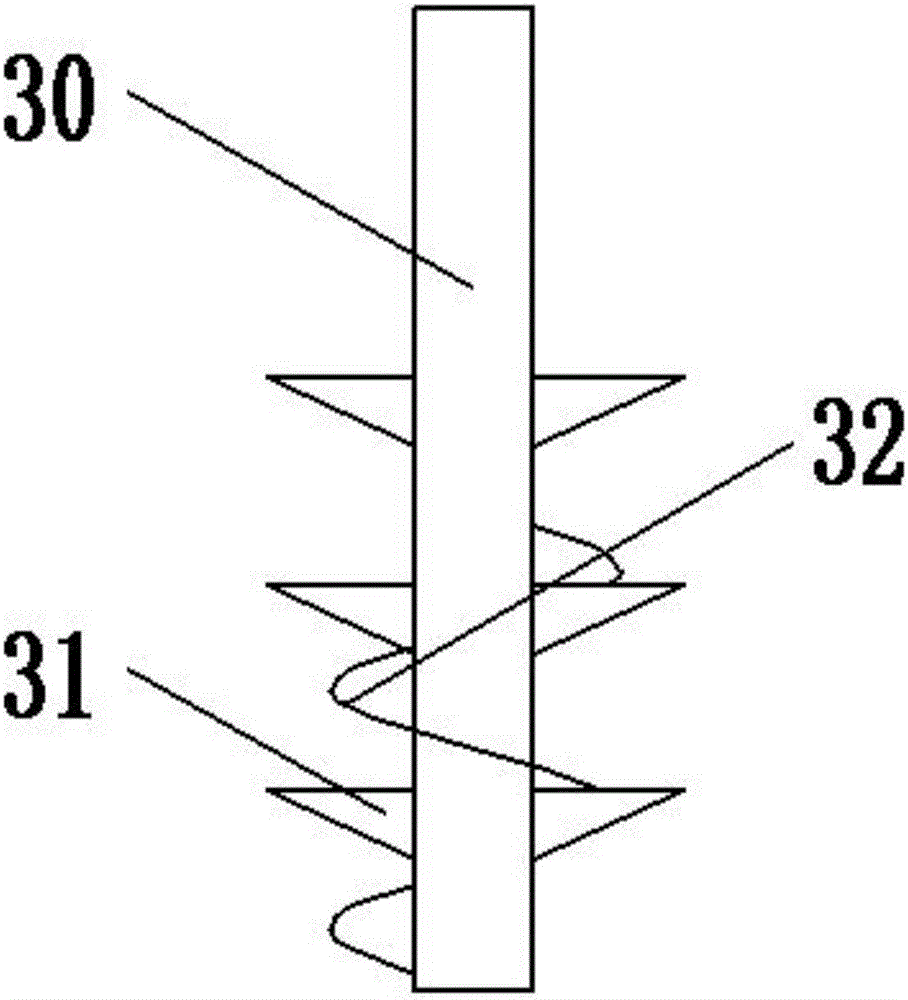

InactiveCN109551349AHeight adjustableReduce laborGrinding carriagesGrinding drivesArchitectural engineeringMotor shaft

The invention discloses a polishing machine for building materials capable of adjusting polishing positions in the technical field of building material polishing. The polishing machine comprises a base; a T-shaped groove is formed in the left side of the top of the base; a slide block is arranged in the T-shaped groove; sleeve rods are arranged on the right side of the top of the base and at the top of the slide block; clamping and dust sucking devices are arranged at opposite ends of two sets of overturning motors through motor shafts; a rotating ball is arranged at the bottom of the slide block through a ball groove; four sets of electric extension rods are arranged at the bottom of the slide block in an annular array mode; the bottoms of the electric extension rods are connected to thebottom of the outer wall of a connecting rod; a polishing motor is arranged at the bottom of the connecting rod; and a bottom motor shaft of the polishing motor is connected with a polishing head. Thedevice can position, clamp and overturn the building materials, drives the connecting rod to adjust the polishing angle through cooperation of the four sets of electric extension rods, drives the polishing machine to move through the slide block to realize adjustment of the polishing positions, and achieves excellent polishing effect and high efficiency.

