Patents

Literature

87results about "Turpentine spirits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

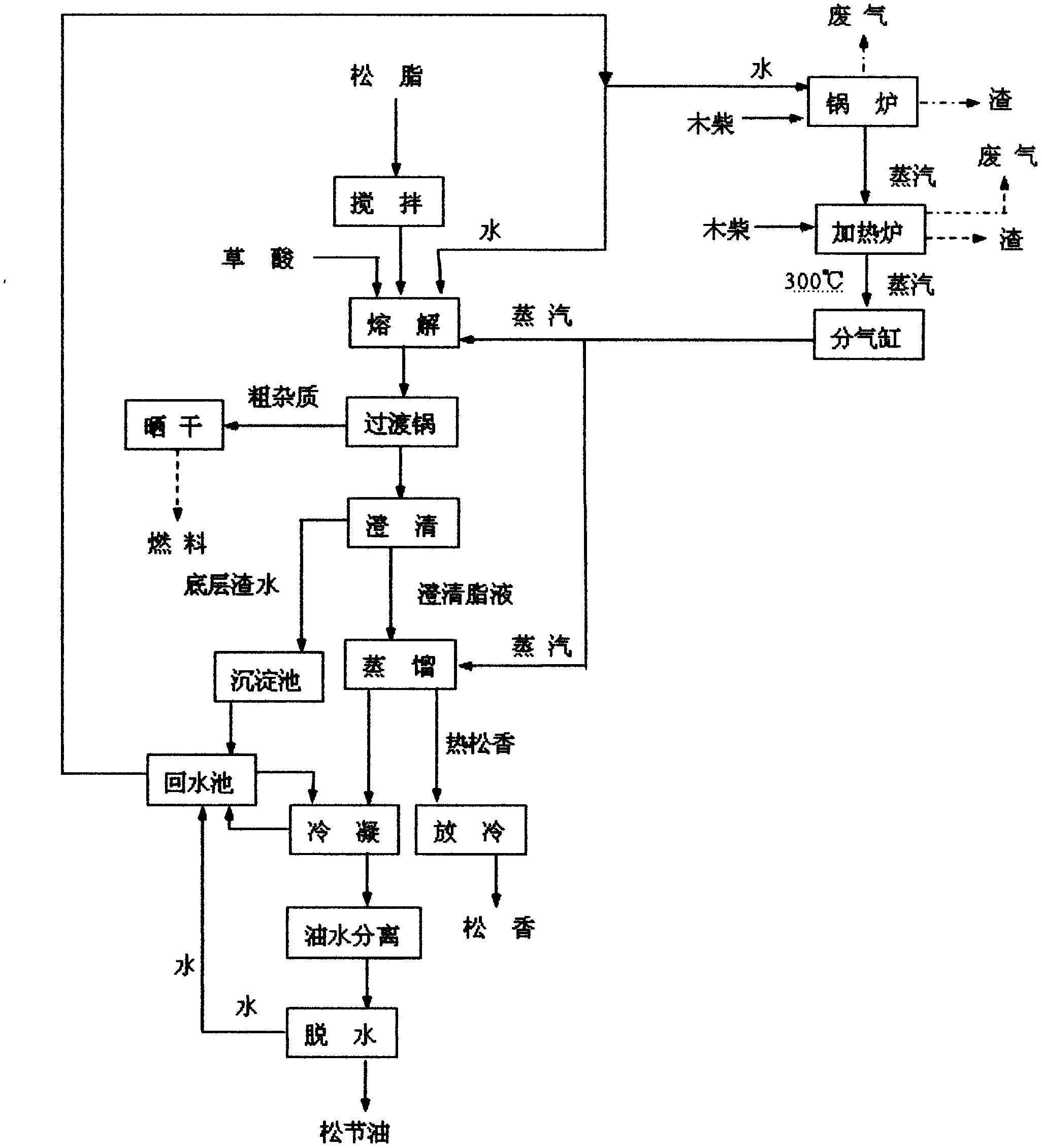

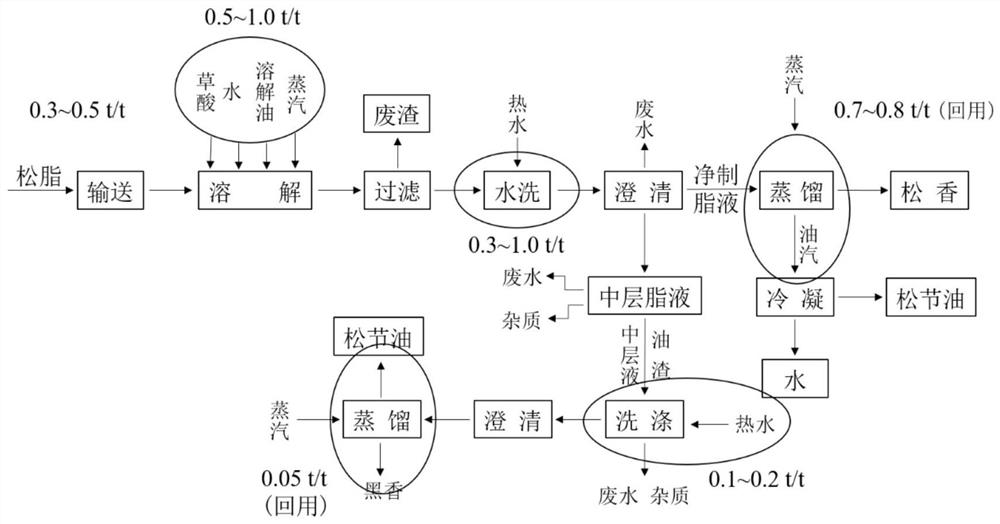

Rosin production technology process

InactiveCN104342034AImprove melting abilityThere will be no meltingChemical industryTurpentine spiritsSteam pressureTurpentine

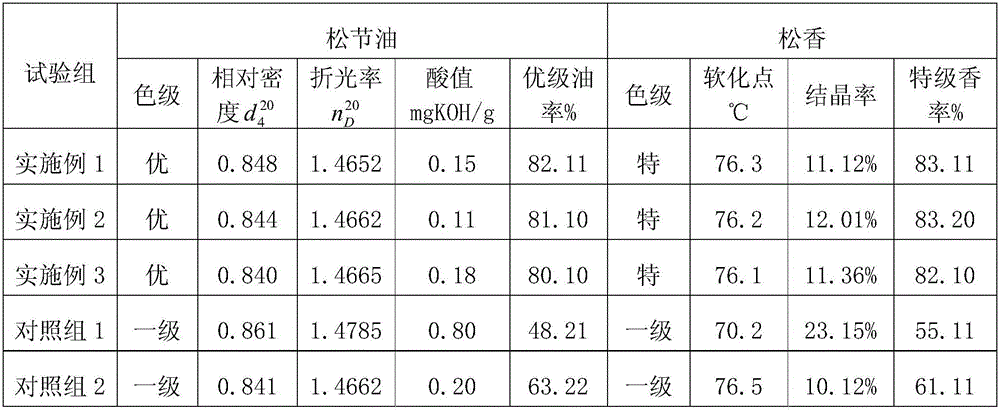

The invention discloses a rosin production technology process. The process comprises the following steps: conveying turpentine to a melting boiler, adding water, turpentine oil, and oxalic acid, wherein the weight ratio of turpentine to water to turpentine oil is 2-4:1-2:1, and the oxalic acid accounts for 0.1 to 0.3% of the turpentine weight; heating the boiler to melt the mixture in the boiler; transferring the melt mixture to a transition boiler; introducing the melt mixture into a clarifying boiler after precipitation in the transition boiler, then transferring the liquid to a steaming boiler to carry out steaming, wherein during the steaming process, water and turpentine oil are continuously steamed out from the liquid. The provided rosin production technology process has the following advantages: the turpentine is fully stirred before melting so as to grind the turpentine, thus the turpentine melting effect is improved, at the same time the phenomenon that some turpentine is not melted during the melting process is avoided, and thus the yield is increased; moreover, the metling is reduced, the energy consumption is reduced, and the rosin color will not turn darker; the condensed hot water can be directly applied to the boiler so as to reduce the temperature difference between the inlet water and outlet water, the boiler efficiency is improved, the steam pressure is more stable, and more energy is saved.

Owner:琼中森富松香加工厂有限公司

Method for producing rosin

ActiveCN102311705AQuality achievedReduce refluxTurpentine spiritsNatural resin purificationTurpentineRosin

The invention provides a method for producing rosin by turpentine, which comprises the following steps of melting, clarifying and distilling. The melted turpentine liquid is pressed in at least two higher-placed furnaces by vapor pressure in the melting process. The subsequent clarifying process is performed after the melted turpentine liquid is stayed in the higher-placed furnaces. The rosin product obtained by the method of the present invention can reach the grade of national superfine standard.

Owner:景东力奥林产集团林业化工有限公司

Heat-shrinkable polyester film

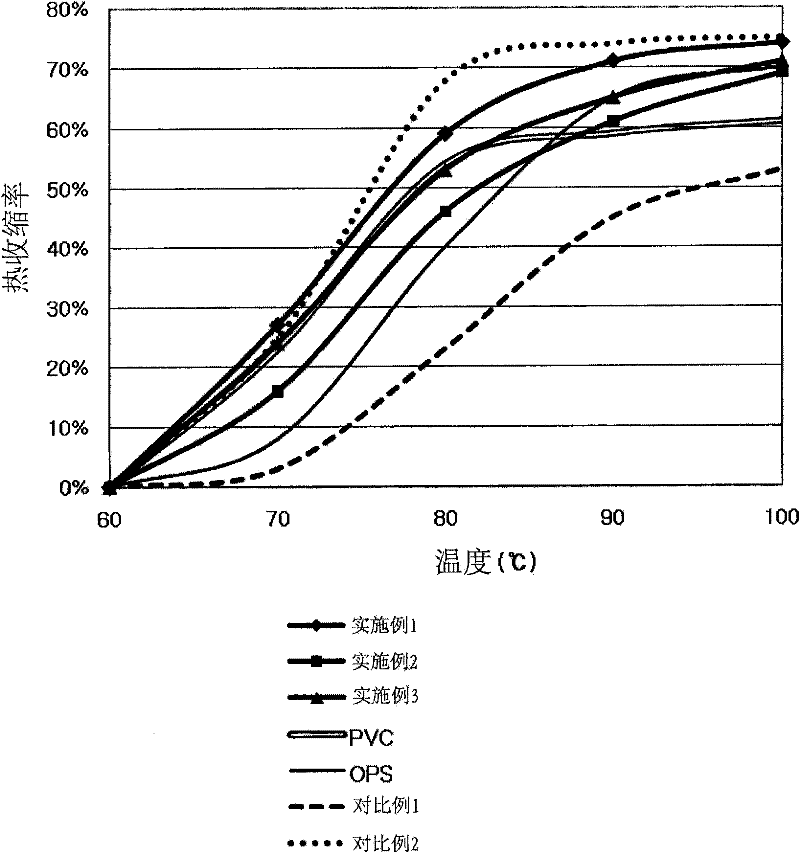

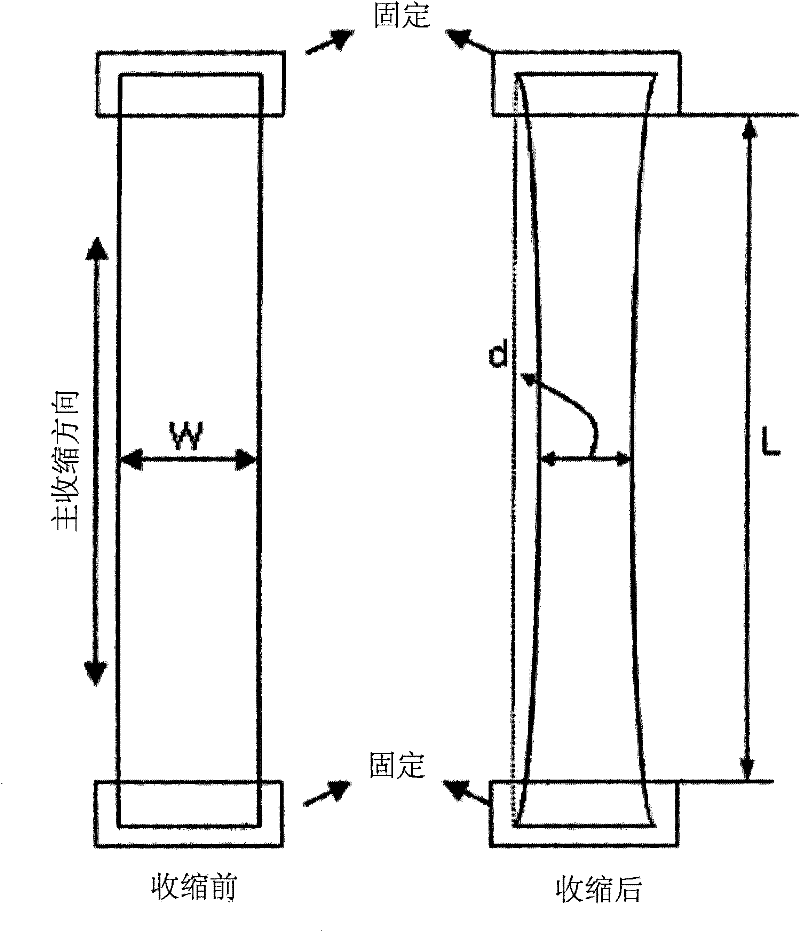

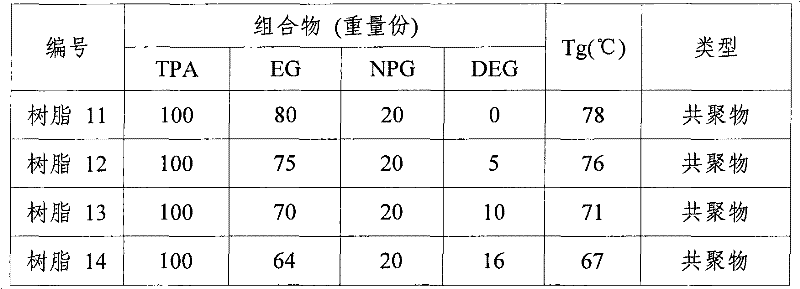

ActiveCN102190867AGood printabilityHigh mechanical strengthFlexible coversWrappersPolyesterDegree Celsius

A heat-shrinkable polyester film having a heat-shrinkage change per degree Celsius (% / DEG C.) along the main shrinkage direction of 1.5 to 3.0 in the range of 60 DEG C. to 70 DEG C., 2.5 to 3.5 in the range of 70 DEG C. to 80 DEG C., 1.0 to 2.0 in the range of 80 DEG C. to 90 DEG C., and 0.1 to 1.0 in the range of 90 DEG C. to 100 DEG C., has a good appearance quality after shrinkage and thus suitable for a wrapping material, particularly a label for a bottle.

Owner:AISIKAMEVO CO LTD

Processing method of pine resin

InactiveCN103087635AQuality improvementImprove solubilityTurpentine spiritsNatural resin purificationOxalatePine resin

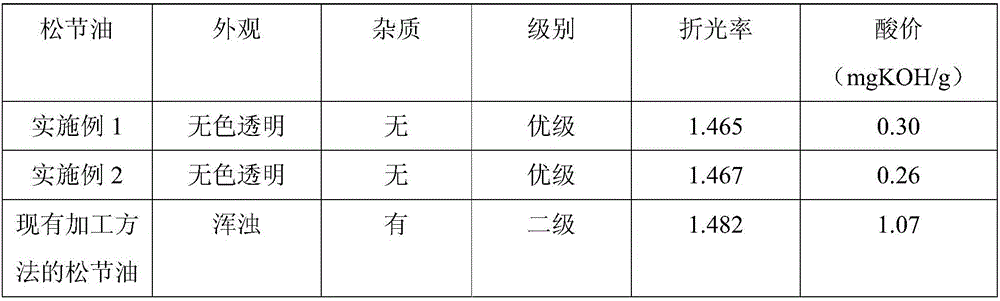

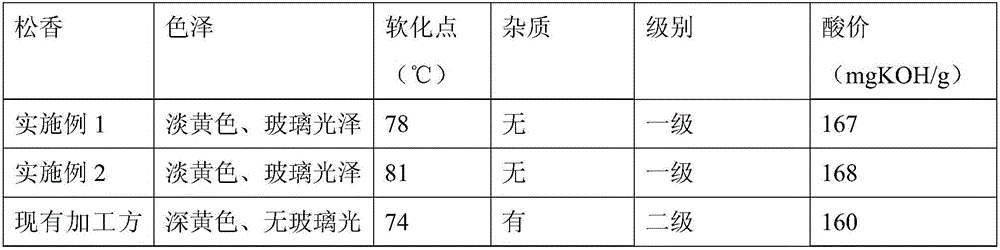

The invention relates to a processing method of pine resin and belongs to the field of rosin production. The processing method of pine resin comprises the following steps of: a, dissolving, namely dissolving the pine resin by adopting a dissolving solution, wherein the dissolving solution comprises the following components in percentage by weight: 55-82% of turpentine oil, 17.5-44.5% of water and 0.1-0.5% of oxalic acid; b, clarifying and colating, namely placing the dissolved pine resin liquid in a transition pot to be clarified and then colating to obtain colature; c, acid washing, namely adding the oxalic acid for washing; d, washing, namely adding hot water for washing; e, clarifying and carrying out refined filtration, namely placing the pine resin liquid into the transition pot to be clarified and then carrying out refined filtration; and f, heating and distilling, namely placing the pine resin liquid in a rectifying tower to be subjected to the heating and distilling, so that rosin and turpentine oil finished products are respectively obtained. The processing method of rosin provided by the invention has the beneficial effect that the qualities of the rosin and turpentine oil obtained by processing pine resin are excellent, so that demand of downstream industries is met.

