Patents

Literature

33results about How to "To achieve the purpose of deoxygenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fresh-keeping refrigerator

ActiveCN101368781AReduce energy consumptionAffect freshnessLighting and heating apparatusDomestic refrigeratorsOxygen ionsAir pump

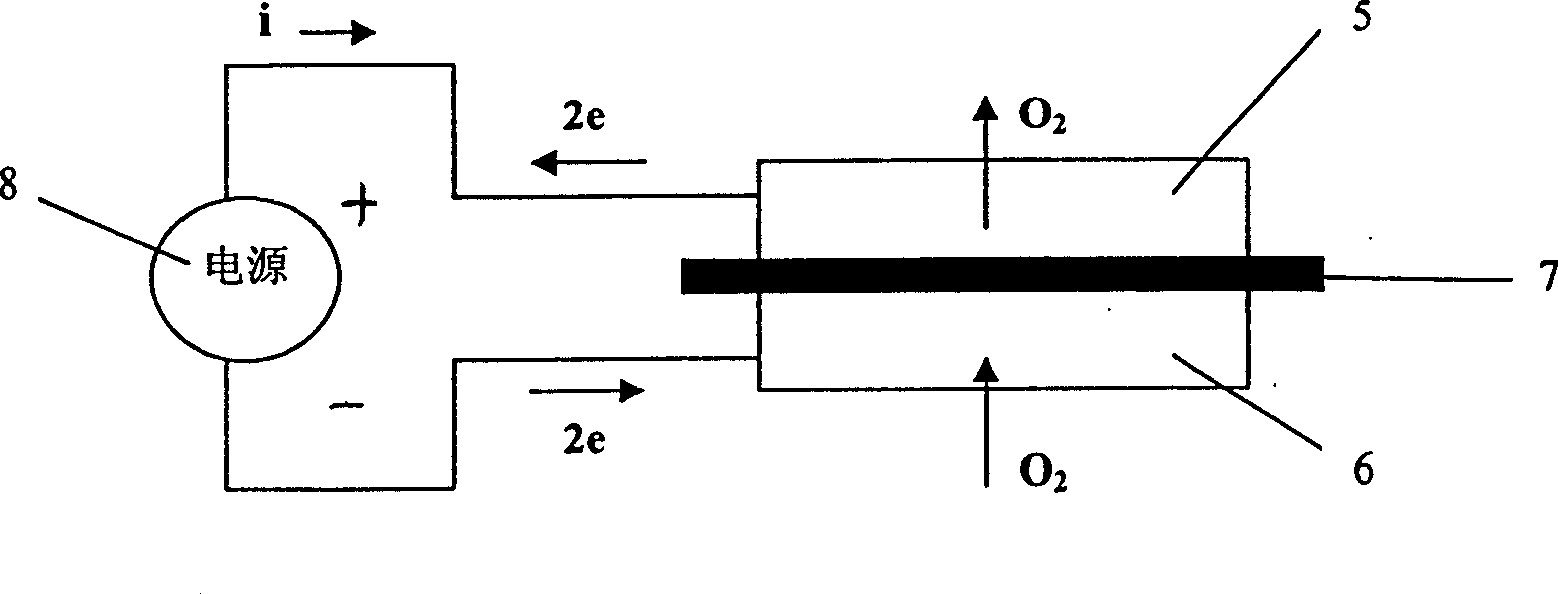

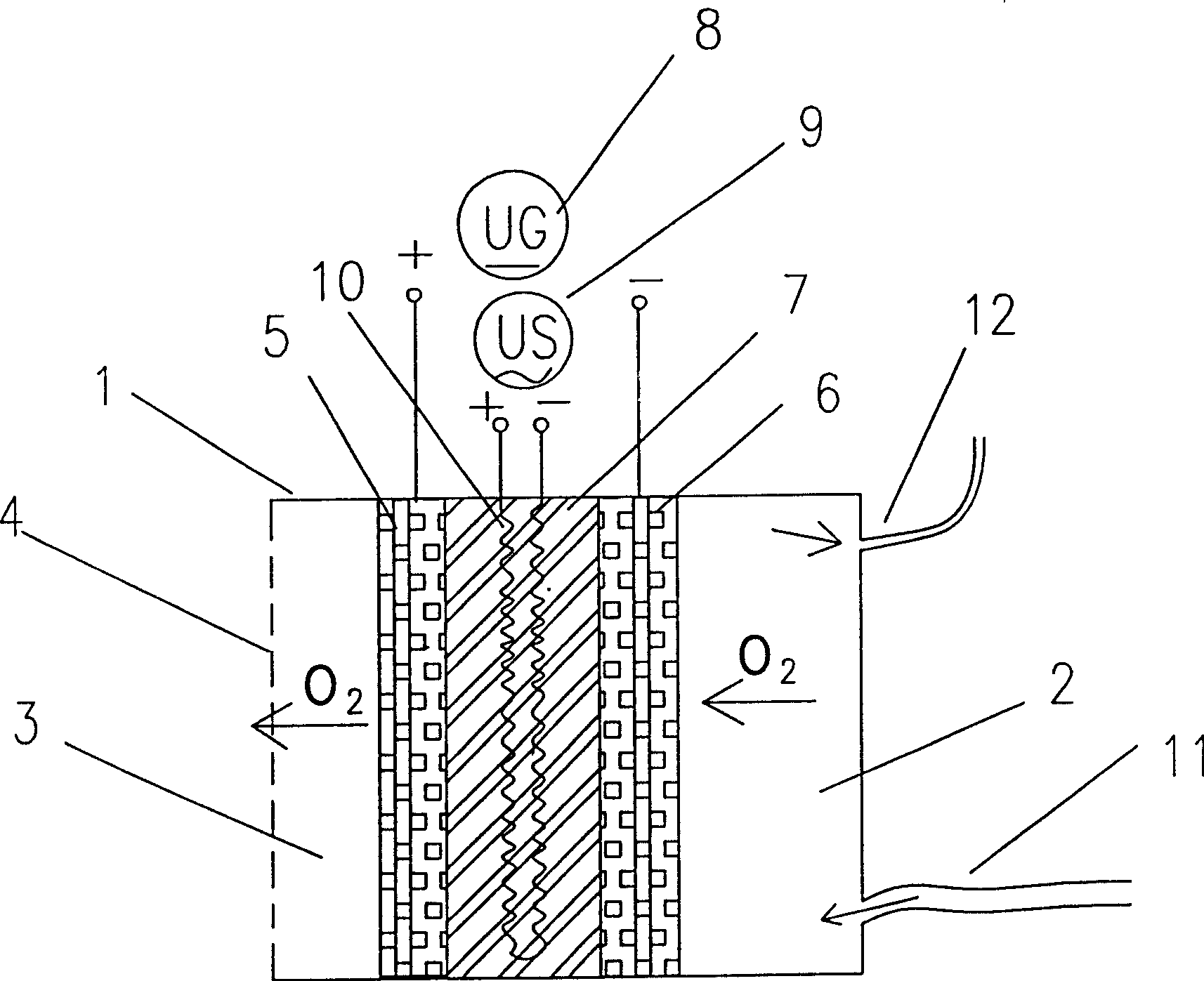

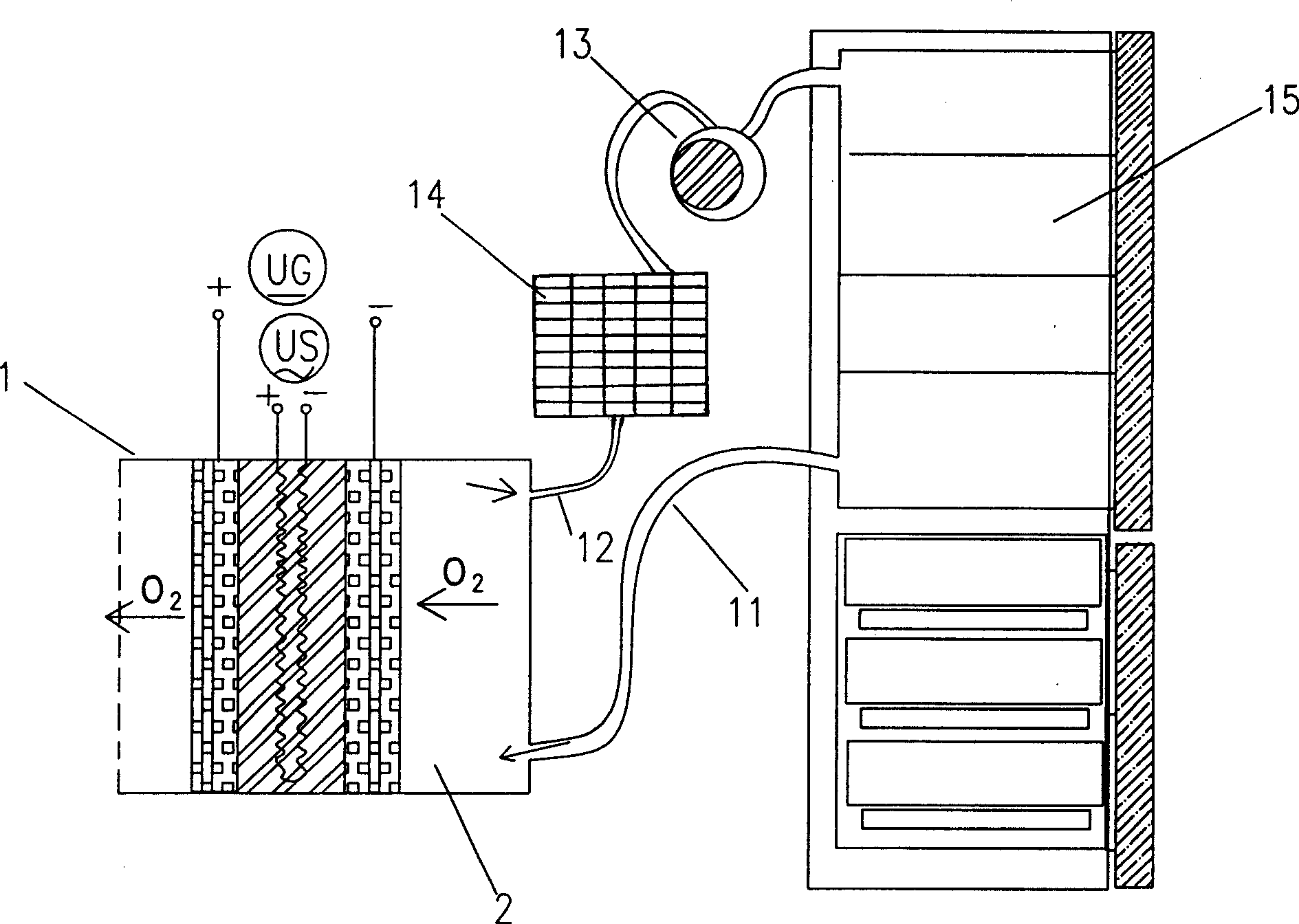

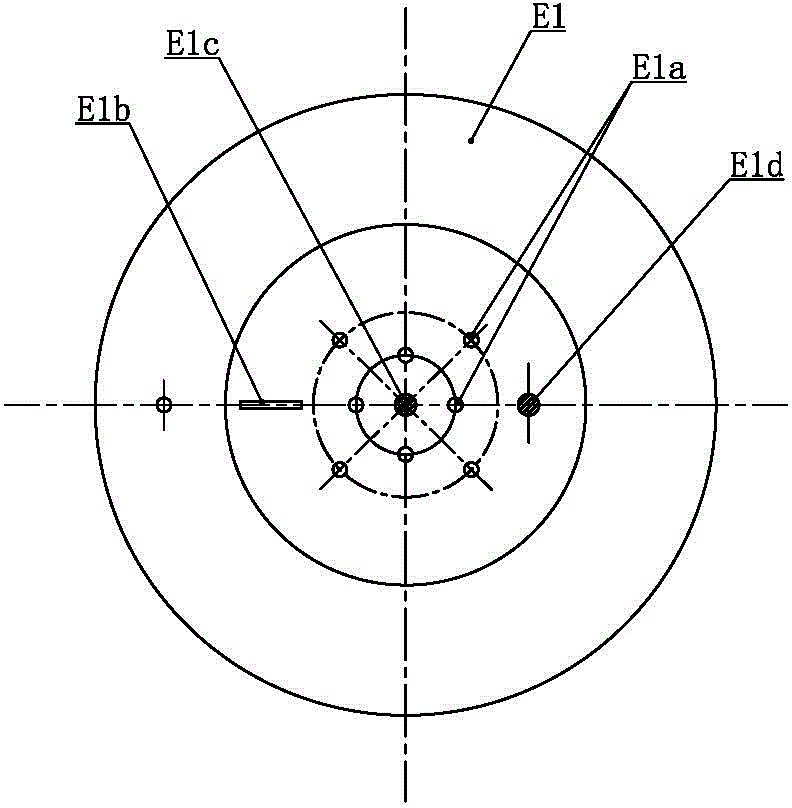

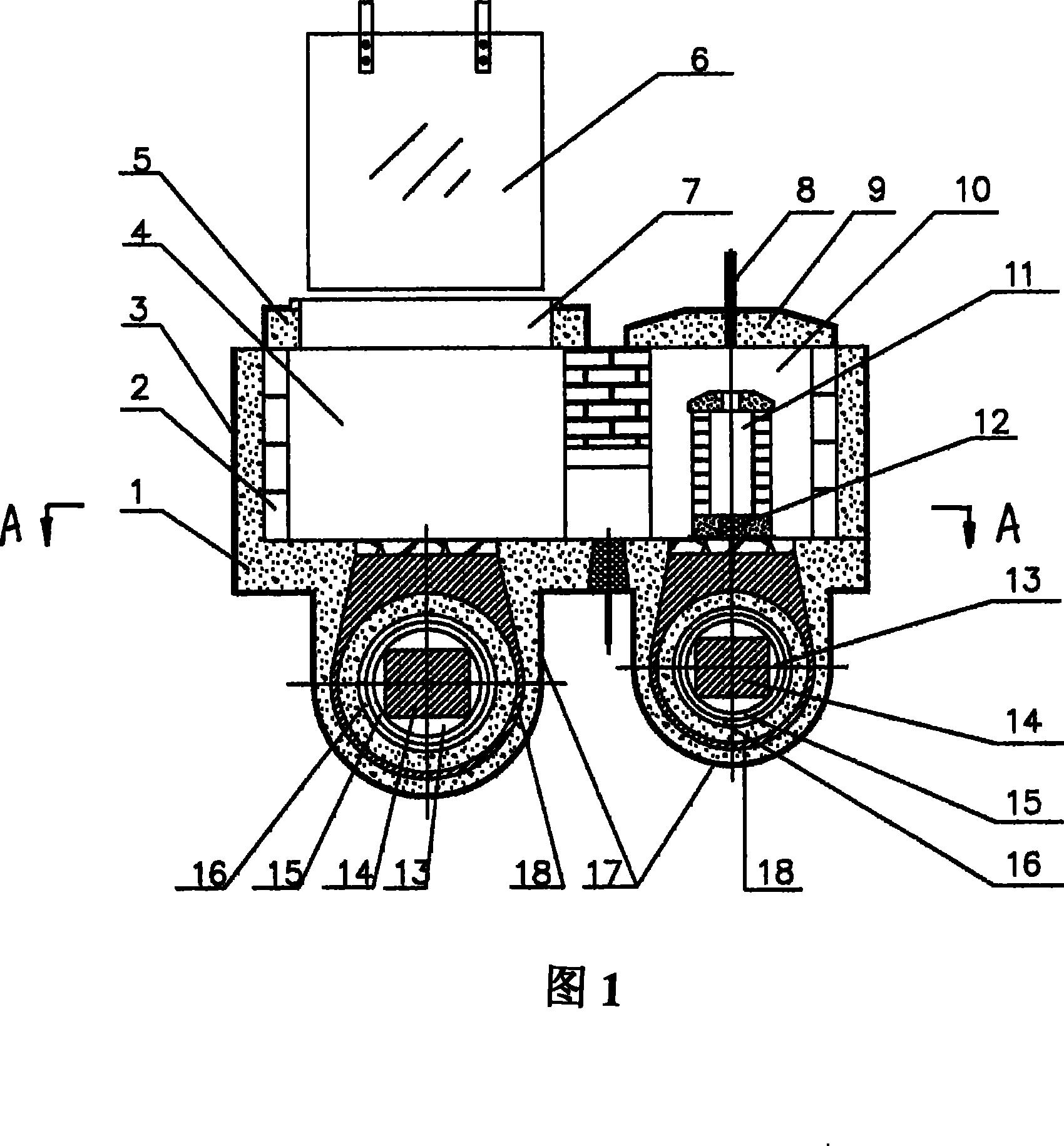

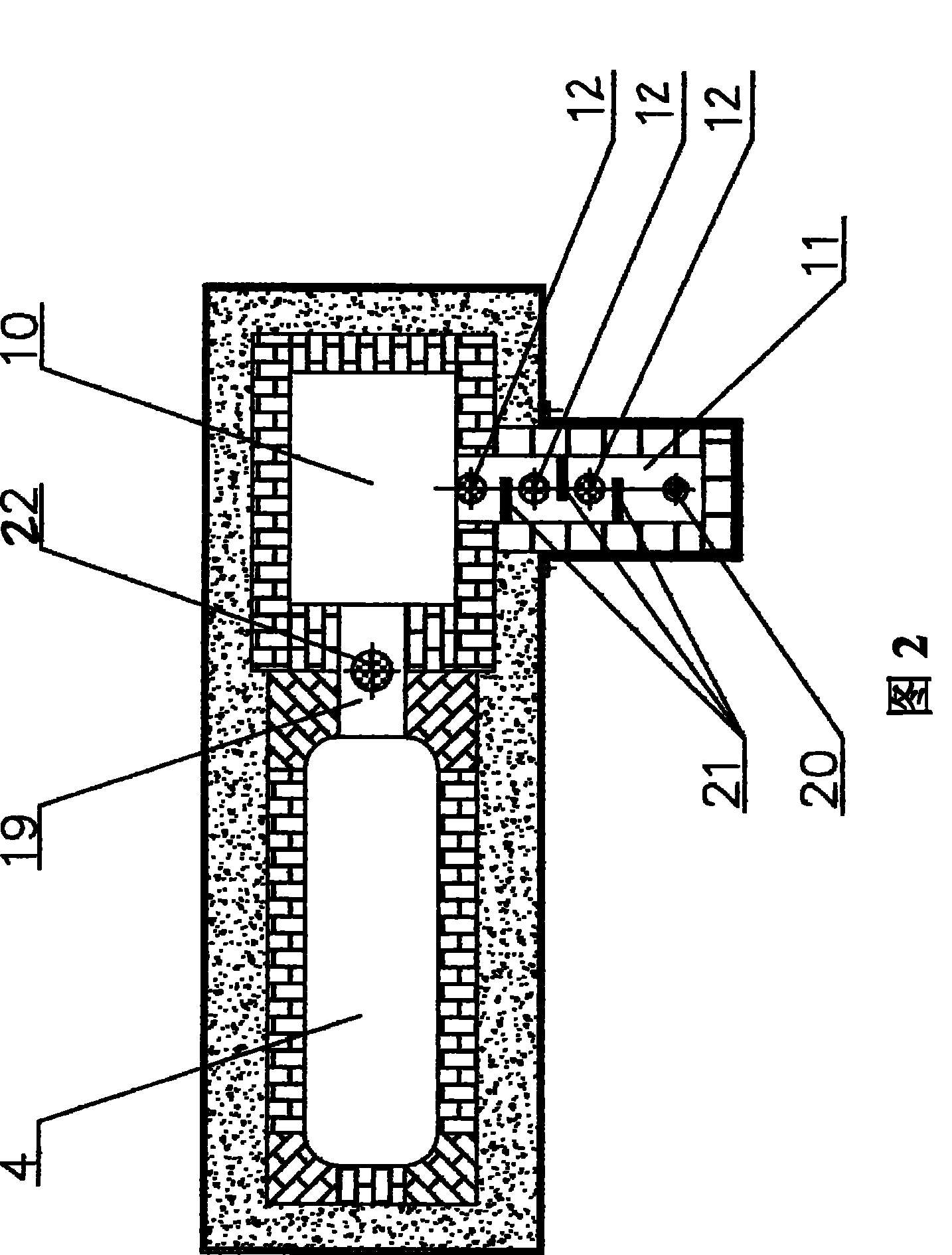

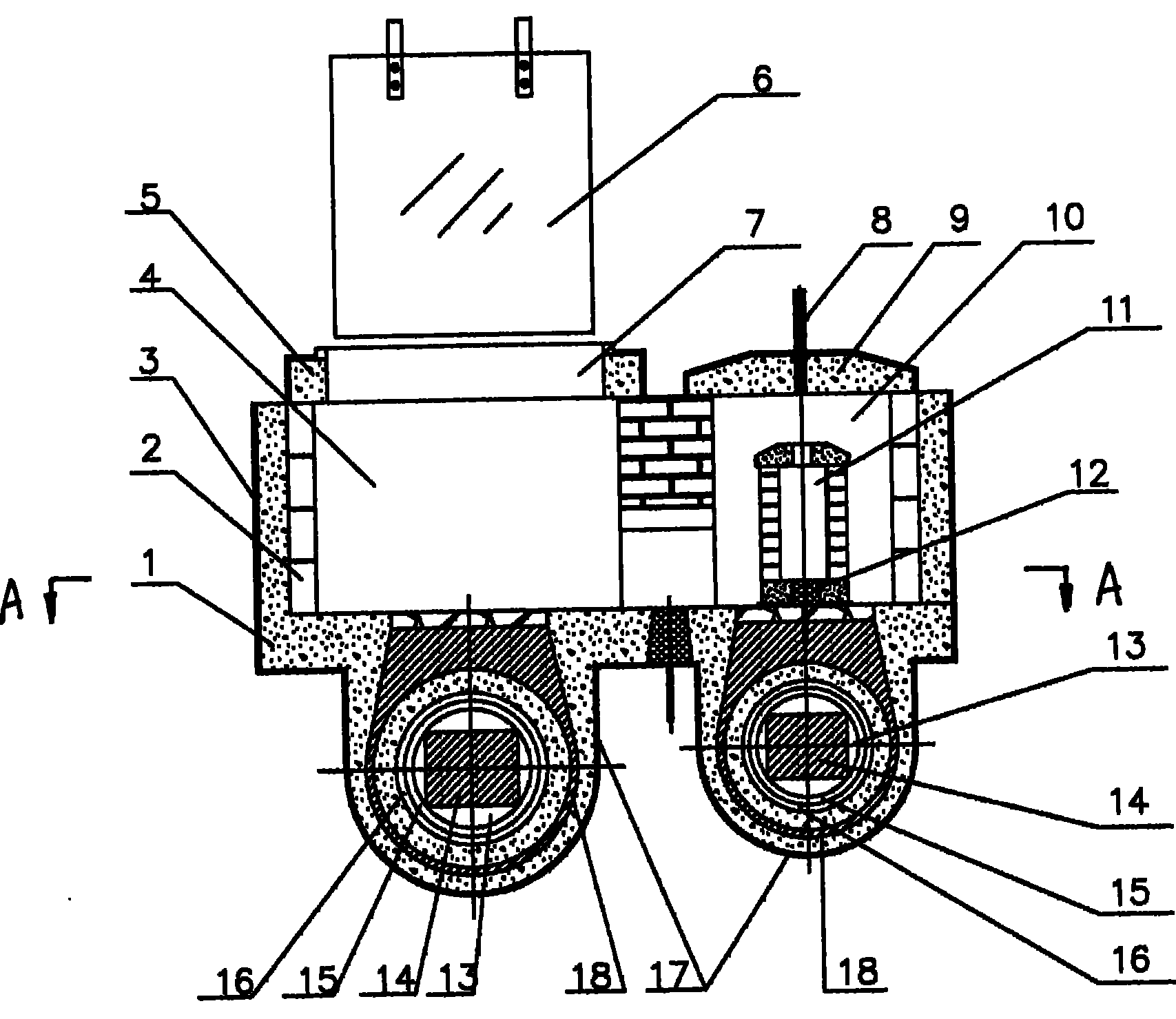

The invention discloses a fresh-keeping refrigerator, which is provided with a cooling space and a deaeration device; the deaeration device is arranged outside the cooling space of the refrigerator; a closed deaeration area is separated in the outer shell of the deaeration device by a solid oxide electrolyte plate; the deaeration area is connected correspondingly with the air inlet and the air outlet of the cooling space of the refrigerator through an air inlet pipe and an air outlet pipe; a conductive cathode is arranged beside the deaeration area of the electrolyte plate, while a conductive anode is