Owner:苏州比雷艾斯电子科技有限公司

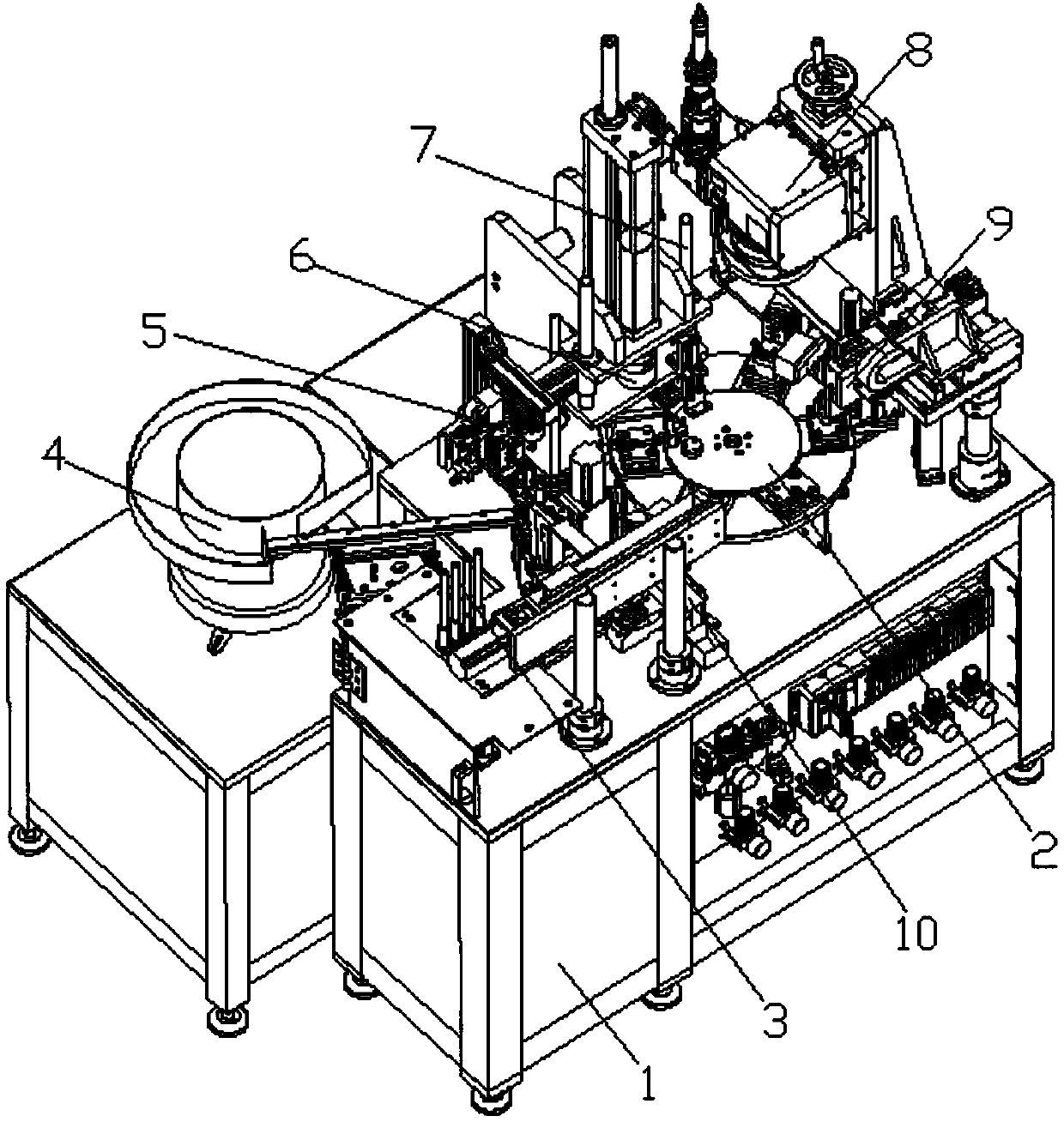

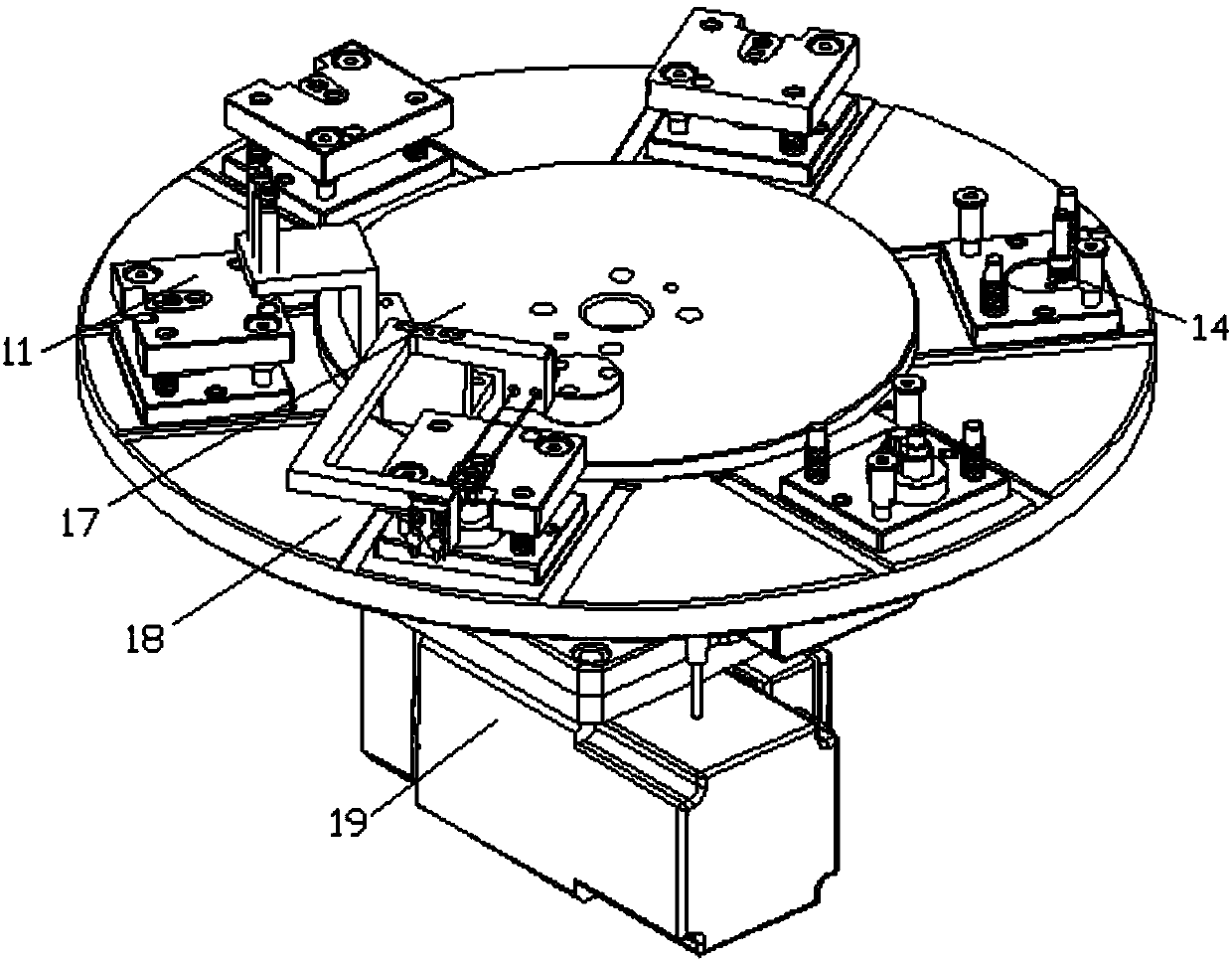

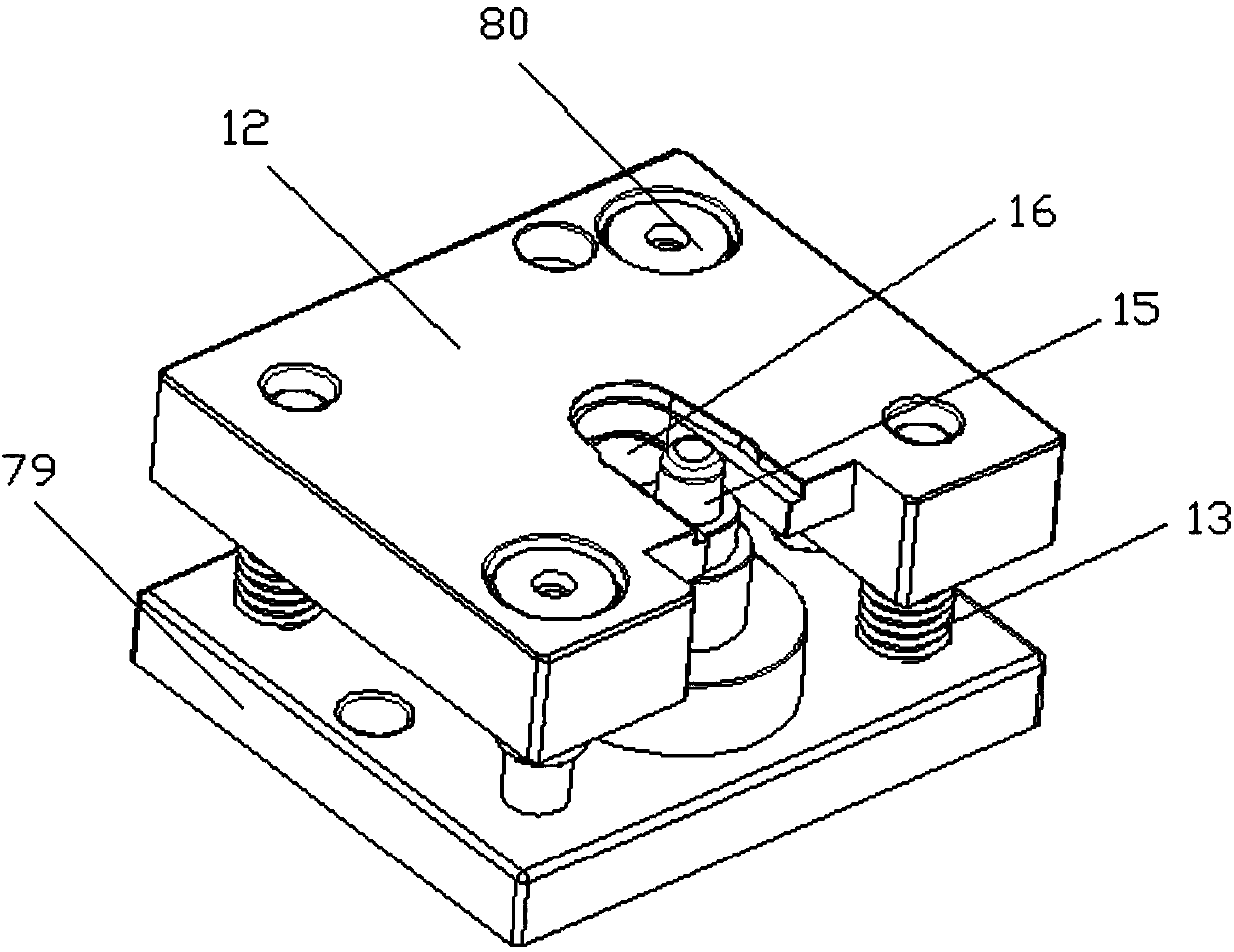

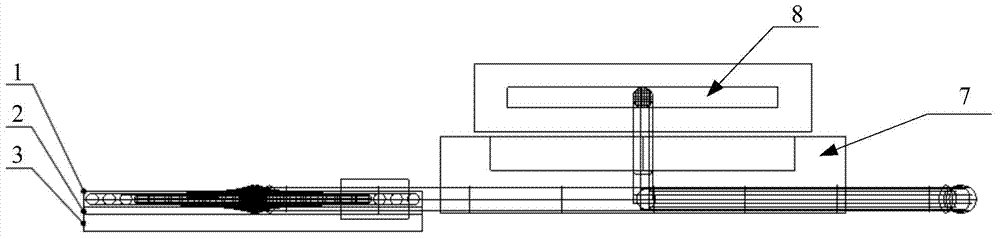

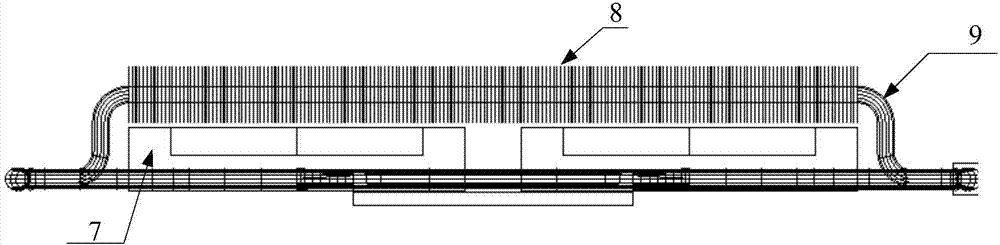

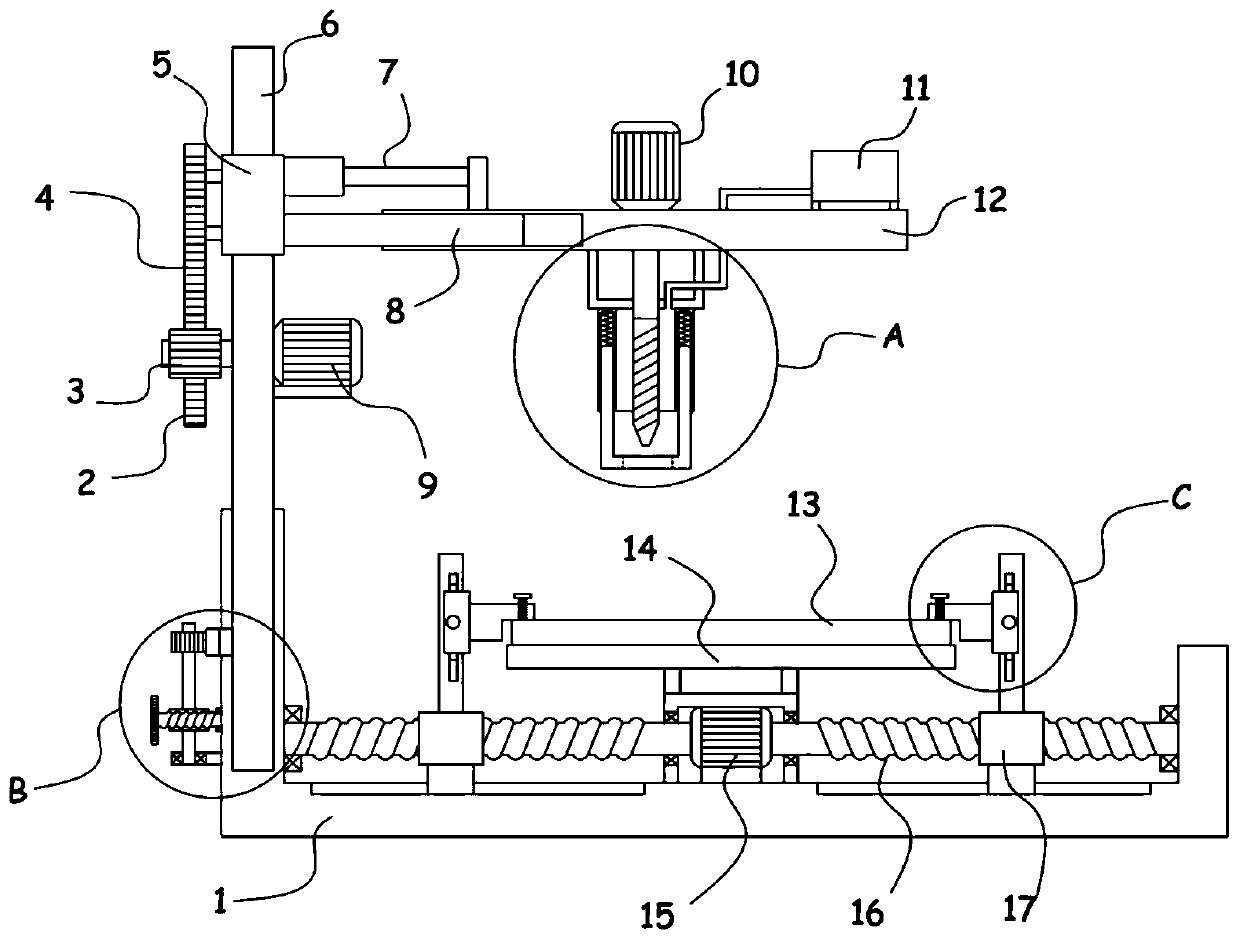

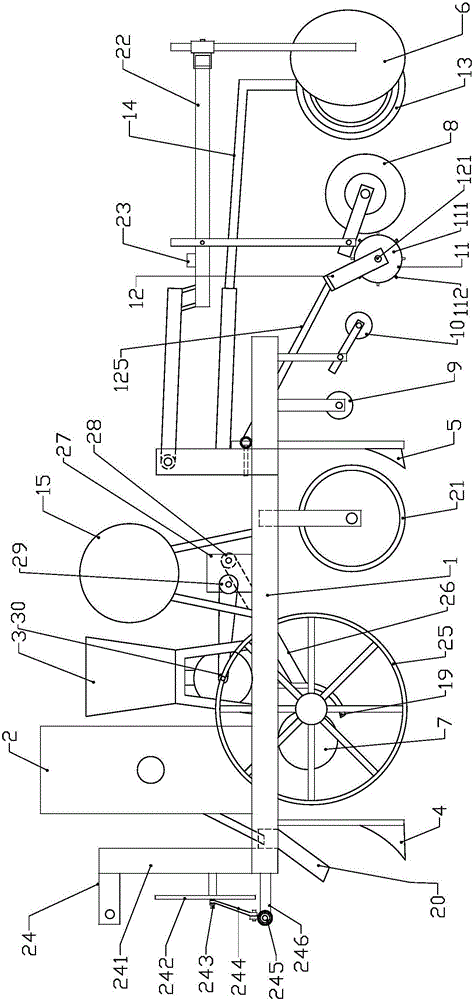

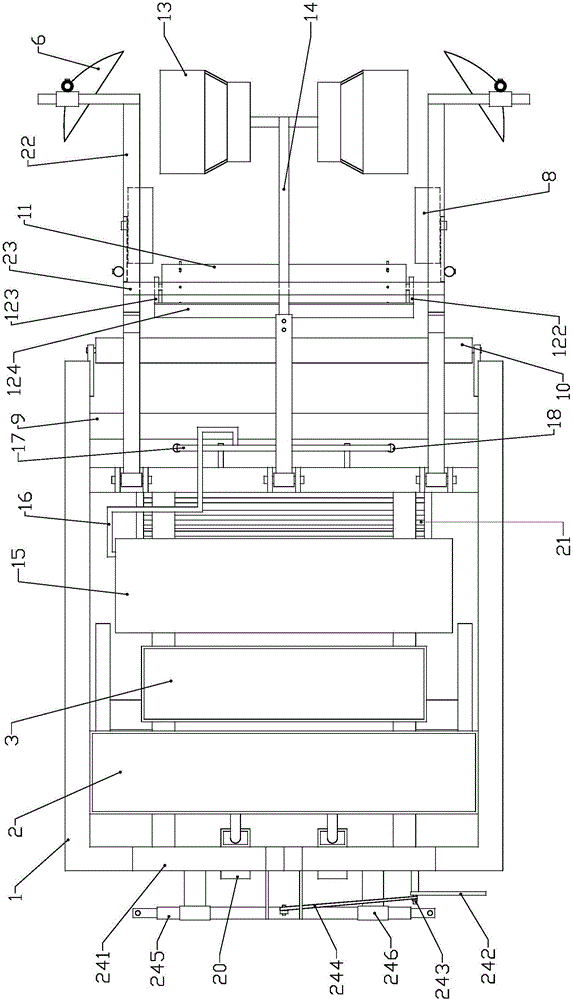

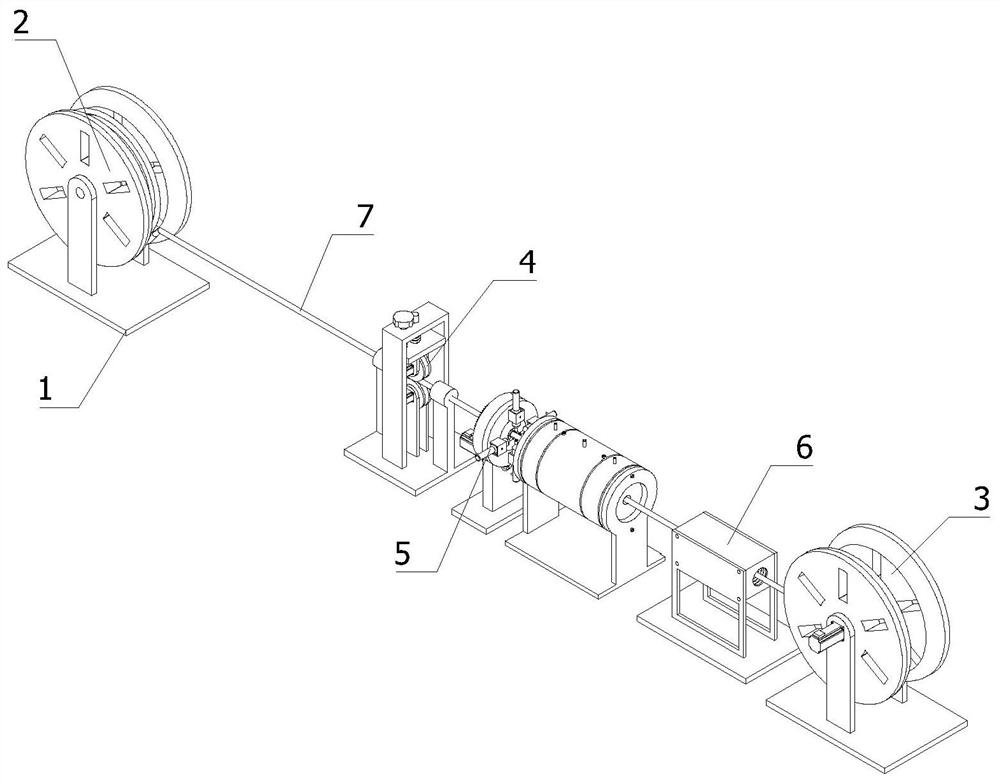

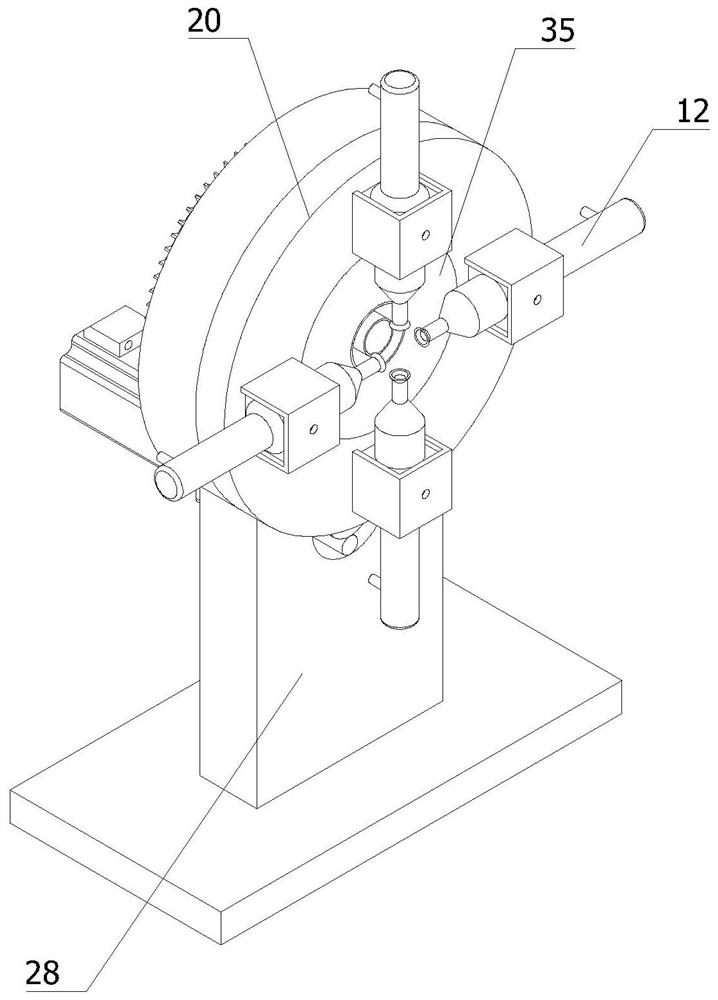

Full-automatic camshaft assembling machine

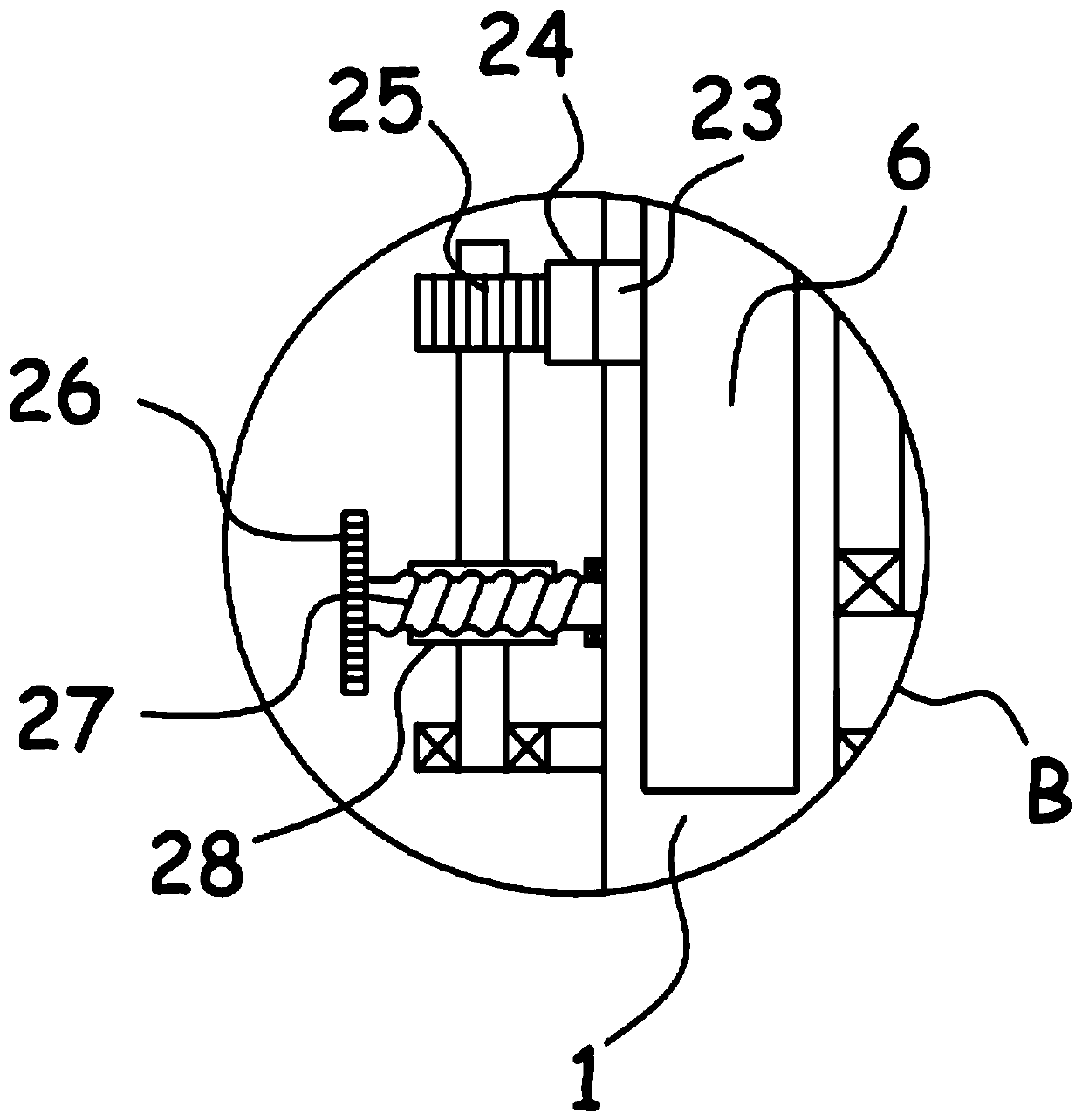

InactiveCN107717435ATimely detectionHigh positioning accuracyAssembly machinesLaser beam welding apparatusDistribution controlButt joint

The invention relates to a full-automatic camshaft assembling machine. The full-automatic camshaft assembling machine comprises a rack and a power distribution control cabinet arranged in the rack; arotating disk device is arranged on the middle portion above the rack; and a shaft feeding device, a cam vibrating feeding disk, a cam feeding device, a press-fitting device, a floating shaft pressingdevice, a laser welding device, a flaw detecting device and a discharging device in butt joint with carrier assemblies are sequentially arranged above the rack in the rotating direction of a rotatingdisk. According to the full-automatic camshaft assembling machine, by means of the shaft feeding device, a shaft is placed in the carrier assembly on the rotating disk device, and the carrier assembly rotates clockwise along the rotating disk and sequentially rotates onto the cam feeding device to perform cam feeding, onto the press-fitting device so as to press a cam into a matching groove of the shaft, onto the floating shaft pressing device to push down the shaft to be clamped with the matching groove, onto the laser welding device to perform laser welding on the matched portion of the shaft and the cam, onto the flaw detecting device to detect bruised damage and scratches, and onto the discharging device to perform discharging; and the assembling process of the cam and the shaft is completed, the positioning precision is high, and defective products are detected in time.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Chip cooling system

ActiveCN104851857AReduce the temperatureLow boiling pointSemiconductor/solid-state device detailsSolid-state devicesHeat fluxEngineering

The invention relates to a chip cooling system, which comprises a chip heat conduction plate used for primary heat exchange, and an annular heat pipe used for secondary heat exchange, wherein a plurality of micro-channels are arranged on the chip heat conduction plate side by side, the micro-channels are connected with a circulating pipeline provided with a pump simultaneously to form a circulating loop, and the circulating loop is filled with liquid I; and the annular heat pipe is sleeved in the circulating loop to form a sleeving structure, the annular heat pipe is filled with liquid II and gas, and the pressure intensity of the gas is always less than the atmospheric pressure intensity. The chip cooling system combines the micro-channels with the annular heat pipe to form a two-stage heat exchange system, the micro-channels can provide large radiating heat flux and can absorb heat on the chip timely, the annular heat pipe fully utilizes effects such as phase change and gravity as a driving force, the radiating efficiency is high, and the cost is low; and the heat passes through the circulating loop and the annular heat pipe from the chip and is radiated to the environment, the radiating power is high, and the effect is good.