Owner:云南茶花林化有限公司

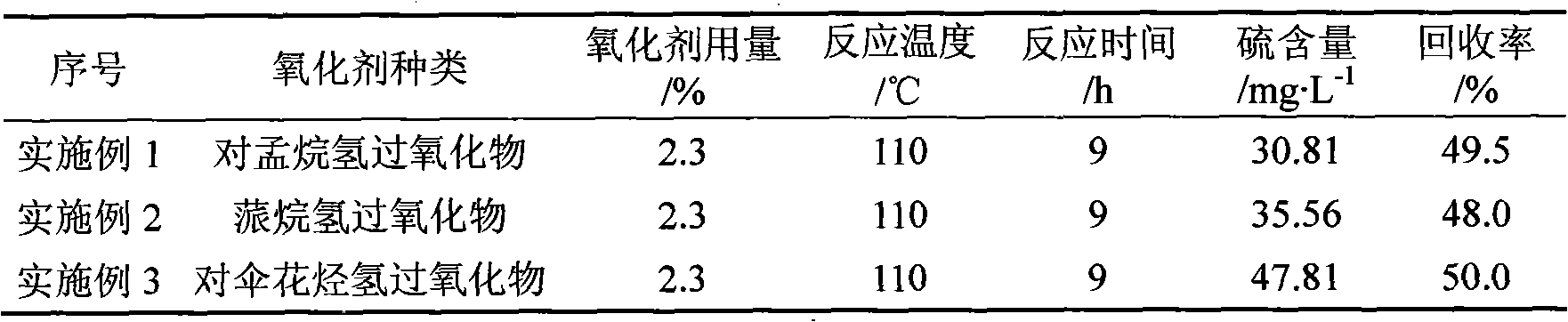

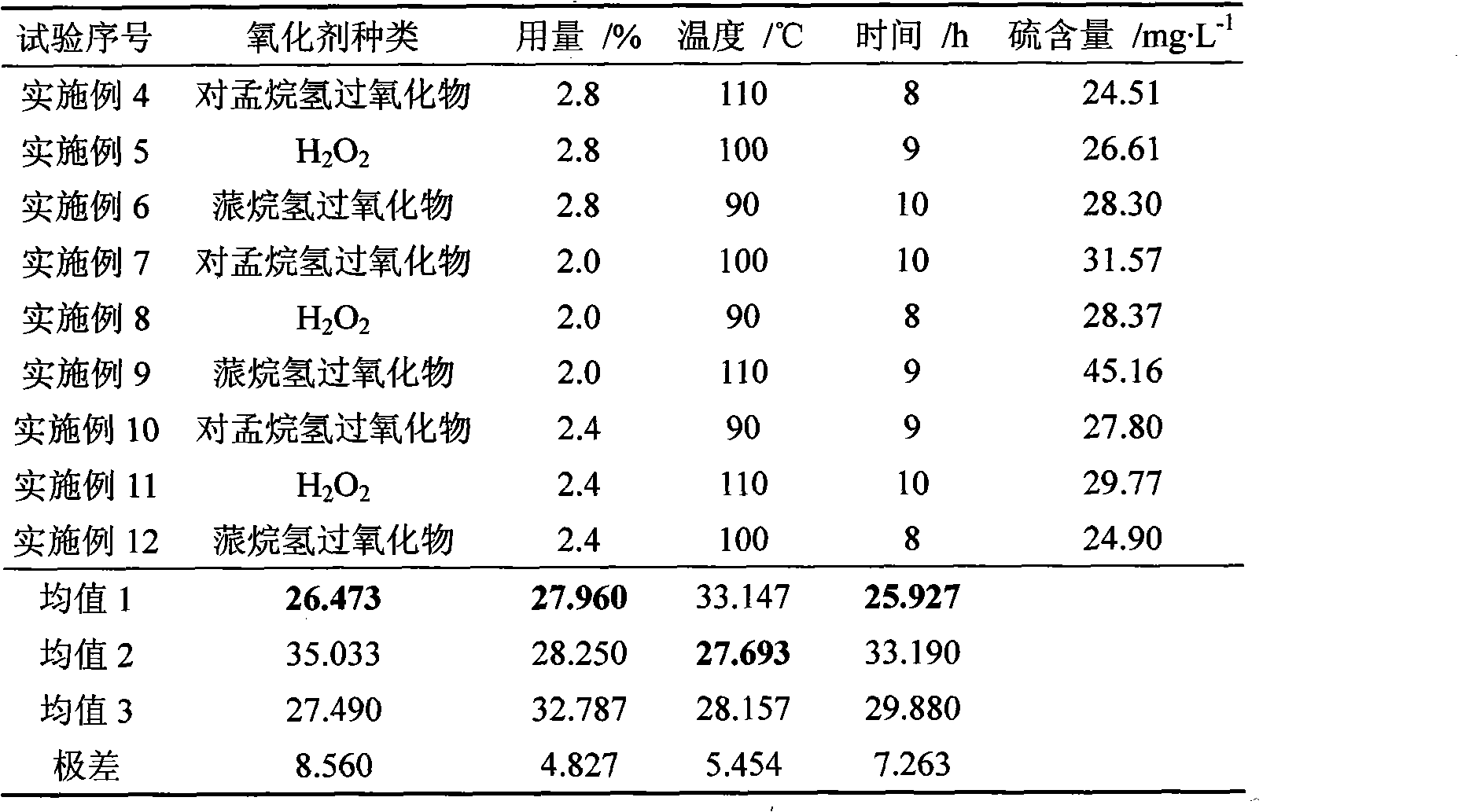

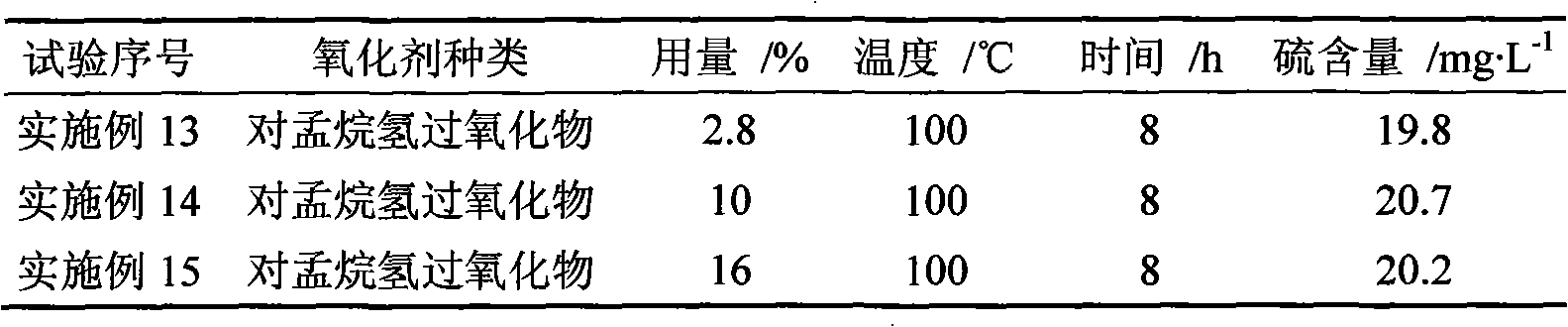

Refining method for desulphurizing and deodorizing crude sulphate turpentine

The invention relates to a refining method for desulphurizing and deodorizing crude sulphate turpentine. The method comprises the following steps: terpene hydroperoxide is taken as oxidation deodorizer, and is added into a reaction bulb with sulphate turpentine which contains sulfur and has putrid odor; the mixture is heated under 50-150 DEG C and is stirred to react for 4-20h; the quantity of oxidation deodorizer added in the reaction accounts for 1%-20% of that of raw material sulphate turpentine, which equals to 0.5-10 times that of theoretical quantity; distilled water is added for washingreaction liquid; water layer is removed by liquid division; organic horizoni is distilled by steam; distillats with different boiling points are segmently collected; and a computer sulfur-chlorine analyzer is utilized to measure the contents of sulfur in each distilled constituent, residue and raw materials, then nearly odorless and colourless refineing sulphate turpentine with the content of sulfur less than or equal to 20mg / l is obtained. The invention combines two processes mutually, namely oxidized desulfurization and deodorization and steam distillation, therefore, no pollutant is generated, and the generated by-product terpene alcohol compound is important spice and emulsifier.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