arranged at the other side of the deaeration area; a heater for heating the solid oxide electrolyte plate is arranged inside the deaeration device; and an air pump is arranged on the pipe communicated between the deaeration device and the cooling space of the refrigerator. Only oxygen ions can pass the electrolyte plate when the electrolyte plate is heated to more than 400 DEG C; the oxygen molecules in the deaeration area get the electrons from the conductive cathode and then turn into oxygen ions; the oxygen ions pass through the electrolyte plate under the effect of the electric field, lose the electrons on the conductive anode and then become oxygen molecules again; and the oxygen molecules are deoxidized through the air pump and then sent into the refrigerator through cooled -hypoxic gas, so that the gas in the cooling space is in a hypoxic state and is more fresh-keeping.

Owner:HENAN XINFEI ELECTRICAL EQUIP

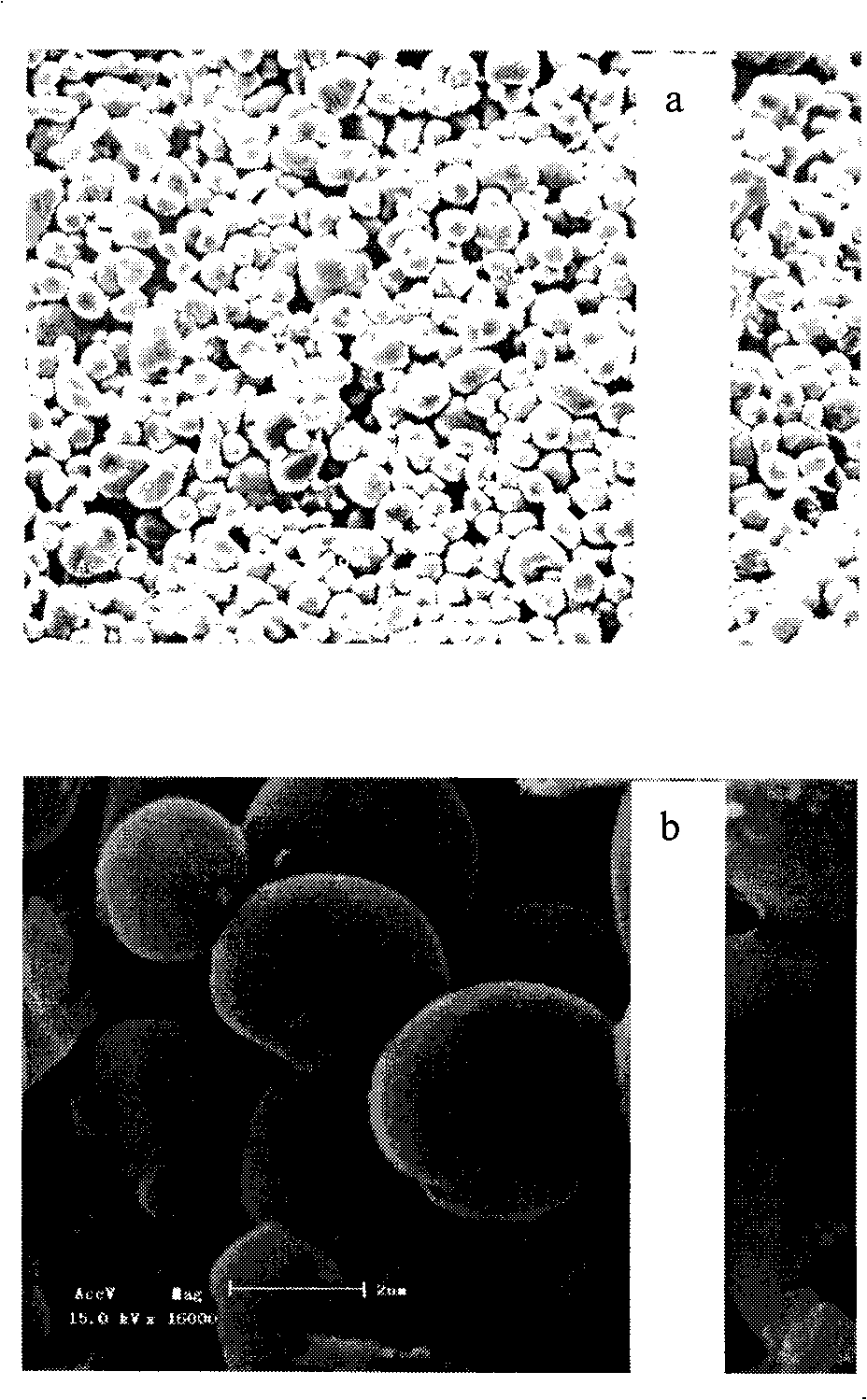

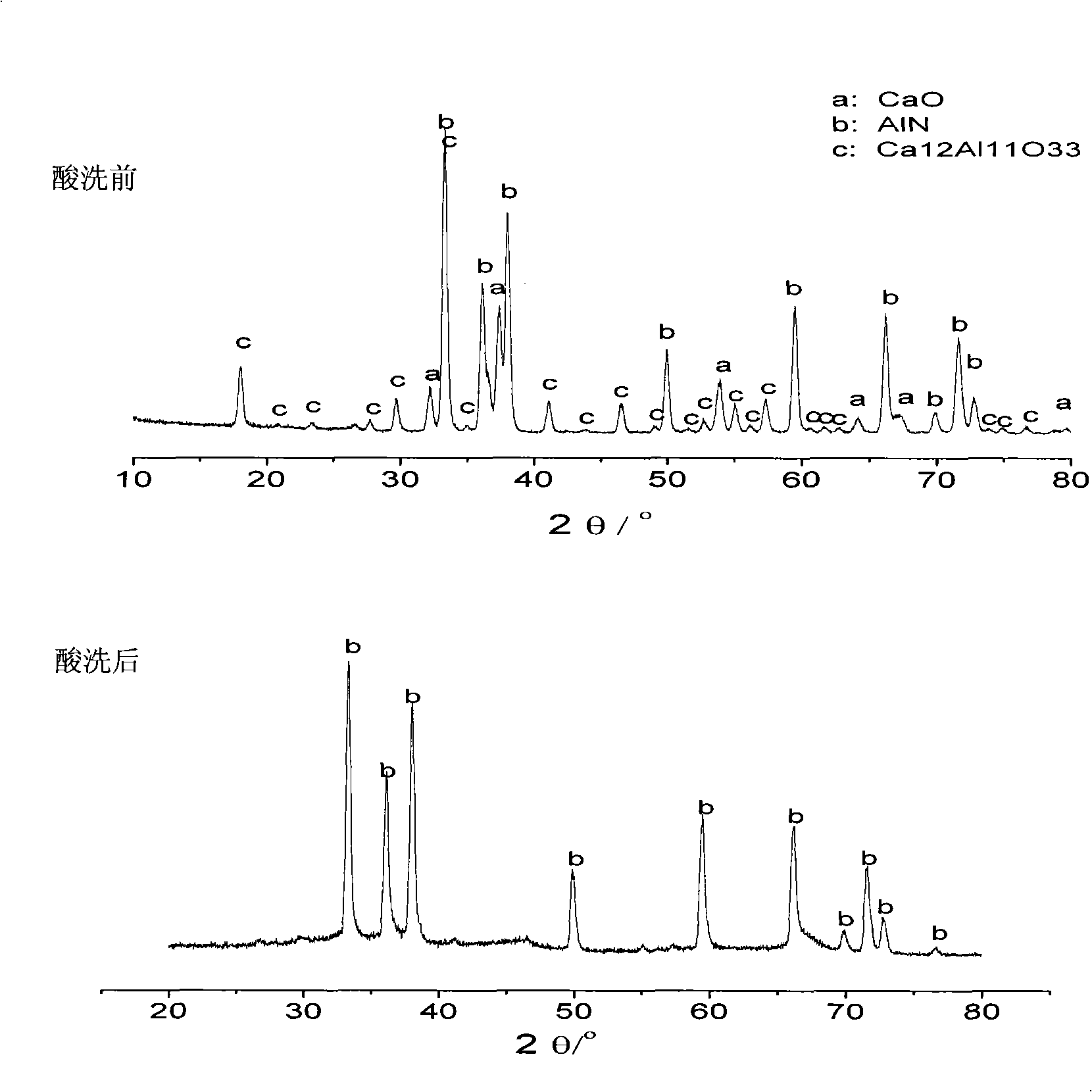

Preparation method for low-oxygen spherical aluminum nitride powder

ActiveCN101525238AEasy to separateTo achieve the purpose of deoxygenationNon oxide ceramicsMaterials preparation

