Method for performing coal and rock repeated hole drilling to form roadway scouring weakening preventing structure

A weak structure and roadway technology, which is applied in earth drilling, ground mining, underground mining, etc., can solve problems such as failure to eliminate rock burst disasters, achieve safe and effective prevention of rock burst, and realize simple and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

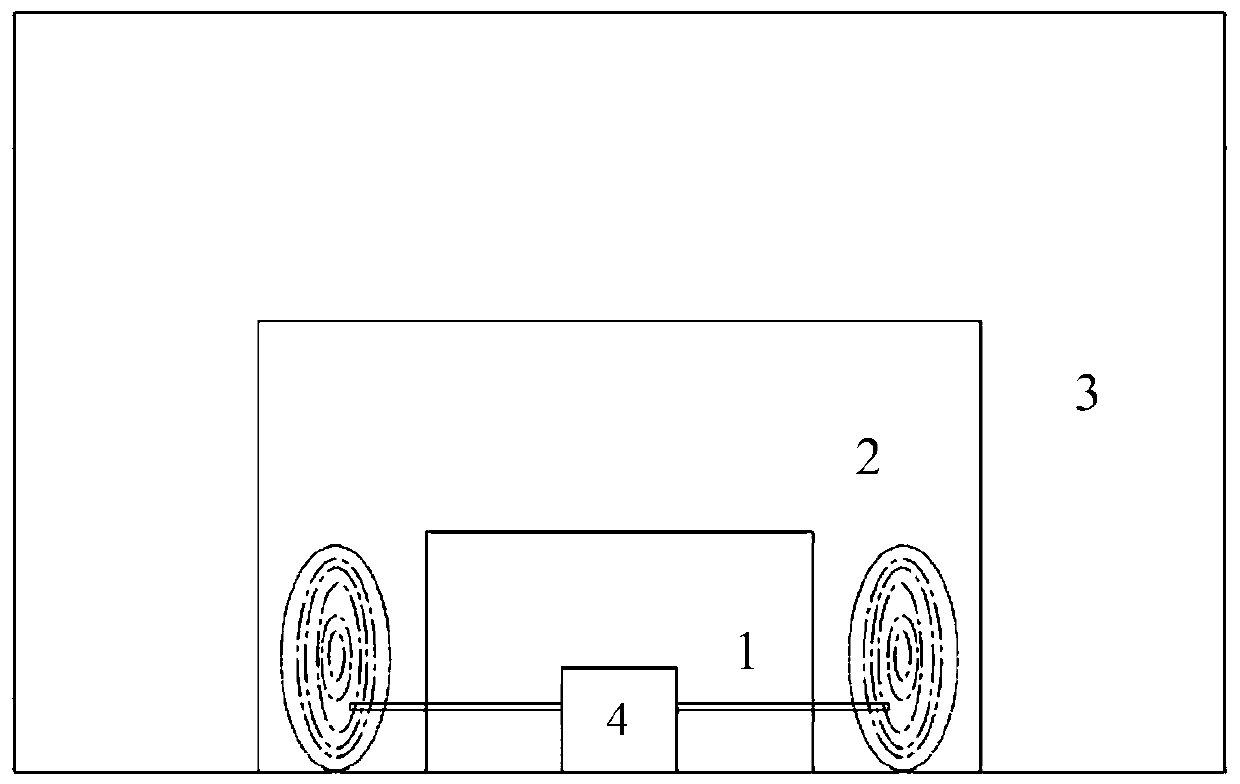

[0025] A method for repeatedly drilling coal rocks of the present invention to form a roadway anti-scour weak structure, the specific steps are as follows:

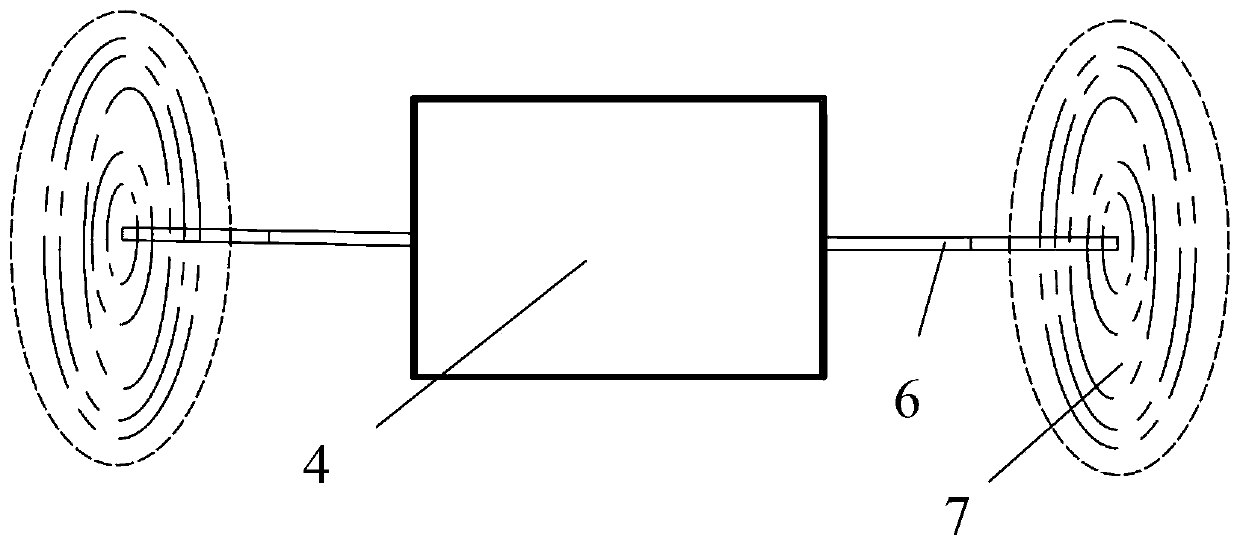

[0026] a. During the process of constructing the roadway 4 along the excavation face 10, Figure 4 As shown, the arrow represents the direction of roadway excavation. Utilize the drilling rig to drill several pressure relief holes 5 at the designated positions of the coal rock mass respectively on the left and right sides of the roadway 4. The designated positions of the coal rock mass are determined according to the coal rock properties and the mine pressure observation records. The 5 positions are symmetrical; the interval between the orifices of the several pressure relief holes 5 is 0.8-3m; the several pressure relief holes 5 are driven into two sides of the vertical roadway; the drilling diameter of the several pressure relief holes 5 is 90-130mm, The hole depth is not less than 20m.

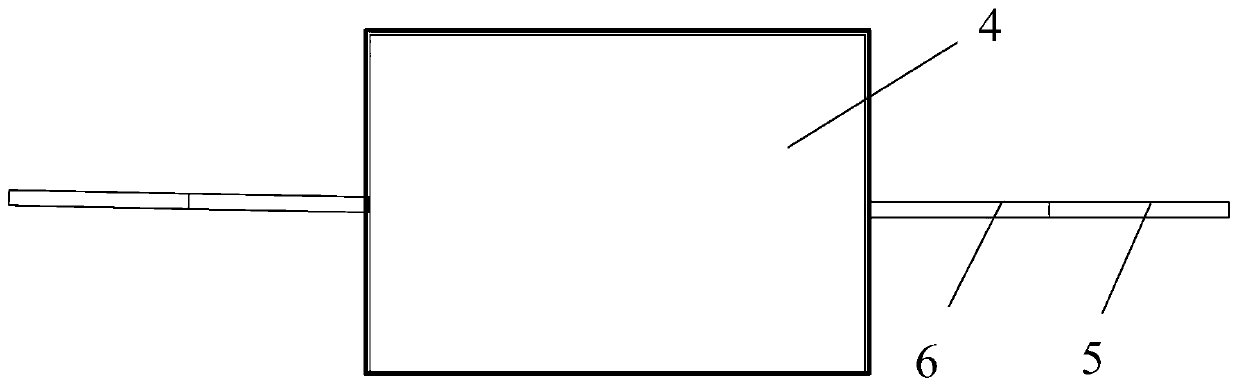

[0027] b. Put steel pipes 6 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com