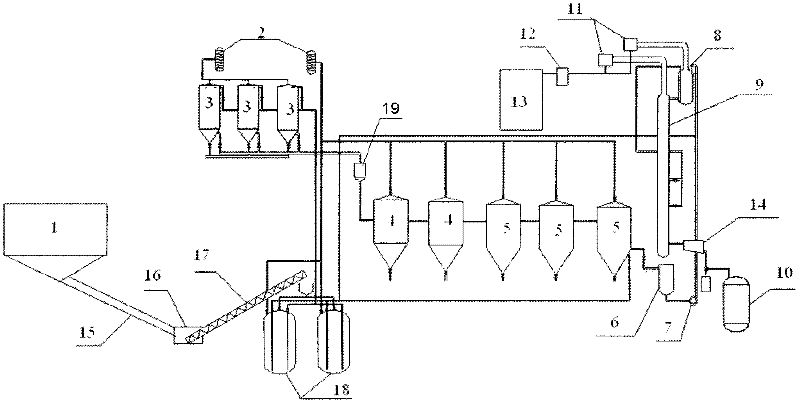

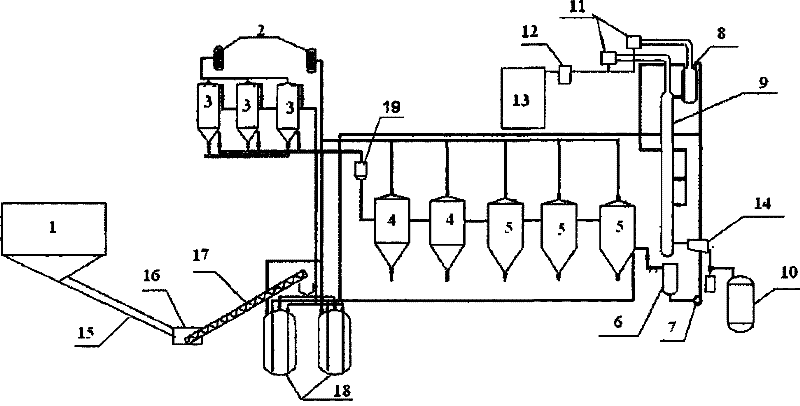

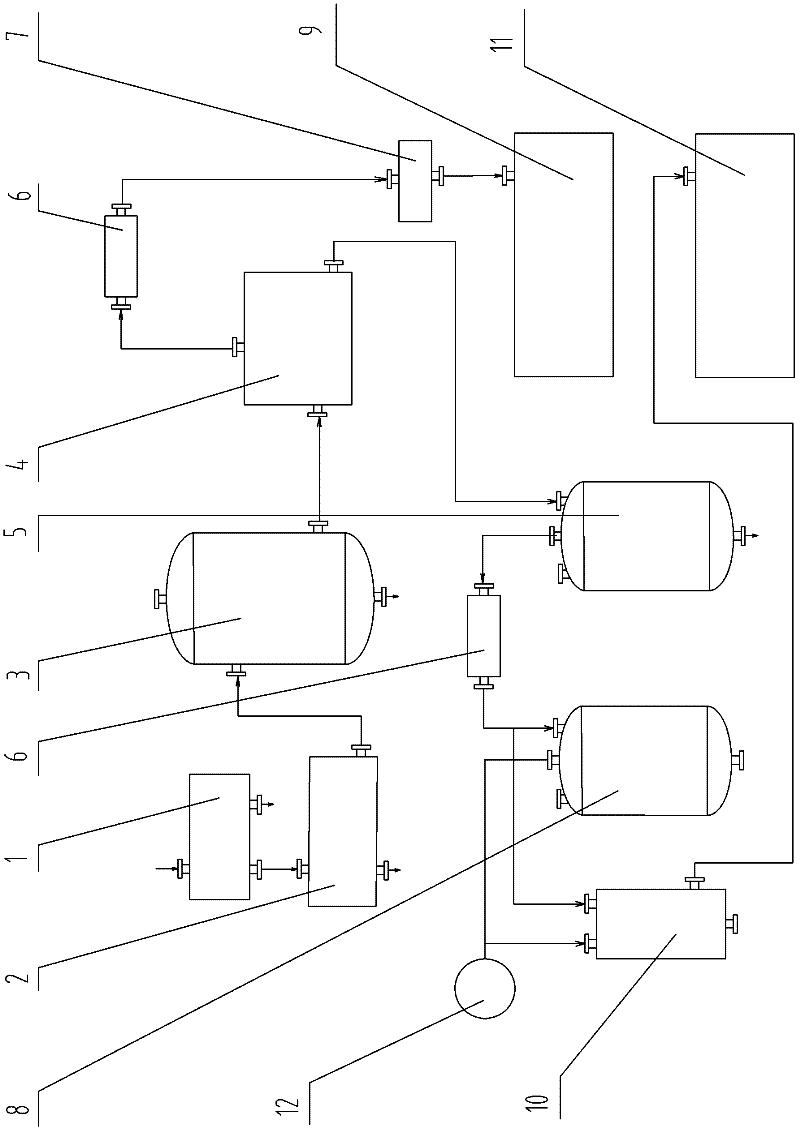

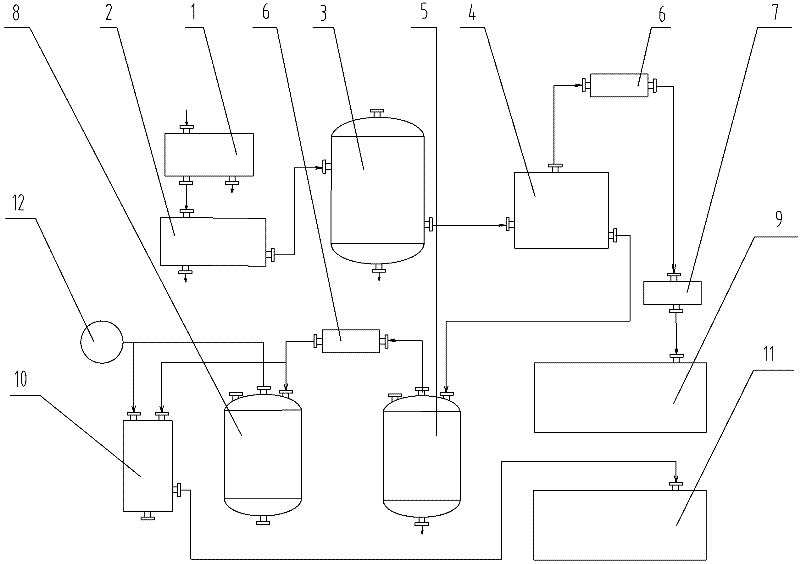

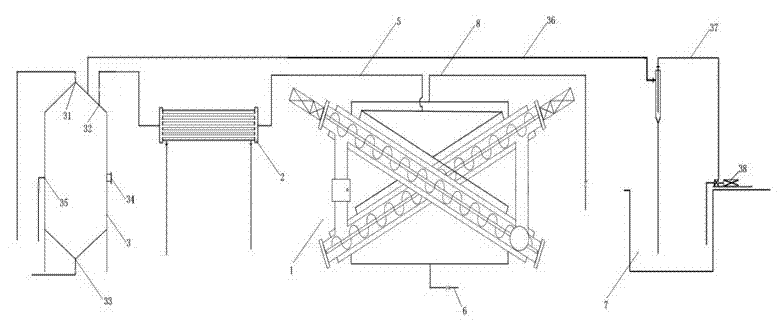

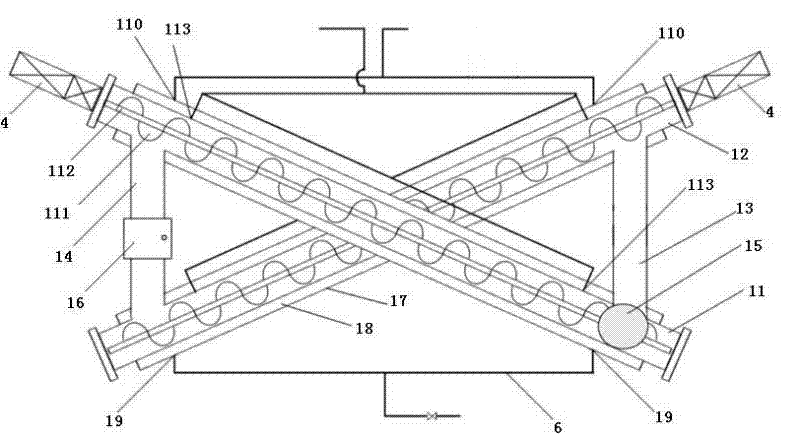

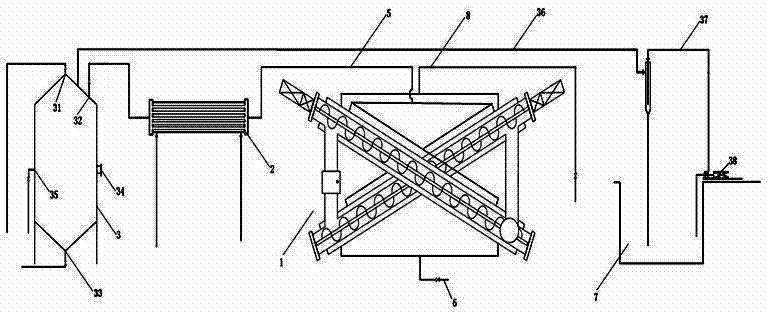

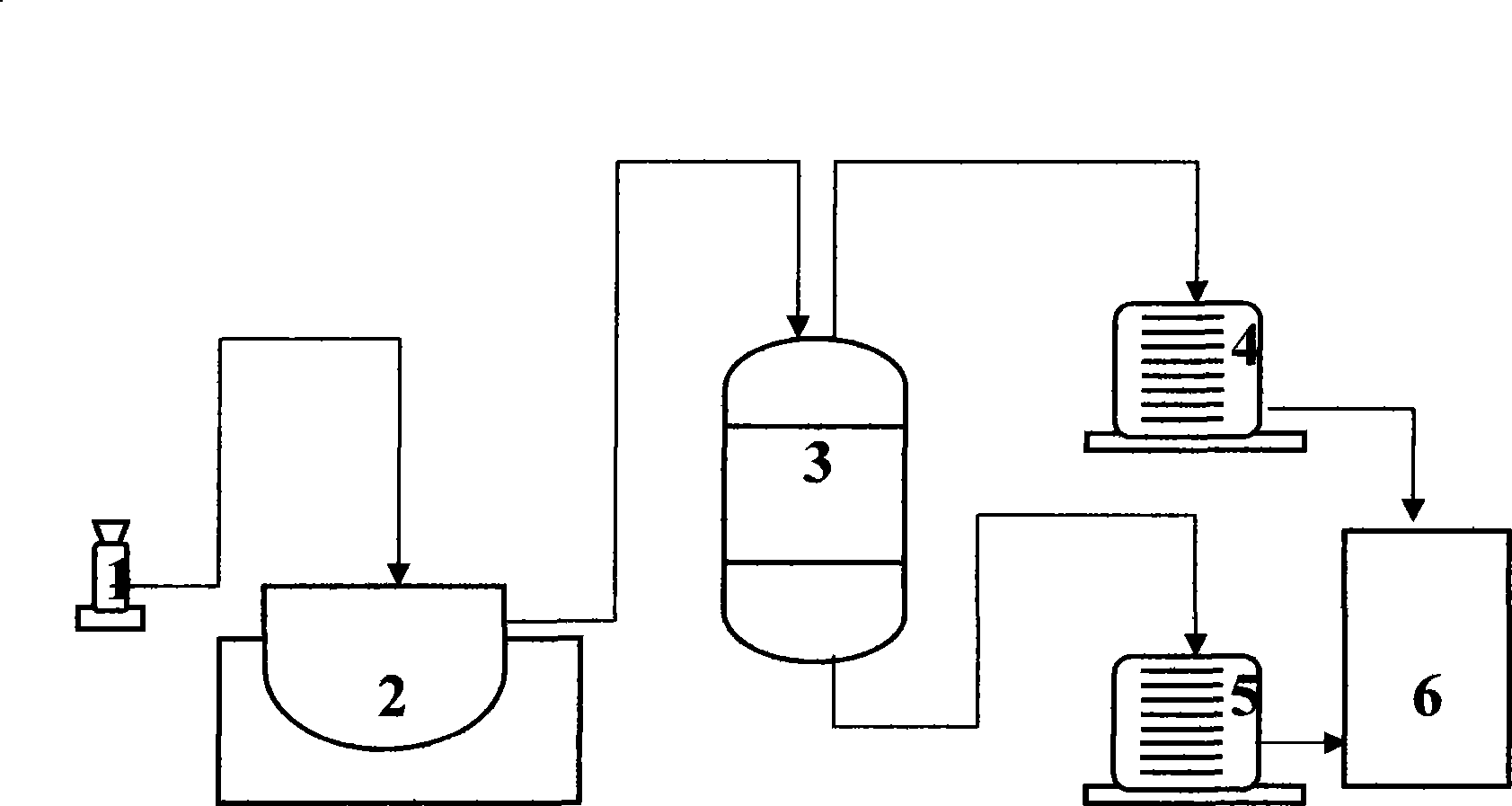

High-efficiency energy-saving low-cost high-quality rosin production process and production line equipment

ActiveCN102643611AShorten production timeIncrease productivityTurpentine spiritsNatural resin purificationProduction lineDistillation

The invention discloses a high-efficiency energy-saving low-cost high-quality rosin production process, which comprises the steps of: firstly carrying out turpentine impurity removal and liquification working procedure: firstly adding a little dissolving oil (5-10%) to turpentine, carrying out pressure filtration with a spiral filter press to remove main mechanical impurities in turpentine, heating refined turpentine at 50-70 DEG C, carrying out pressure filtration with a chamber filter press to further separate the mechanical impurities of turpentine, and inputting the purified turpentine liquid to a turpentine liquid storage tank; and then carrying out turpentine liquid distillation working procedure: inputting the purified turpentine liquid to a distillation tank, separating out rosin and turpentine oil, inputting the turpentine liquid with turpentine oil separated into a reaction kettle, carrying out reduced-pressure distillation to distill heavy turpentine oil, then keeping on heating to gasify the rosin liquid, condensing the rosin vapor into rosin liquid, and inputting to a rosin finished product storage tank. The production line equipment comprises the filter press, the turpentine liquid storage tank, the distillation tank, the reaction kettle, the rosin finished product storage tank, a heavy oil storage tank, a turpentine oil storage tank and a heavy turpentine oil storage tank.

Owner:桂林兴松林化有限责任公司

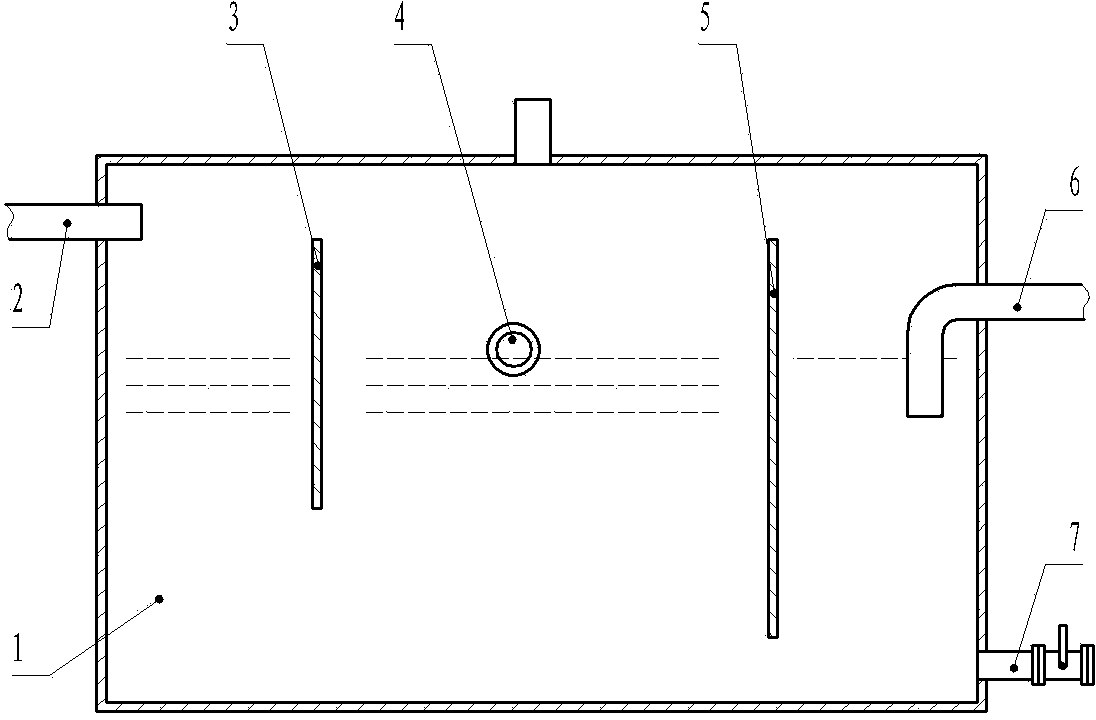

Oil-water separator

InactiveCN104069649AReduce oil contentSave resourcesTurpentine spiritsLiquid separationEngineeringOil water

The invention discloses an oil-water separator and relates to the technical field of rosin production equipment. The oil-water separator comprises a separating box body with a liquid inlet formed on one side, and a water outlet formed on the other side, wherein the separating box body is internally equipped with two partitions which sequentially divide the separating box body into an oil-water mixing cavity, an oil-water separating cavity and a drainage cavity; the lower parts of the oil-water mixing cavity, the oil-water separating cavity and the drainage cavity are communicated; an oil outlet is formed in a side wall of the oil-water separating cavity; a water outlet is formed at the upper part of the drainage cavity; and a dewatering outlet is formed at the lower part of the drainage cavity. Compared with the prior art, according to the oil-water separator, an oil-water mixture entering the separating box body enters the oil-water separating cavity through the oil-water mixing cavity, oil and water are thoroughly separated in the oil-water separating cavity, an oil content of water drained by the drainage cavity is low, and resources are saved.

Owner:GUANGXI ZHONGCHANG RESIN

Desulfurization deordorization refining method of crude sulfate turpentine

ActiveCN104449395ASimple refining processReduce energy consumptionTurpentine spiritsMolecular sieveSorbent

The present invention provides after-oxidation waster-washing separation and adsorption combined process so as to achieve efficient refining of crude sulfate turpentine. According to the present invention, the oxidant is a sodium hypochlorite solution with an effective chlorine content of 3-10%, and the adsorbent is a mixture of modified active carbon and a water absorption molecular sieve; the key of the specific refining method is that the primary after-oxidation waster-washing separation is performed, and then adsorption with the adsorbent is performed to remove irritating odor, such that the organic sulfur content in the crude sulfate turpentine can be efficiently removed, and the total sulfur content can meet the 10 ppm standard required by the industrial application requirement; and with the excessive oxidation, the application of the modified active carbon and water absorption molecular sieve mixture as the adsorbent, and other means, the refining process is simplified, the energy consumption is reduced, and the refining cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