The invention provides a preparation method for low-oxygen spherical aluminum nitride powder and pertains to the field of non-oxide ceramic powder material preparation technology. The low-oxygen spherical aluminum nitride powder can be obtained through the following steps: ball-grinding, evenly mixing and then drying aluminum nitride powder and appropriate amount of spherical auxiliary materials for deoxidation; placing the mixture in a graphite crucible with certain loading density, heating to 1,550 to 1,900 DEG C in N2 or Ar and preserving for 0 to 20 hours, and then cooling with the crucible; mechanically crashing the product and heating to 600 DEG C in a muffle furnace for carbon emission, then washing in a hydrochloric acid solution with 5 to 20 mass percent concentration and fully washing the product after acid cleaning in de-ionized water for 2 to 10 times; after drying, obtaining the aluminum nitride powder with 3 to 15mum median particle diameter, more than 90 percent sphericity and less than 1wt percent oxygen content. The preparation method provided by the invention can achieve spherical particle morphology and granulation at the same time required by the high thermal-conductivity aluminum nitride filling.

Owner:TSINGHUA UNIV

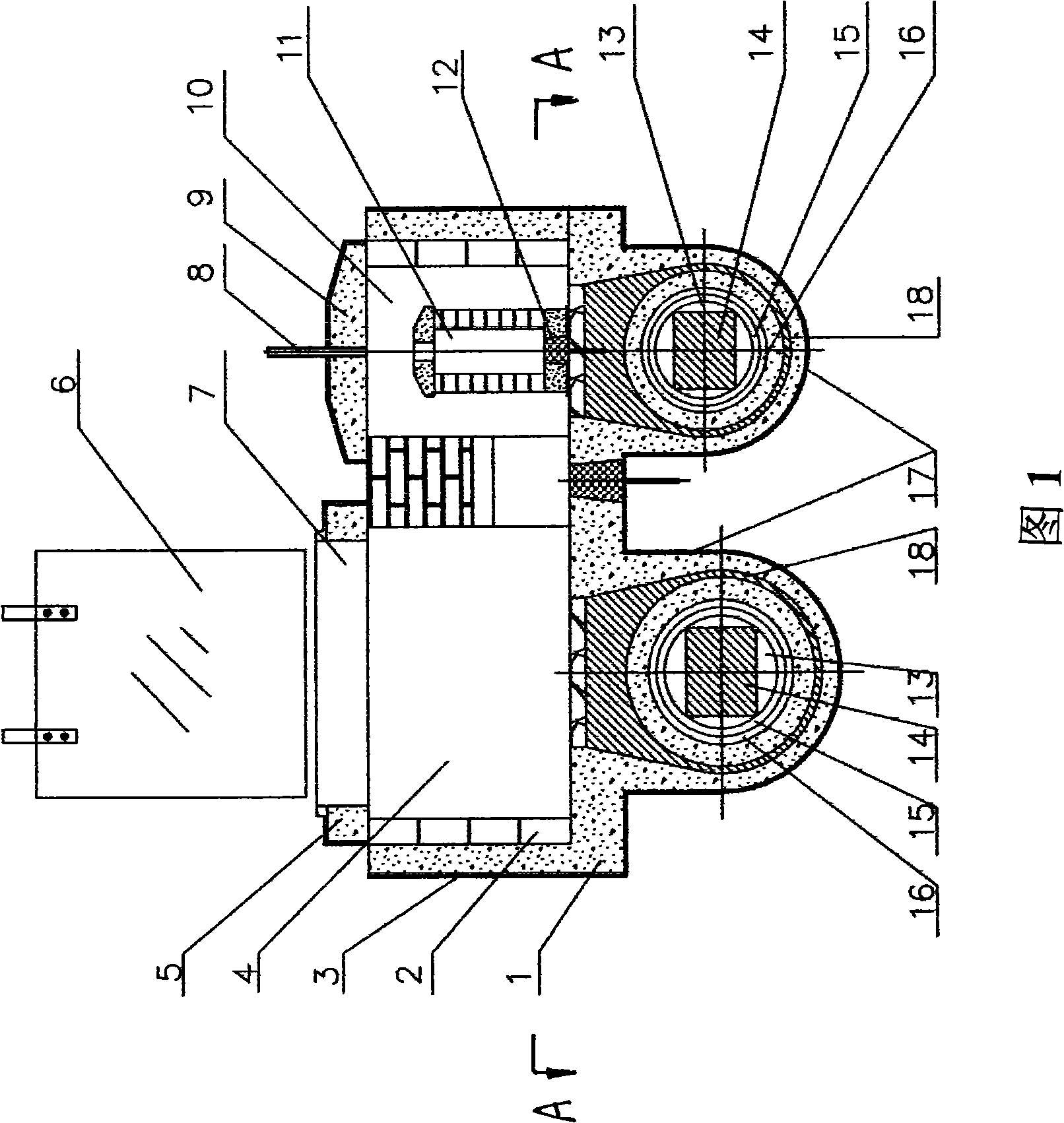

Method for continuously converting and casting oxygen-free copper ingot

The invention provides a continuous blowing and casting method of oxygen-free copper ingots, which pertains to the metal smelting and casting technical field and is carried out according to the technical steps as follows: A. cathode copper is firstly melted in a smelting furnace, and melted copper liquid enters a deoxidation furnace through a bottom blowing chute; B. carbon monoxide gas or the mixed gas of carbon monoxide and nitrogen enters the copper liquid in the bottom blowing chute through the bottom blowing chute and enters the deoxidation furnace with the copper liquid to realize the deoxidation and the degassing of a first stage; C. when passing through a diversion trench arranged in a bottom blowing furnace end, the carbon monoxide gas or the mixed gas of carbon monoxide and nitrogen enters the copper liquid in the diversion trench for realizing the deoxidation and the degassing of a second stage to the copper liquid in the diversion trench; D. the copper liquid after the second stage of deoxidation and degassing enters a crystallizer through a casting gate arranged in the bottom blowing furnace end. The oxygen content of an oxygen-free copper ingot base produced by the method of the invention can stably reach not only less than 5ppm, but also less than 3ppm.