Owner:东营慧达科技创业服务有限公司

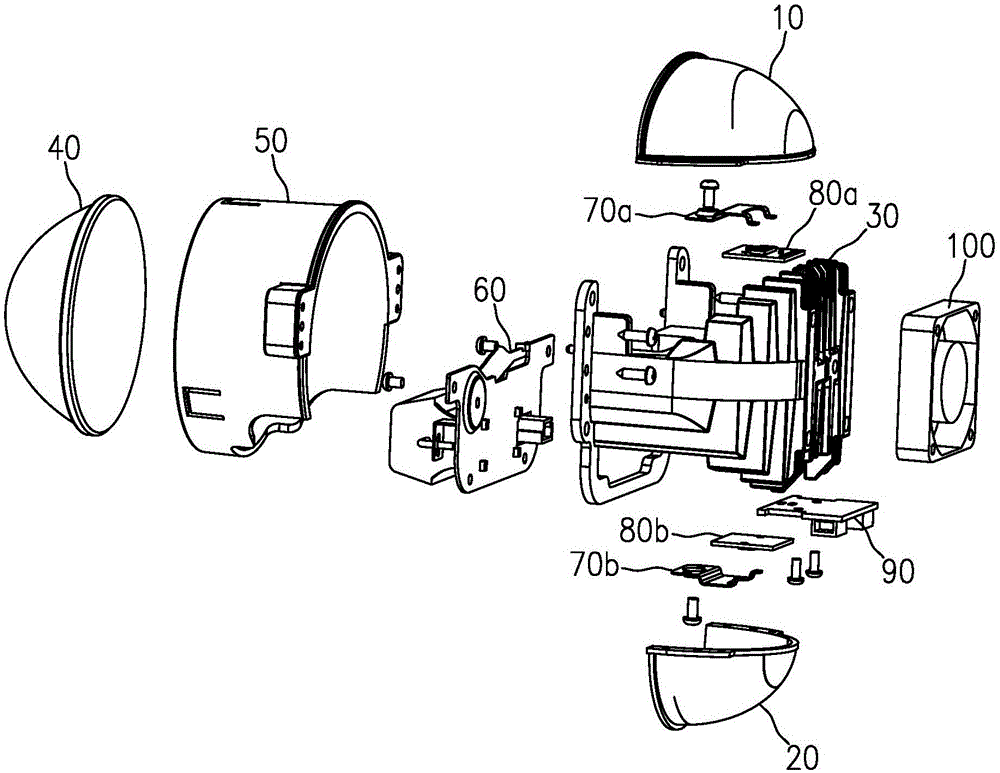

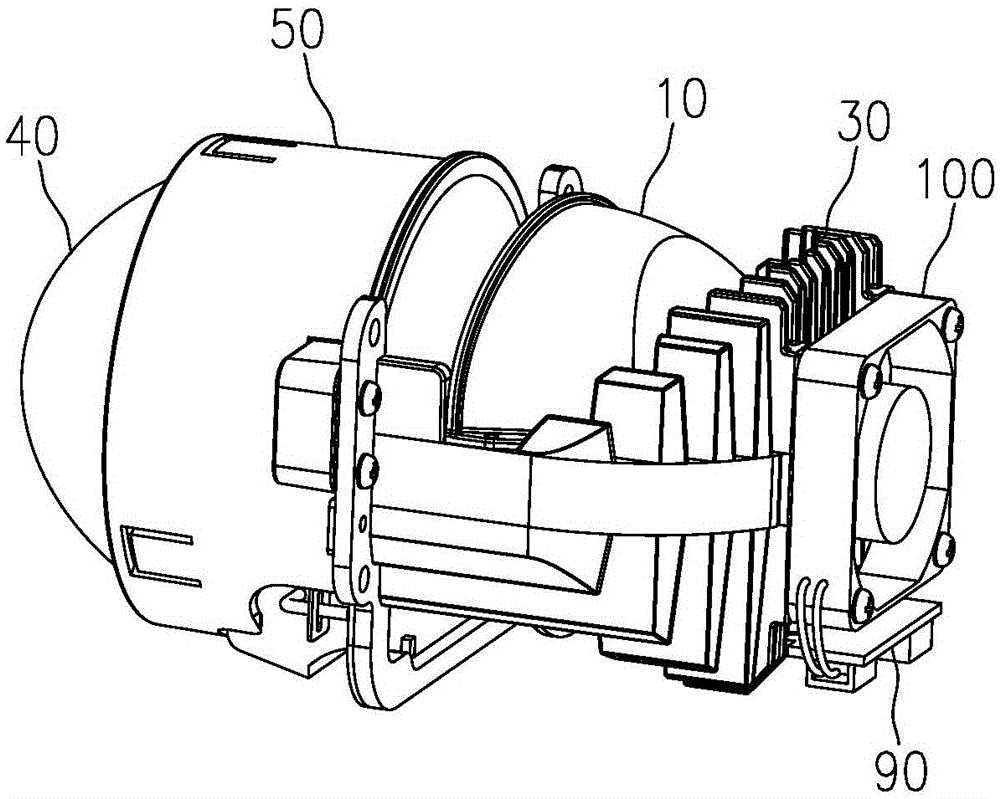

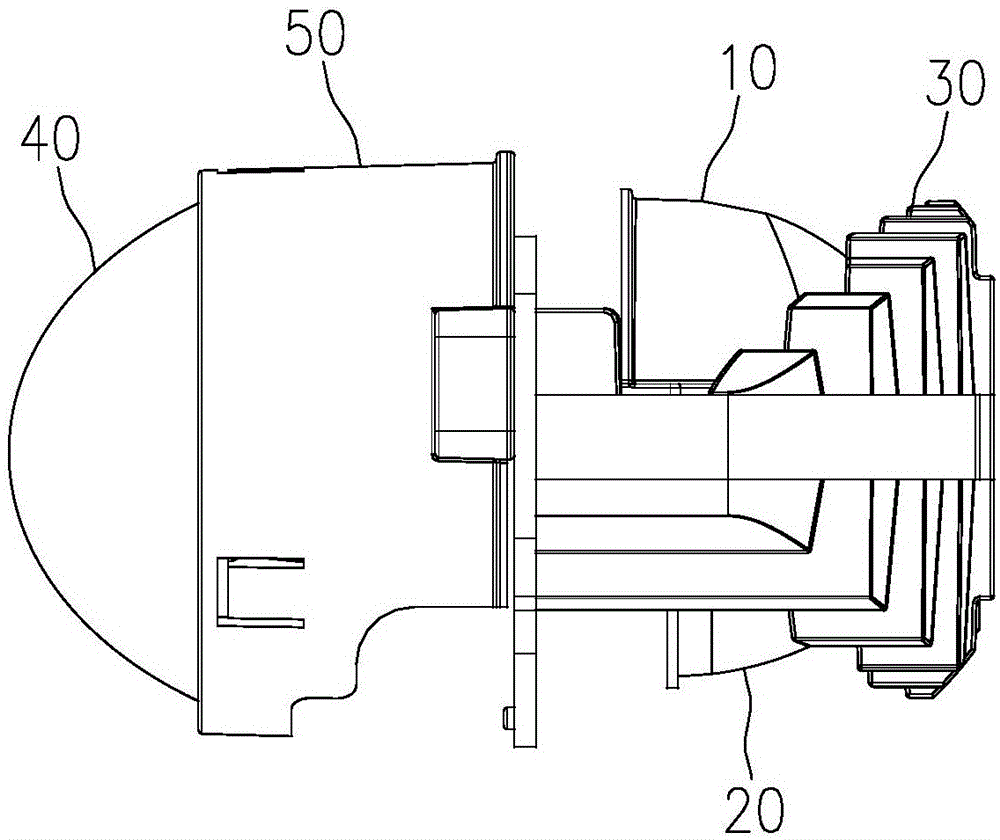

High-efficiency LED (Light-Emitting Diode) dual chip high-low beam integrated automobile headlamp module

ActiveCN105020652AConvenient lightingImprove driving comfortVehicle headlampsPoint-like light sourceVisual field lossWorking environment

The invention relates to a high-efficiency LED (Light-Emitting Diode) dual chip high-low beam integrated automobile headlamp module. The high-efficiency LED dual chip high-low beam integrated automobile headlamp module comprises an LED light source, a reflection cup, a heat sink, a lens and a sleeve, wherein a locating platform for arranging the LED light source is arranged on the heat sink; the LED light source is of an upper LED light source and lower LED light source combined dual light source structure; the reflection cup is of an upper reflection cup and lower reflection cup combined dual reflection cup structure; an upper reflection cup locating platform and a lower reflection cup locating platform are respectively arranged at the upper side and the lower side of the locating platform; and a plurality of parallel fin-shaped cooling plates are arranged at the outer sides of the upper reflection cup locating platform and the lower reflection cup locating platform on the heat sink; and gaps are formed between the adjacent cooling plates. The high-efficiency LED dual chip high-low beam integrated automobile headlamp module is good in illumination effect and heat dissipation effect, high in illumination level and clear in visual field, and ensures that an automobile headlamp is in a safe and stable working environment, thus greatly improving the driving safety and prolonging the service life of the automobile headlamp.

Owner:东莞市荣海光电科技有限公司

Day firming oil-control essence and preparation method therefor

ActiveCN111297754AReduce secretionInhibition of secretionCosmetic preparationsToilet preparationsBiotechnologyHamamelis mollis

The invention discloses day firming oil-control essence and a preparation method therefor, and discloses new application of a bixa orellana seed extract serving as an oil control astringent. The bixaorellana seed extract can effectively reduce sebum secretion and shrink pores; the prepared essence comprises the following oil control ingredients in weight percentage: 0.1%-0.5% of silica, 0.1%-1% of tea extract and 3%-5% oil control compound, and the following astringents in weight percentage: 0.01%-0.5% of bixa orellana seed extract, 2%-5% of quinine fungus extract and 1%-8% of witchhazel water; and the pores can be effectively shrunk and skin is fine and smooth by combining the bixa orellana seed extract, the quinine fungus extract and the witchhazel water. By combining the oil control ingredients with the astringent ingredient of the essence disclosed by the invention, oil secretion of face skin can be effectively inhibited, and excess oil is absorbed in time to prevent clogging caused by the fact that the oil is accumulated and oxidized in the pores; and the effect of shrinking the pores is obviously improved.