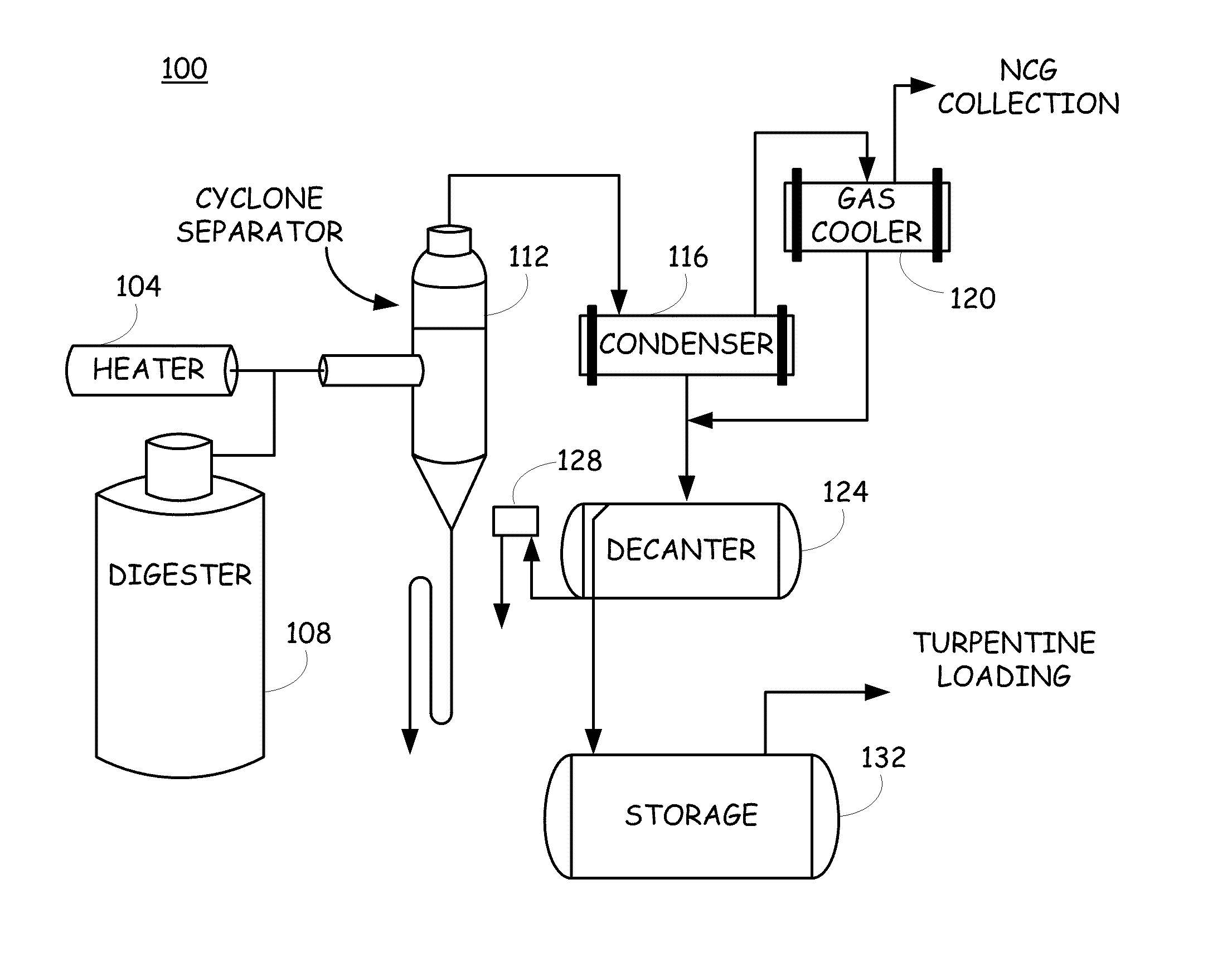

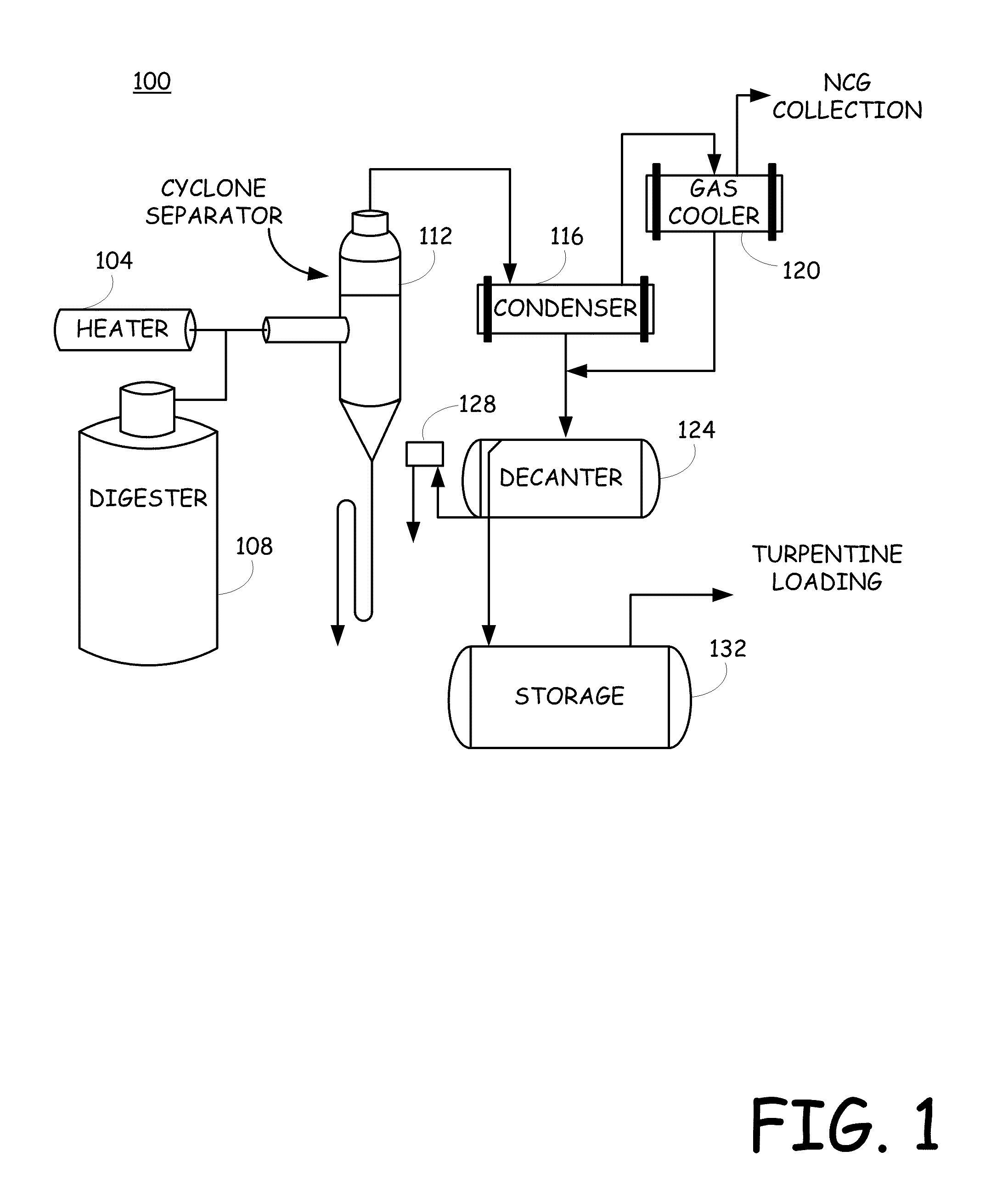

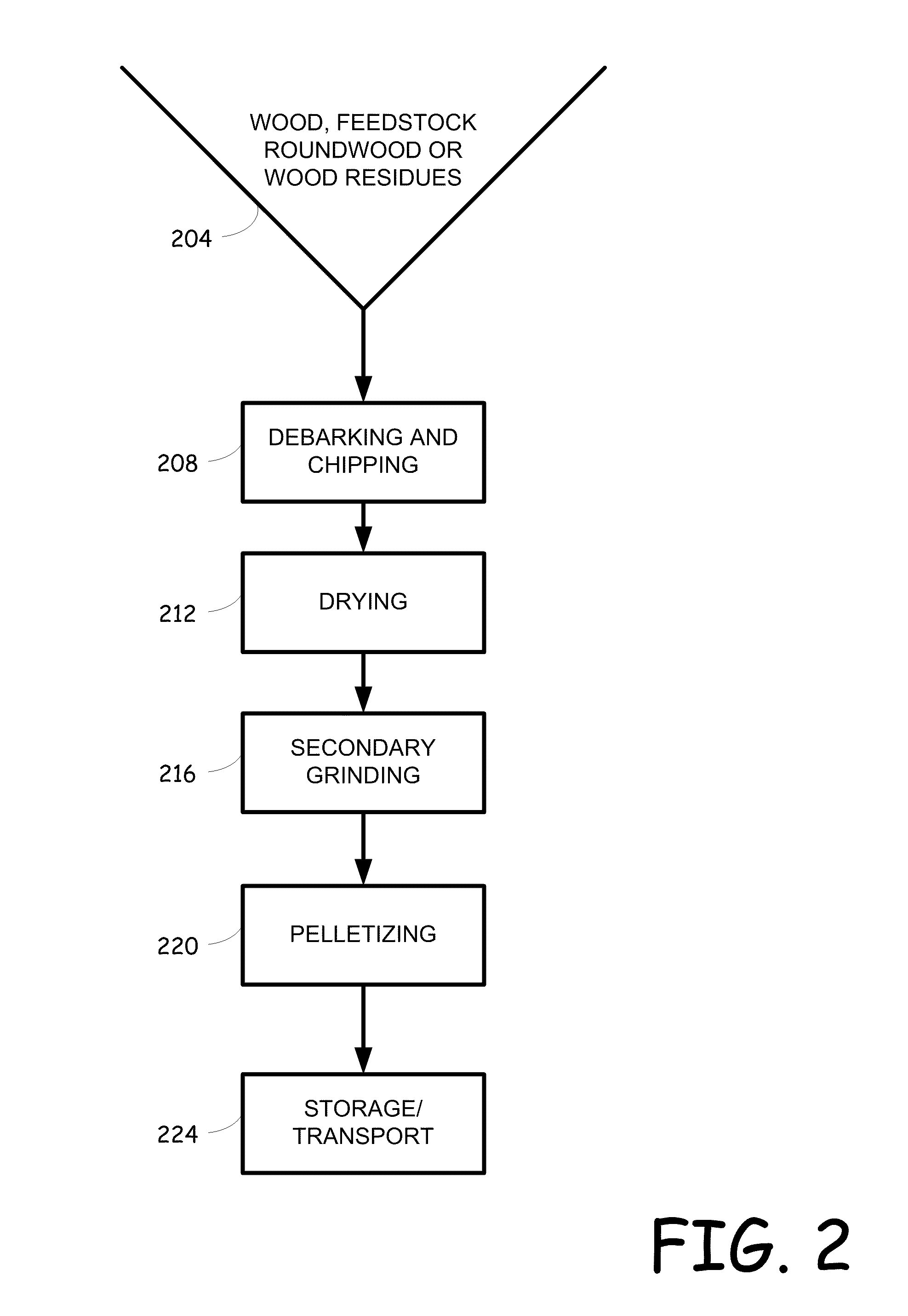

System and method for recovering turpentine during wood material processing

InactiveUS20110301326A1Reduction in capitalReduce operating costsDrying solid materials with heatDirect heating destructive distillationTurpentinePulp and paper industry

A system, method and configuration for recovering turpentine during the manufacturing of wood chips, wood pellets or other substances that may include turpentine. In general, a turpentine recovery system is used to capture turpentine from exhaust of a dryer as wood chips are being dried. Advantageously, application of the various techniques disclosed herein can result in the recovery of turpentine that can then be sold to generate revenue and, may contribute to a reduction in the capital and operation costs for emission controls for the dryer exhaust.

Owner:FOXEN ROBERT J

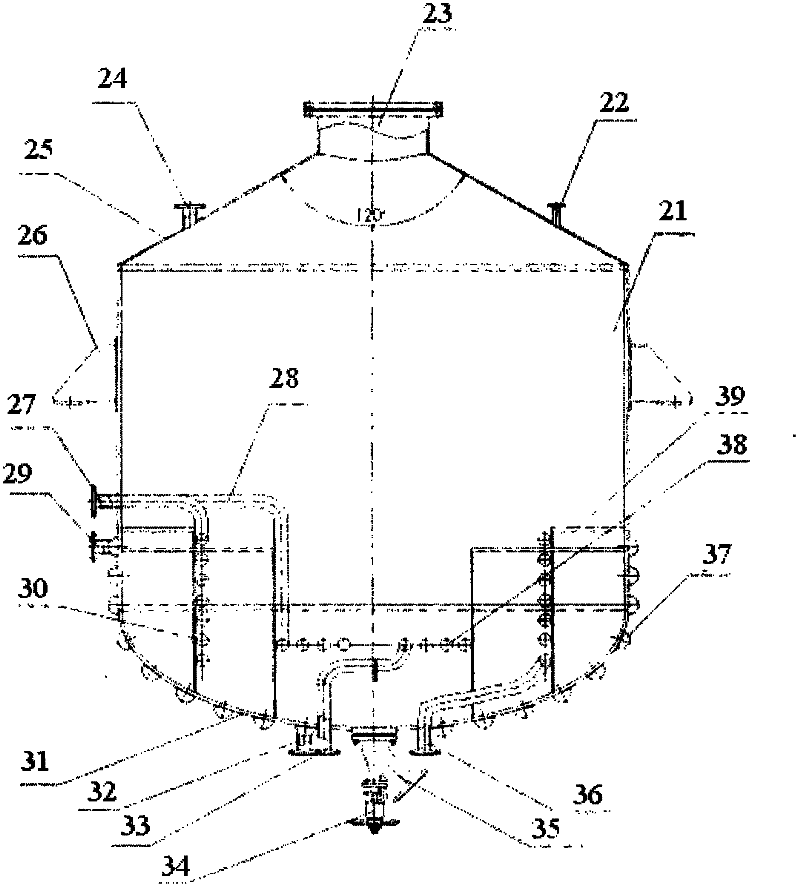

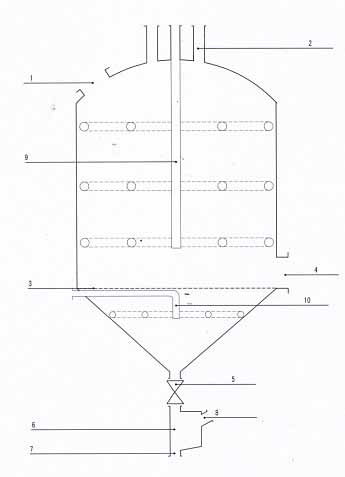

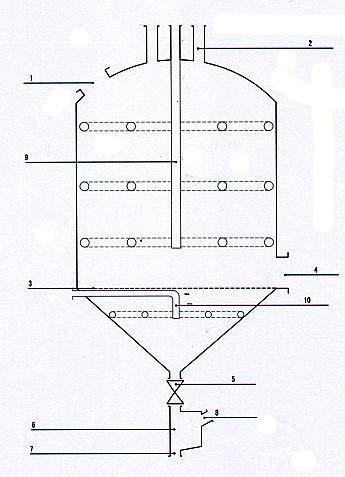

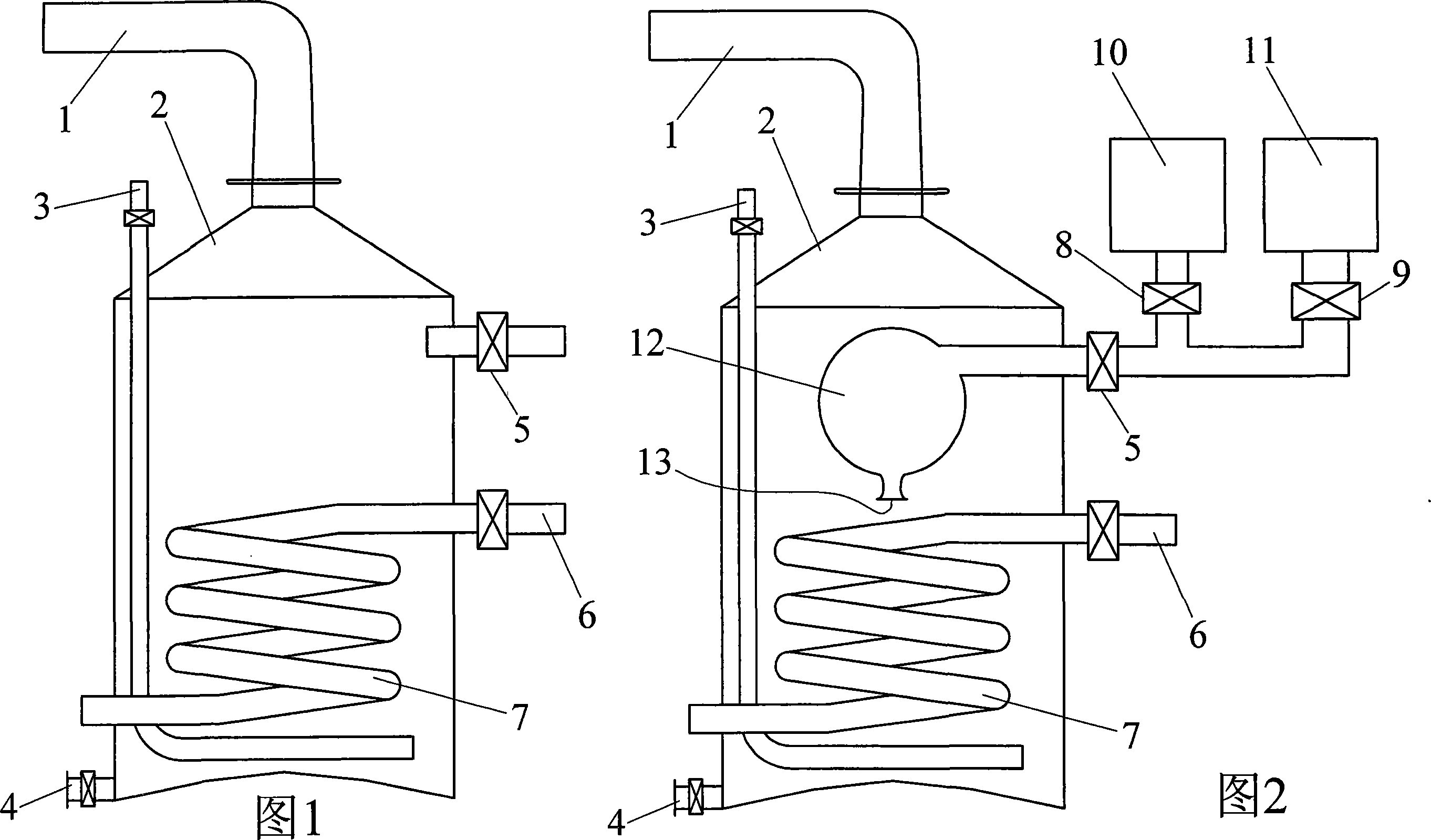

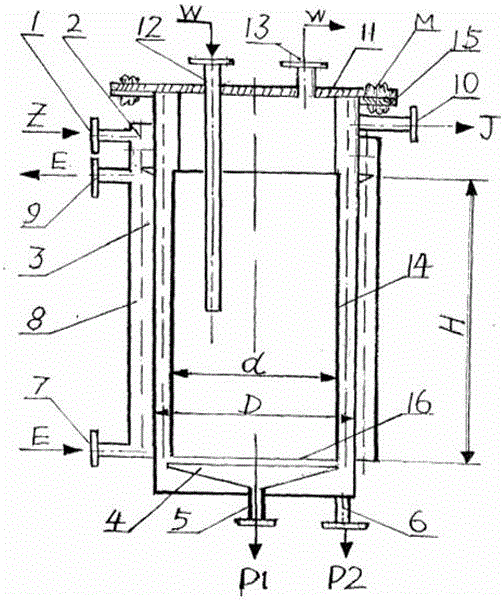

Landing rosin dissolution and separation device

InactiveCN102140312ALess impuritiesEasy to processTurpentine spiritsNatural resin purificationTurpentineEngineering

The invention discloses a landing rosin dissolution and separation device. The device comprises a metal container with a cylindrical cone bottom, the container is provided with an arched sealed top, the upper part of the container is provided with a feeding hole and an emptying pipe, a porous screen plate is arranged in the cut position of the cylinder and the cone bottom of the container, a slagdischarge hole is formed at the lower end of the cylinder and the upper edge of the screen plate, a gate valve is arranged at the lower part of the funnel-shaped cone bottom, a rosin and turpentine gas diversion tank is arranged below the gate valve, the lower part of the tank body is provided with a rosin outlet, the upper part of the tank body is provided with a turpentine gas diversion obliquepipe, upper and lower steam jet systems are arranged in the container by using the screen plate as the boundary, steam pipes are crossed vertically and horizontally, and the open angle of jet holes is from level limited 0 to negative 90 degrees. Through the device, rosin with little impurity is obtained, convenience is provided for further processing a rosin finished product, meanwhile, oil watervapor is condensed and transformed into turpentine, and the turpentine serving as a solvent does not need to be added; and the device is simple and convenience for operation, and has one-step effect.

Owner:古远亮

Colophony processing equipment and colophony processing method

InactiveCN101177589AShorten the timeHigh purityNatural resin processTurpentine spiritsDistillationEddy current

The invention discloses rosin processing equipment and a processing method by using the equipment. The invention comprises a distillation pot or tower; the distillation pot or tower is provided with a material feeding channel which is respectively communicated with an oleoresin tank and a steam tank outside the distillation pot or tower; the material feeding channel extends inside the distillation pot or tower to form an eddy current mixing chamber, the bottom of the eddy current mixing chamber is provided with a material and pressure unload outlet. As the invention mixes and separates the oleoresin in the eddy current mixing chamber in advance and then feeds the mixture into the distillation furnace, the oleoresin is heated and separated when feeding, which can greatly shorten the time of heating the oleoresin to instillation temperature through shut-gas steaming and also greatly shorten the distilling-separation time of the following give-gas steaming, thus the separated rosin can have better purity, color and quality.