Owner:ZHEJIANG HAILIANG

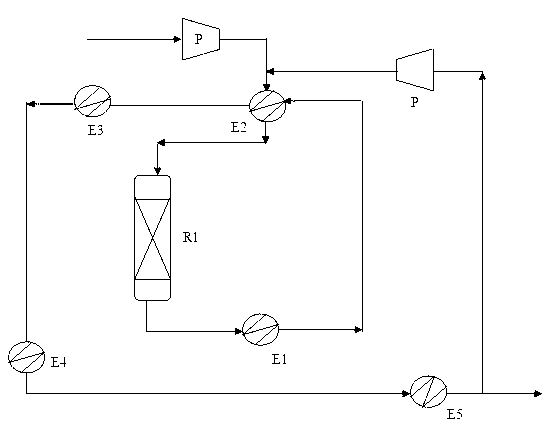

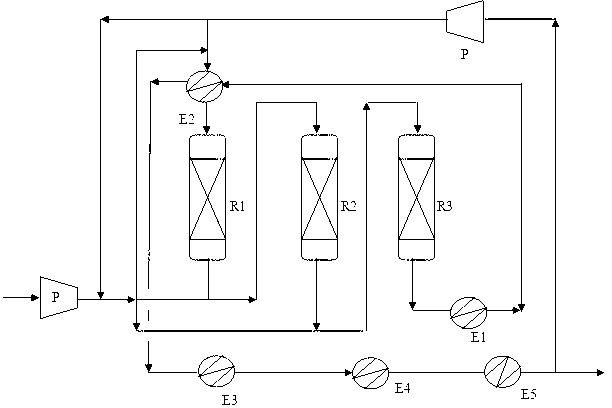

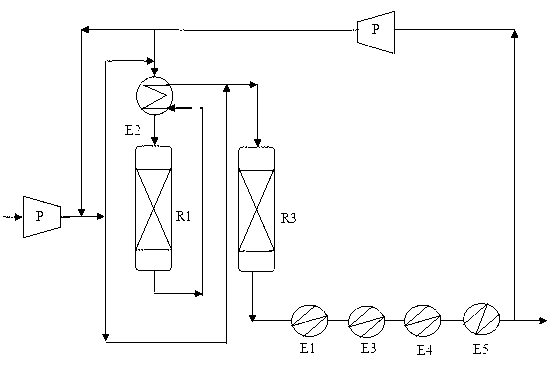

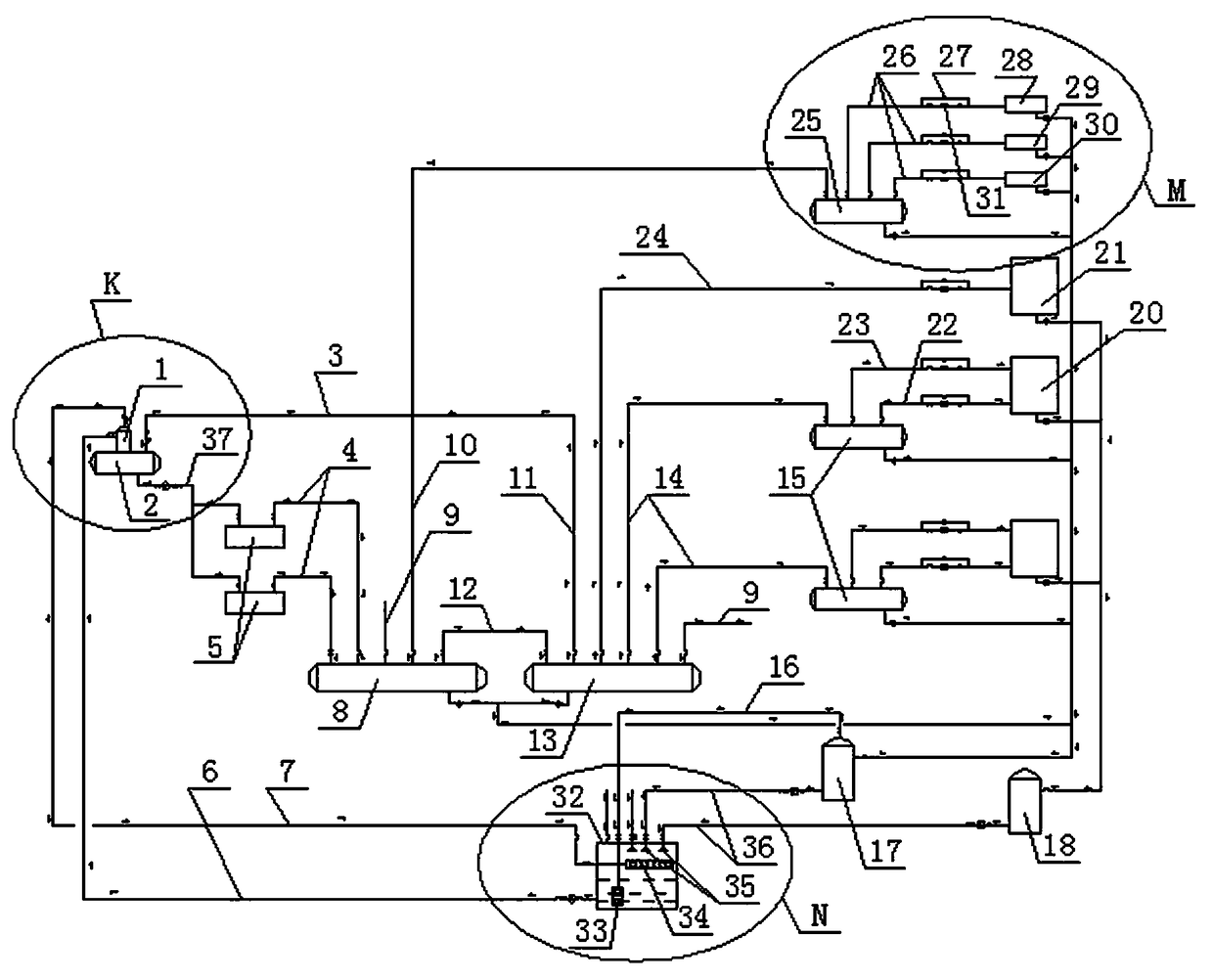

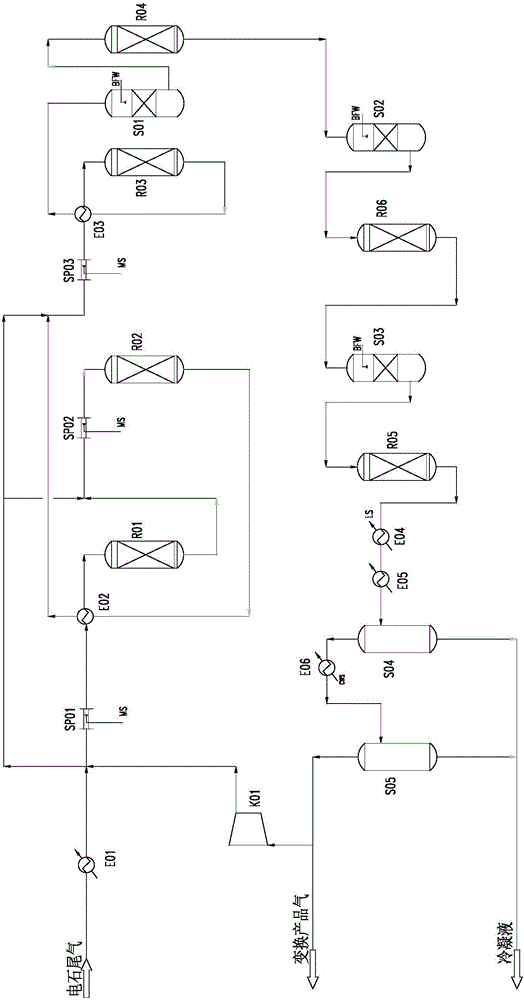

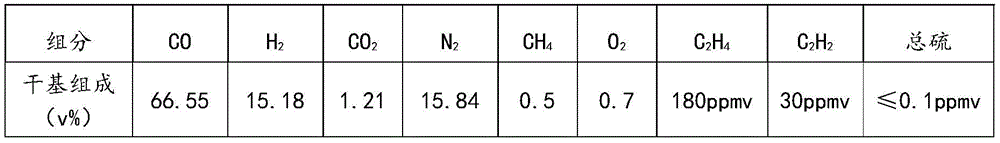

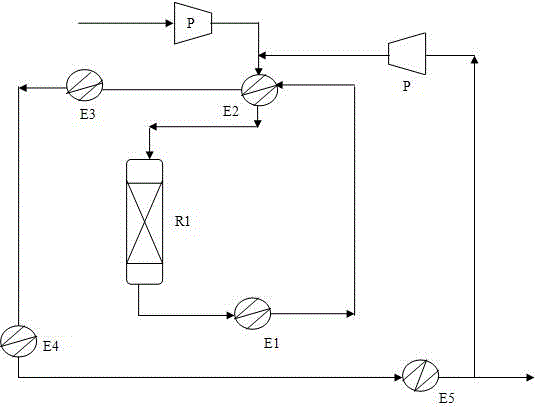

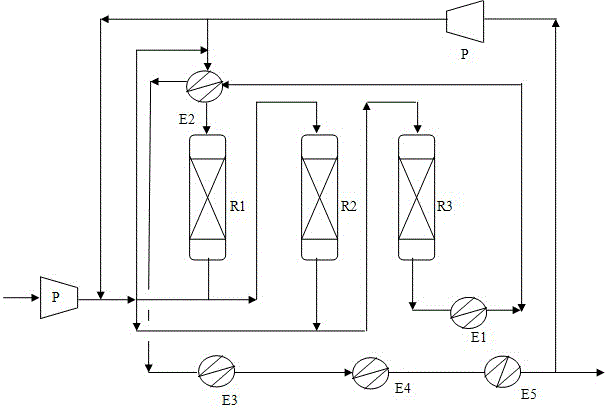

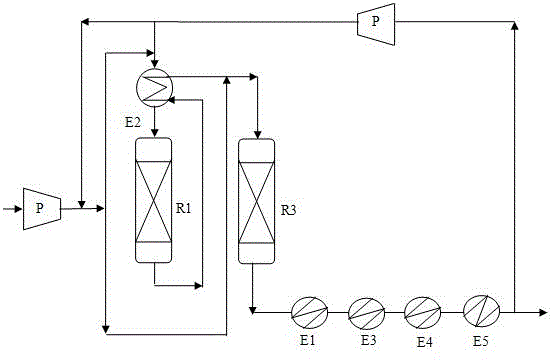

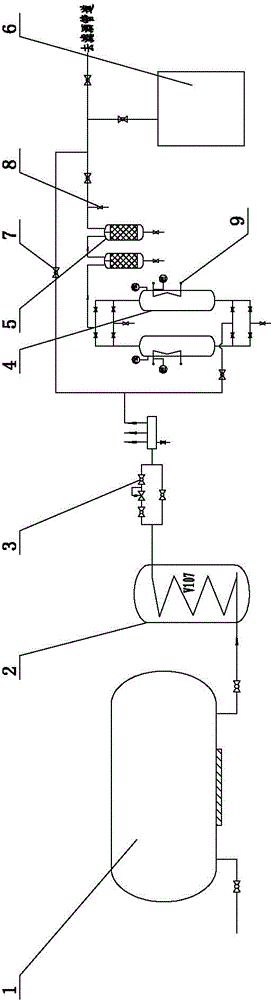

Process of catalytic deoxidation of oxygen-containing coal bed methane and comprehensive utilization of reaction heat

ActiveCN102994185AReduce energy consumptionTo achieve the purpose of deoxygenationGaseous fuelsSteam generation using hot heat carriersChemistryMethane

The invention discloses a process of catalytic deoxidation of oxygen-containing coal bed methane and comprehensive utilization of reaction heat; in the presence of a catalyst, methane and oxygen in the raw material of coal bed methane are subject to a catalytic combustion reaction for deoxidation; a lot of reaction heat is released during the reaction process; according to the volume flow rate of the raw material coal bed methane to be processed and the oxygen content of the raw material coal bed methane, a single or a plurality of serially-connected adiabatic reactors are selected as the catalytic reactor; after the reaction, the high-temperature deoxidized gas is subject to four-stage heat recovery; after the four-stage heat utilization, a part of the deoxidized gas enters a next processing section, and a part of the deoxidized gas returns to the deoxidation reaction system; the generated steam is used for pushing the raw material gas and the circulation gas in the deoxidation process to a turbocompressor, or is used for power generation. The process of the invention realizes full and reasonable utilization of heat by reaction heat multistage recovery, effectively reduces process energy consumption, is wide in application scope, and is a clean, low-consumption catalytic deoxidation process for gas rich in combustible gas.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

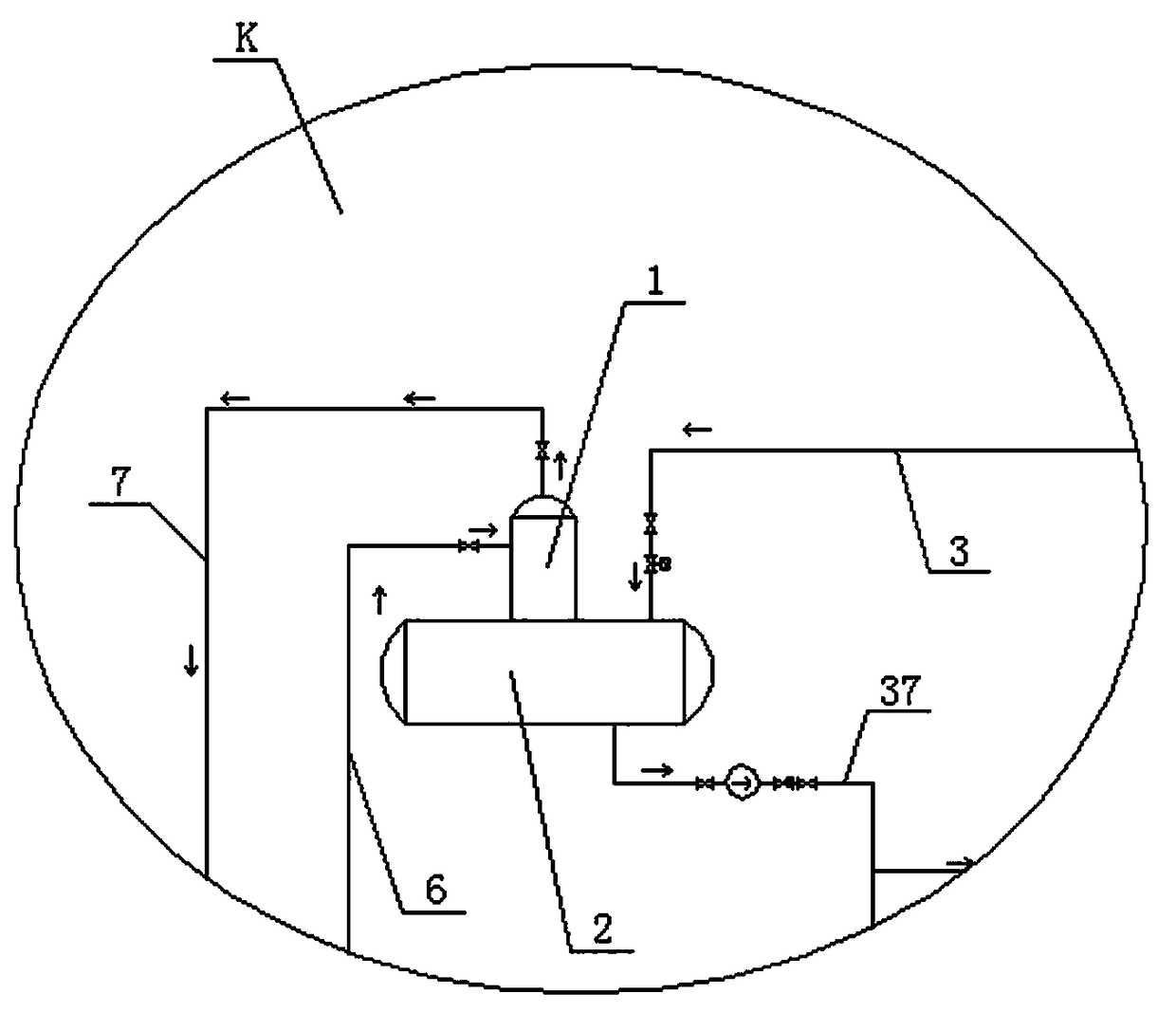

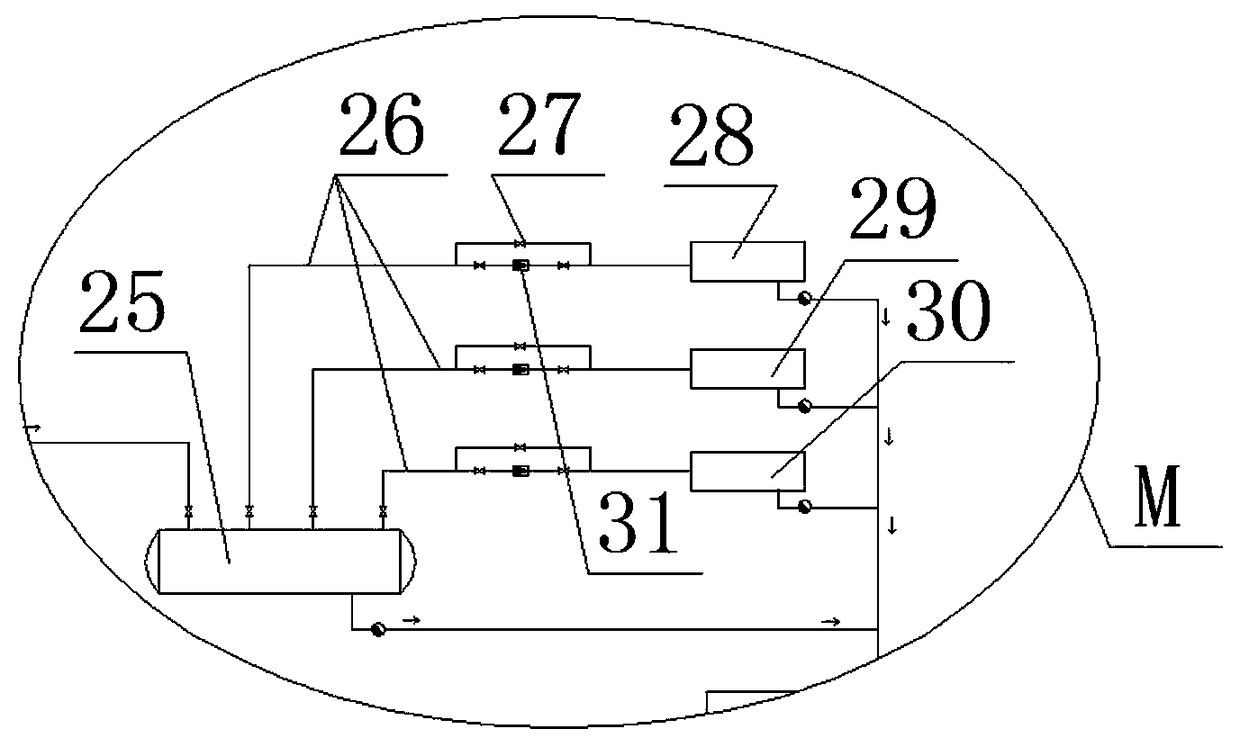

Fire-proof device of pressurizing nitrogen-making oil tank and working method thereof

ActiveCN107954001AIncrease bleed air pressureIncreased bleed air pressureFuel tank safety measuresWeight reductionAutomatic controlExplosion protection

The invention discloses a fire-proof device of a pressurizing nitrogen-making oil tank and a working method thereof, and belongs to the technical field of fire and explosion protection. Bleed air pressure of an engine is increased by using a self-pressurizing mode, and a nitrogen gas with high concentration is separated from the bleed air through a hollow fiber membrane after impurity removing anddrying and is injected to the oil tank through a control system according to the need so that oxygen gas in the oil tank is removed; in addition, a turbo expander and a compressor are combined for generating expansion work, the work output by the expander drives the compressor to compress the bleed air of the engine, the gas pressure is further increased so as to reach the needed pressure of thehollow fiber membrane for separation, and nitrogen-making efficiency is improved. Nitrogen-enriched gas is charged into the oil tank, oxygen content in the oil tank is reduced, and a flow of the gas can be regulated by automatically controlling devices in a nitrogen-charging process, so that needed inert gas is generated. The oil tank is located in a non-combustion state, and the purpose of fire and explosion protection is achieved. The fire-proof device can be automatically controlled, and has the advantages of high inerting efficiency, less energy consumption and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

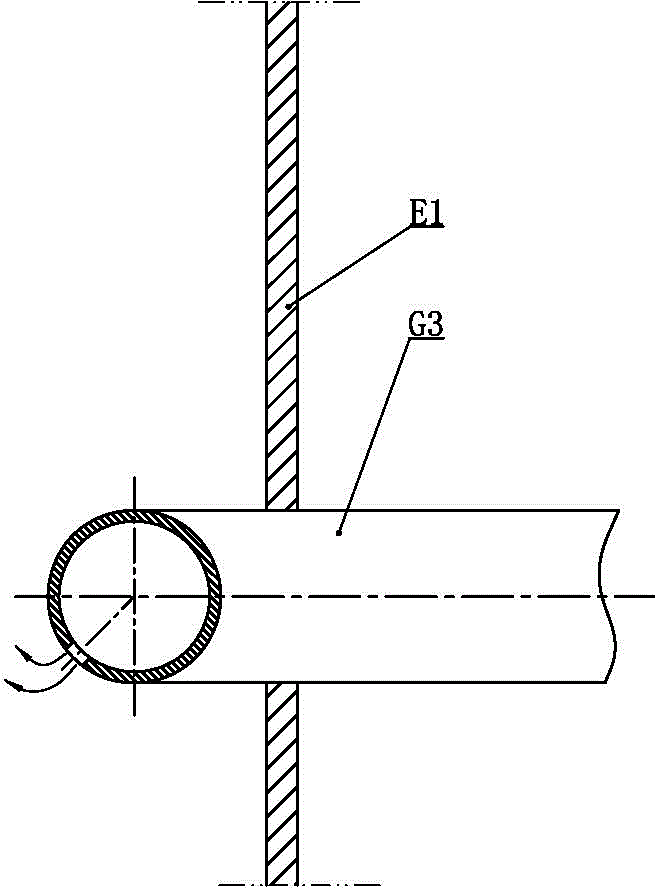

Deoxidation method and device for converter gas

InactiveCN105886695AIncrease partial pressureIncrease chance of contactManufacturing convertersCopper platingRoom temperature

The invention provides a deoxidation method and device for converter gas. The deoxidation method includes the following steps that the converter gas is subjected to dust removal, and the dust content in the converter gas with dust removed is smaller than 5 mg / nm<3>; the converter gas with dust removed is conveyed into a deoxidation device which is filled with stainless steel balls with surfaces plated with copper, the temperature in the deoxidation device is controlled to be 150-300 DEG C, and the oxygen content in deoxidized converter gas is smaller than 200 ppm; the deoxidized converter gas is air-cooled to room temperature and conveyed to a downstream microbial anaerobic fermentation procedure. According to the requirements of raw converter gas in the microbial anaerobic fermentation process, a simple and efficient novel deoxidizing agent is designed, that is, the surfaces of the stainless steel balls are plated with a layer of copper. Oxygen is consumed according to the principle that copper and oxygen react to generate copper oxide, and the aim of deoxidation is achieved. The deoxidation device is easy to design, economical, reasonable and capable of removing oxygen in the converter gas at low energy consumption to meet the requirements of the fermentation process.