Owner:I&B GUANGZHOU BIOLOGICAL TECH CO LTD

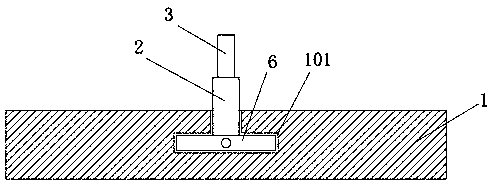

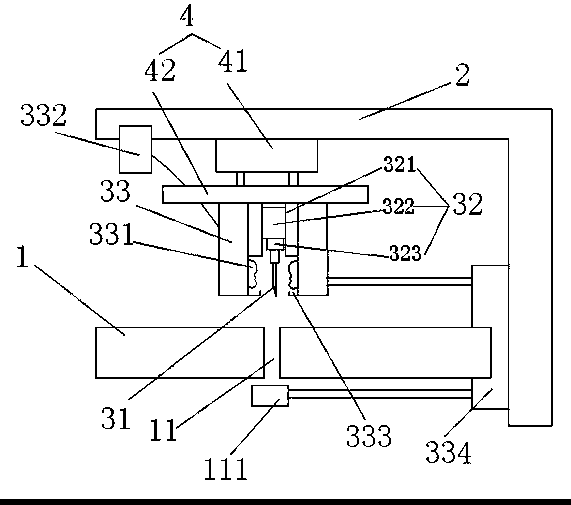

Efficient cutting device for sofa leather

ActiveCN104263860AAbsorb in timeTimely processingLeather clicking/perforating/clickingMetal working apparatusMechanical engineeringStructure control

The invention belongs to the field of sofa processing and relates to an efficient cutting device for sofa leather. The cutting device comprises a cutting table, a cutting structure arranged above the cutting table, and a mounting frame used for mounting the cutting structure, wherein a cutting joint strip is arranged on the cutting table; the cutting structure comprises a cutting knife arranged over the cutting joint strip, a control structure used for controlling the cutting knife to move up and down, and pressure heads which are arranged on the two sides of the cutting knife and used for stabilizing the leather; the cutting structure is mounted on the mounting frame through a drive structure; the drive structure is used for controlling the cutting structure to move up and down. The cutting device is simple in structure, easy to operate, high in cutting efficiency, small in cutting error, little in environmental pollution and relatively environment-friendly; generated dust can be absorbed and processed in time.

Owner:ZHEJIANG ANJI HUIYE FURNITURE

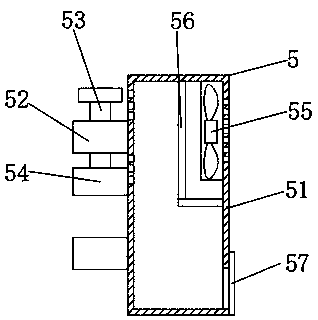

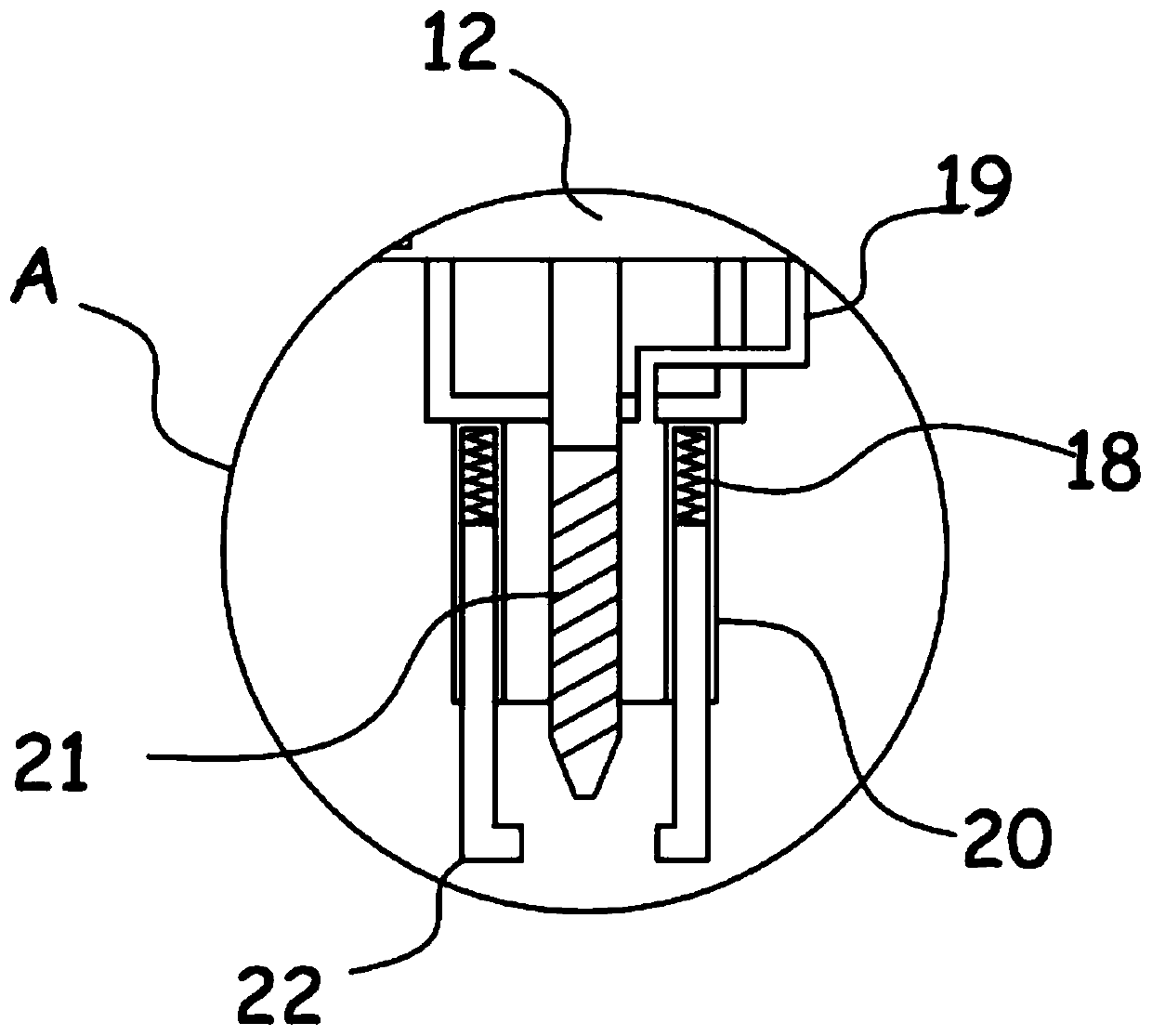

PCB perforating device for electronic processing

InactiveCN111050482AFlexible and efficient drilling operationsAvoid pollutionPrinted circuit manufactureCleaning using gasesElectric machineryDrill bit

The invention discloses a PCB perforating device for electronic processing and relates to the technical field of building construction. The PCB perforating device comprises a fixing frame; a supporting seat for supporting a PCB is fixed on the fixing frame; a double-shaft motor is fixed on the fixing frame; a clamping mechanism for clamping and fixing the PCB is connected onto the double-shaft motor in a driving manner; and a steering mechanism for driving a sleeve plate to rotate is arranged on the fixing frame. According to the device of the invention, the clamping mechanism is arranged to transversely clamp the PCB of the supporting seat; a clamping block is used for clamping and fixing the PCB; position stability during drilling is ensured. A translation mechanism can adjust the transverse position of a drill bit. The steering mechanism can steer the drill bit relative to the fixing frame, so that the drill bit can be flexibly adjusted to move to any position of the PCB, and therefore, the drilling operation of the PCB is flexible and efficient. A dust collecting mechanism can gather dust generated in a drilling process and absorb the dust in time, and therefore, the situationthat the PCB is polluted due to the diffusion of the dust is effectively avoided.

Owner:南京奥亚美电子科技有限公司

Planting method of selenium-enriched rice

InactiveCN106718454AGuaranteed absorptionStable early growthExcrement fertilisersFertilising methodsPaniclePaddy field

The invention relates to the technical field of high-quality crops planting, and particularly relates to a planting method of selenium-enriched rice; the planting method of the selenium-enriched rice includes steps of rice seedling cultivation, transplanting and rice fertilization; according to the planting method, base fertilizer is applied to the transplanting rice before transplanting the rice seedling for 1-3 days; after completing the seedling transplanting for 10-15 days, the selenium-enriched fertilizer is applied; the selenium-enriched fertilizer includes selenium-enriched compound, potash fertilizer, silicon fertilizer, nitrogen fertilizer and phosphatic fertilizer; at the beginning period of rice panicle emergency and flowering, the rice is further added with selenium-enriched fertilizer. The planting method has good practicability and promotion prospect.

Owner:CHENGDU YUYA TECH

Air convection crushing device with preliminary crushing function

ActiveCN106733006AGuarantee unimpededAbsorb in timeDirt cleaningGrain treatmentsDevice formEngineering

The invention discloses an air convection crushing device with a preliminary crushing function. The air convection crushing device comprises a base, wherein a crushing box is arranged at the top of the base; a material placing rack and a crushing device is arranged inside the crushing box; a preliminary crushing chamber is formed in the top of the a filtering plate; a support plate is arranged at the top of the preliminary crushing chamber; a feeding pipe, a crushing motor and a dust sucking pipe are arranged at the top of the support plate. The air convection crushing device is simple in structure, reasonable in design and convenient to use; an air inputting device and an air extracting device are arranged, so that hot air can be input into the crushing box by the air inputting device and is used for crushing the material, then the air is exhausted by the air extracting device, so that the device forms air convection and is capable of continuously heating the material and avoiding excessive pressure intensity in the crushing box; filter screens are arranged in an air inlet branch pipe, an air outlet branch pipe and a dust sucking branch pipe; the smoothness of the branch pipes can be ensured; the production efficiency is greatly improved.

Owner:JIANGSU WANLI BIOTECH CO LTD

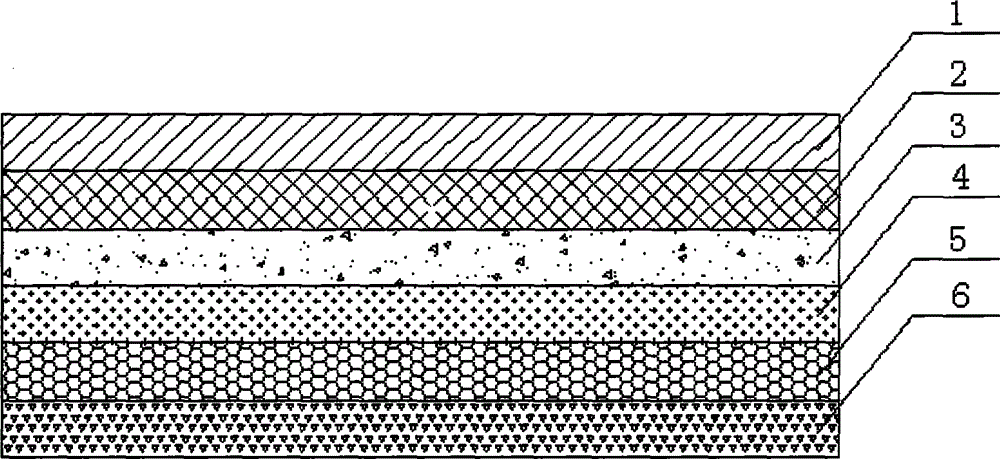

Medical nursing cushion

InactiveCN104800002AGood water absorption and breathabilityFeel comfortable on the skinAbsorbent padsBaby linensFluff pulpWoven fabric

The invention discloses a medical nursing cushion, and belongs to the technical field of nursing materials. The medical nursing cushion comprises an antibacterial layer, a water permeable layer, a water absorption layer, an air ventilation layer, a waterproof layer and a bottom layer in sequence from top to bottom, wherein the antibacterial layer, the water permeable layer, the water absorption layer, the air ventilation layer, the waterproof layer and the bottom layer are extruded and compounded together; the antibacterial layer is provided with pure cotton fabric in which a sterilization material is added; the water permeable layer is a layer which is of a net surface structure; the water absorption layer is provided with fluff pulp, macromolecular absorption resin and cotton; the waterproof layer is provided with a plastic thin film; the bottom layer is made of non-woven fabric. By using the medical nursing cushion, the cleanness, the dryness, the comfortableness and the freshness can be maintained, and the medical nursing cushion has the advantages of being good in water-absorbing capacity and less likely to leak.

Owner:陈亚婷

Cultivation method for advancing high-yield period of Atemoya

The invention discloses a cultivation method for advancing the high-yield period of Atemoya, which belongs to the field of Atemoya cultivation. The cultivation method for advancing the high-yield period of Atemoya comprises steps of (1) big cup seedling breeding, (2) soil fumigation treatment, (3) rooting treatment, (4) backbone branch culture, (5) fertilizer management and pest control, (6) retraction pruning treatment. Root damages in the process of Atemoya transplantation can be avoided, and the infection of pathogens in soil is lightened; the healthy growth of the root system is maintained, and nutrients in soil can be timely absorbed; the survival rate of transplantation is improved; the rapid growth of plants is promoted; the cultivation cycle of permanent backbone branches is shortened; and the high-yield period is advanced.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

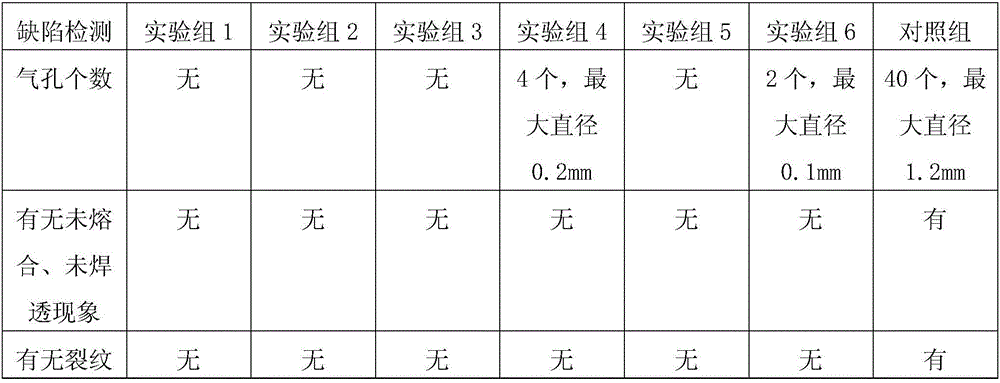

Aluminum alloy welding process

InactiveCN106825871AHigh tensile strengthDoes not affect aestheticsArc welding apparatusWelding/cutting media/materialsSlagMegasonic cleaning

The invention discloses an aluminum alloy welding process and belongs to the technical field of metal welding. The aluminum alloy welding process comprises the following steps: (1) a welding area of the surface of an aluminum alloy plate is put into a cleaning fluid for ultrasonic cleaning and then dried; (2) the welding area of the to-be-welded aluminum alloy plate is heated to 150-200 DEG C; (3) the welding area of the to-be-welded aluminum alloy plate is heated to 750-830 DEG C, a degasifier is sprayed to the welding area of the aluminum alloy plate, and the aluminum alloy plate is welded with a special aluminum alloy welding wire; (4) the welded part of the aluminum alloy plate is subjected to solid solution at the temperature of 300-450 DEG C, and the aluminum alloy plate is subjected to degasification treatment through ultrasonic waves; (5) the welded part of the aluminum alloy plate after solid solution treatment is transferred to cold water and cooled to the room temperature; (6) clearing and removal of welding powder or slag are performed. With the adoption of the aluminum alloy welding process, the pore problem can be effectively solved, and incomplete fusion, incomplete penetration and cracking phenomena are unlikely to occur.