Owner:潘永鑫

Turpentine recovery process

InactiveCN113413659ASolve the blockageAvoid cloggingHollow article cleaningTurpentine spiritsFiltrationTurpentine

The invention relates to the technical field of turpentine recovery, and discloses a turpentine recovery process. The turpentine recovery process comprises a turpentine raw material. According to the turpentine oil recovery process,a cleaning mechanism is arranged, so that the problem that a large filtering hole net is blocked due to the fact that most of existing turpentine oil recovery devices are not provided with cleaning mechanisms is solved, the effect of regularly and rapidly cleaning impurities from the top of a large-hole filtering net main body is achieved; a cam repeatedly impacts a small-hole filtering net main body by means of a vibration mechanism, so that a vibration effect can be realized, the filtration and recovery effect of turpentine is improved;a discharging mechanism is adopted, and a driving motor B is started, a spiral push rod is made to rotate, sundries are spirally and horizontally moved and finally discharged out of a recycling box body through a fixing opening, so that the sundries are cleaned, and the sundries are prevented from breeding bacteria in the recycling box body for a long time. According to the turpentine oil recovery device, integrated processing can be achieved, the recovery rate is increased, and the cost is saved.

Owner:ZHEJIANG ZHENGRONG FLAVORS & FRAGRANCES

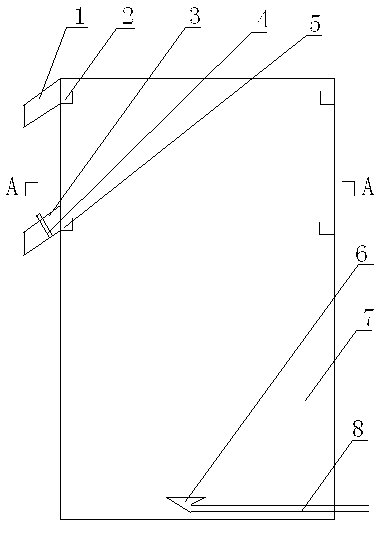

Slag evaporating system for extracting turpentine oil from molten slag

The invention discloses a slag evaporating system for extracting turpentine oil from molten slag. The system comprises a slag evaporating machine, a cooler and a recovering tank which are communicated in sequence, wherein the slag evaporating machine comprises a first slag evaporating tank (11) and a second slag evaporating tank (12) which are arranged crossly; communication pipes (13) and (14) are arranged to communicate the first slag evaporating tank (11) and the second slag evaporating tank (12); the lower end of the first slag evaporating tank (11) is provided with a slag inlet (15); the communication pipe (14) is provided with a slag outlet; each slag evaporating tank is coated with a tank sleeve; an enclosed steam cavity is formed between the tank sleeve and the outer wall of each slag evaporating tank; the lower section and the upper section of the tank sleeve are provided with a water discharging hole and a steam inlet hole respectively; a shaft with a spiral impeller is arranged in each slag evaporating tank; and the tank wall is provided with a turpentine oil outlet. The system has the advantages of skillful and reasonable structural design, high specificity, special design for extracting turpentine oil from molten slag, full evaporation and boiling of turpentine slag, high recovering rate of turpentine oil and the like. The molten slag is recovered, so that waste is changed into treasure, the resource is saved, the enterprise cost is lowered, and the economic benefit of an enterprise is increased.

Owner:南华松香林产有限公司

Saponifiable matter extraction method and saponifiable matter extraction device

Disclosed are saponifiable matter extraction method and a saponifiable matter extraction device. Saponifiable matters are allowed to stay in a black liquor tank and are extracted from black liquor by separating, and surfactant accounting for 0.2-0.5% of the black liquor by weight or sodium sulfonate accounting for 1%-2% of the black liquor by weight is added in the separating process. The saponifiable matter extraction device comprises the black liquor tank which is provided with at least two saponifiable matter outlets, one saponifiable matter outlet is located at the top of the black liquortank, other saponifiable matter outlets are lower than the first saponifiable matter outlet and provided with openable gates. The speed of separating and rising of the saponifiable matters can be increased, the time of retention and separation of the saponifiable matters can be adjusted according to production conditions, the saponifiable matters are recycled timely, and accordingly deteriorationof the saponifiable matters is prevented, and the extraction rate of the saponifiable matters is increased.

Owner:湖南骏泰新材料科技有限责任公司

Separation method of middle-layer resin liquid

ActiveCN102775914AImprove the level ofShort processTurpentine spiritsNatural resin purificationCentrifugationTurpentine

The invention discloses a separation method of middle-layer resin liquid. Liquid-solid-liquid three-phase separation is carried out on complete middle-layer resin liquid through the steps of adding oil of turpentine in middle-layer resin liquid and heating to expand specific gravity difference among raw materials of the middle-layer resin liquid on the basis of centrifugal sedimentation rotation speed difference of a horizontal screw centrifugal machine, the separation principle of a screw conveyor and the centrifugation principle of a disk centrifuge. The separation method has the advantagesof short process flow, large processing capacity, production continuity, low energy consumption, low production cost and little environment pollution; moreover, the level of the separated clean resinliquid is high.

Owner:YUNNAN MEISENYUAN FOREST PRODS TECH

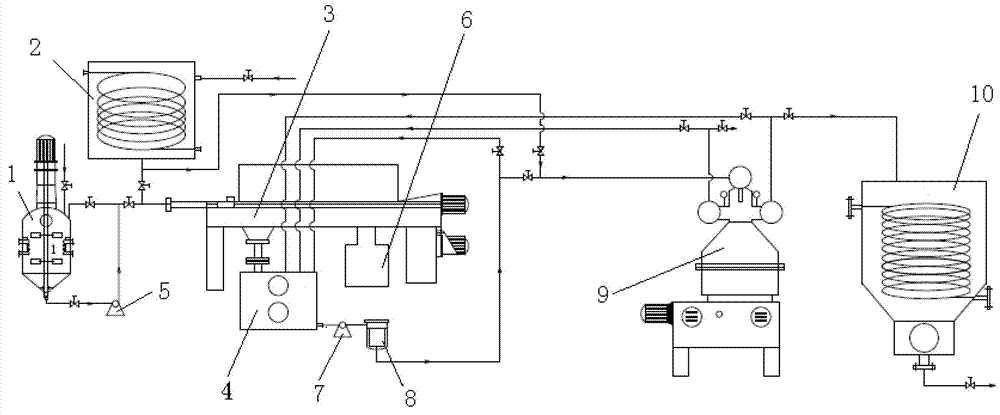

Method for producing ground rosin

A method for producing ground rosin comprises the use of a steam boiler, a steam superheater, a dissolving pot with a stirrer, a centrifugal separator, a grease pressing pot, a distillation pot, a cooler, an oil-water separator, a slag evaporating pot with steel plate mesh at the bottom thereof, oil storage tanks and processing equipment. The process disclosed by the invention is very low in energy consumption, raw material residue can meet the heat source required for the production, coal or firewood are not used, no sulfur dioxide and sewage emissions occur in the combustion process. The recovery of rosin can reach 98%, the indicators, other than the color, of produced rosin, can meet the Grade 1 of National Standard.

Owner:ANNING TAIFENGLIN CHEM

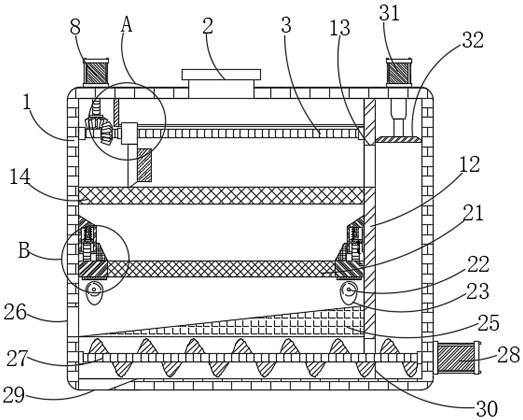

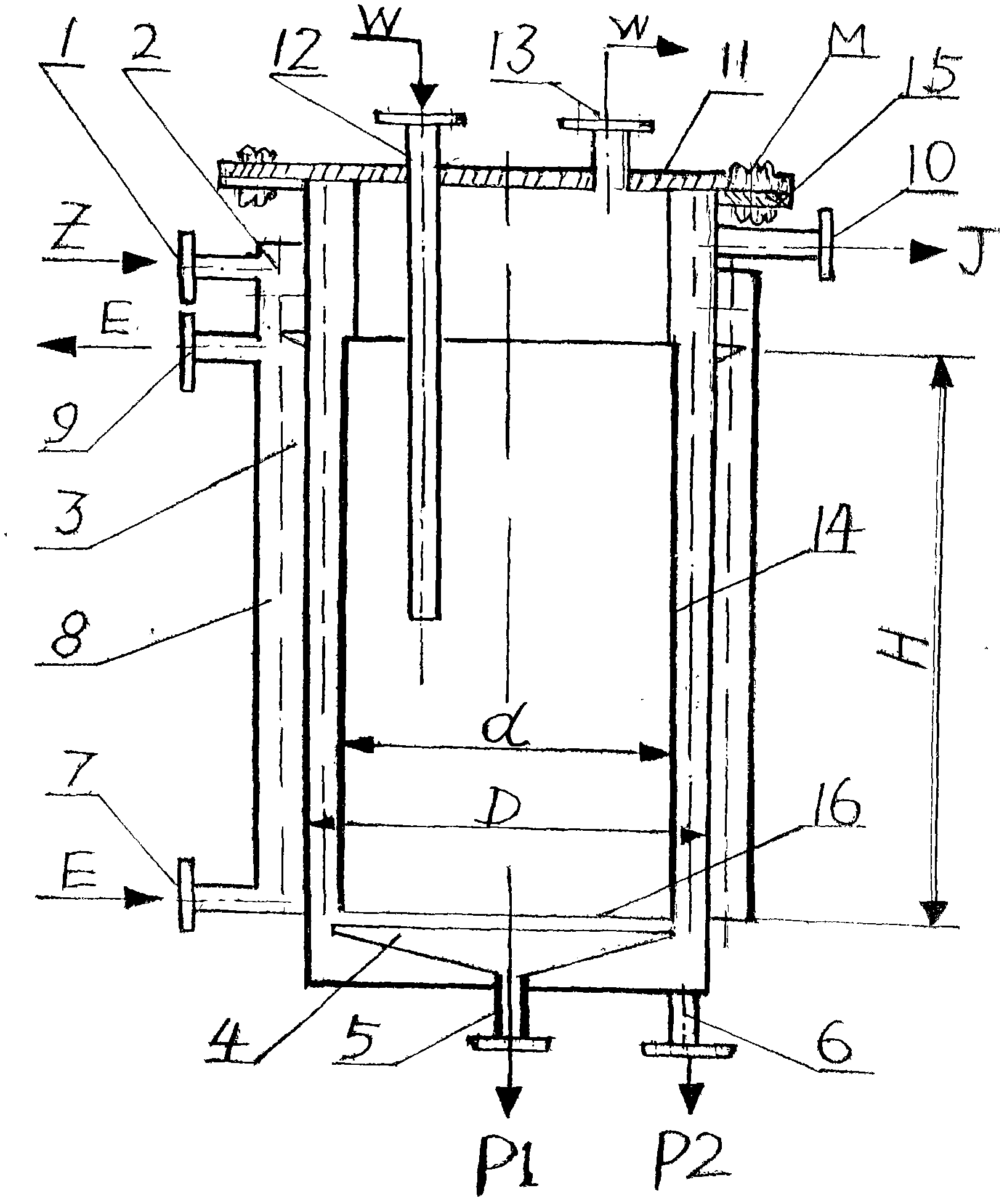

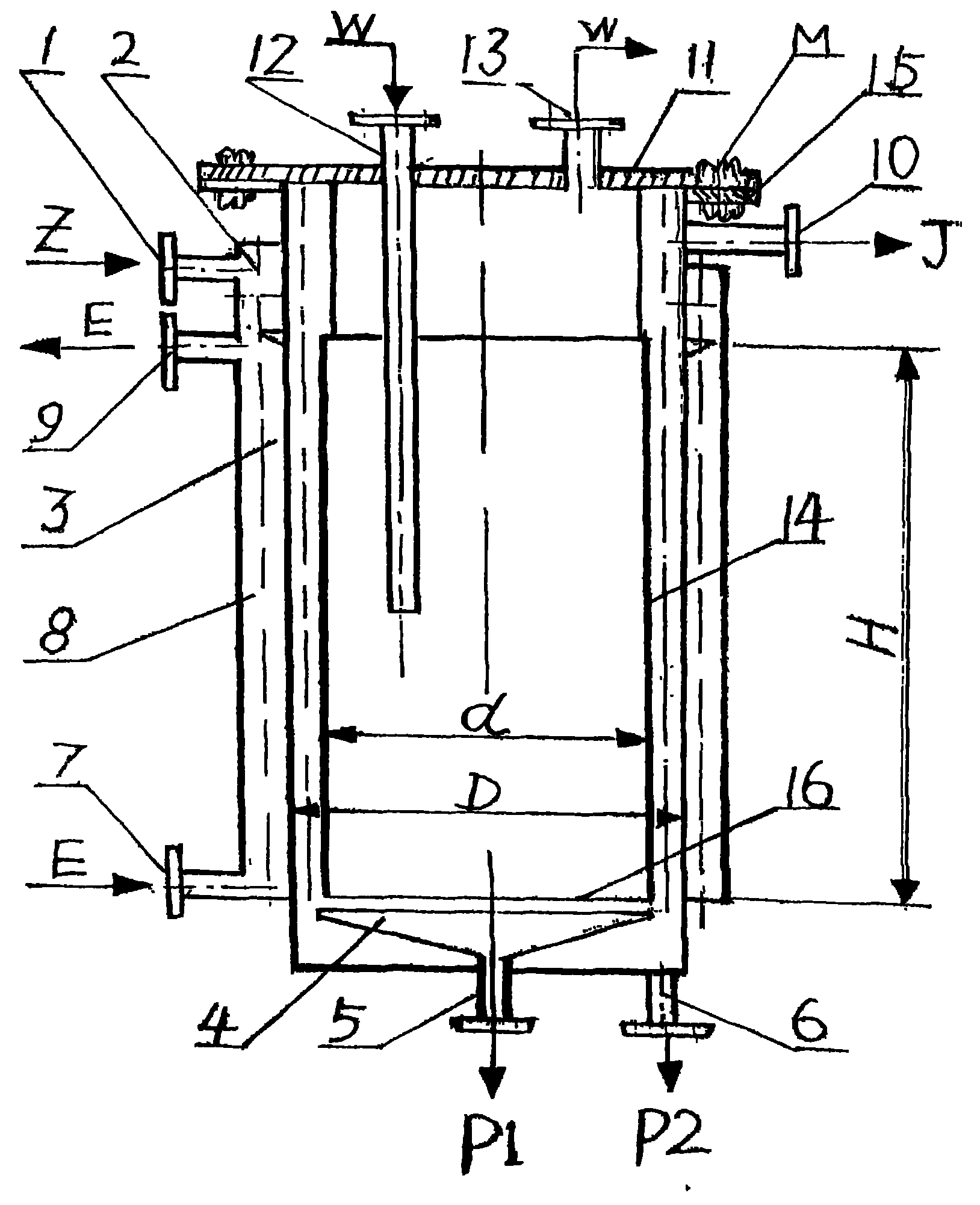

Resin short path distiller and resin distillation process

ActiveCN102321436ALower distillation temperatureReduce volumeTurpentine spiritsNatural resin purificationThermal energyDistillation

The invention relates to a resin short path distiller and a resin distillation process. The distiller comprises a feed opening 1, a resin liquid distribution ring 2, a molecule evaporation surface 3, a turpentine tray 4 and an outlet 5, a rosin outlet 6, a heating jacket 8, a molecule evaporation tube consisting of a vacuum interface 10 and a flange 11, and a molecule cooler consisting of a waterinlet 12, a water outlet 13, a tooth-shaped corrugated molecule cooling surface 14, a flange 15 and a seal bottom. The evaporation surface is preheated to 130DEG C to 140DEG C, and vacuumized to 50Pato 100Pa; after cooling liquid is injected into the cooler, the pre-heated resin liquid is put into the resin liquid distribution ring; the resin liquid is distributed into a liquid membrane which flows downwards along the molecule evaporation surface and is heated by the evaporation surface, so that molecule distillation is carried out; turpentine molecules escape from the liquid surface and arecooled by the molecule cooling surface into turpentine which flows down to the tray and flows into a storage tank P1 from the outlet 5; and the rest rosin of the liquid membrane flows into a storage tank P2 from the outlet, and the distillation process lasts for 10s to 15s. The resin distillation process provided by the invention is simple and easy to operate, saves above 70 percents of heat compared with a distillation process, so that the color of the rosin is lighter.