Owner:上海宝钢气体有限公司

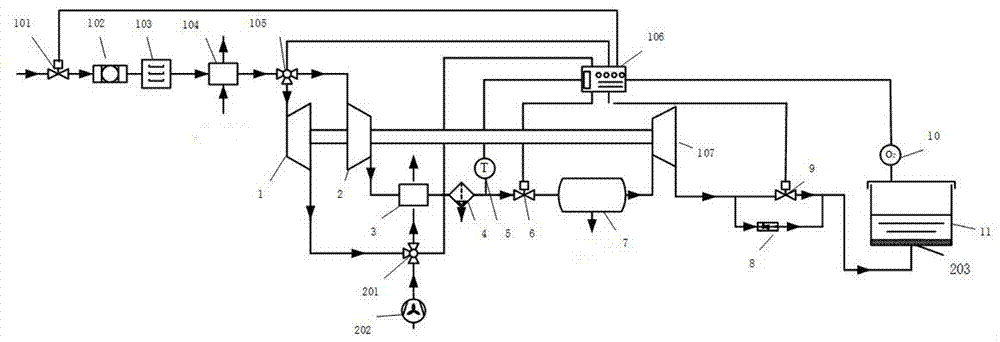

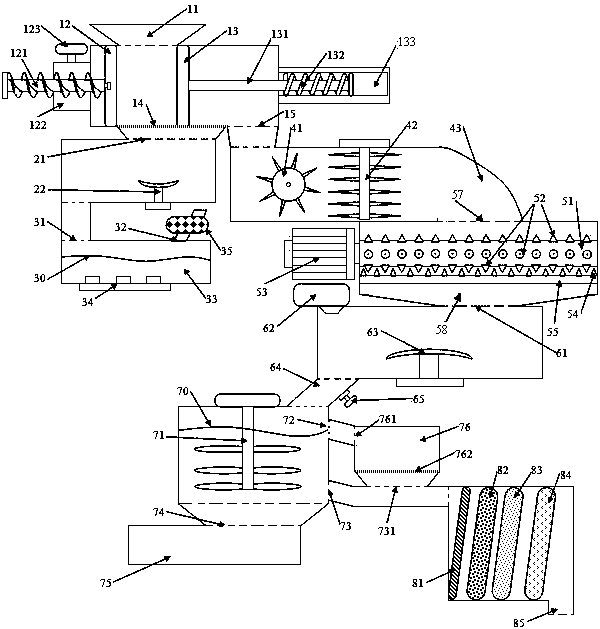

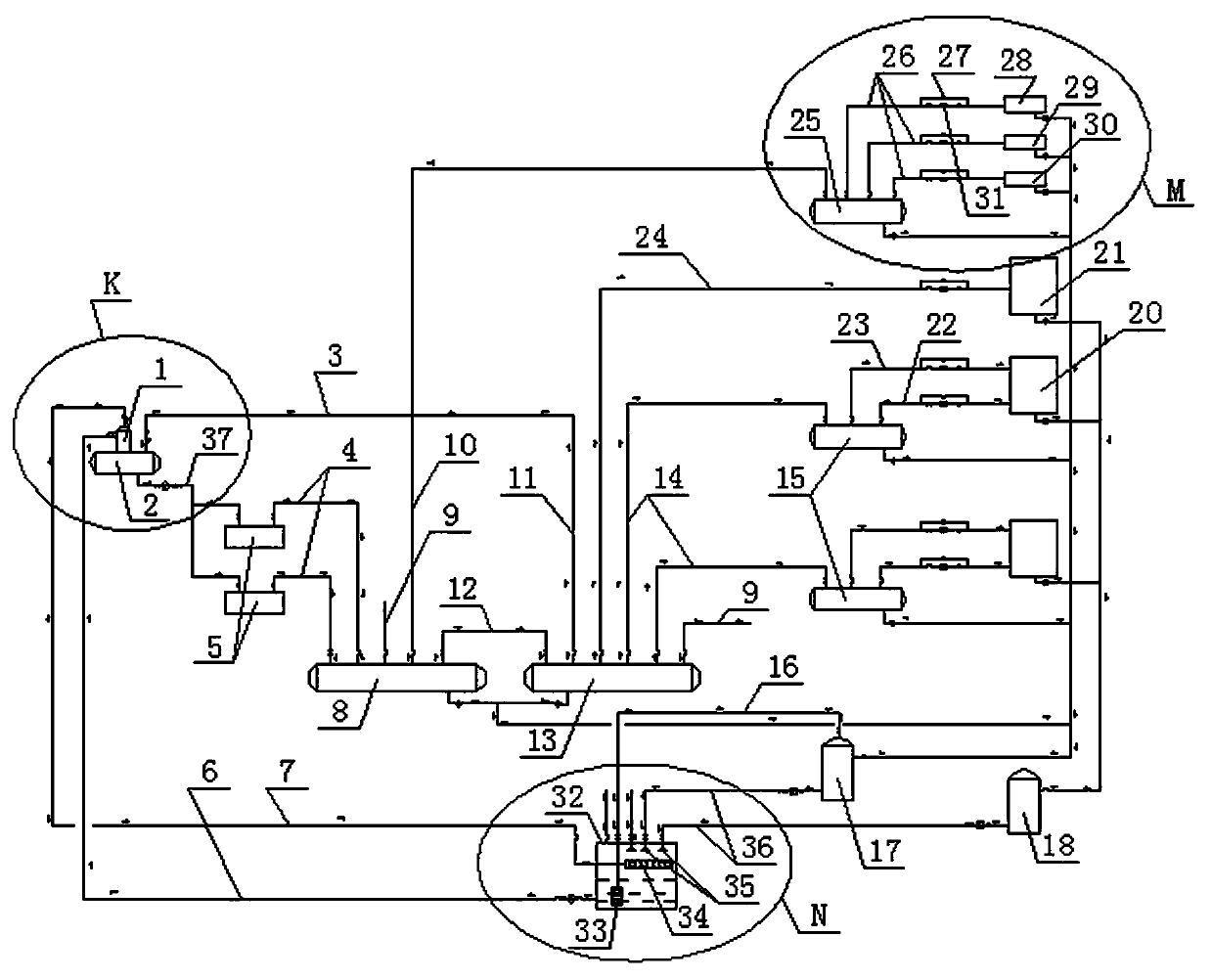

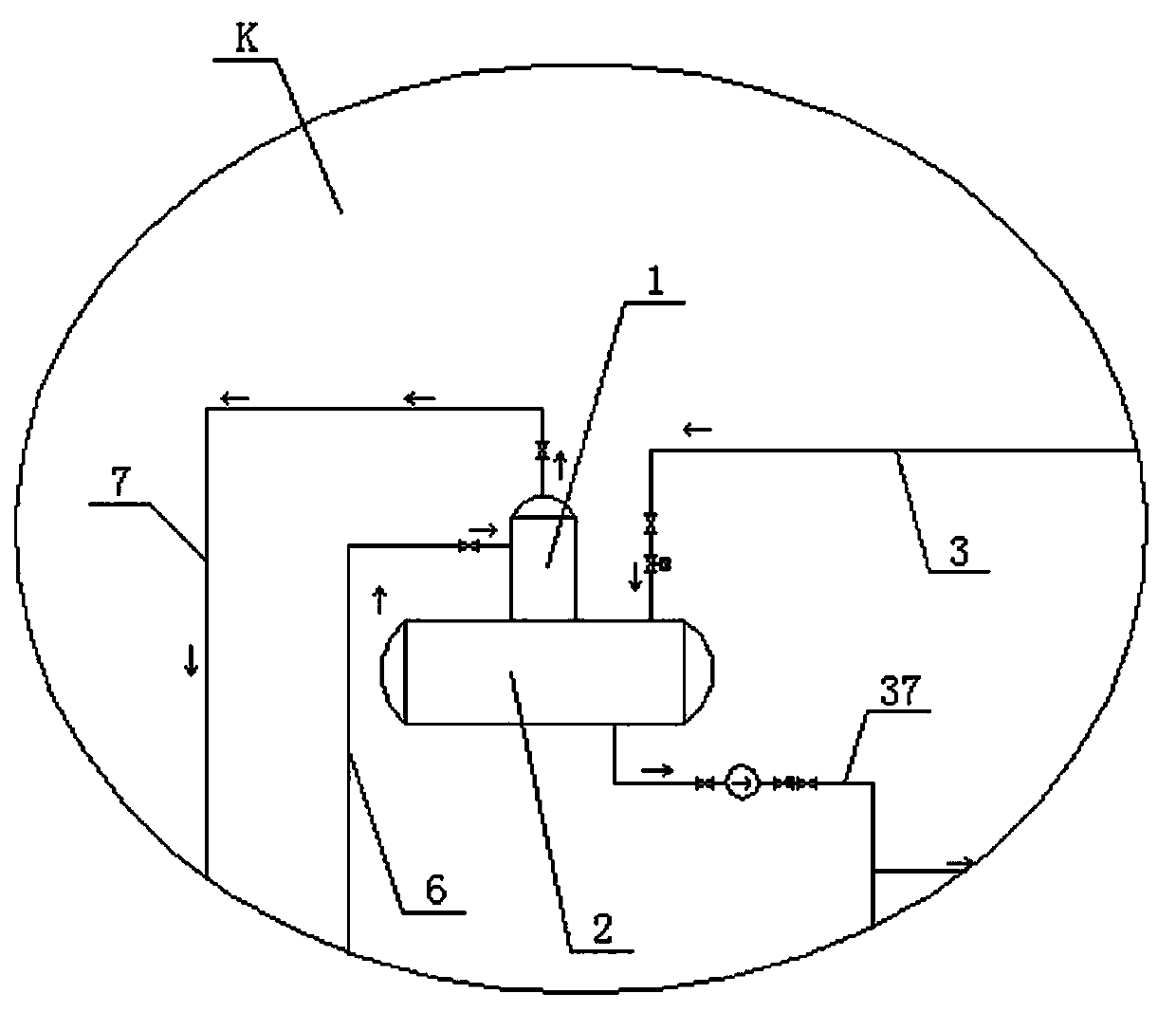

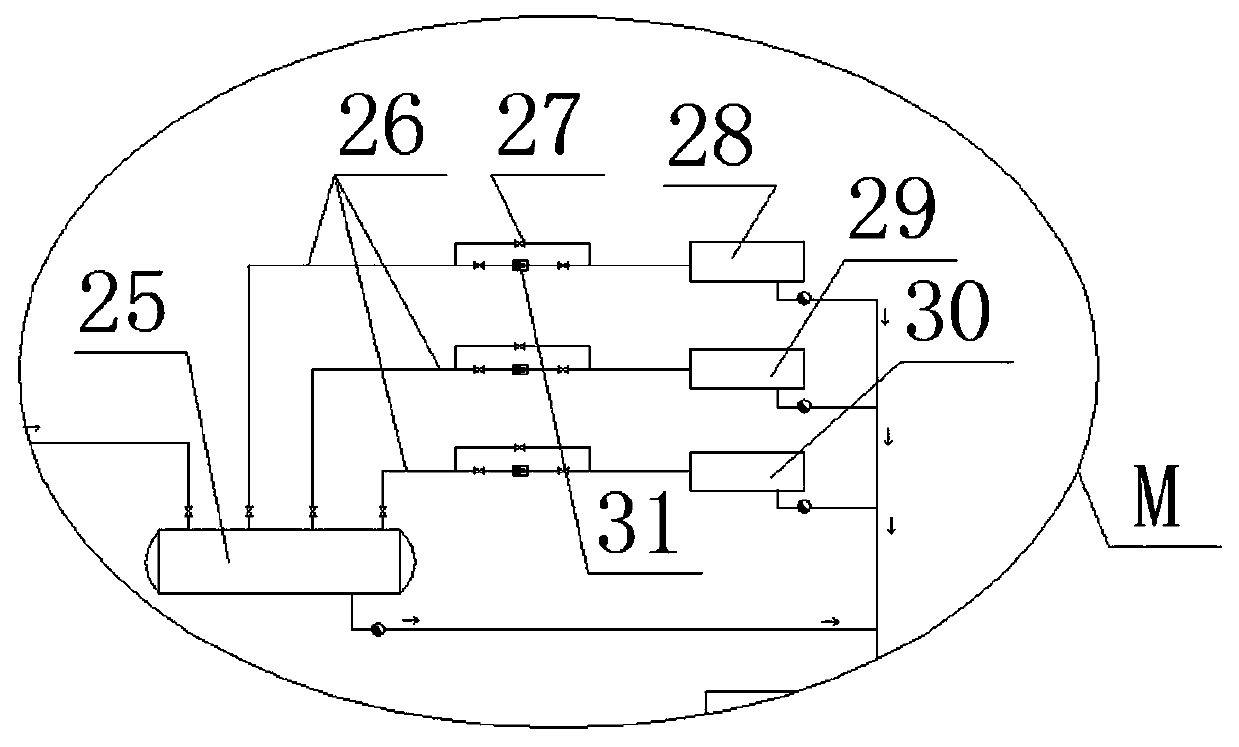

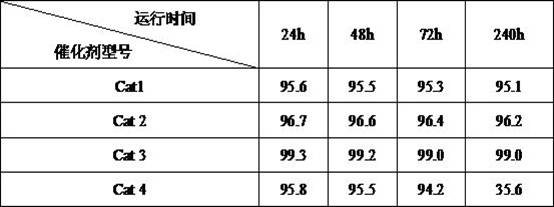

A steam supply system for a cigarette factory

ActiveCN108895423AImprove utilization efficiencyReduce consumptionLiquid degasificationFeed water supplyEngineeringAir conditioning

A steam supply system for a cigarette factory belonging to the technical field of steam transmission and supply, including boilers, high pressure cylinder, low pressure cylinder, A sub-cylinder for silk production, Heat exchanger, air conditioning cylinder, high-pressure condense water recovery tank, A low-pressure condense water recovery tank and a condense water tank, the boiler is connected with the high-pressure cylinder through the first pipe, the high-pressure cylinder is connected with the low-pressure cylinder through the second pipe, the high-pressure cylinder is connected with the filament-making production cylinder through the third pipe, the low-pressure cylinder is connected with the heat exchanger through the fourth pipe, and the low-pressure cylinder is connected with the air conditioning cylinder through the fifth pipe; The high-pressure steam in the boiler is divided into high-pressure steam and low-pressure steam by the high-pressure cylinder and low-pressure cylinder, and the steam is supplied to different workshops and related equipments respectively, so the utilization efficiency of the steam is improved.