Owner:玉林博飞商贸有限公司

Automatic punching type peanut seeding machine

The invention discloses an automatic punching type peanut seeding machine, belonging to the agricultural machinery. The automatic punching type peanut seeding machine structurally comprises a stander, a fertilizer box, a seed box, a ridging coulter, a guttering coulter and an earthing coulter, wherein a seed sowing device is arranged at the lower part of the seed box; a compaction wheel is arranged between the guttering coulter and the earthing coulter; a film laminating frame is arranged at the rear part of the stander; a film pressing wheel is arranged at the lower part of the stander at the rear part of the film laminating frame; a punching press wheel is arranged behind the film pressing wheel, comprises a wheel body and a protruded upright post and is connected with the stander through a connecting device; and the connecting device comprises a rotating shaft, a left end plate, a right end plate, a connecting plate and a connecting rod, a wheel body of the punching press wheel is arranged on the rotating shaft, and the left end plate and the right end plate are respectively arranged at two ends of the rotating shaft. The automatic punching type peanut seeding machine has the characteristics that an automatic punching function is realized, the human input is reduced, the labor intensity is relieved, the ground surface temperature can be decreased, the burning of seedlings in summer is prevented, rainwater can be timely absorbed, hardened soil on films can be broken, and the like.

Owner:高唐县农业局 +1

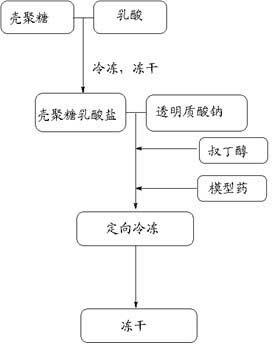

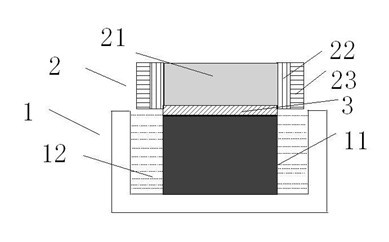

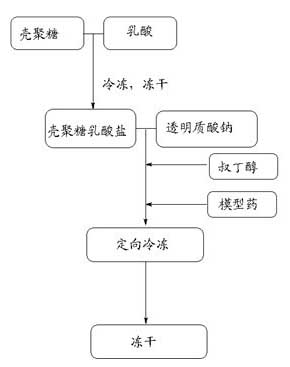

High-ventilated degradable medicine-carrying skin wound dressing as well as preparation method and device thereof

ActiveCN102210885AHigh air permeabilityImprove water absorptionDomestic cooling apparatusLighting and heating apparatusMoisture retentionSodium hyaluronate

The invention discloses a high-ventilated degradable medicine-carrying skin wound dressing as well as a preparation method and device thereof, and belongs to the technical field of medical new materials. The high-ventilated degradable medicine-carrying skin wound dressing comprises the following components in percentage by weight: 45-50% of chitosan lactate; 45-50% of sodium hyaluronate and 5-10%of antibiotic. In the porous bioactivity dressing provided by the invention, a composite material of the chitosan lactate and the sodium hyaluronate is utilized as a substrate, and the antibiotic is loaded on the substrate. The dressing based on a special refrigerating process has the advantages of vertical pore ducts, high ventilation property, high hydroscopicity and moisture retention, therebyincreasing the permeability of the wound surface; the redundant exudate can be immediately absorbed while the moisture on the surface of the wound cannot be excessively evaporated. The dressing has long-term and effective effect on treating the surface of the wound so as to avoid the pain of the patient caused by frequent dressing change.

Owner:PKU HKUST SHENZHEN HONGKONG INSTITUTION +1

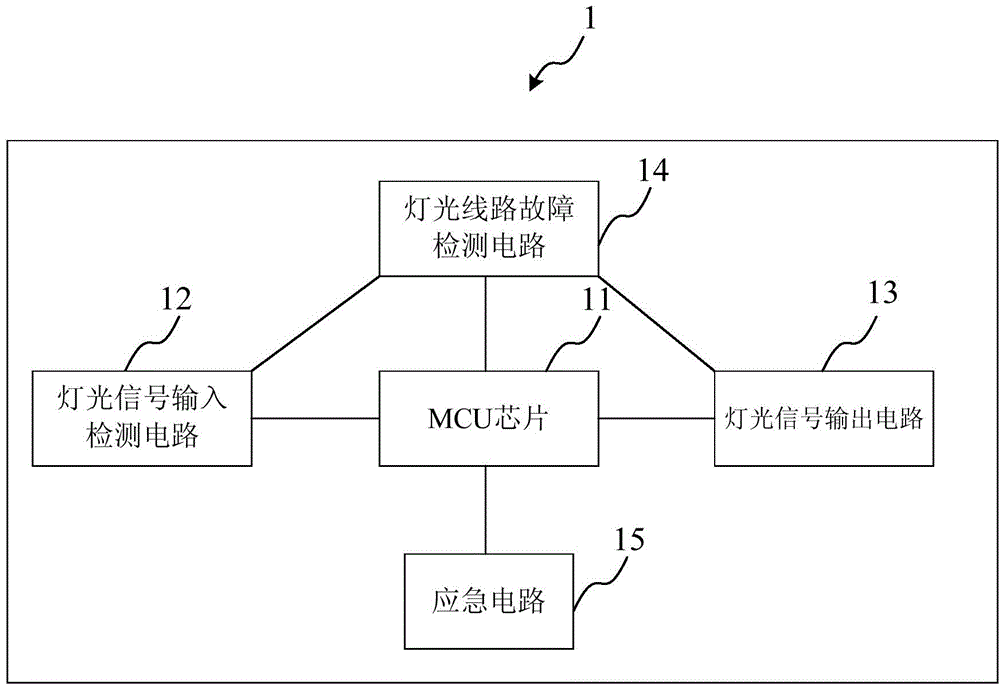

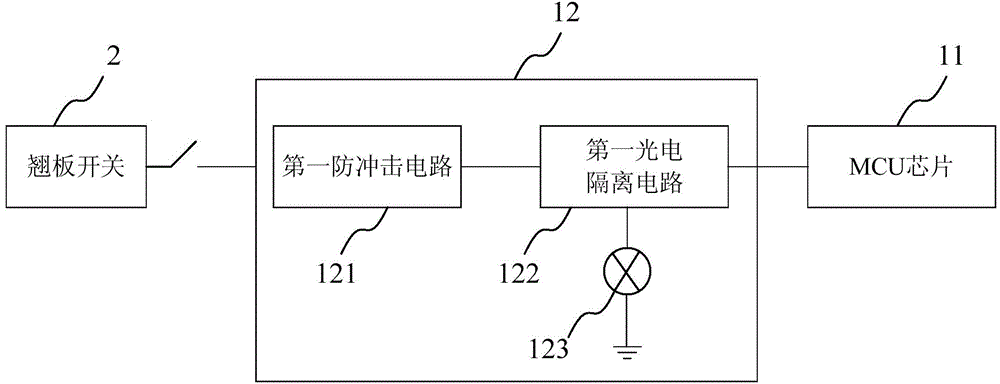

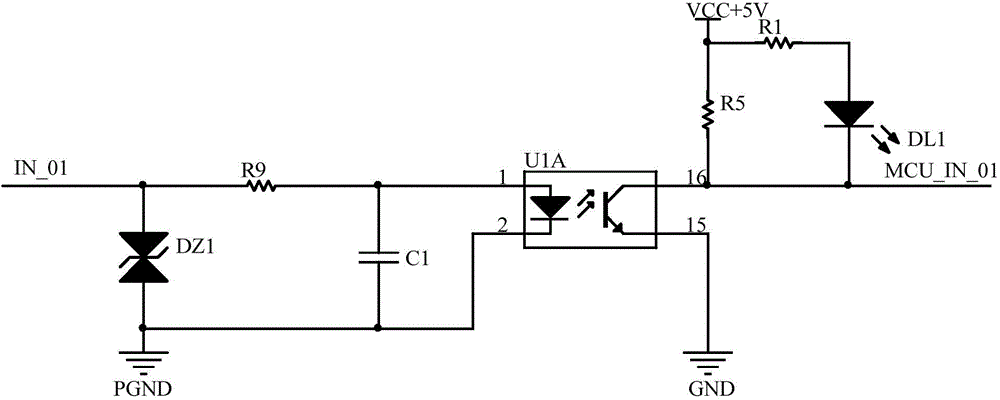

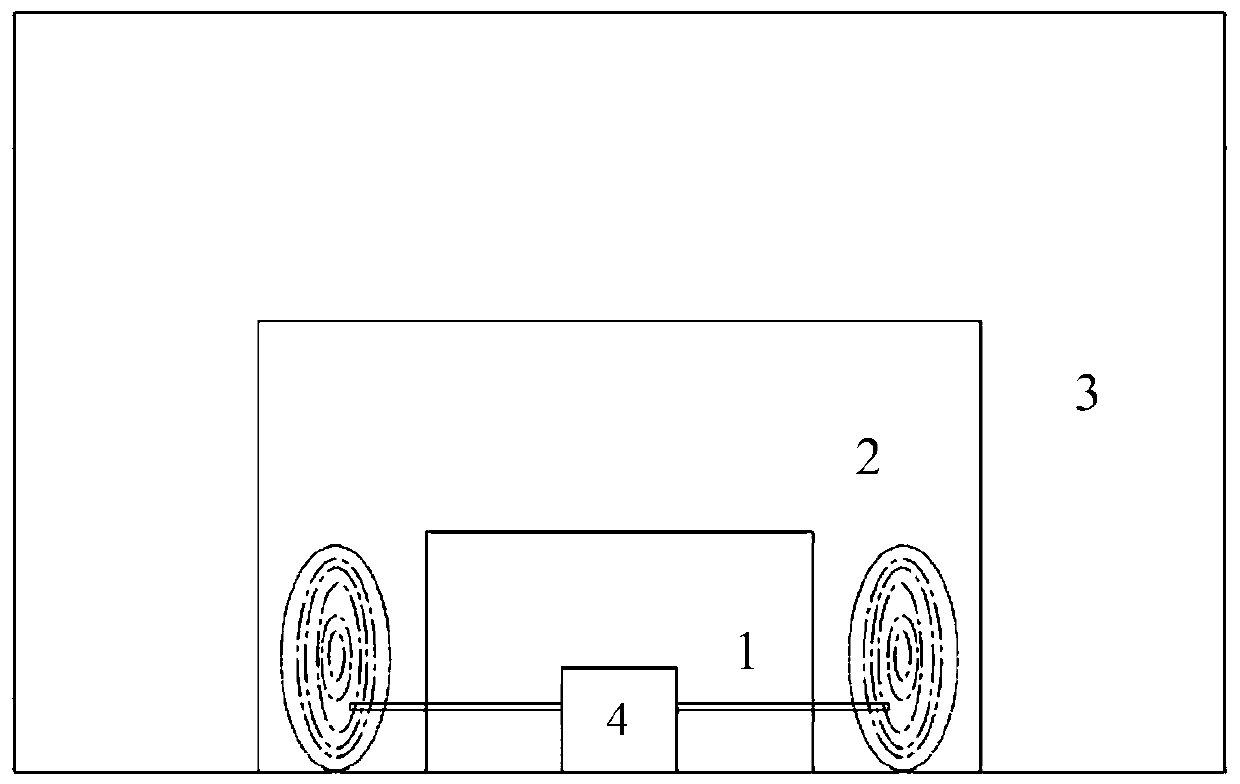

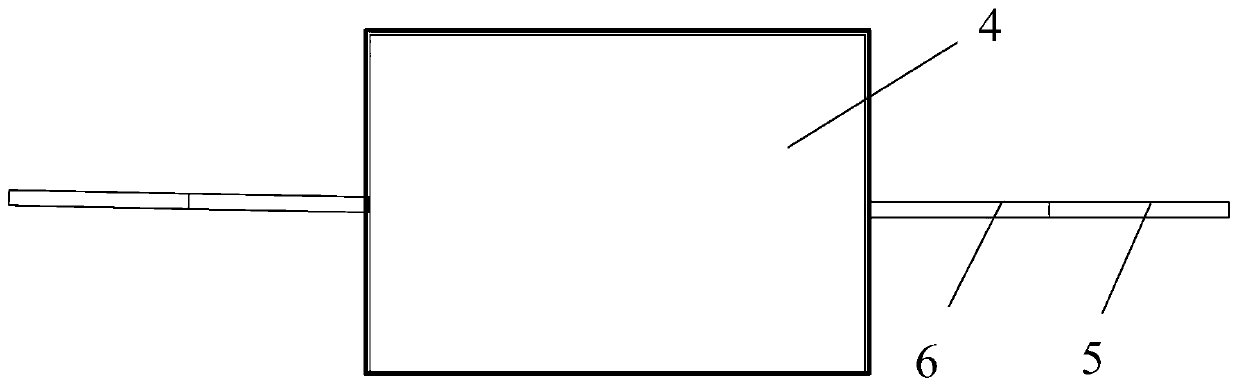

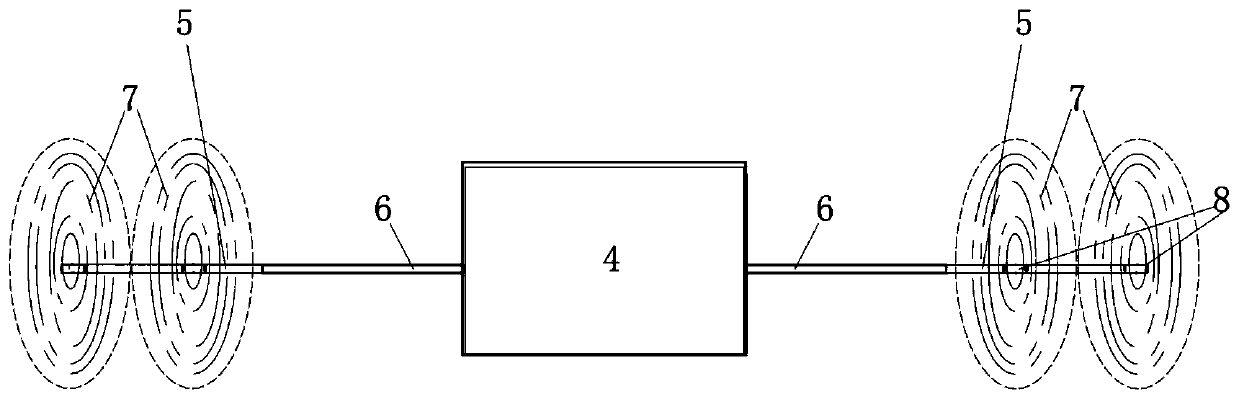

Light control module

InactiveCN106211493ASave wiring spaceSave wiringElectric light circuit arrangementComputer moduleSystem stability

The invention provides a light control module, which comprises an MCU chip, a light signal input detection circuit, a first photoelectric isolation circuit, a first indication lamp, a light signal output circuit, and a light circuit fault detection circuit, wherein the MCU chip is used for controlling input and output of light signals and fault detection; the light signal input detection circuit comprises a first anti-impact circuit for eliminating input spikes and preventing voltage impact; the first photoelectric isolation circuit is used for isolating high voltage signals in the light signals and then inputting the light signals to the MCU chip; the first indication lamp is used for indicating the light signals; the light signal output circuit outputs corresponding light signals according to the instruction of the MCU chip; and the light circuit fault detection circuit at least comprises a current detection chip for determining fault of the light circuit through detecting current changes in the light circuit. Problems of complicated wiring in the case of circuit fault detection on the light control module, reduced electrical system stability, and a large wiring amount and large occupied space of the whole light control module can be effectively solved.

