Colophony processing equipment and colophony processing method

A processing equipment and rosin technology, which is applied in the field of rosin processing equipment for processing rosin, can solve the problems of poor rosin quality and long heating time, and achieve the effects of simple structure, good quality and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

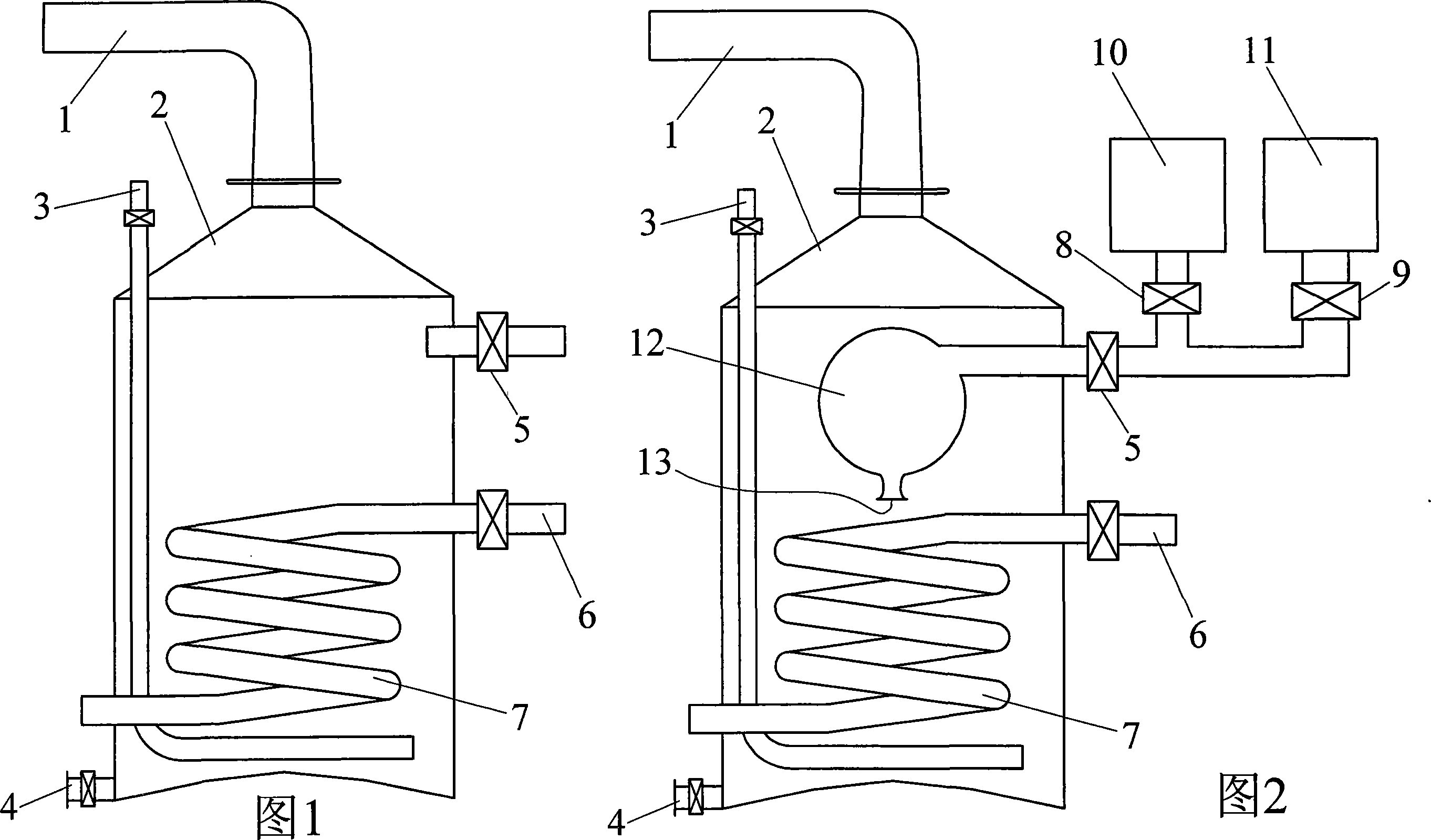

[0012] Embodiment: referring to Fig. 2, the present invention is to arrange open gas steam pipe 3 and closed gas steam heat exchanger 7 in still pot 2, and the feed channel of still pot 2 is communicated with turpentine tank 10 and steam respectively outside still pot or tower The tank 11 and the feed channel of the distillation pot 2 extend into a vortex mixing chamber 12 in the distillation pot or tower, and a discharge pressure relief port 13 is provided at the lower end of the vortex mixing chamber 12 . Wherein, the vortex mixing chamber 12 is arranged on the top of the distillation pot 2, and its volume is greater than that of the feed channel, and the discharge pressure relief port on it is smaller than the feed channel. Such a structure can make turpentine and steam fully expand in the vortex mixing chamber , the combined surface of turpentine and steam is larger, which is beneficial to the pre-separation of turpentine in turpentine; the feed channel is a tangential inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com