Method for extracting pine product and wood fiber from pinaster root

A wood fiber and product technology, applied in the field of chemical extraction of organic matter, can solve the problems of high cost and high selling price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

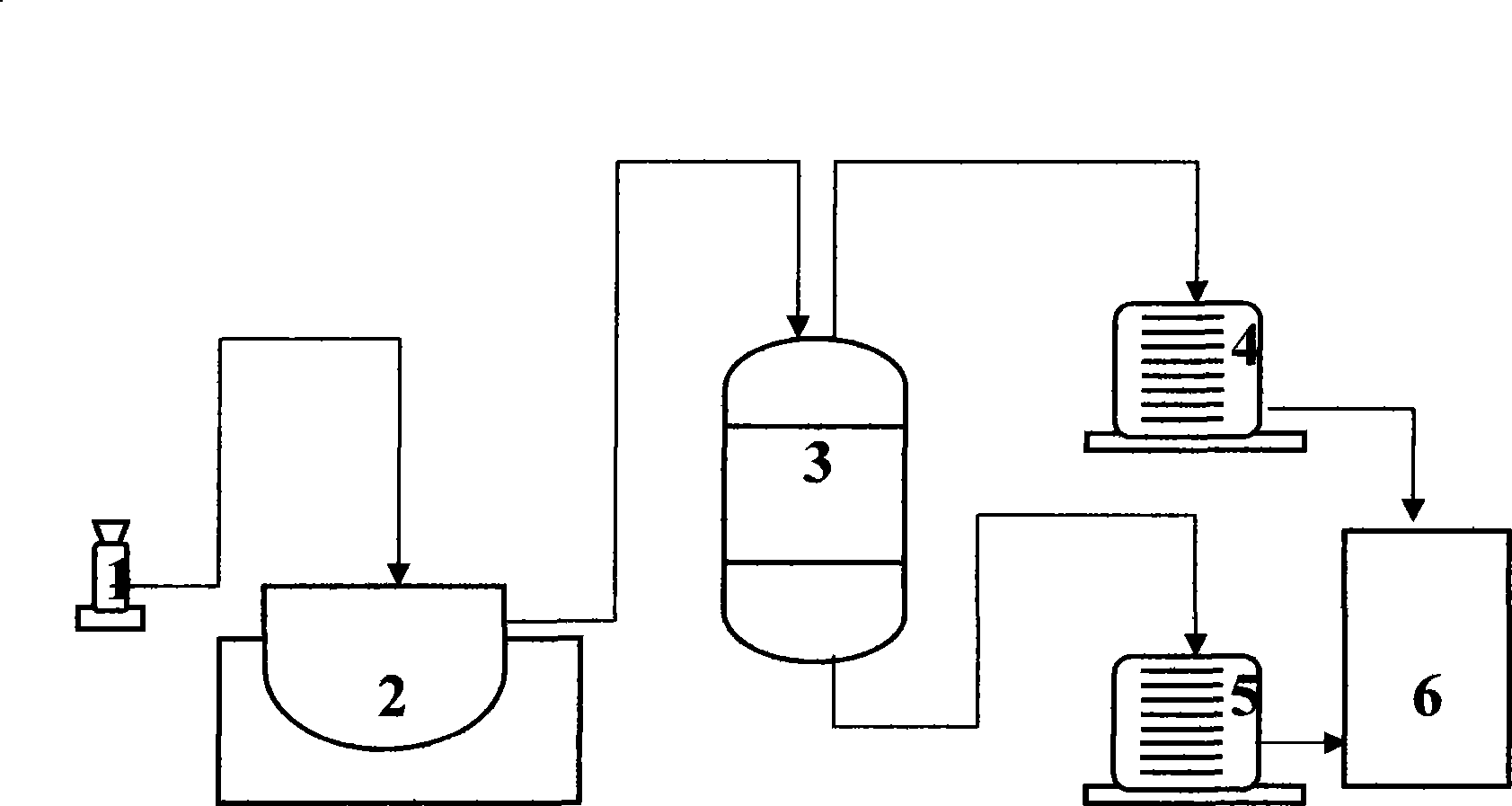

Image

Examples

Embodiment 1

[0015] 500 kilograms of pine roots are removed and pulverized (1) into 0.5 cm small wood chips, then put into the soaking tank (2) and soaked for 2 hours to get the clarified filtrate by suction filtration. Reciprocate three times like this again filtrate merges and injects in the distiller (3) and carries out distillation, and what remains in the soaking tank is 296 kilograms of very pure wood fibers and can be sold to paper mills etc. The distiller recovers the organic solvent through shallow distillation at 60-100 degrees and recycles it; when the temperature reaches the fraction of 100-150 degrees, 71.3 kilograms of crude turpentine can be obtained by cooling (4), and 45.7 kilograms of pure turpentine can be obtained after refining. Cut is 25.6 kilograms of pine light oil; When temperature reaches deep distillation 150-300 degree cut, obtain 44.6 kilograms of turpentine oil through cooling (5), obtain turpentine oil total quality as 70.2 kilograms with above-mentioned; Dist...

Embodiment 2

[0017] 500 kilograms of pine roots are removed and crushed into 3.5 cm small wood chips, and then put into a soaking tank to soak for 4 hours to obtain a clarified filtrate. Reciprocate three times like this again filtrate merges and injects in the distiller and carries out distillation, what remains in soaking pool is very pure wood fiber 315 kilograms and can sell to paper mill etc. The distiller undergoes shallow distillation at 60-100 degrees to recover the organic solvent and recycle it; when the temperature reaches the fraction of 100-150 degrees, 65.5 kg of crude turpentine can be obtained, and 39.9 kg of pure turpentine can be obtained after refining, and the rest is turpentine 25.6 kilograms; Obtain 38.2 kilograms of turpentine oils when temperature reaches deep distillation 150-300 degree cut, obtain turpentine oil total quality as 63.8 kilograms with above-mentioned; Distillation remaining heavy oil obtains the rosin of 70.06 kilograms through cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com