Air convection crushing device with preliminary crushing function

A technology of preliminary crushing and air convection, used in cleaning methods and utensils, removing smoke and dust, grain processing, etc., can solve problems such as reduced service life, damage to machinery and equipment, fire, etc., to improve service life, improve production efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

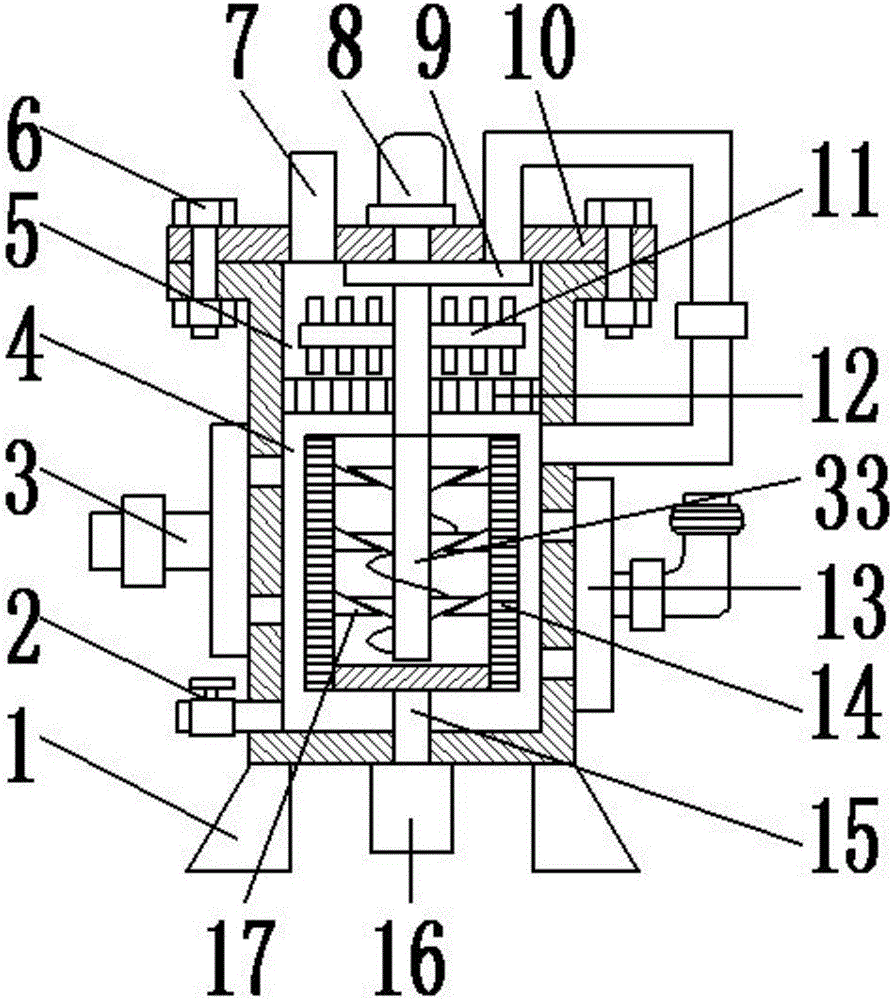

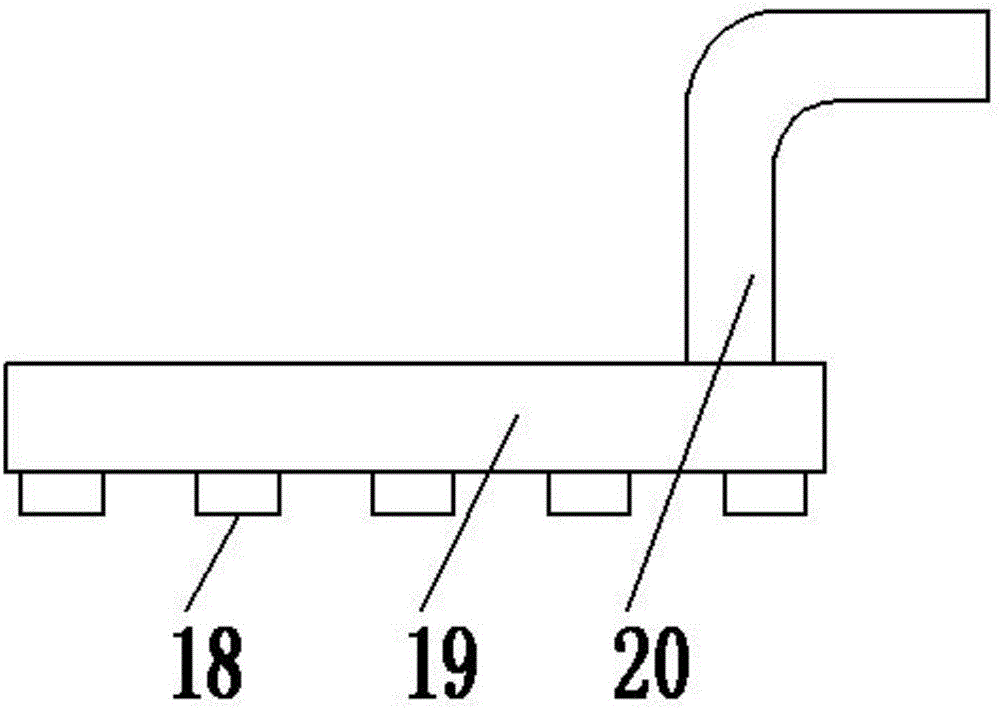

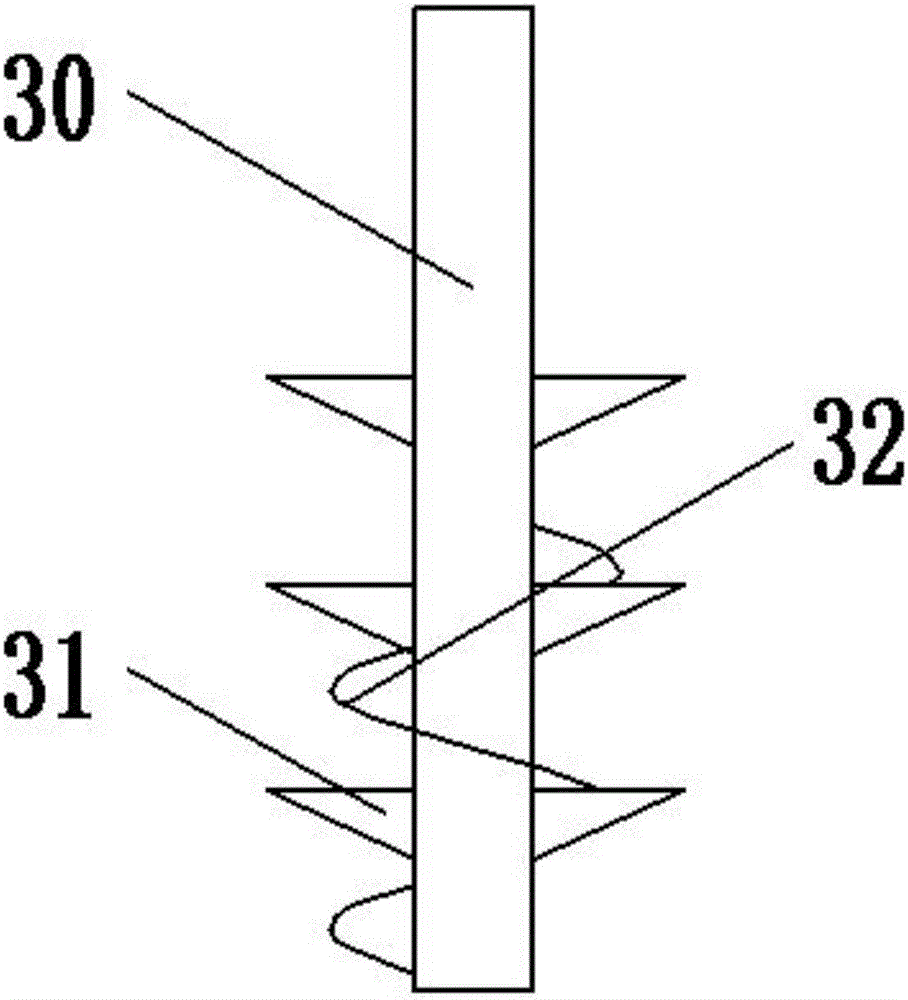

[0018] see Figure 1-5 , a kind of air convection crushing equipment with preliminary crushing function, comprising a base 1; the top of the base 1 is provided with a crushing box 4, which is used to make the device, ensures the stability of the device, and is convenient for the staff to dispose of the device. Installation of the device; the interior of the crushing box 4 is provided with a material placement rack 14 and a crushing device 33 for crushing the material; the right side of the crushing box 4 is provided with a gas input device 13, and the left side is provided with a gas extraction device 3 and discharge pipe 2; the top of the crushing box 4 is provided with a filter plate 12; the left and right ends of the filter plate 12 are fixedly connected to the left and right inner walls of the crushing box 4; the top of the filter plate 12 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com