Owner:MCC BAOSTEEL TECH SERVICE

Method for performing coal and rock repeated hole drilling to form roadway scouring weakening preventing structure

InactiveCN110374599ASafe and effective preventionAvoid destructionUnderground miningSurface miningStructure of the EarthCoal

The invention discloses a method for performing coal and rock repeated hole drilling to form a roadway scouring weakening preventing structure. A drilling machine is utilized for drilling a hole in anassigned position, repeated rotating is performed to fracture a coal and rock mass, a roadway scouring weakening preventing structural layer is formed, and energy released by impacting mine pressureis absorbed. According to the method, on the two edges of a roadway, hole drilling is performed to crack the coal and rock mass, a 6-12 m steel pipe is arranged in drilled holes in a sleeved manner, cracking pressure relief can be repeatedly performed on the coal and rock mass many times through the steel pipe, but a roadway supporting and protecting layer is not damaged; and meanwhile hole drilling is performed in the 6-12 m steel pipe many times to form a weak structural layer, and the energy of the impacting mine pressure is absorbed. According to the method, on the premise that the roadwaysupporting and protecting layer is effectively protected, the energy of the impacting mine pressure can be effectively absorbed, the damage degree to a roadway by the impacting mine pressure is weakened, a great significance is achieved for preventing and treating the impacting mine pressure, repeated hole drilling is a simple and effective coal and rock mass cracking method, very wide application is achieved during roadway pressure relief, and very high practical value is achieved in coal mine.

Owner:CHINA UNIV OF MINING & TECH

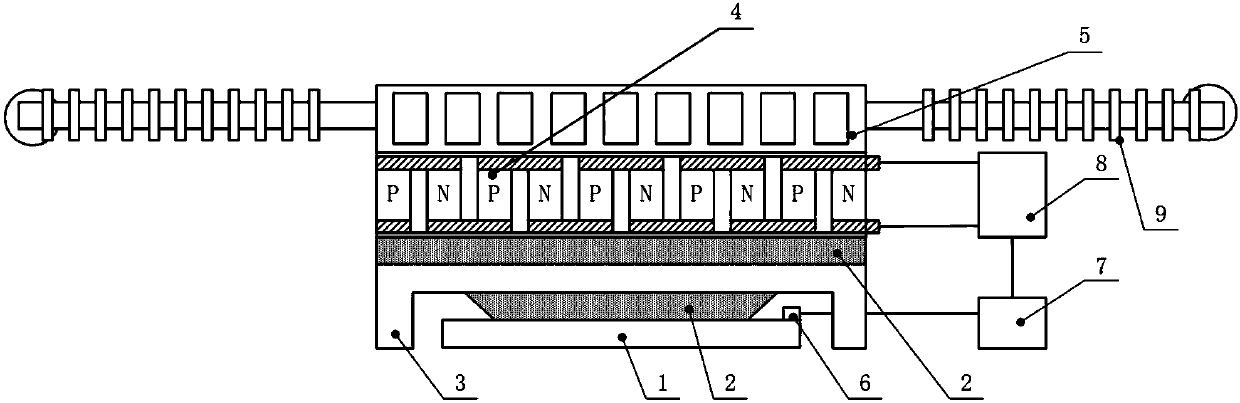

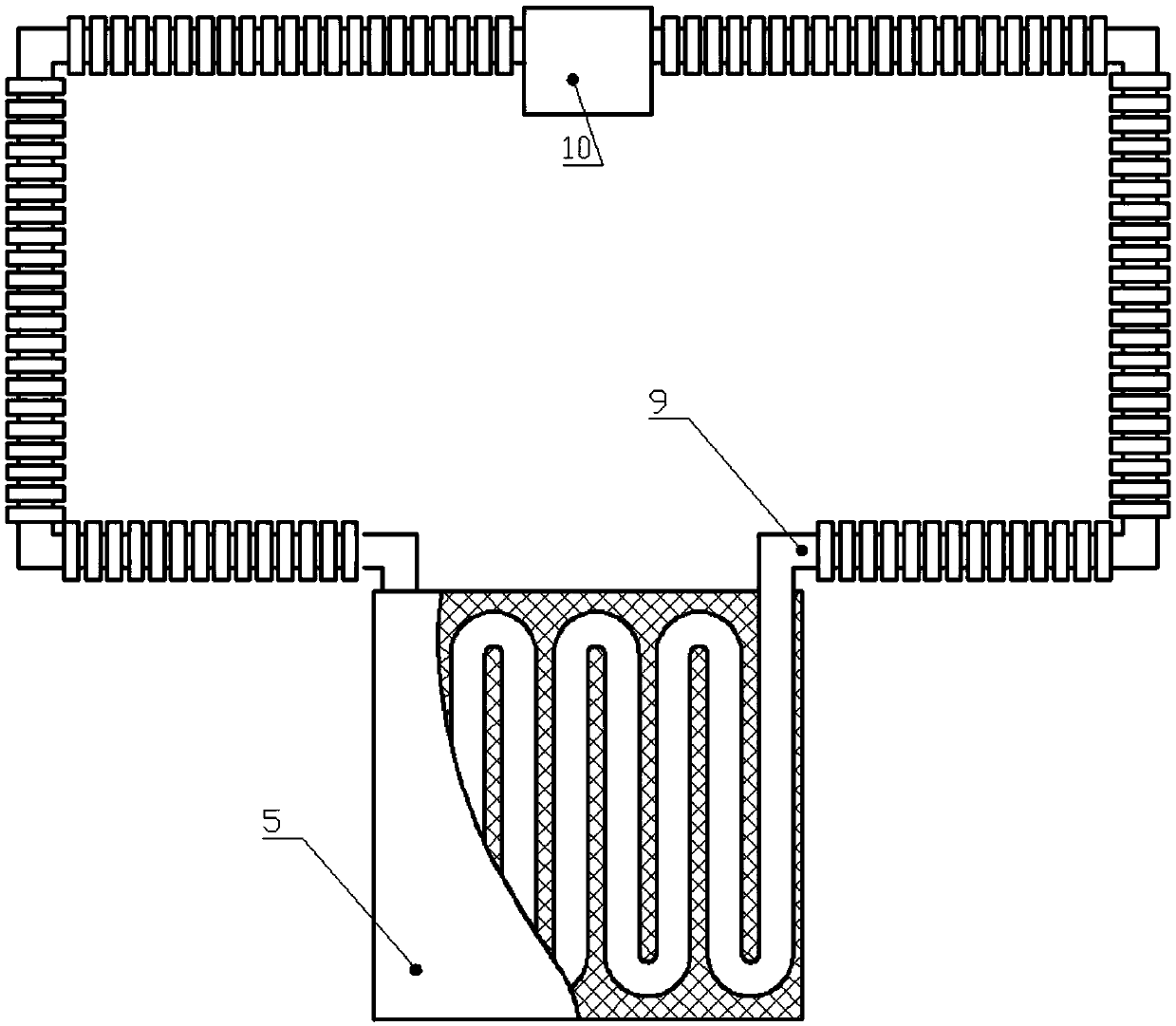

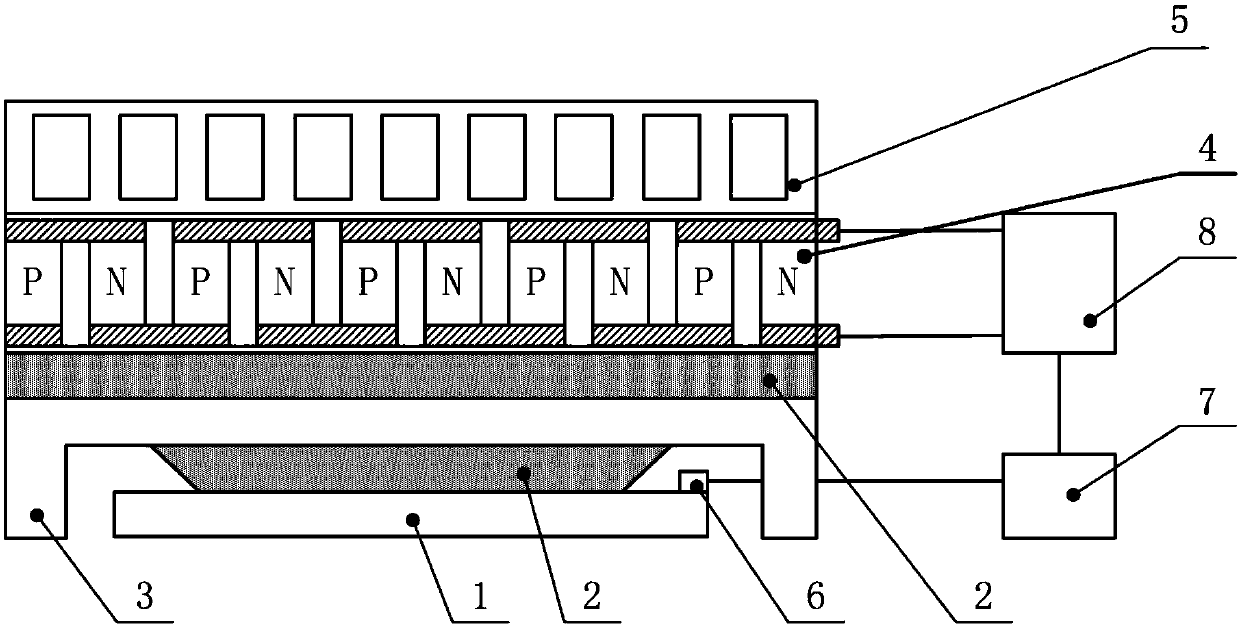

Chip cooling system

InactiveCN107678524ASmall thermal inertiaAbsorb in timeDigital data processing detailsMachines using electric/magnetic effectsHeat flowCooling effect

The invention relates to a chip cooling system comprising a semiconductor cooler used for actively exchanging heat in a transporting manner, and a chip radiator used for performing heat convection, wherein the semiconductor cooler is connected with a power supply; one side of the semiconductor cooler is a heating end while the other side is a cooling end, the heating end can be fit with a chip tobe cooled, and the cooling end is fit with the chip radiator; a superfine channel is arranged in the chip radiator, the chip radiator is connected with a circulating pipe with a power device to form acirculating loop, and cooling liquid is filled in the circulating loop. According to the system provided by the invention, the semiconductor cooler and the chip radiator are combined to form a two-stage heat exchange system, the semiconductor cooler provides relatively large heat dissipation heat-flow density through actively transporting heat energy, heat on the chip can be absorbed in time, andthe chip radiator dissipates heat to the external environment via the circulating pipe; the system is heat in heat dissipation efficiency, low in cost, free of noise, controllable in cooling capacityand good in cooling effect.

Owner:XI AN JIAOTONG UNIV

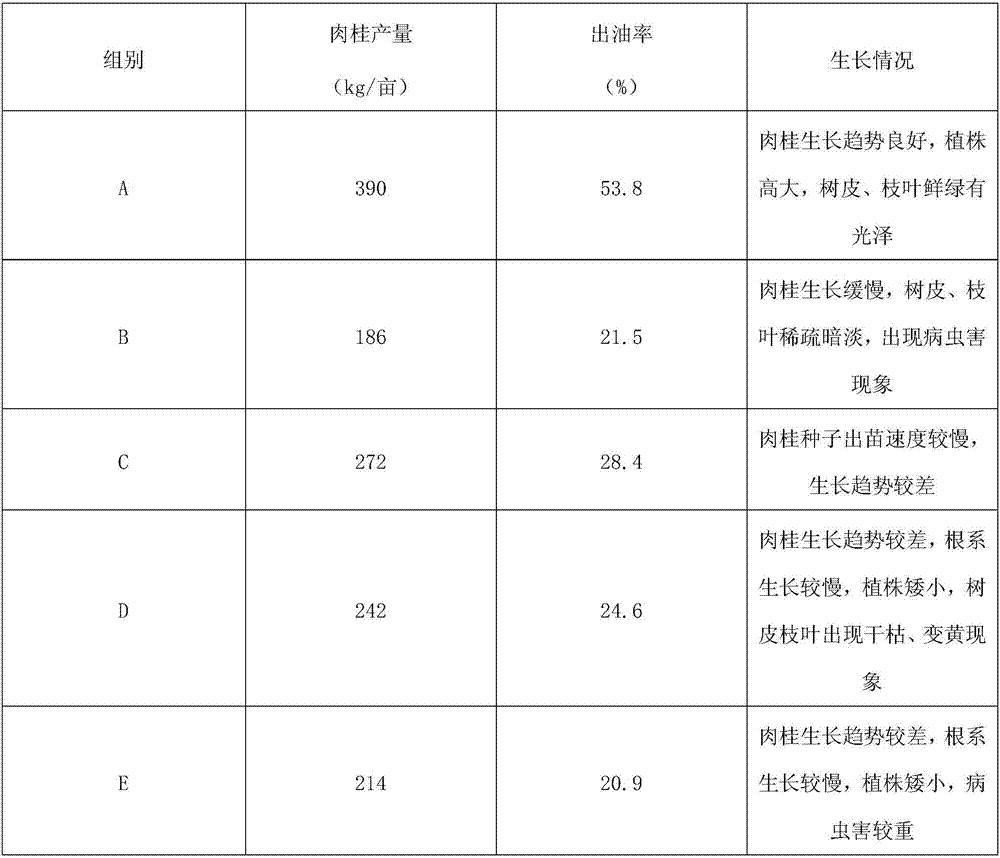

High-yield cultivation method for cinnamons

InactiveCN106922462AIncrease vitalityRapid emergenceBiocideSeed and root treatmentHabitNutrient content

The invention discloses a high-yield cultivation method for cinnamons, pertaining to the technical field of cinnamon cultivation. The high-yield cultivation method comprises the following steps: deeply studying growth habits of cinnamons; and controlling water and fertilizers reasonably of cinnamons in different growth periods. Therefore, the high-yield cultivation method for cinnamons is obtained. The high-yield cultivation method for cinnamons has the following beneficial effects: requirements for different nutrient compositions of cinnamons in different growth periods are satisfied, thereby making fertilizers more effective; compared with the prior art, the yield of cinnamons is greatly increased; the oil extraction rate of cinnamons is higher; economic value of cinnamons is improved; and the high-yield cultivation method is suitable for promotion and application in the field.