Owner:CHINA TOBACCO HENAN IND

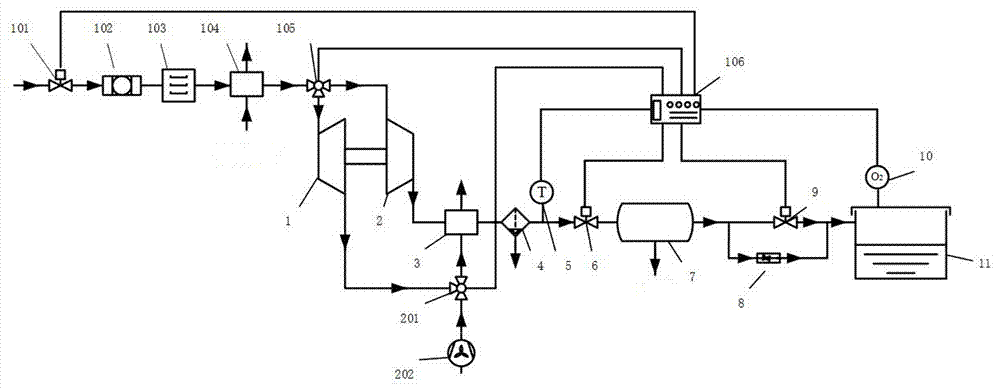

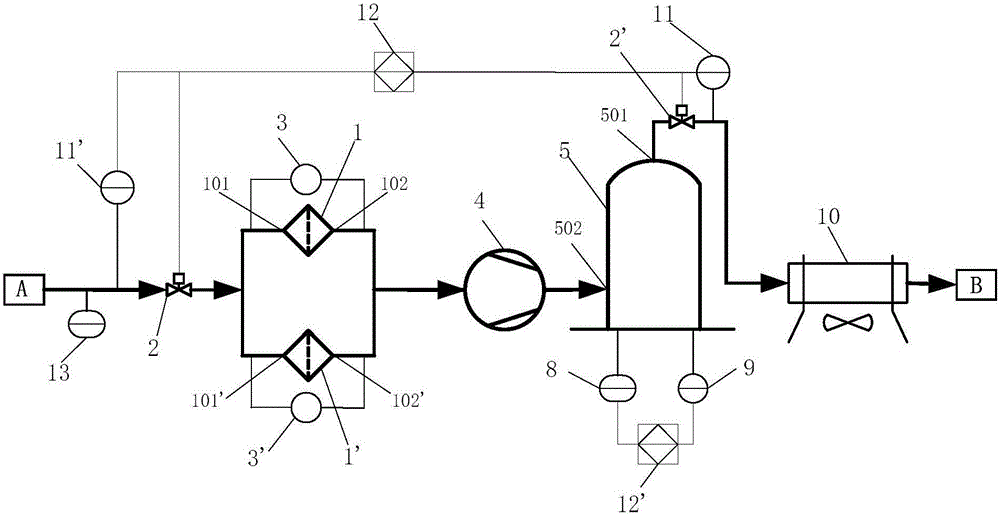

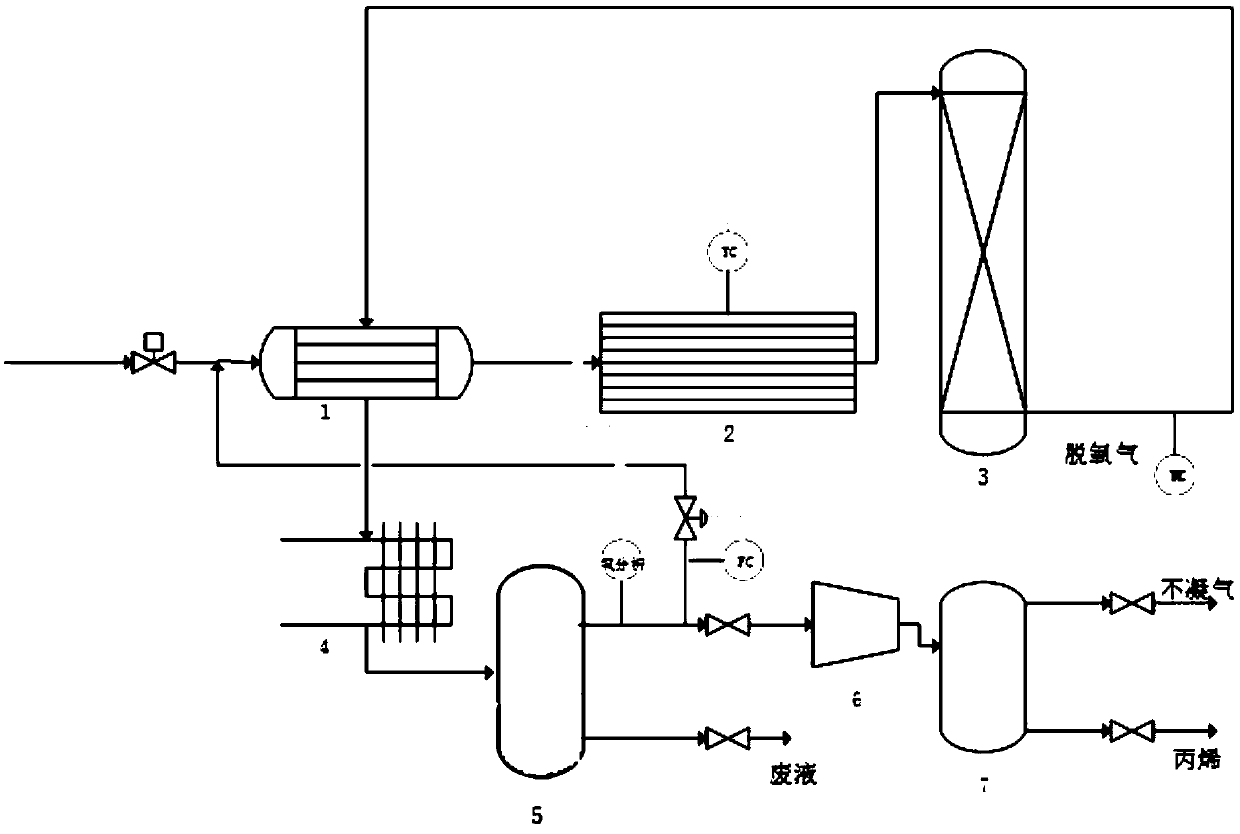

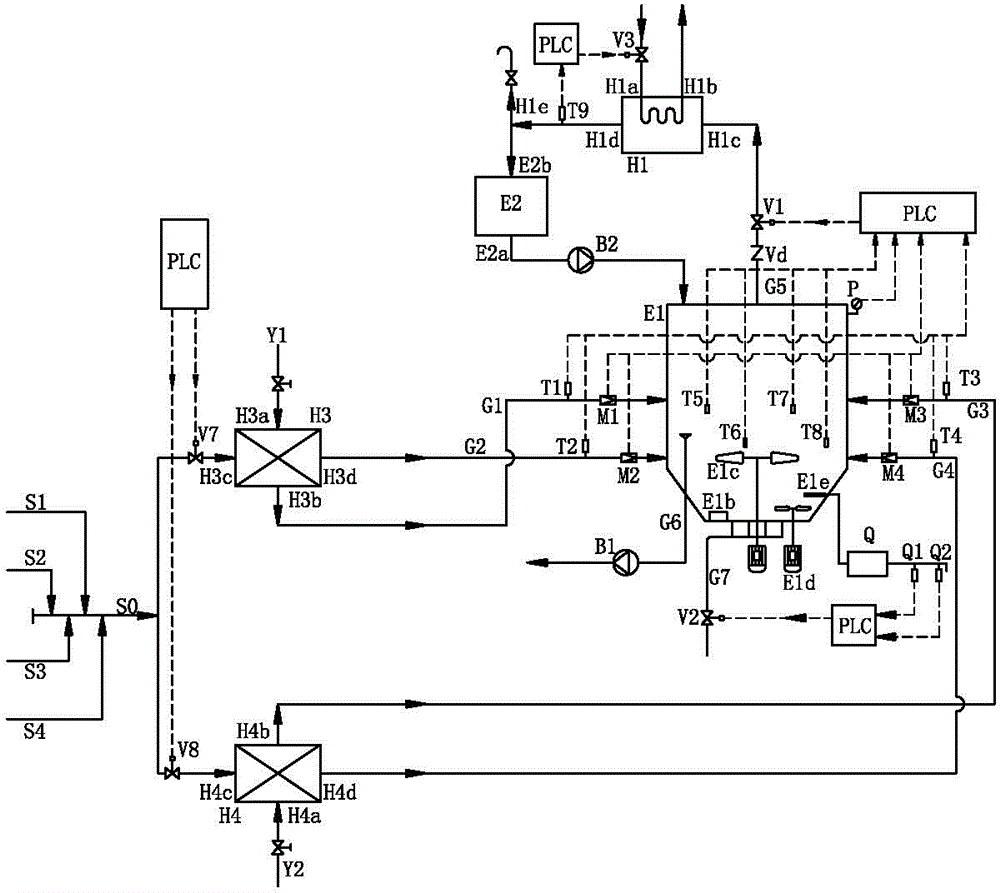

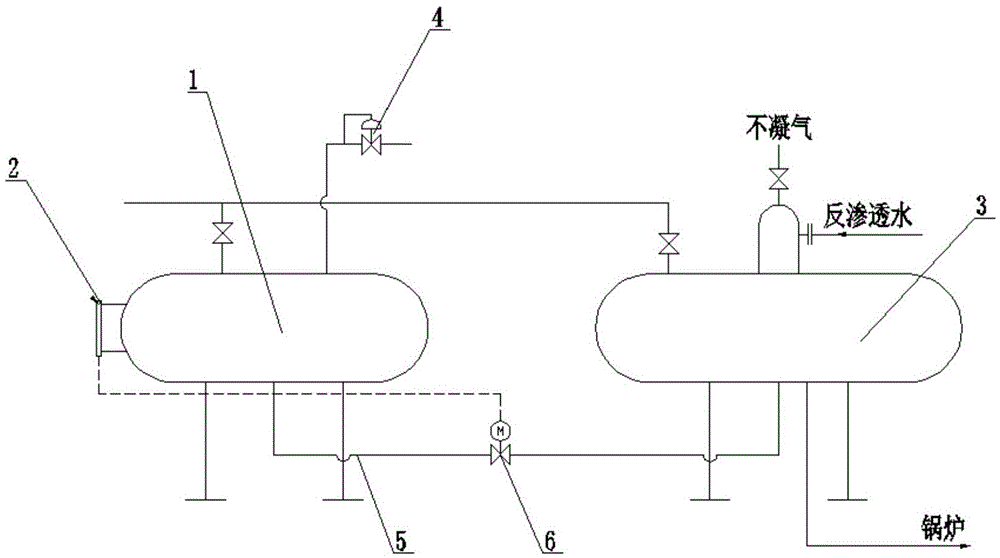

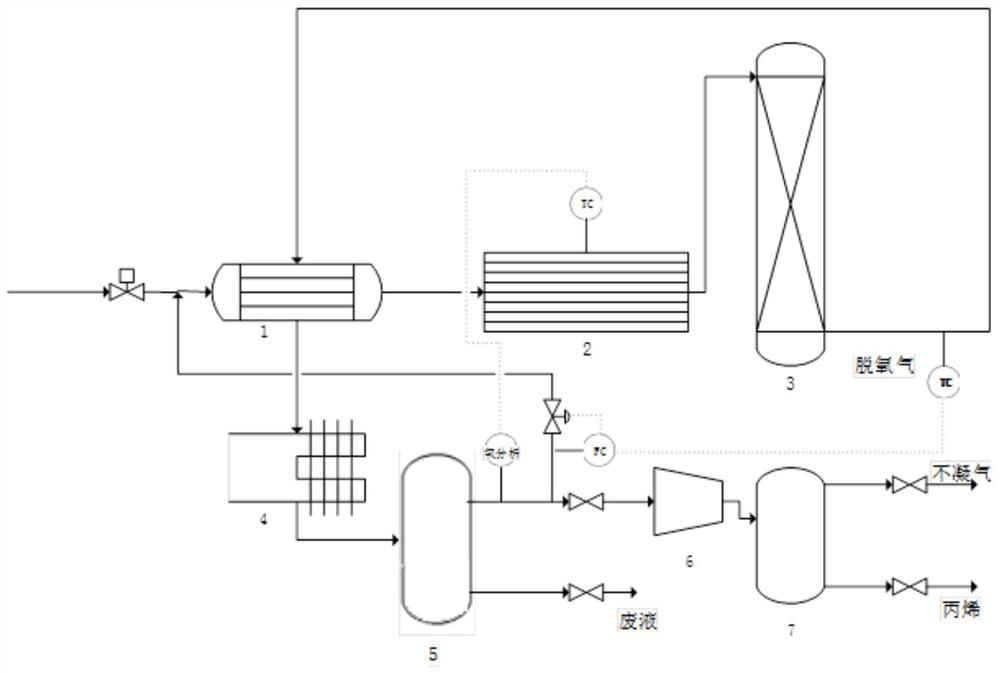

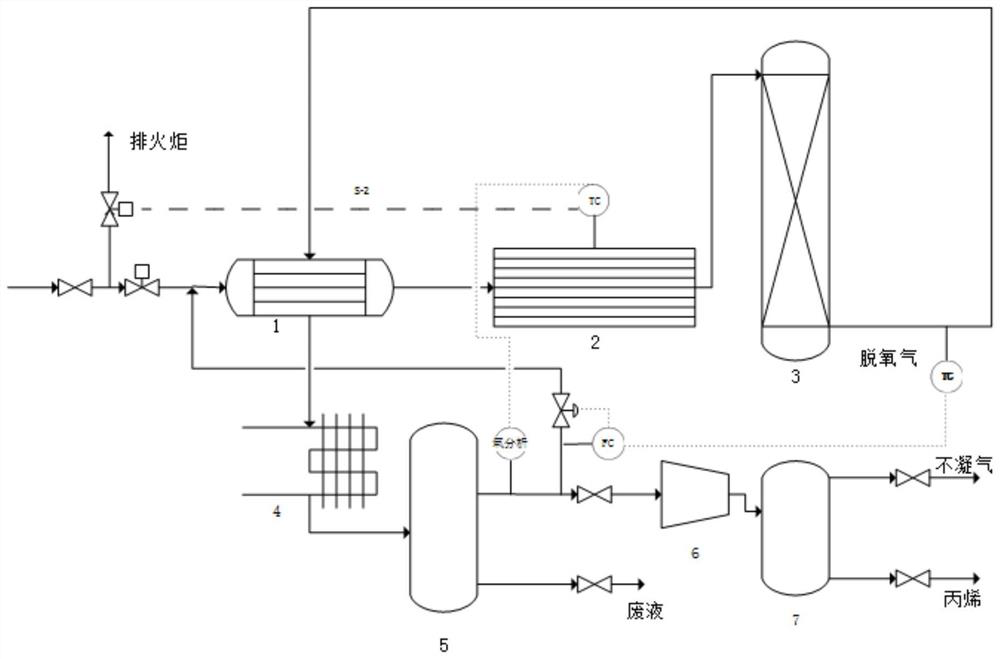

Propylene gas catalytic deoxidation device with temperature and tail gas oxygen concentration control and method

ActiveCN110559842ATo achieve the purpose of deoxygenationSuppress generationGas treatmentHydrocarbon purification/separationRefluxGas phase

The invention discloses a propylene gas catalytic deoxidation device with temperature and tail gas oxygen concentration control and a method and relates to the technical field of chemical tail gas treatment. A raw material, namely a propylene tail gas, is subjected to heat exchange by using a heat exchanger, is further heated to a reaction operation temperature by using an electric heater and is fed into a deoxidation reactor, the deoxidation reactor is internally provided with a catalyst bed layer, a gas obtained after a deoxidation reaction exchanges heat with the raw material gas, is cooledby using an air condenser and is fed into a gas-liquid separation tank, a liquid phase generated in the reaction process is separated, a gas phase is pressurized by using a compressor and is fed intoa noncondensable gas separation tower, a noncondensable gas is separated from the gas phase, and pure propylene is separated from the liquid phase; and a tail gas oxygen analyzer is arranged on a fourth outlet pipeline, the content of tail gas oxygen can be detected, and reflux treatment is implemented through the fourth outlet pipeline if the content is higher than a normal value. The device isapplicable to process treatment such as temperature runaway of a bed layer and standard exceeding of tail gas oxygen contents caused by reasons such as fluctuation of oxygen contents and degradation of catalyst activity in an olefin deoxidation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