Owner:陆让先

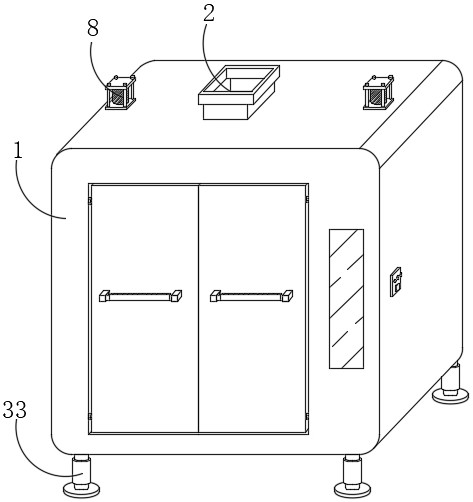

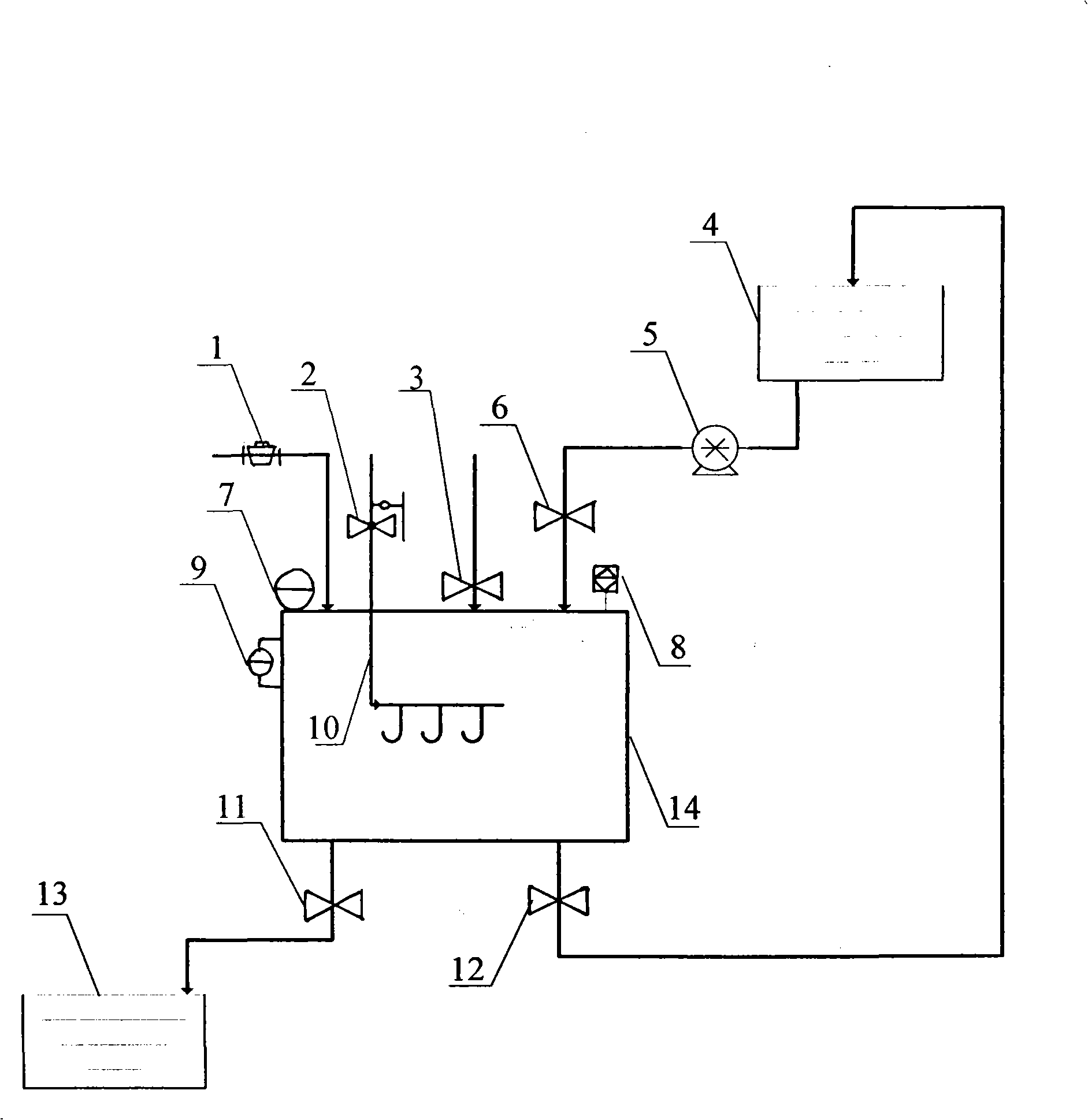

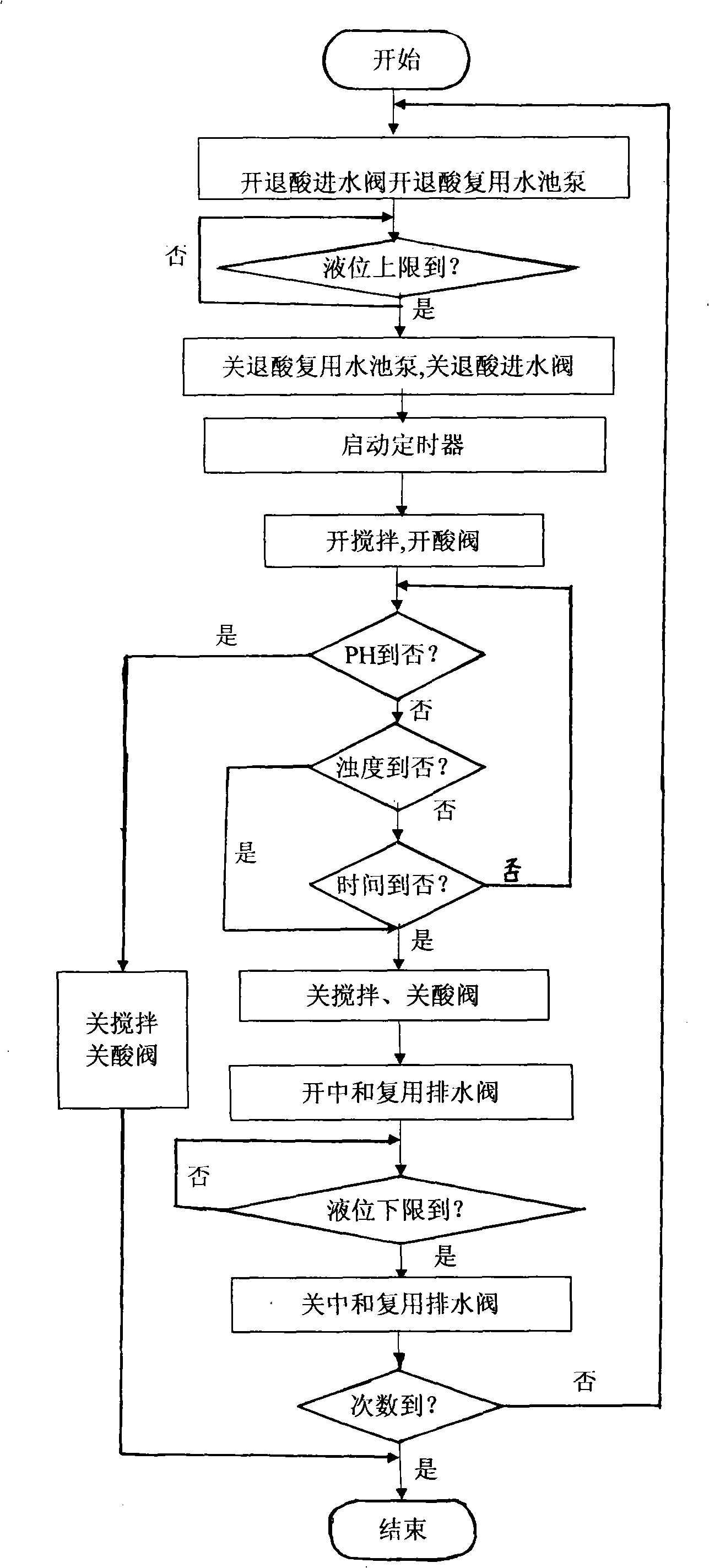

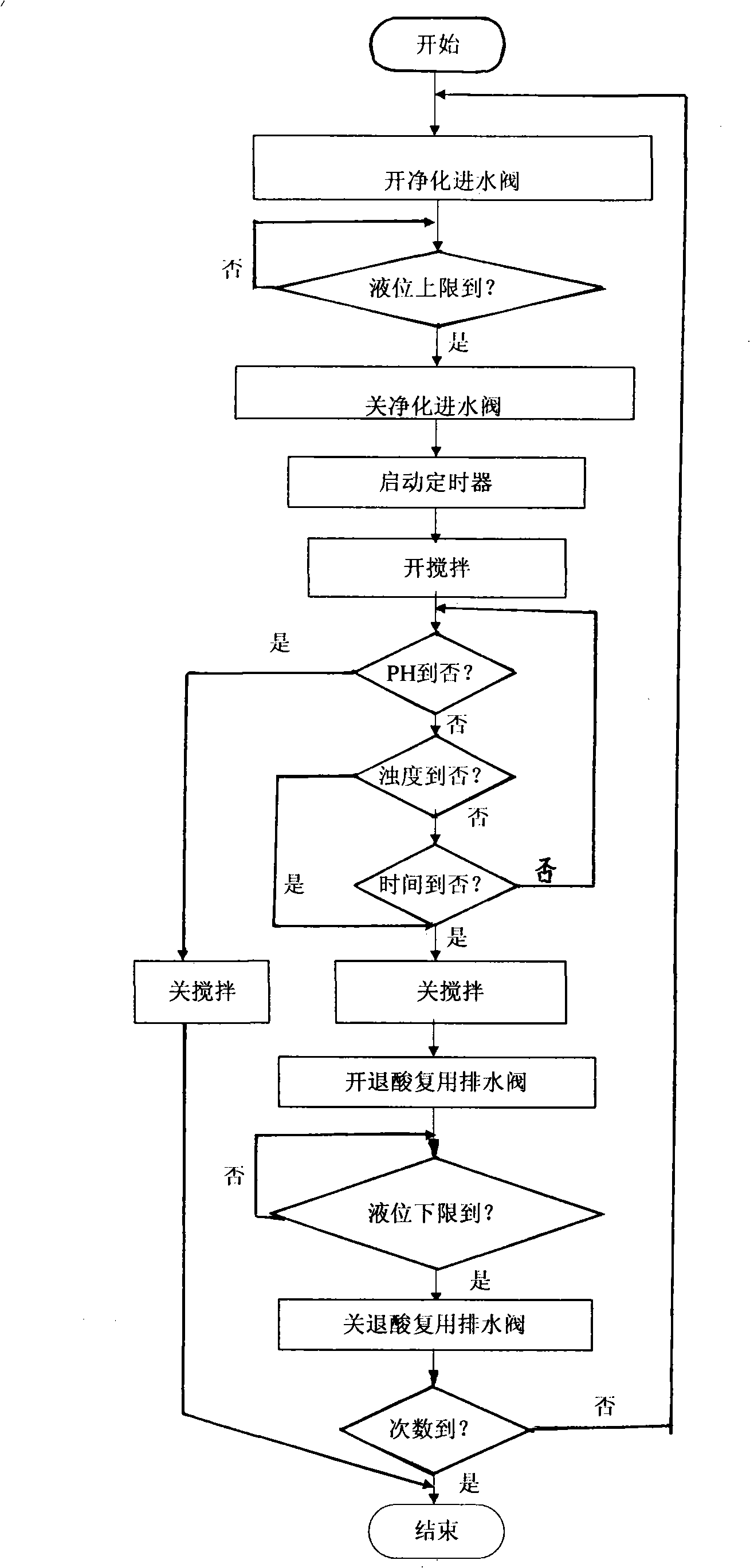

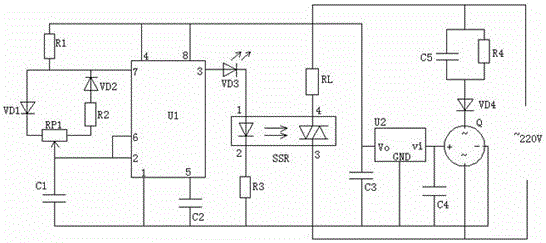

Automatic control system for neutralization process in gelatin production

InactiveCN101348693AAccurate control of PH valueAccurate control of turbidityTurpentine spiritsTotal factory controlAutomatic controlControl system

The invention relates to an automatic control system in a neutralization procedure of the gelatin production process, which comprises a neutralizing pool (14); the neutralizing pool (14) is provided with a compressed air pipeline (10); an acidity adjusting valve (1), a purified water inlet valve (3), a liquid level sensor (7), a PH sensor (8) and a turbidity sensor (9) are correspondingly arranged on the neutralizing pool (14); an acid retreating multiplex water pool (4) is communicated with the neutralizing pool (14) by an acid retreating multiplex water pump (5) and an acid retreating multiplex water valve (6); an electromagnetic valve (2) is communicated with the compressed air pipeline (10); the acid retreating multiplex water pool (4) is communicated with the neutralizing pool (14) by an acid retreating multiplex drain valve (12); a neutralization multiplex water pool (13) is communicated with the neutralizing pool (14) by a neutralization multiplex drain valve (11); and the automatic control system also comprises a PLC control unit and a computer system for realizing the neutralization control. The automatic control system can well ensure the quality of extracted ossein, promote the economical benefit and improve the production efficiency.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