Owner:陆川县君丰现代农业有限公司

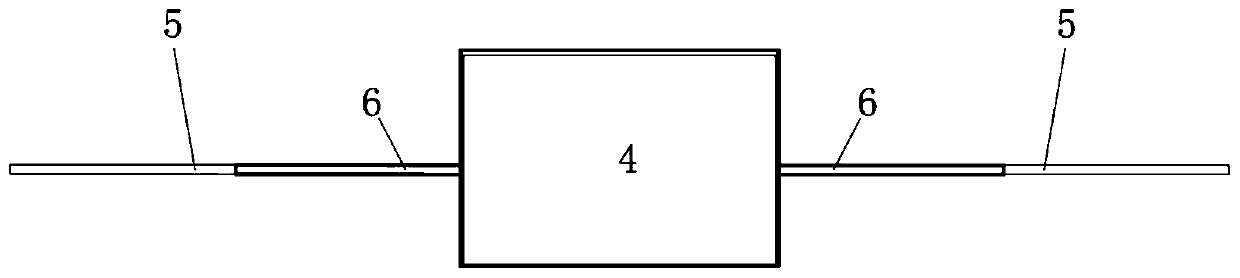

PBT (polybutylene terephthalate) fiber production technology

InactiveCN105088383AHigh purityLittle flexibilityMelt spinning methodsMonocomponent polyesters artificial filament1,4-ButanediolPolyethylene terephthalate

The invention discloses a PBT (polybutylene terephthalate) fiber production technology comprising steps as follows: 1) high-purity terephthalic acid and 1,4-butanediol are placed in a dryer to be dried at the temperature of 120-150 DEG C for 2-3 h, and the purity of the terephthalic acid is 80%-90%; 2) the dried terephthalic acid and the dried 1,4-butanediol are weighed and placed in an esterification reactor, a catalyst and sodium sulfate are added, and an esterification reaction is performed at the temperature of 200-260 DEG C for 2-3 h; 3) a reaction product is placed in a polycondensation kettle, a polycondensation reaction is performed at the reaction temperature of 350-380 DEG C for 2-4 h through stirring under the vacuum condition, and PBT polyester is prepared; 4) the prepared PBT polyester is subjected to melt spinning by a screw type spinning machine, oiling, balancing, winding and drafting treatment are performed after cooling, and PBT fibers are obtained. The PBT fibers prepared with the technology are good in stability and elasticity, low in production cost and suitable for mass production.

Owner:TAICANG HONGYI CHEM FIBER

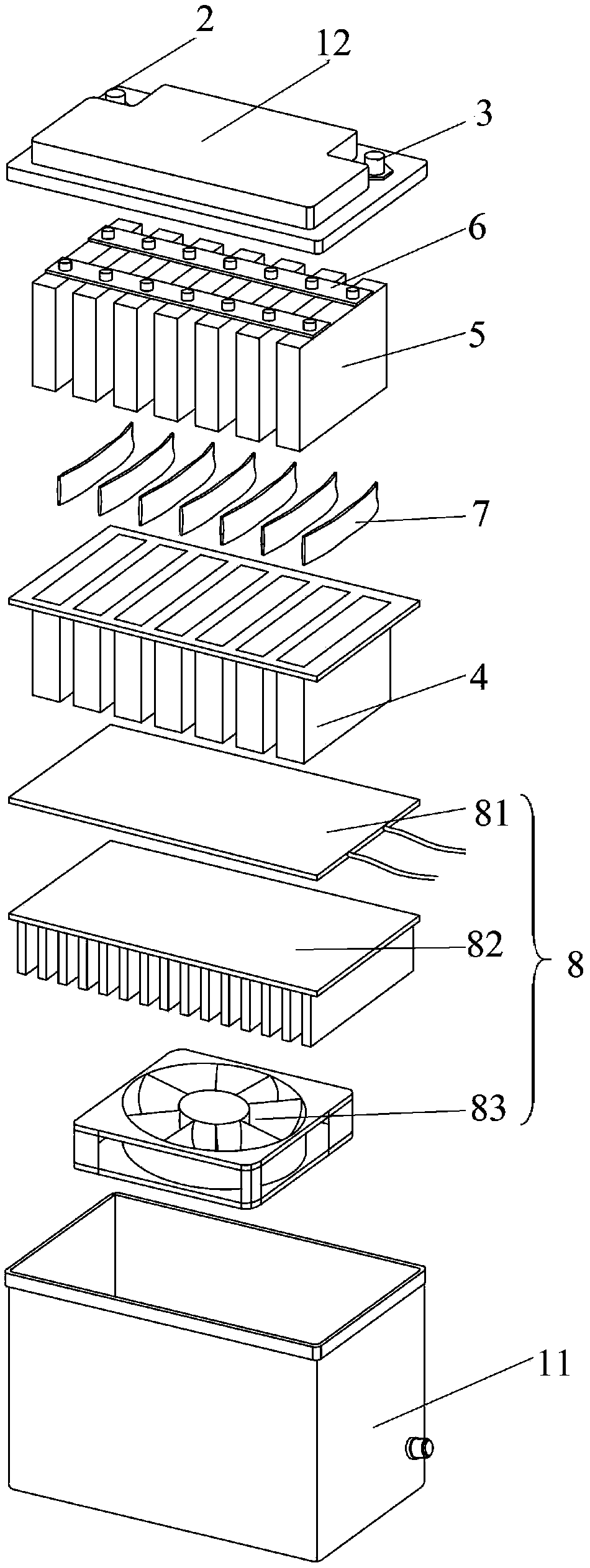

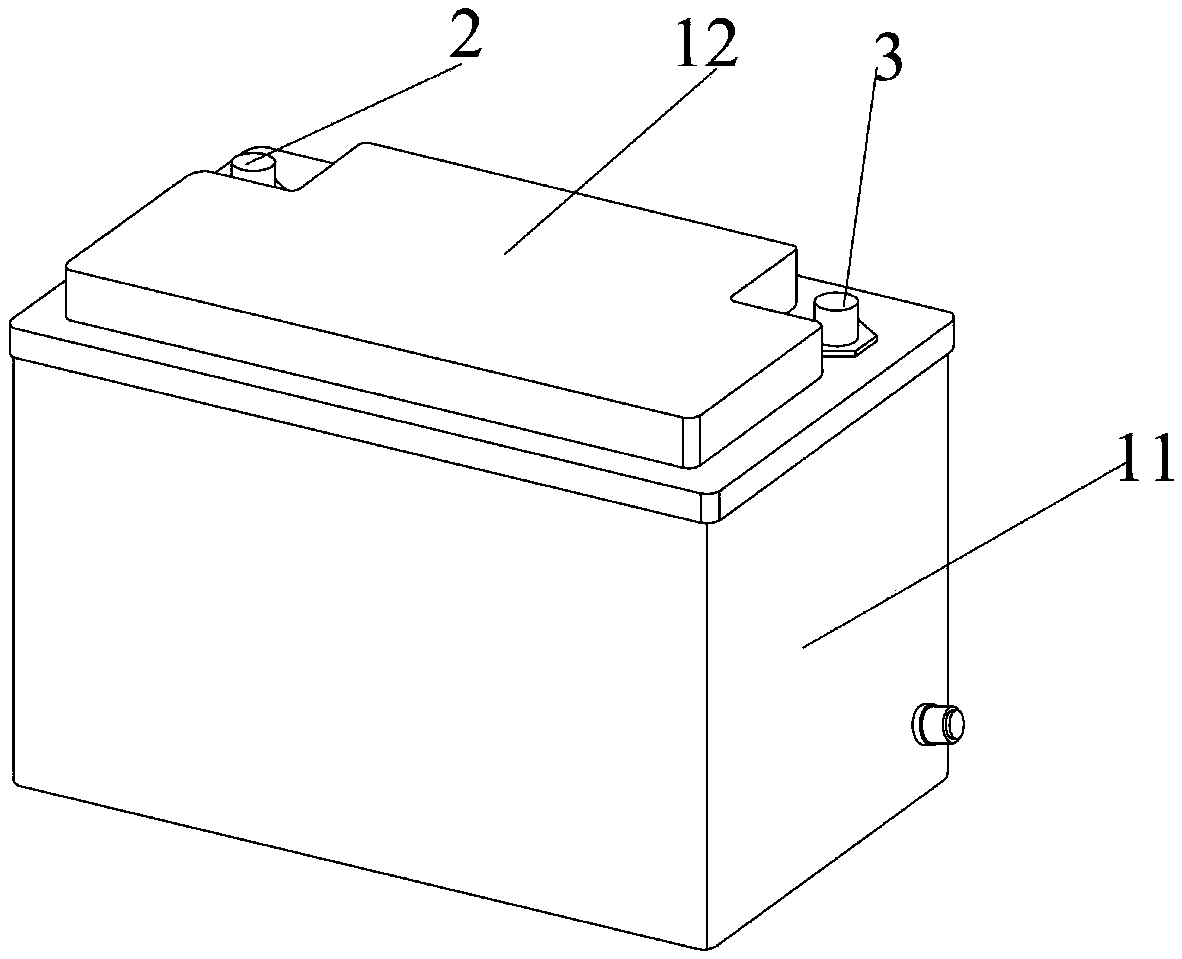

A lithium battery module

PendingCN109065774AProtection securityAvoid it happening againCurrent conducting connectionsSmall-sized cells cases/jacketsElectrical batteryMonomer

The invention discloses a lithium battery module, comprising: a module shell, a positive electrode column, a negative electrode column, a monomer shell, a battery monomer, a bus bar assembly, an automatic fire extinguishing device and an automatic cooling device, wherein, the root of the positive electrode column or the negative electrode column is provided with a flexible fuse electrode; The single housing is provided with a plurality of, and laminated on the inside of the module housing; The monomer shell is composed of non-conductive insulating material. The battery cell is fixedly installed inside the battery cell; The automatic fire extinguishing device is arranged inside the single shell; The automatic cooling device is arranged at the bottom end of the module housing. The lithium battery module provided by the invention is provided with a power-off protection device, which can automatically cut off the power supply connection when a short circuit occurs inside or outside the battery; An automatic fire extinguishing device is arranged, and the fire extinguishing device is automatically turned on when a fire occurs, so that the disaster situation can be effectively controlled;It is equipped with automatic cooling device to control the temperature of the battery module in the proper range, and the safety factor is very high.