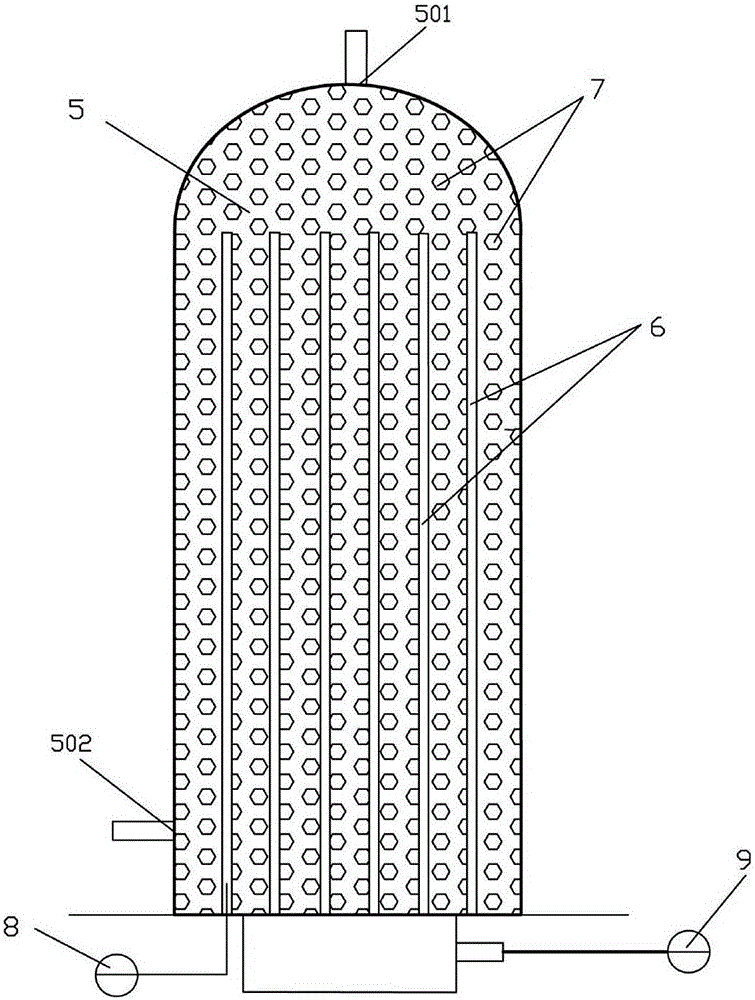

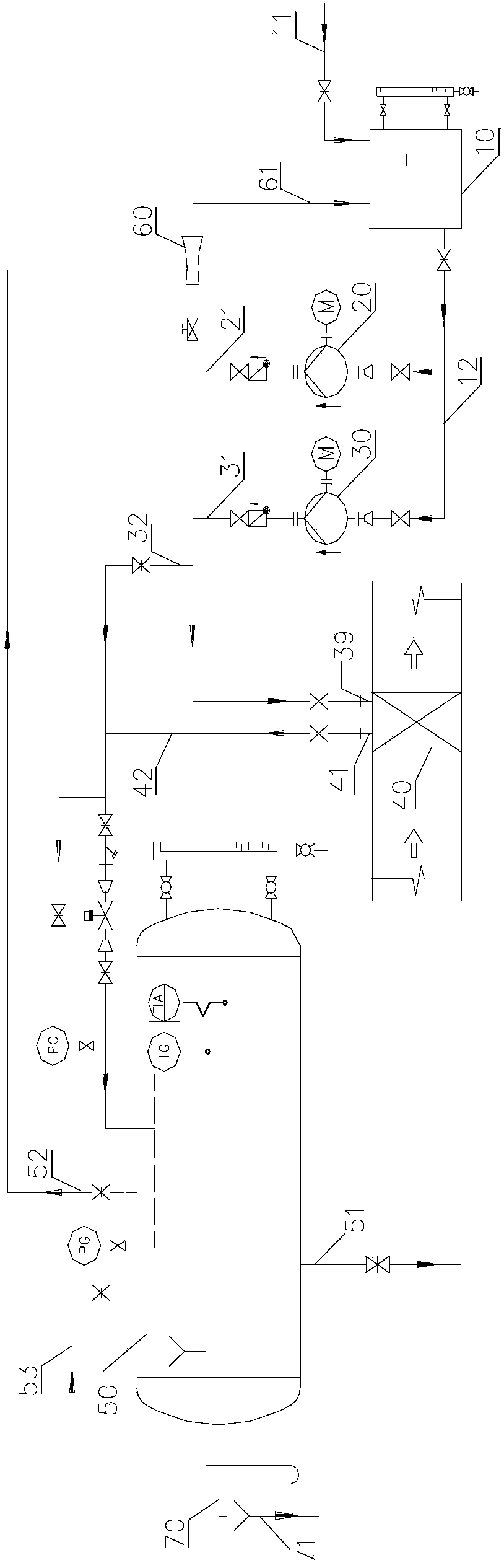

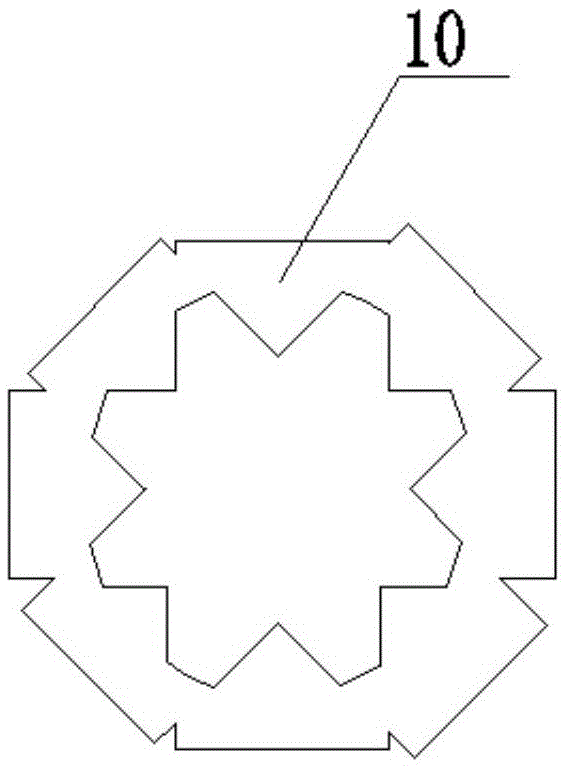

Novel thermodynamic vacuum deaeration system

PendingCN107940440AGood oxygen removal effectGood energy saving effectLiquid degasificationFeed-water heatersSoftened waterEngineering

The invention provides a novel thermodynamic vacuum deaeration system. The novel thermodynamic vacuum deaeration system comprises a softened water tank (10), a softened water pump (20), a coal economizer (40), a deaerator water feeding pump (30), a deaerator (50) and a vacuum ejector (60); a vacuum ejection pipeline for carrying out pressure reduction on the deaerator is connected to the softenedwater tank (10), the softened water pump (20), the vacuum ejector (60) and the deaerator (50); and a water injection pipeline for injecting water into the deaerator is connected to the softened watertank (10), the deaerator water feeding pump (30), the coal economizer (40) and the deaerator (50). The thermodynamic vacuum deaeration system has the advantages of being good in energy saving performance, high in working efficiency, good in waste heat recovery function and the like.

Owner:CERI PHOENIX INDAL FURNACE CO TD +1

Medical waste comprehensive treatment method

InactiveCN110125145AAchieve primary high-efficiency separationEasy to handleSolid waste disposalElectric arc furnaceMedical waste

The invention relates to a medical waste comprehensive treatment method. The treatment method depends on a medical waste comprehensive treatment device which comprises a compression chamber, a liquidstirring chamber, a liquid alloy processing chamber, a primary crushing chamber, a fine crushing chamber, a solid disinfection chamber, a classification chamber and a water treatment chamber. After the specific steps, the medical waste can be classified on basis of liquid alloy treatment, water treatment, pyrolysis treatment and electric arc furnace treatment, the specific treatment of different substances in the medical waste can be more effectively carried out after the classification is carried out, so that the treatment efficiency and the treatment effect of the medical waste are greatly improved, and the treatment resources are not wasted.

Owner:聂凤玲

Cast steel and production technology thereof

The invention relates to the field of cast steel, in particular to cast steel. The cast steel is prepared from the following raw materials by mass percent: 0.31%-0.36% of carbon, 0.35%-0.6% of silicon, 1.1%-1.4% of manganese, 0-0.035% of phosphorus, 0-0.035% of sulfur, 0.03%-0.08% of aluminum and the balance of iron. The invention further relates to a production technology of the cast steel. According to the cast steel, the technical problem of low strength of existing cast steel is solved; the tensile strength, elongation percentage, reduction of cross section and impact toughness of the caststeel are 20%-50% higher than similar products; and the cast steel is mainly applied to cast of engineering machinery parts.

Owner:泉州市恒通机械配件有限公司

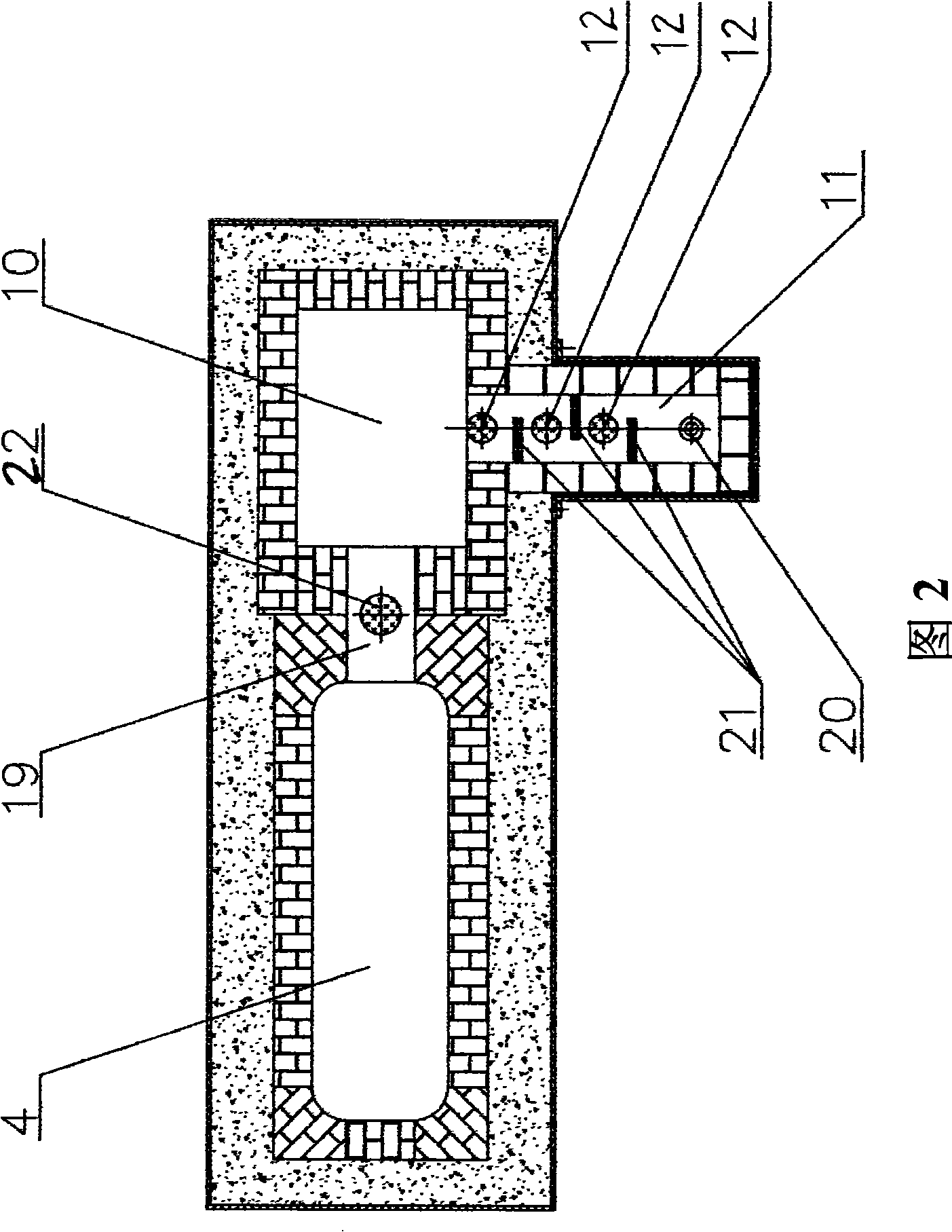

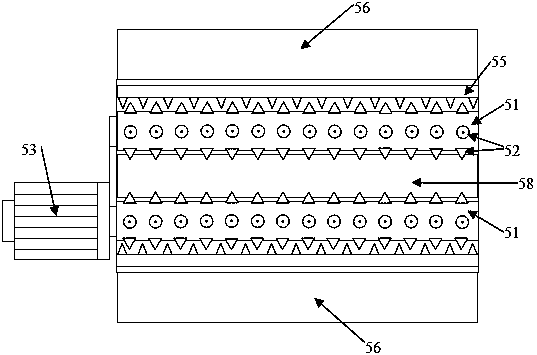

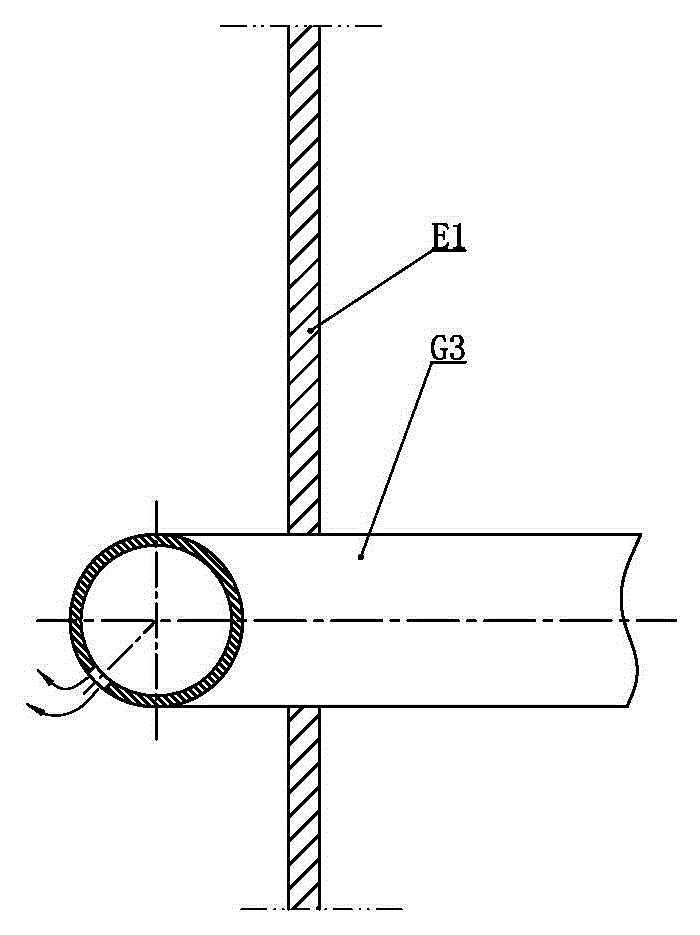

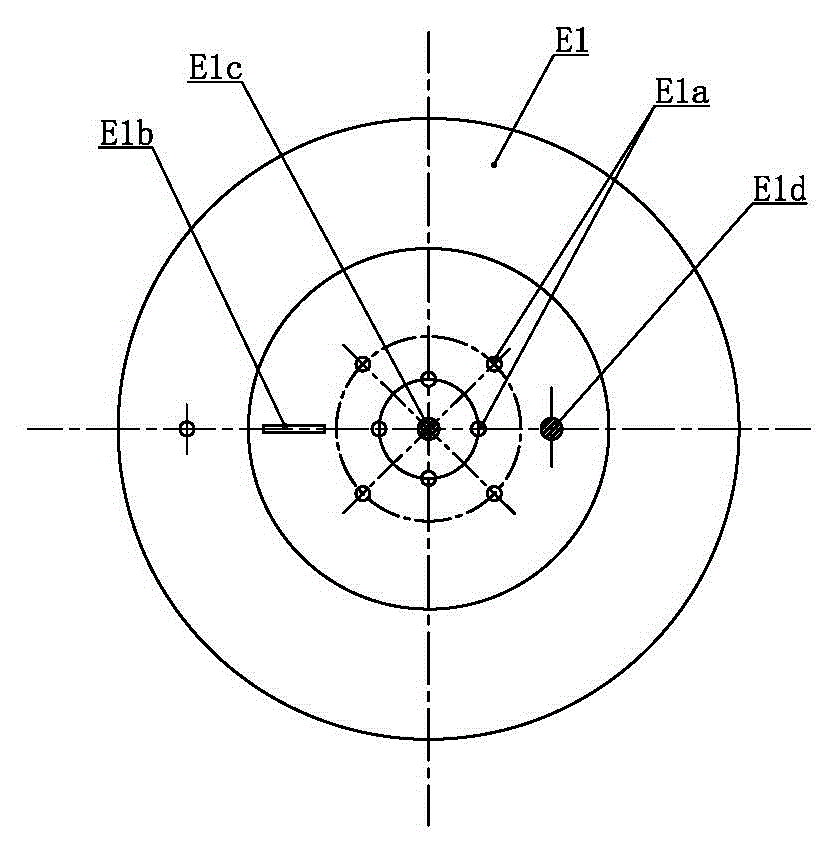

One-stage deoxidizing device for indirect heat-exchange forcible mixed exhaust steam recovery of condensate water and desalted water

InactiveCN104089271ADoes not affect normal operationAvoid pressure suffocation and poor drainage of condensateLiquid degasificationImpellerBuffer tank

The invention relates to a one-stage deoxidizing device for indirect heat-exchange forcible mixed exhaust steam recovery of condensate water and desalted water. A first water inlet pipe, a second water inlet pipe, a third water inlet pipe and a fourth water inlet pipe are connected onto a pressure-bearing buffer tank, wherein the first water inlet pipe and the third water inlet pipe are located on the upper layer, and the second water inlet pipe and the fourth water inlet pipe are located on the lower layer; mixed condensate water is introduced into the second water inlet pipe and the fourth water inlet pipe respectively after subjected to heat exchange with synthesis ammonia desalted water and conversion desalted water through a third heat exchanger and a fourth heat exchanger, the synthesis ammonia desalted water and the conversion desalted water are introduced into the first water inlet pipe and the third water inlet pipe respectively after subjected to heat exchange through the third heat exchanger and the fourth heat exchanger; buffer tank exhaust steam is cooled into buffer tank exhaust steam condensate water by a first heat exchanger, the buffer tank exhaust steam condensate water is injected into the pressure-bearing buffer tank by a condensate water collecting tank and a second water pump, and non-condensable gas is discharged simultaneously; a water outlet pipe of the buffer tank is connected with an inlet of a first water pump, and an outlet of the first water pump is connected to a boiler water replenishing pipe; and a forcible mixing impeller is mounted at the middle-lower part of the inner cavity of the pressure-bearing buffer tank, and a blow-down pipe is connected to a bottom plate of the pressure-bearing buffer tank. According to the device, the utilization rate of condensate water waste heat is high, and the operation is reliable.

