Processing method for improving rosin product quality

A processing method and product quality technology, applied in the field of rosin processing, can solve the problems of long time, affecting the quality of rosin, and not being able to process in large quantities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

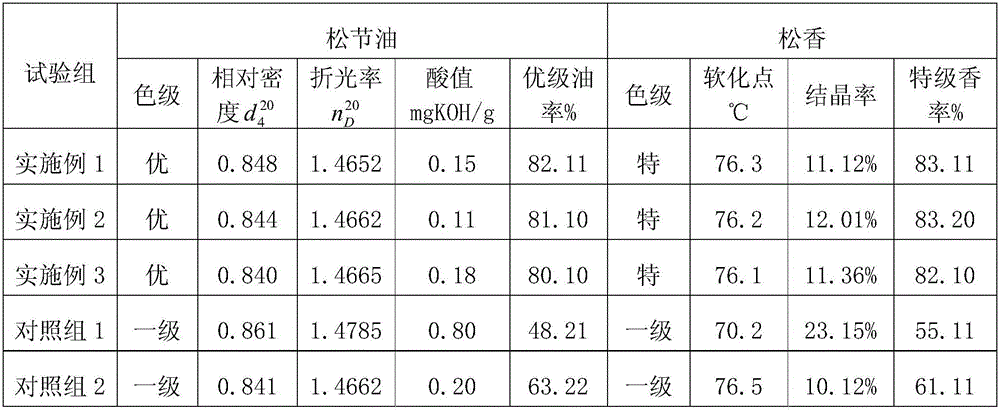

Embodiment 1

[0027] Take water treatment agent according to the weight ratio of water: superoxide: sodium dithionate: reduced iron powder: sodium chloride=85:3:5:4:3, add superoxide to tap water or industrial water after leaving standstill 2h, Continue to add sodium thionite powder to the water and let it stand for 30 minutes, then add reduced iron powder and sodium chloride powder in turn, let it stand for 22 hours, and extract the supernatant as hypoxic sterile water for later use.

[0028] The raw material rosin is stored and transported with hypoxic sterile water, after the turpentine is crushed, the rosin is soaked and washed with hypoxic sterile water. The weight percentage of the components is: 20% hypoxic sterile water, 20% medium oil, 1‰ oxalic acid, and the balance is turpentine; the dissolved fat liquid is steam-pressed into the high-level tank, cooled in the high-level tank, and ultrasonically washed , After preliminary clarification, enter the clarification pot for further cla...

Embodiment 2

[0030] Weigh the water treatment agent according to the weight ratio of water: superoxide: sodium dithionite: reduced iron powder: sodium chloride = 95:1:1:2:1, add superoxide to tap water or industrial water and let it stand for 2.5 hours , continue to add sodium thionite powder to the water and let it stand for 40 minutes, then add reduced iron powder and sodium chloride powder in turn, let it stand for 23 hours, and extract the supernatant as hypoxic sterile water for later use.

[0031] The raw material rosin is stored and transported with hypoxic sterile water, after the turpentine is crushed, the rosin is soaked and washed with hypoxic sterile water. The weight percentage of the components is: 30% hypoxic sterile water, 30% medium oil, 3‰ oxalic acid, and the balance is turpentine; the dissolved fat liquid is steam-pressed into the high-level tank, cooled in the high-level tank, and ultrasonically washed , After preliminary clarification, enter the clarification pot for ...

Embodiment 3

[0033] According to water: superoxide agent: sodium dithionite: reduced iron powder: sodium chloride=90:2:3:3:2 weight ratio takes water treatment agent, adds superoxide agent to tap water or industrial water after leaving standstill 3h, Continue to add sodium thionite powder to the water and let it stand for 60 minutes, then add reduced iron powder and sodium chloride powder in turn, let it stand for 24 hours, and extract the supernatant as hypoxic sterile water for later use.

[0034]The raw material rosin is stored and transported with hypoxic sterile water, after the turpentine is crushed, the rosin is soaked and washed with hypoxic sterile water. The weight percentage of the components is: 25% hypoxic sterile water, 25% medium oil, 2‰ oxalic acid, and the balance is turpentine; the dissolved fat liquid is steam-pressed into the high-level tank, cooled in the high-level tank, and ultrasonically washed , After preliminary clarification, enter the clarification pot for furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com