Owner:深圳市诚思品科技有限公司

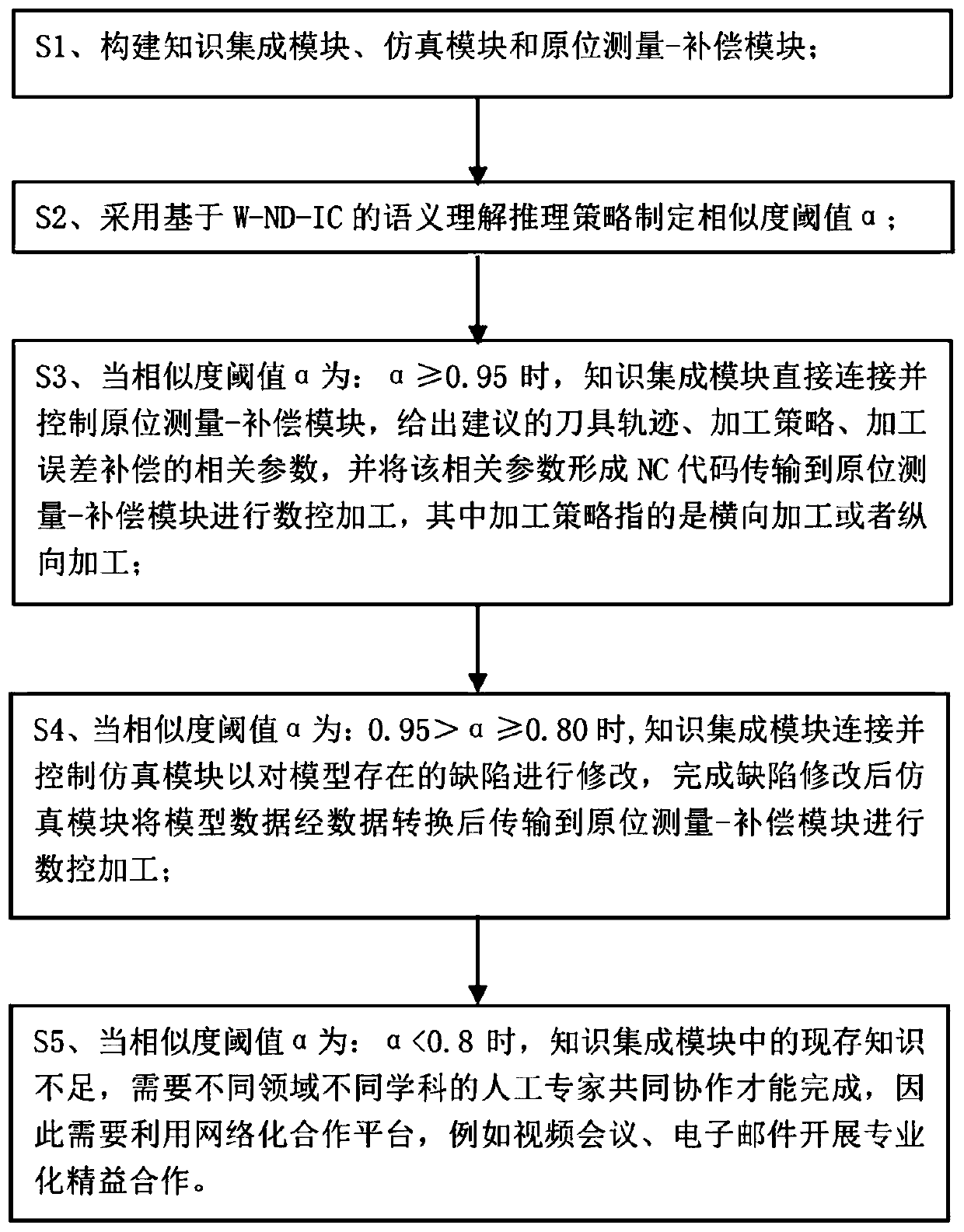

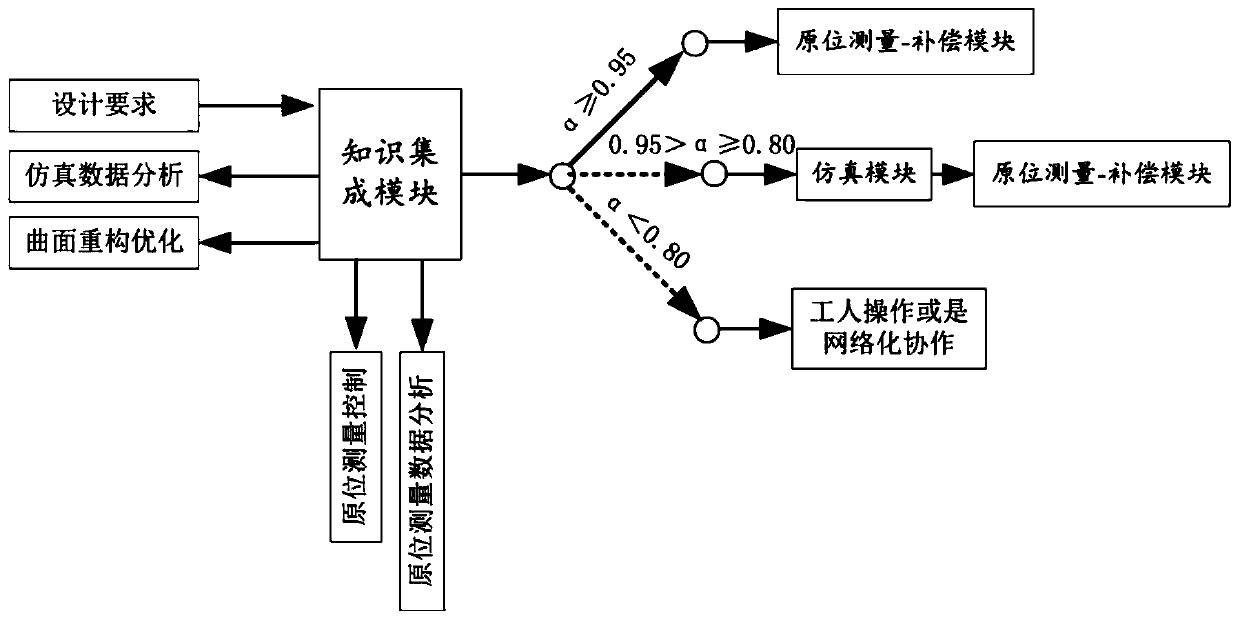

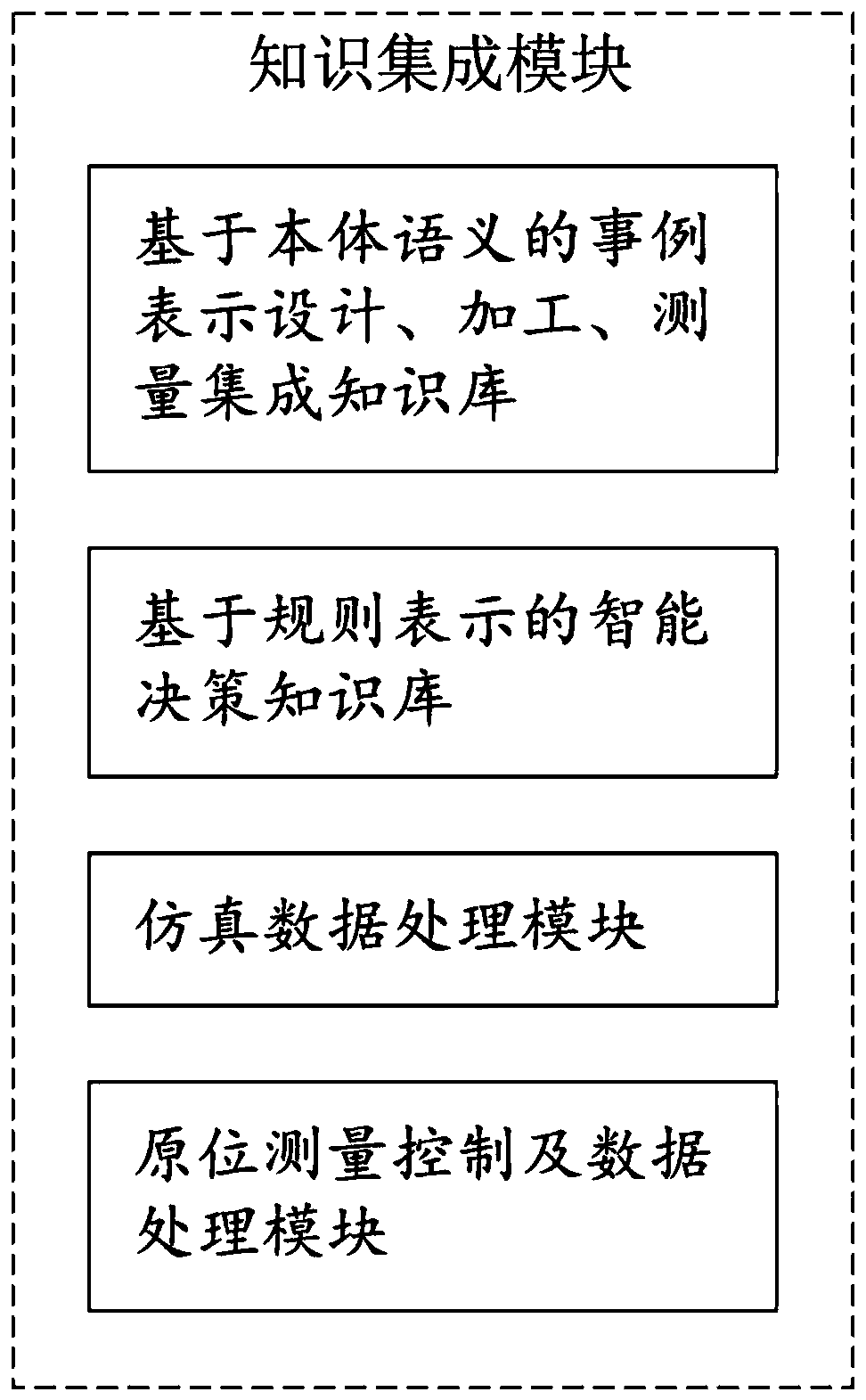

Knowledge expression model-based complex curved surface digital manufacturing method

ActiveCN110244657AAbsorb in timeEasy maintenanceProgramme controlComputer controlNumerical controlClosed loop

The invention discloses a knowledge expression model-based complex curved surface digital manufacturing method, and the method comprises the following steps that S1, a knowledge integration module, a simulation module and an in-situ measurement-compensation module are constructed; S2, a similarity threshold alpha is established by adopting a semantic understanding reasoning strategy based on W ND IC; S3, when alpha is more than or equal to 0.95, the knowledge integration module is directly connected with and controls the in-situ measurement-compensation module; S4, when alpha is more than or equal to 0.80 and less than 0.95, the knowledge integration module is connected with and controls the simulation module to modify the defects existing in the model, after the defect modification is finished, the simulation module transmits the model data to the in-situ measurement-compensation module after data conversion, and the in-situ measurement-compensation module carries out numerical control machining; and S5, when alpha is less than 0.8, the cooperation of human experts is required to complete the process; and the knowledge expression model-based complex curved surface digital manufacturing method establishes an integrated knowledge expression model in three fields of through design, processing, simulation optimization and measurement, and based on this, a knowledge base and an inference mechanism are constructed, and the knowledge expression model-based complex curved surface digital manufacturing method provides theoretical and technical support for intelligent closed-loop manufacturing of the complex curved surface part.

Owner:HEFEI UNIV

Absorbable orthopedic instrument material capable of prompting growth of bone tissues and preparation method thereof

InactiveCN103721297AFilm thickness is easy to controlPromote tissue growthAnodisationSurgeryMicro arc oxidationPolarization density

The invention discloses an absorbable orthopedic instrument material capable of prompting growth of bone tissues and a preparation method thereof. The material is prepared by compounding a medical absorbable high-molecular polymer, a degradable pure magnesium or magnesium alloy which is loaded with BaTiO3 piezoelectric ceramics, can conduct piezoelectric signals and serves as a conductive carrier material, and grapheme for improving the electric polarization effect. When the absorbable orthopedic instrument material is in use, an electric signal produced by the piezoelectric ceramics under the action of an external load can be effectively conducted to organism tissues around an orthopedic instrument by the conductive carrier material to stimulate the growth of early hard tissues at a bone injury position and promote healing of the bone tissues. The BaTiO3 piezoelectric ceramics is loaded on the conductive carrier material through a dual loading technology consisting of electrophoresis-micro-arc oxidation and sol sealing, coating and film forming. Meanwhile, the conductive carrier material and the grapheme can also enhance the polarization effect and stress sensitivity of the piezoelectric ceramics. A bar material or a plate material is prepared firstly by means of a thermal die pressing, extruding or pulling method, and the orthopedic instrument is made by means of polarization and machining.

Owner:SOUTHEAST UNIV

Expandable biodegradable polymeric stents for combined mechanical support and pharmacological or radiation therapy

InactiveUS20070129793A1Avoid residual stressAbsorb in timeStentsBlood vesselsAngioplasty balloonRadiation therapy

An expandable biodegradable polymeric stent is fabricated with biodegradable polymer fibers (Poly-L-lactic acid, PLLA) in a coil shape that is constructed with both central and external or internal peripheral lobes. It is delivered and expanded using a conventional angioplasty balloon system. The disclosed stent can serve as a temporary scaffold for coronary vessels after PTCA or for peripheral endovascular stenting, or it can provide mechanical palliation for strictures of ductile organs (trachea, esophagus, bile and pancreatic ducts, ureter etc.). The disclosed stent also serves as a unique device for specific local drug delivery. Therapeutic agents (chemical compounds, protein enzyme and DNA sequences) and cells can be loaded into the stent and gradually released to target tissues. Local radiation therapy can also be delivered by a specially adapted stent.

Owner:TEXAS STENT TECH

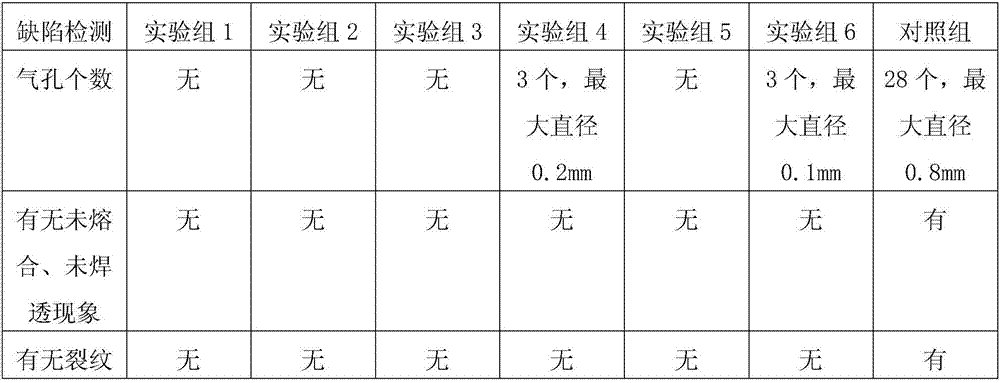

Method for welding molybdenum alloy

ActiveCN106862732AInhibition of sensitization tendencySmall mechanical propertiesArc welding apparatusWelding/cutting media/materialsActive agentDirect current

The invention discloses a method for welding molybdenum alloy, belonging to the technical field of metal welding. The method comprises the steps: (1) after cleaning, drying the welding area of molybdenum alloy; (2) manufacturing a special welding wire for the molybdenum alloy; (3) degassing at high temperature; (4) taking out a molybdenum alloy workpiece, spraying an active agent until the thickness is 0.2-0.8mm on the he welding area of molybdenum alloy, heating the special welding wire for the molybdenum alloy to dry, and then welding the molybdenum alloy workpiece, wherein the welding method adopts TIG wire filling welding, adopts a direct-current straight polarity power supply and determines welding process parameters; (5) cooling; (6) inspection. The method can reduce the quantity of joint holes, improve weldability, reduce cracks, refine parent crystalline grains so as to improve the tensile property of welded joints, and obtain good welding quality.

Owner:宝鸡市蕴杰金属制品有限公司

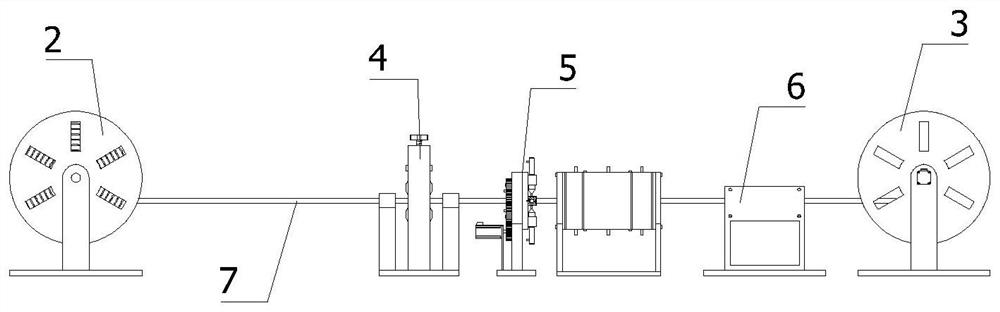

Intelligent cable spraying production line

ActiveCN113578631ASpray evenlyIntegrated work to achieve absorptionSpray boothsStructural engineeringAir knife

The invention relates to the field of cable spraying, in particular to an intelligent cable spraying production line. The intelligent cable spraying production line comprises a conveying device, a spraying device and a drying device; the conveying device comprises a feeding frame, a rolling frame, and a roller conveying mechanism; the spraying device comprises a comprehensive paint spraying procedure and a smooth paint removing procedure; the smooth paint removing procedure comprises a bottom frame, a conical air suction bin, an annular air knife and a closed sleeve; the comprehensive paint spraying procedure is provided with a plurality of spraying guns used for spraying cables; a plurality of air inlets are formed in the annular air knife; and a plurality of air outlets are formed in the conical air suction bin and the closed sleeve. Preliminary spraying of the surface of a cable is achieved, sprayed paint on the surface of the cable is further modified through the annular air knife, the surface of the sprayed paint of the cable is smooth, even spraying of the cable is guaranteed, paint gas on the cable is absorbed through the closed sleeve and the conical air suction bin, and environmental pollution is avoided.

Owner:芜湖挺优机电技术有限公司

Method for applying farming fertilizer liquid to fruit trees

InactiveCN102084748APromote growthMeet the nutritional requirements for growth and developmentFertilising methodsFruit treeSoil fertility

The invention provides a method for applying farming fertilizer liquid to fruit trees, which comprises the following steps of: 1, digging a pool capable of containing 6-8 cm<3> of water along the line among lines of every 80-120 cm<2> of trees in an apple tree garden, laying plastic cloth at the bottom of the pool and dropping water for fermenting the farming fertilizer liquid; 2, when the temperature is low, making a plastic supporting shed for raising the temperature; 3, pricking around 2 / 3 main trunk of a crown projection; and 4, regulating the pH value of the fermented farming fertilizer liquid to be between 6.0 and 7.0, and pouring into holes with a bucket or mud pump. The method for applying the farming fertilizer liquid ensures that the fertility and the soil fertility of the fruit garden are increased and the fruit garden becomes a mellow-soil field in further, therefore, the capacity of preserving the fertilizer and water by the fruit garden is greatly improved.

Owner:李光明

Method for forming roadway anti-impact weak structure layer by fracturing coal rock mass through coal rock pulse controllable strong waves

InactiveCN111350503AReduce manufacturing costReduce threatMining devicesDisloding machinesMining engineeringMechanical engineering

The invention discloses a method for forming a roadway anti-impact weak structure layer by fracturing a coal rock mass through coal rock pulse controllable strong waves, and is suitable for the technical field of coal mine underground roadway tunneling and mining safety. A drilling machine is used for drilling a hole in a designated position, water is injected into the drilled hole, high-voltage electric pulse equipment is placed at the designated position, the drilled hole is sealed and fractured, the roadway anti-impact weak structure layer is formed, and energy released by impact mine pressure is absorbed. A steel pipe can protect the high-voltage electric pulse equipment from being smoothly taken out of the drilled hole, and meanwhile the drilled hole is protected from damaging a roadway supporting layer. On the premise that the roadway supporting layer is effectively protected, the energy of the impact mine pressure is effectively absorbed, so that the damage degree of the impactmine pressure to a roadway is weakened, the method has important significance for prevention and treatment of the impact mine pressure, and the pulse controllable strong waves are used for fracturingthe coal body to achieve safety, novelty and practicability of the weak structure layer. The method has wide practicability in the technical field.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com