Chip cooling system

A cooling system and chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of limited cooling and heat dissipation capacity of heat pipes, affecting the use and life of computers, and poor air-cooling heat dissipation efficiency, achieving good heat conduction effect and cost. Low, high heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in combination with specific drawings and implementation examples.

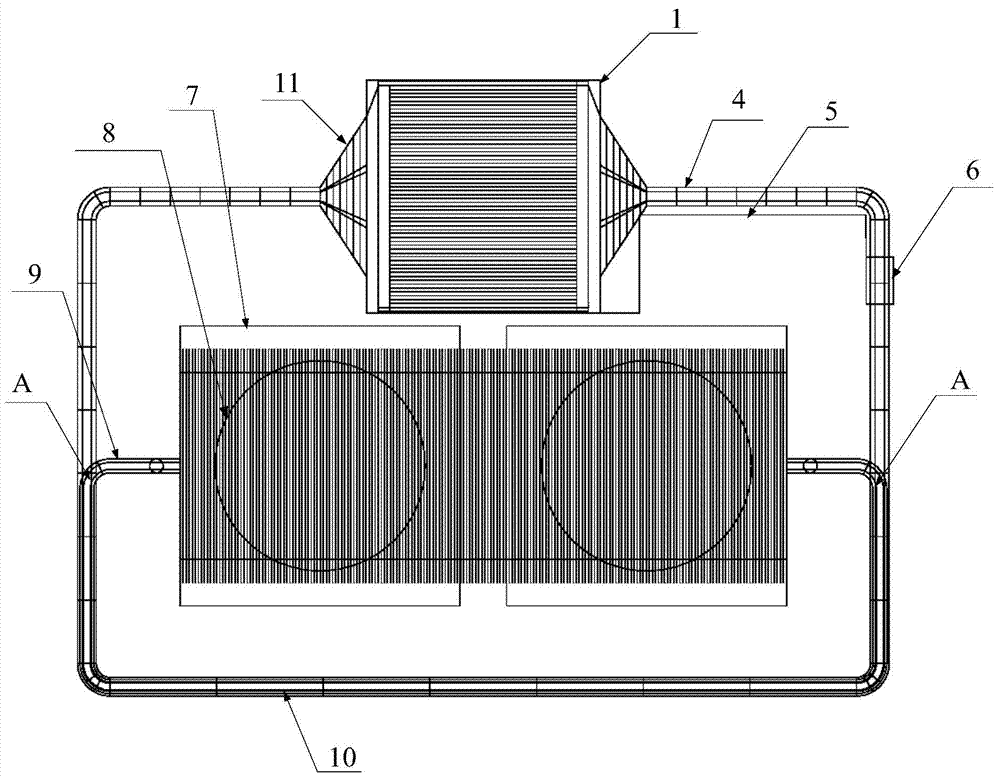

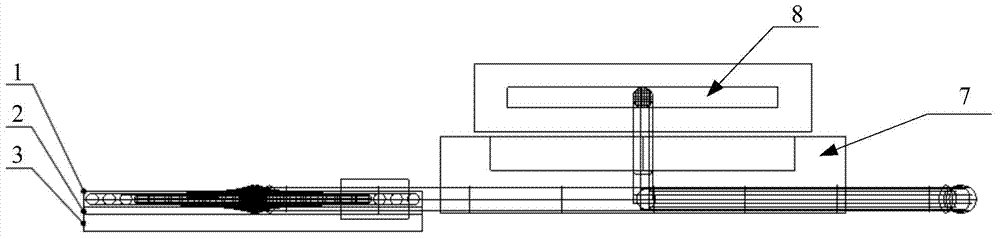

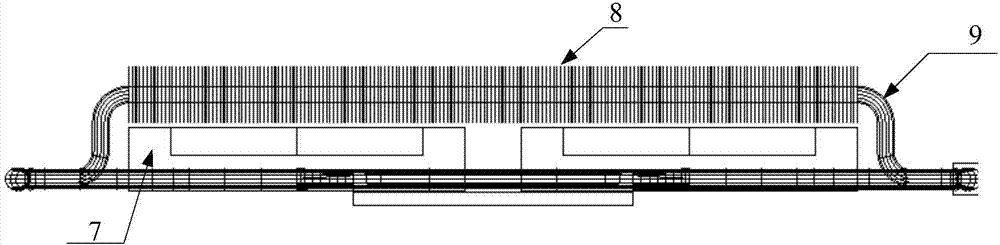

[0034] Such as Figure 1 to Figure 3 As shown: the present invention includes a chip heat conduction plate 1 and an annular heat pipe 9. Several fine channels are arranged side by side on the chip heat conduction plate 1, and the fine channels are connected to a circulation pipe 4 at the same time to form a circulation loop, wherein the circulation pipe 4 is connected with the micro The connecting part of the channel expands to form a pipeline expansion section 11, and the circulation loop is filled with liquid I. Liquid I is a liquid metal, specifically a gallium indium tin alloy, the freezing point is below 10 degrees Celsius, and the chemical properties are stable at room temperature, non-toxic and harmless. High thermal conductivity; a pump is provided on the circulating pipeline 4, and the pump adopts a metal electromagnetic pump 6, and the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com