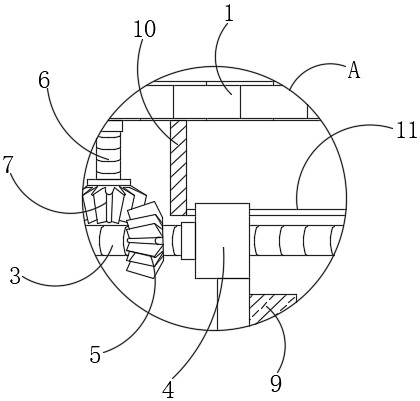

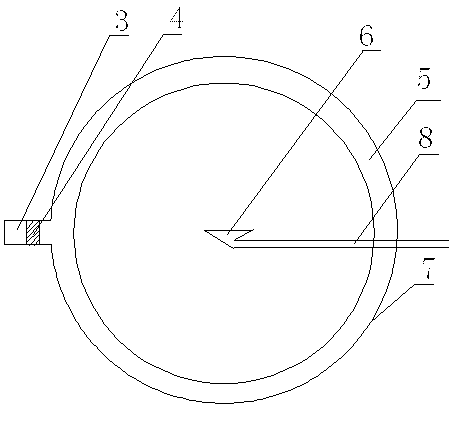

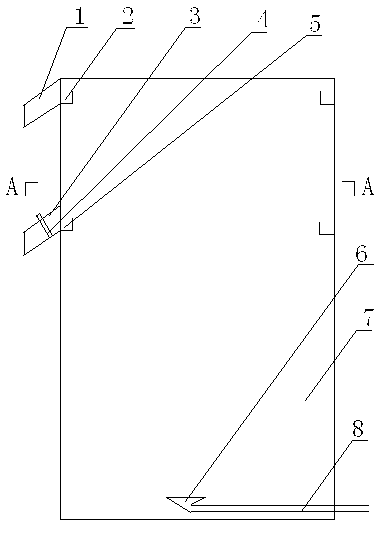

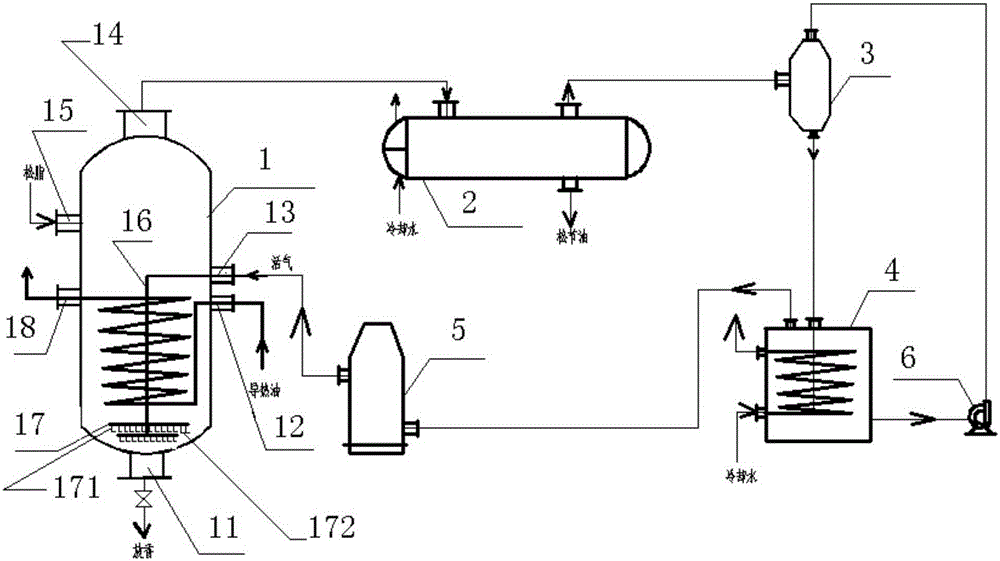

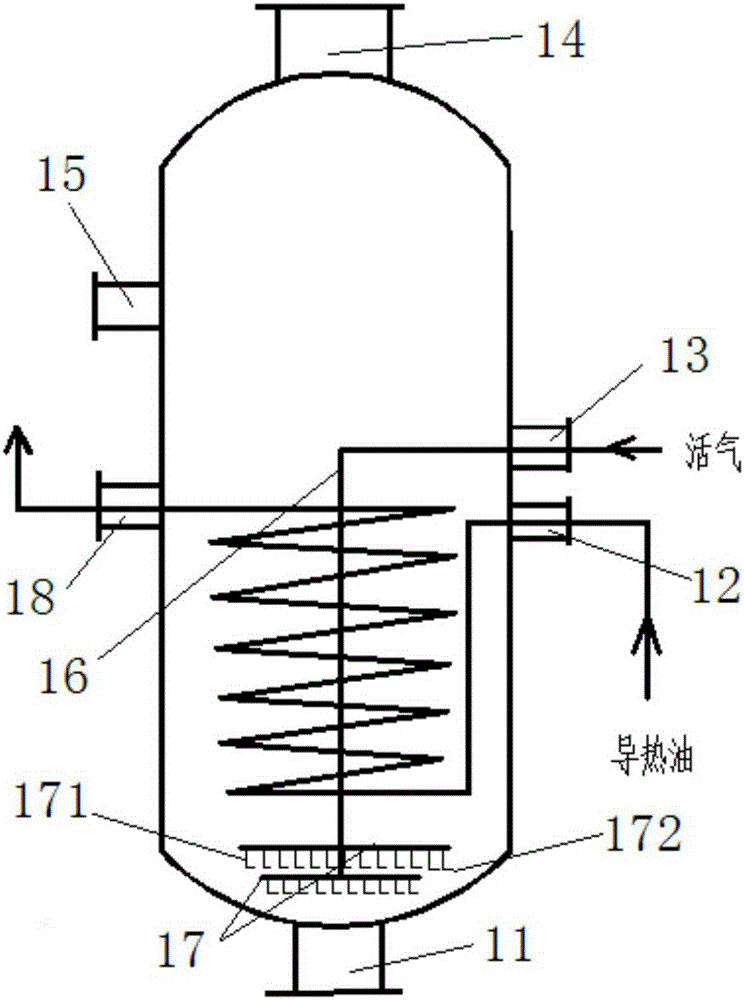

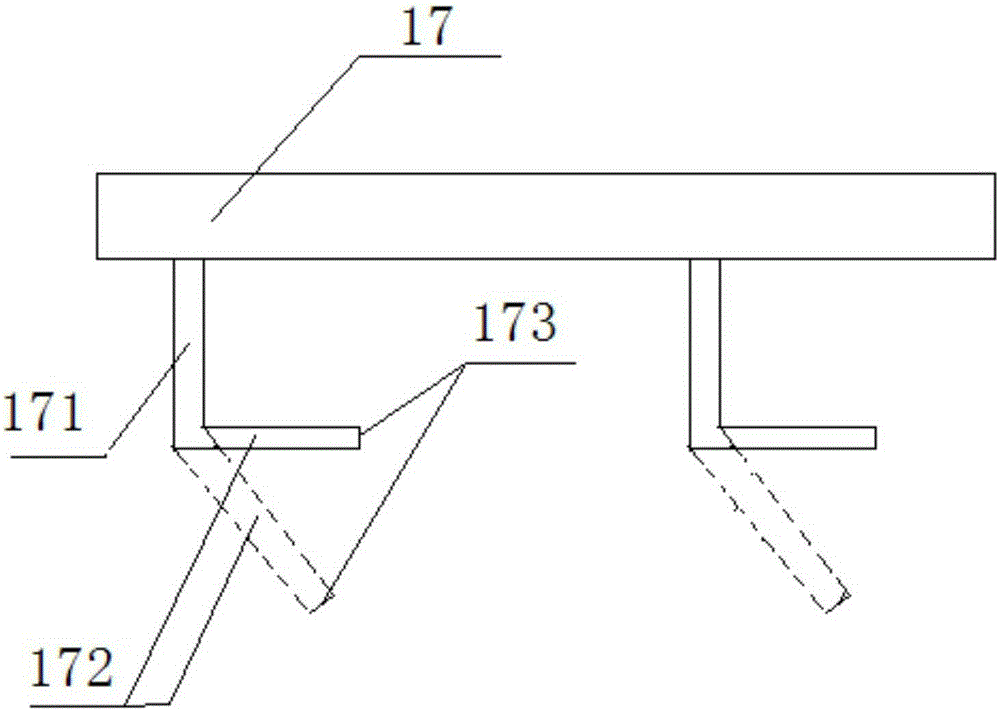

Live air tangent jetting spinning type rosin distillation device and use thereof

ActiveCN105199607AImprove heat transfer performanceEnhanced mass transferTurpentine spiritsNatural resin purificationRosinEngineering

The invention discloses a live air tangent jetting spinning type rosin distillation device. The live air tangent jetting spinning type rosin distillation device comprises a closed air tube and a live air tube, wherein the live air tube comprises an air guiding tube and a coiled tube; the coiled tube is provided with a live air guiding hole; the live air guiding hole extends downwards to form a guiding tube and a branch tube connected with the guiding tube; and an angle between the guiding tube and the branch tube is greater than or equals 90 degrees and is smaller than 180 degrees. According to a method for distilling rosin by using the rosin distillation device, the pressure of fed live air is controlled to be 0.03-0.2 Mpa, namely, distillation pressure is 0.03-0.2 MPa, and distillation temperature is 170-400 DEG C. The device is low in modification cost and easy to implement, and is used for rosin processing; production speed of products in a rosin distillation process can be increased effectively; and meanwhile, after rosin is processed by the device, effects of saving energy and reducing emission can be achieved.

Owner:GUANGXI UNIV

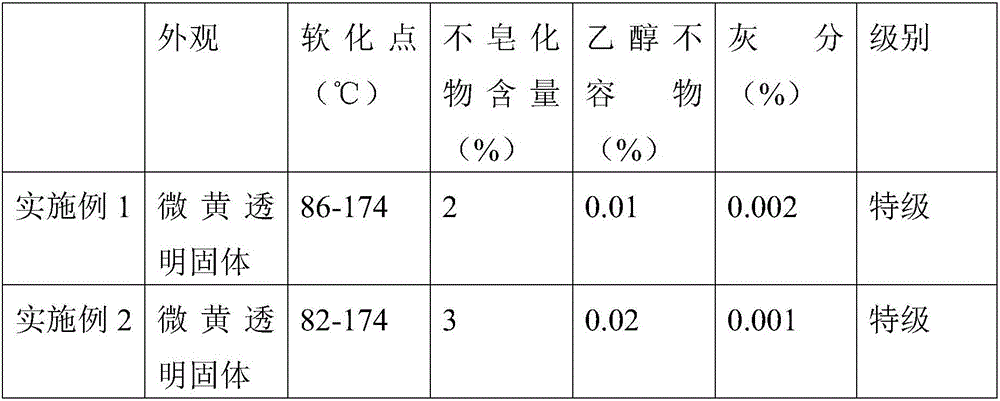

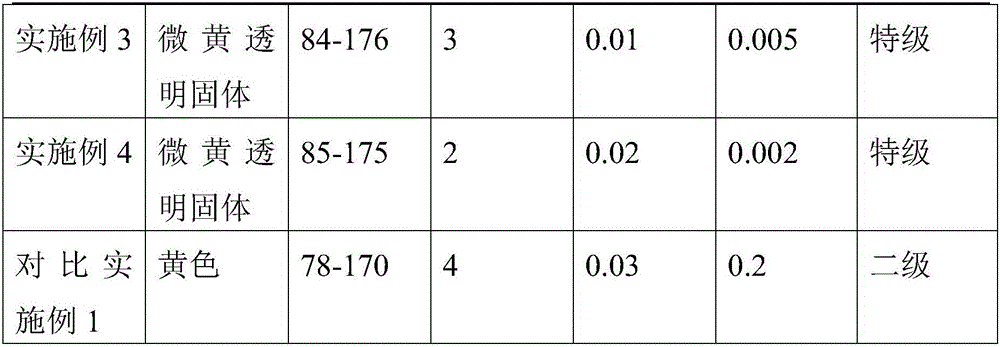

Preparation method of colophony and turpentine

InactiveCN106189870AImprove solubilityPlay a warm-up effectTurpentine spiritsNatural resin purificationOrganic solventDistillation

The invention discloses a preparation method of colophony and turpentine, and belongs to the technical field of the processing of rosin. The method comprises the following steps: (1) dissolving: conveying rosin into a dissolving pan, introducing water vapor at the bottom of the dissolving pan, and heating rosin; (2) water cleaning: adding dissolved rosin liquid into hot water, and cleaning the dissolved rosin liquid; (3) clarification: putting the rosin liquid of the dissolved rosin in a high pan, making the rosin liquid stay for a period of time, putting the rosin liquid of an upper layer in the high pan into a clarifying pan, and carrying out clarification; (4) distillation: putting the clarified rosin liquid into a preheating rosin storage pan, carrying out preheating, then putting the preheated rosin liquid into a continuous distilling pan, and carrying out distillation to finally obtain colophony and turpentine. According to the preparation method of rosin and turpentine, dimethyl acetamide is added into dissolving liquid as an organic solvent for dissolving rosin; the dissolution of rosin is further promoted; a dissolution time of the blocky rosin is shortened. Meanwhile, rosin is also cleaned with cleaning liquid before being dissolved; the surface of rosin are cleaned cleanly, and then subsequent dissolution and purification steps are carried out; the quality of colophony and turpentine is improved.

Owner:广西兴业县新贵松脂厂

Production method of ground rosin

InactiveCN105567090ASimple processIncrease productionTurpentine spiritsNatural resin purificationDistillationTurpentine

The invention discloses a production method of ground rosin; the production method includes the steps of crushing, device cleaning, dissolution agent addition, water removal, feeding, standing, turpentine releasing, distillation, oil-water separation, residue cleaning, residue distillation, residue removal and the like. The production method disclosed by the invention is extremely low in energy consumption, raw material residues can meet heat sources required for the production, and fire coal or firewood is not used; no sulfur dioxide is discharged and no any produced sewage is discharged in the combustion process of residue biomass fuels with wood properties; the recovery rate of rosin can reach 98%, and the produced rosin has the performance indicators reaching the grade 1 of national standards.

Owner:ANNING TAIFENGLIN CHEM

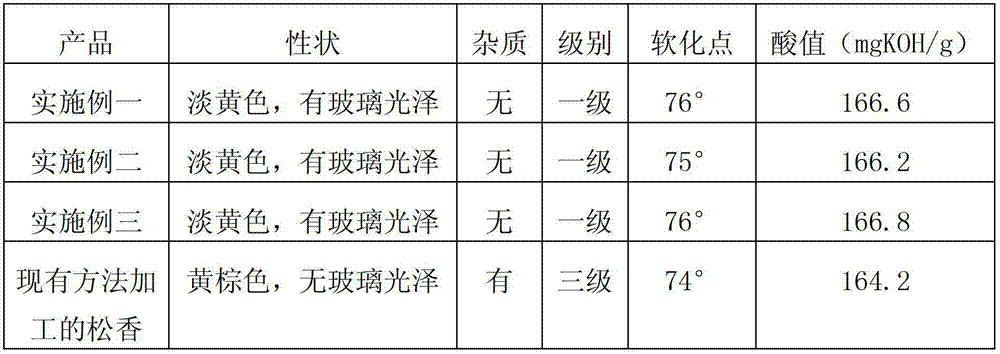

Processing method for improving rosin product quality

InactiveCN106349936AAct as a spectrum bactericidalImprove the bactericidal effectTurpentine spiritsNatural resin purificationDistillationWater quality

The invention relates to the field of rosin processing, and discloses a processing method for improving the rosin product quality. The processing method comprises the processes of pretreatment, dissolution, water washing, clarification, distillation and finished product segmented recovery; water for production is pretreated; low-oxygen sterile water is used for rosin storage and cleaning; meanwhile, an ultrasonic cleaning process is added for improving the turpentine oil and rosin quality; for the pretreatment, rosin is crushed, and is soaked and flushed by the low-oxygen sterile water; the processing method solves the problems that in the pretreatment process in the prior art, the low-oxygen sterile water quality treatment is complicated, the reagent treatment can cause secondary pollution, and substances such as pigment in the rosin cannot be fully removed in the water washing process of commonly used resin processing; the goals of simply and efficiently treating the low-oxygen sterile water, avoiding secondary pollution and improving the turpentine oil and rosin quality are achieved.

Owner:广西兴业县新贵松脂厂

Rosin processing method

InactiveCN106590437ALight and uniform colorHigh purityTurpentine spiritsNatural resin purificationSolventRosin

The invention relates to the technical field of rosin production, in particular to a rosin processing method. The rosin processing method specifically includes steps: smashing rosin; adding a solvent; melting, and roughly filtering; performing tangential flow film separation; distilling; cooling to obtain solid-state rosin. By adopting the rosin processing method, impurity ingredients in rosin can be removed effectively, and the obtained solid-state rosin is shallow and uniform in color and high in purity.

Owner:临沧方源林产品有限公司

Method for extracting pine product and wood fiber from pinaster root

InactiveCN101486878AReasonable removalLow priceNatural resin processTurpentine spiritsDistillationFiltration

The invention discloses a method for abstracting series pine product and wood fiber from pine roots. The main technical proposal is as follows: after soil impurities on the pine roots are removed by pretreatment, the pine roots are crushed into small block crumbs; and then the crumbs are soaked in an organic solvent in a container for two hours, therefore, after the crumbs are soaked for three times repeatedly, pine fiber after soaking can be obtained by filtration and separation and sold to paper making factories and the like. Soaking solutions of the three times are merged and injected into a distiller for distillation separation. Firstly, the organic solvent and water flow out by light distillation; secondly, the turpentine oil crude product flows out from an initial distillation point; and then after being refined, the turpentine oil crude product becomes turpentine oil. When a final distillation point is reached, distillate becomes pine-stump light oil crude product by cooling; and after being refined, the pine-stump light oil crude product can be used as fuel oil; finally, the remained flows out and cooled, and then maroon and transparent wood rosin is obtained. The implementation of the method not only cleans the pine roots of pine oil pollution in forests of mountains, but also lowers the manufacture cost, thus leading forest chemical to develop a new industrial path.

Owner:王嘉兴

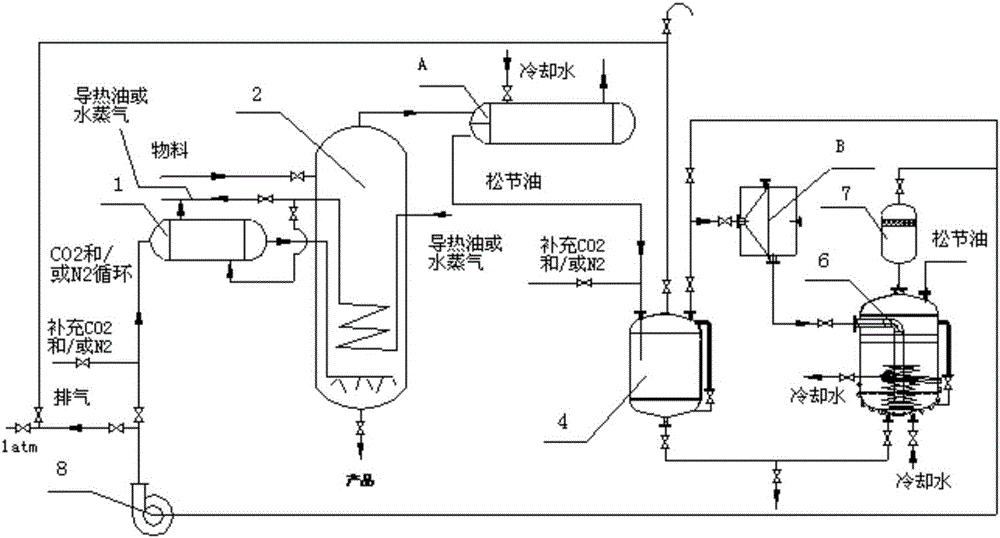

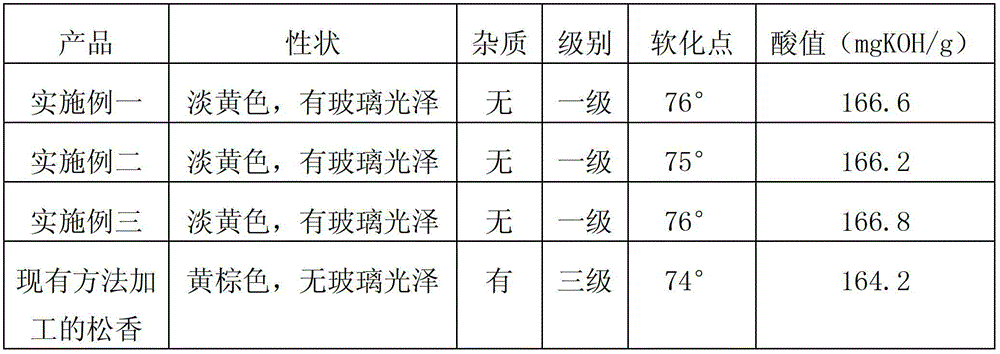

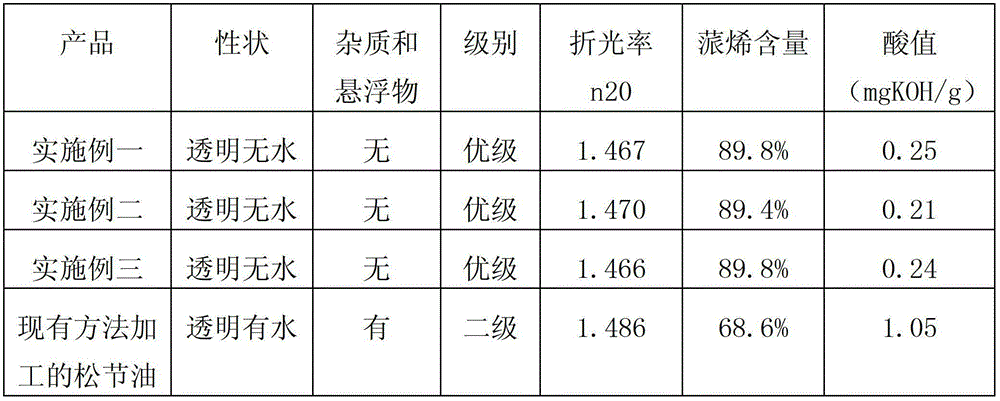

Energy-saving and clean production method for distilling rosin and process equipment

InactiveCN105820759AFacilitate desorptionAccelerate evaporationChemical industryTurpentine spiritsProcess equipmentDistillation

The invention discloses an energy-saving and clean production method for distilling rosin. The energy-saving and clean production method is a technique for distilling the rosin employing CO2 and / or N2 as a circulating activated gas. In the production process of separating the rosin and turpentine by rosin distillation, CO2 and / or N2 are introduced as the activated gases, so that partial pressure of the component in the turpentine of the distillation system is reduced; desorption of the turpentine is promoted to easily distill the rosin; meanwhile, the activated gas also plays a rosin stirring role; interphase heat transfer an mass transfer of the distillation system are intensified; the distillation speed and the product quality are improved. The energy-saving and clean production method has the advantages that the circulating activated gas does not generate a phase change in the rosin distillation process; phase change heat when super-heated steam is used as the activated gas is saved; the energy consumption is reduced, so that the investment cost on equipment is reduced; the obtained product does not contain moisture; the rosin is free of a crystallization phenomenon; the technique is transparent and not turbid. The CO2 and / or the N2 are used in cycle, so that the distillation process is fully sealed operation, is free of three wastes, and is the energy-saving and clean production method.

Owner:GUANGXI UNIV

Processing method of pine resin

InactiveCN103087635BQuality improvementImprove solubilityTurpentine spiritsNatural resin purificationOxalateFiltration

The invention relates to a processing method of pine resin and belongs to the field of rosin production. The processing method of pine resin comprises the following steps of: a, dissolving, namely dissolving the pine resin by adopting a dissolving solution, wherein the dissolving solution comprises the following components in percentage by weight: 55-82% of turpentine oil, 17.5-44.5% of water and 0.1-0.5% of oxalic acid; b, clarifying and colating, namely placing the dissolved pine resin liquid in a transition pot to be clarified and then colating to obtain colature; c, acid washing, namely adding the oxalic acid for washing; d, washing, namely adding hot water for washing; e, clarifying and carrying out refined filtration, namely placing the pine resin liquid into the transition pot to be clarified and then carrying out refined filtration; and f, heating and distilling, namely placing the pine resin liquid in a rectifying tower to be subjected to the heating and distilling, so that rosin and turpentine oil finished products are respectively obtained. The processing method of rosin provided by the invention has the beneficial effect that the qualities of the rosin and turpentine oil obtained by processing pine resin are excellent, so that demand of downstream industries is met.

Owner:云南茶花林化有限公司

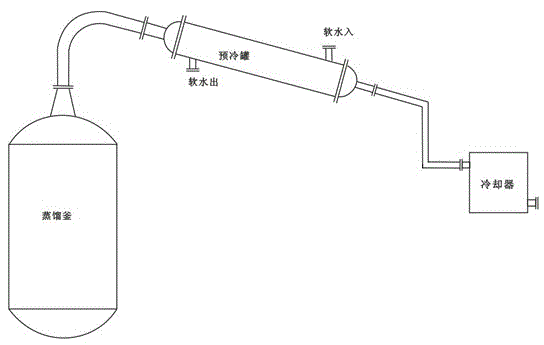

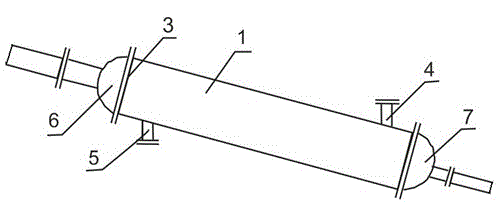

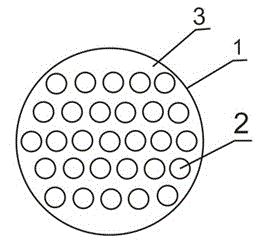

Precooling technique and device for recovering turpentine

InactiveCN102746794AHigh recovery rateEasy to separateChemical industryTurpentine spiritsWater vaporWater resources

The invention discloses a precooling technique and device for recovering turpentine. The technique is implemented by arranging a precooling device between a distilling kettle and a cooler. The precooling device comprises a precooling tank, wherein a plurality of vapor pipes are arranged in the precooling tank; both ends of each vapor pipe are opened at seal layers on both sides of the precooling tank; the wall of the precooling tank is provided with a water inlet and a water outlet; an upper cover and a lower cover of the precooling tank are flexibly connected with the tank body; a mixture of turpentine and vapor distilled out of the distilling kettle enters the precooling tank; and after cooling water is introduced into the precooling tank to perform precooling, the mixture enters the cooler to be further cooled into a liquid. The precooling technique and device disclosed by the invention have strong pertinence; the device has a simple structure; the precooling technique has the advantage of simple steps, and is very easy to operate; the invention has the advantages of high turpentine cooling rate and favorable oil-water separation effect, and can enhance the recovery rate of the turpentine; and the hot water after precooling can be reutilized, thereby saving the energy consumption and water resources, maximally lowering the cost and enhancing the effectiveness.

Owner:南华松香厂

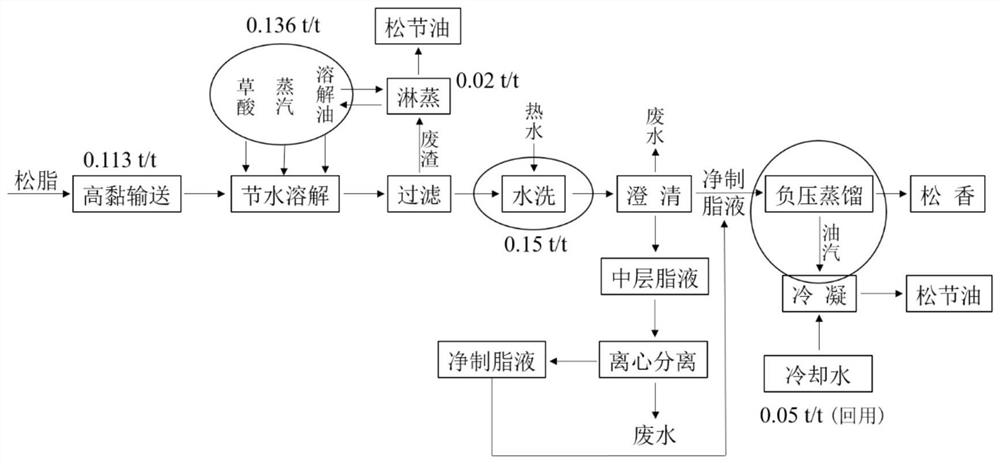

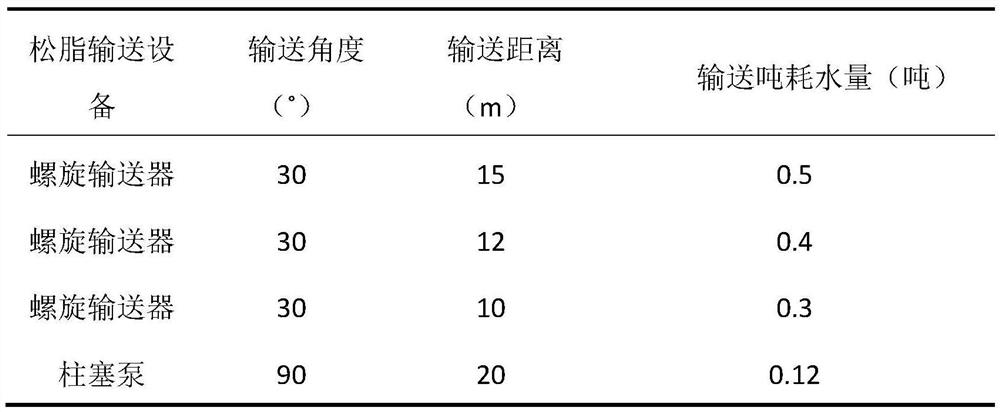

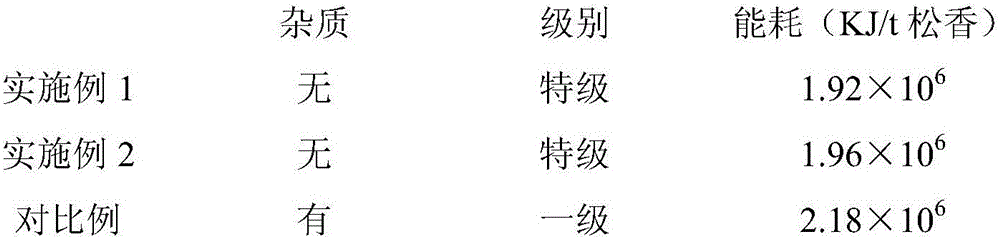

Low-water-consumption and low-emission turpentine processing method

ActiveCN112080206AReduce viscosityReduce consumptionTurpentine spiritsNatural resin purificationLiquid waterDistillation

The invention discloses a method for processing rosin with low water consumption and low emission. The invention belongs to the field of water-saving processing of turpentine. The method comprises thefollowing steps: 1) water-saving conveying: not adding water into turpentine, and conveying the turpentine by adopting a plunger pump; 2) water-saving dissolving: not adding liquid water into the turpentine in the turpentine dissolving process, and dissolving the turpentine by adopting an oil-steam mixture generated by mixing hot dissolved oil and high-temperature steam by using a vertical continuous dissolver; 3) water-saving washing: enhancing the contact between water and the grease liquid by adopting a small amount of repeated hot water washing mode and forced stirring, then standing forlayering to discharge water and impurities at the lower layer, separately collecting to a middle-layer grease liquid tank, putting middle-layer grease liquid into a dissolving kettle, adding a small amount of dissolved oil, heating for dissolving, and separating by a horizontal screw centrifuge and a butterfly centrifuge to obtain pure lipid liquids; and 4) water-saving distillation: distilling the turpentine by adopting a conduction oil heating and reduced pressure distillation process in a turpentine distillation and separation process.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

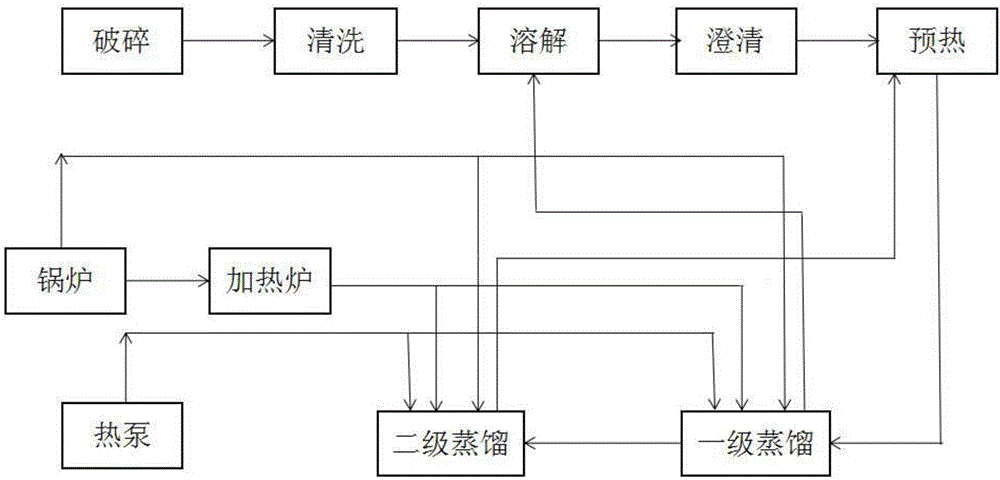

Energy-saving rosin processing method

InactiveCN106349944ATake advantage ofTo achieve the purpose of energy savingChemical industryTurpentine spiritsExhaust gasChemistry

The invention disclsoes an energy-saving rosin processing method, and belongs to the technical field of production of rosin. The method comprises: crushing and washing rosin particles; putting the rosin particles into a melting pot for melting; putting melted rosin liquid into a high-level pot and a clarifying pot for clarifying; putting the clarified rosin liquid into a pre-heating rosin storage pot for pre-heating; putting the pre-heated rosin into a continuous distillation pot for distilling, wherein heat for pre-heating the rosin liquid before melting and distillation is obtained from high-temperature tail gas and oil gas, which are released through distillation, and heat needed by distilling comprises steam from a boiler, superheated steam from a heating furnace and heat which is absorbed and raised through a heat pump. By adopting the energy-saving rosin processing method, the high-temperature tail gas and the oil gas in the distillation pot are recycled, and the heat pump, namely a heat raising device, is arranged in a distillation process, so that the heat of surrounding air in a processing process is sufficiently utilized; when the heat pump is used, hot air temperature needed by the boiler and the heating furnace is also reduced, so that fuel consumed by the boiler and the heating furnace is reduced, and the aim of saving energy is realized.

Owner:广西兴业县新贵松脂厂

High-efficiency turpentine distillation device

InactiveCN106390502ALower distillation temperatureDistillation regulation/controlTurpentine spiritsEvaporationTurpentine

The invention discloses a high-efficiency turpentine distillation device which comprises a molecular evaporation cylinder and a molecular cooler, wherein the molecular evaporation cylinder is shaped like a straight cylinder; a heating jacket is arranged on the cylinder outer wall of the molecular evaporation cylinder; a heating source inlet is formed in the lower part of the heating jacket; a heat source outlet is formed in the upper part of the heating jacket; a connecting flange is arranged at the top of the molecular evaporation cylinder; a vacuum pump interface, a turpentine liquid inlet and a turpentine liquid distribution ring are arranged formed below the connecting flange; a turpentine oil receiving disk, a turpentine oil outlet and a rosin outlet are formed at the bottom of the molecular evaporation cylinder; the inner cylinder wall surface from the turpentine liquid distribution ring to the turpentine oil receiving disk is a molecular evaporation surface; the diameter of the molecular evaporation surface is in the range of 200 mm to 1200 mm; and the vertical length of the molecular evaporation surface is in the range of 1500 mm to 2500 mm. The high-efficiency turpentine distillation device saves the steps of directly evaporating and reducing the distillation temperature and can save energy by more than 70% compared with the distillation method.

Owner:陆丽曼

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com