Owner:江苏安众环保技术有限公司

Method for continuously converting and casting oxygen-free copper ingot

The invention provides a continuous blowing and casting method of oxygen-free copper ingots, which pertains to the metal smelting and casting technical field and is carried out according to the technical steps as follows: A. cathode copper is firstly melted in a smelting furnace, and melted copper liquid enters a deoxidation furnace through a bottom blowing chute; B. carbon monoxide gas or the mixed gas of carbon monoxide and nitrogen enters the copper liquid in the bottom blowing chute through the bottom blowing chute and enters the deoxidation furnace with the copper liquid to realize the deoxidation and the degassing of a first stage; C. when passing through a diversion trench arranged in a bottom blowing furnace end, the carbon monoxide gas or the mixed gas of carbon monoxide and nitrogen enters the copper liquid in the diversion trench for realizing the deoxidation and the degassing of a second stage to the copper liquid in the diversion trench; D. the copper liquid after the second stage of deoxidation and degassing enters a crystallizer through a casting gate arranged in the bottom blowing furnace end. The oxygen content of an oxygen-free copper ingot base produced by the method of the invention can stably reach not only less than 5ppm, but also less than 3ppm.

Owner:甘肃海亮新能源材料有限公司 +1

Block iron boron compound material and preparation method thereof

The invention discloses a block iron boron compound material and a preparation method thereof. Each element of the block iron boron compound material comprises the following chemical components in percentage by weight: 8.8 to 12.5 percent of B and the balance of Fe and unavoidable impurity elements. A preparation process comprises six steps of batching, adding graphite powder, adding a forming agent, mixing materials, forming and performing vacuum sintering; the finally prepared material is single-phase Fe2B or a material which consists of Fe2B and FeB. According to the block iron boron compound material and the preparation method thereof, oxygen in raw materials is removed by adding the graphite powder and excessive B; a process flow is simplified; the material with excellent performance is prepared; the block iron boron compound material is mainly used for manufacturing an abrasion resistant and corrosion resistant part and a corresponding coating.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

Preparation method for Fe(OH)3 colloid with negative zeta potential

InactiveCN102424425ATo achieve the purpose of deoxygenationReduce filterIron oxides/hydroxidesZeta potentialElectrical conductor

The invention provides a preparation method for Fe(OH)3 colloid with a negative zeta potential. The invention is characterized by comprising the following steps: (1) using electrochemical deaeration equipment as operation equipment; (2) preparing softened water by using a sodium ion exchanger without cations and using the softened water as a water supply for the electrochemical deaeration equipment; (3) using iron as an anode of an electrolytic bath of the electrochemical deaeration equipment and a conventional conductor material as a cathode; (4) allowing Fe2<+> produced after consumption of iron of the anode of the electrolytic bath to combine with OH<-> produced by the cathode so as to generate Fe(OH)2, and dissolving Fe(OH)2 in the softened water to allow oxygen to react so as to produce the Fe(OH)3 colloid with a negative zeta potential. The invention has the advantages of an obvious effect and strong operability.

Owner:张小安

A steam supply system for a cigarette factory

ActiveCN108895423BImprove utilization efficiencyReduce consumptionLiquid degasificationFeed water supplyEngineeringAir conditioning

The invention discloses a steam supply system for a cigarette factory, which belongs to the technical field of steam transportation and supply. , Low-pressure condensate recovery tank and condensate tank, the boiler is connected to the high-pressure sub-cylinder through the first pipeline, the high-pressure sub-cylinder is connected to the low-pressure sub-cylinder through the second pipeline, and the high-pressure sub-cylinder is connected to the silk production sub-cylinder through the third pipeline. The low-pressure sub-cylinder is connected to the heat exchanger through the fourth pipe, and the low-pressure sub-cylinder is connected to the air-conditioning sub-cylinder through the fifth pipe; the high-pressure steam in the boiler is divided into high and low through the setting of the high-pressure sub-cylinder and the low-pressure sub-cylinder The two parts of the steam supply the steam for different workshops and related equipment in a targeted manner, which improves the utilization efficiency of the steam.

Owner:CHINA TOBACCO HENAN IND

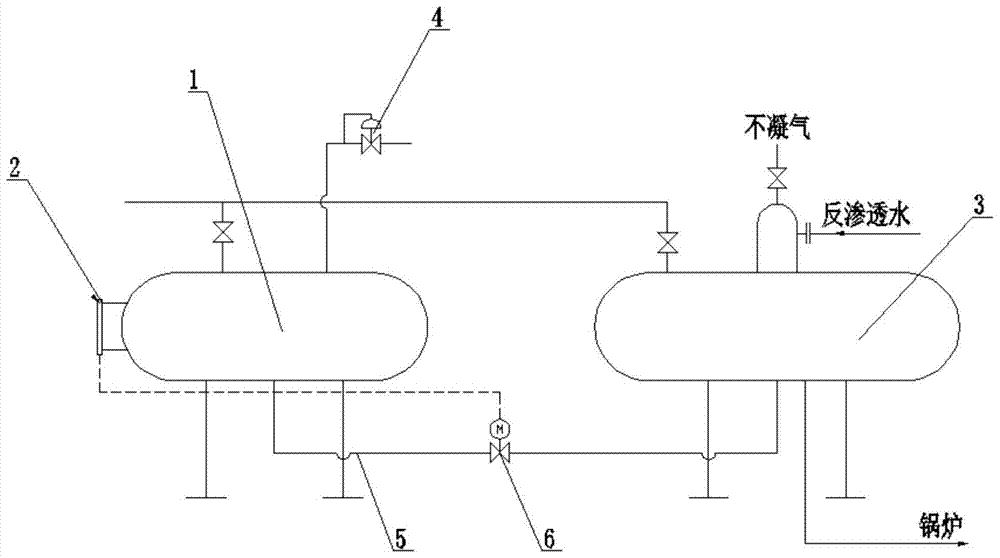

Condensation automatic water return system

ActiveCN105570871BAdjust working pressureRealize liquid level automatic controlLiquid degasificationFeed water supplyAutomatic controlSteam pressure

The invention discloses an automatic condensation water return system which is characterized in that a condensation water recovery tank is connected with a boiler through a deaerator; the deaerator comprises a deaeration head and a water storage tank; the deaeration head is connected with the condensation water recovery tank through a steam pipeline; the bottom of the water storage tank is provided with a communicating pipeline; the bottom of the condensation water recovery tank communicates with the bottom of the deaerator through the communicating pipeline; an electric valve is arranged in the middle of the communicating pipeline; the top of the condensation water recovery tank is provided with an automatic pressure regulating device; the automatic pressure regulating device is used for regulating the steam pressure of the condensation water recovery tank through a pressure regulating valve; the side end of the condensation water recovery tank is provided with a liquid level meter. By using the automatic condensation water return system, the self working pressure of the condensation water recovery tank can be regulated, and the pressure difference between the condensation water recovery tank and the deaerator is made artificially, so that the automatic control of liquid levels of the condensation water recovery tank and the deaerator can be realized; and the deaerator head is used for carrying out thermal deaeration on reverse-osmosis water entering the deaeration head by virtue of flash vaporization steam generated by returned condensation water, and the communicating pipeline is used for returning condensation water to the deaerator, so that the equipment fault is reduced, water and electricity are saved, and equipment operation safety is greatly improved.

Owner:BEIJING NEW BUILDING MATERIALS PLC +1

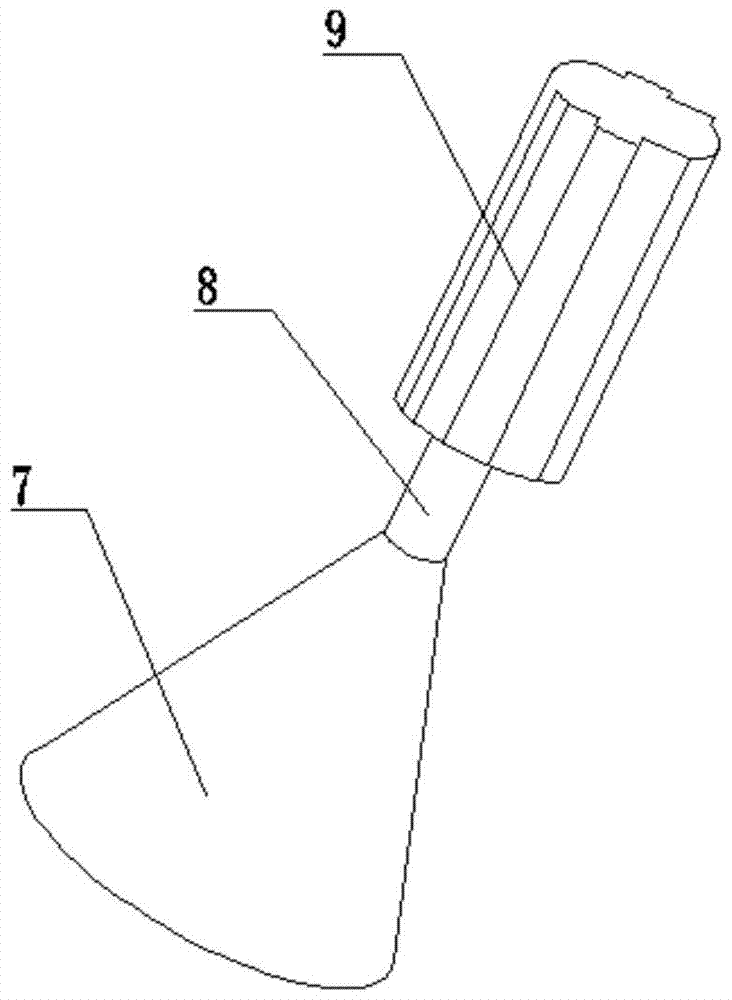

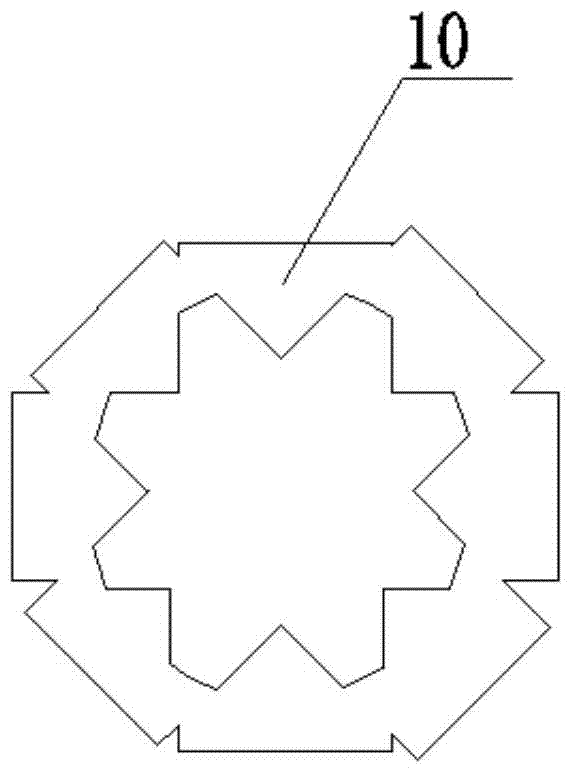

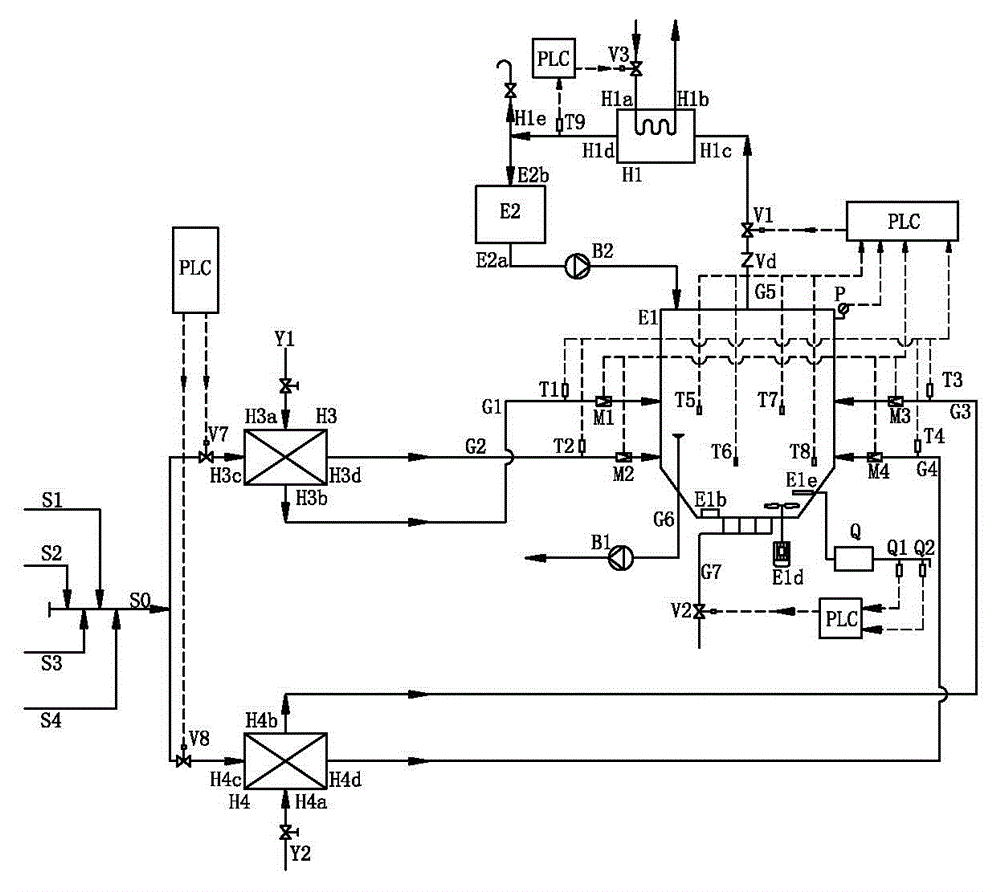

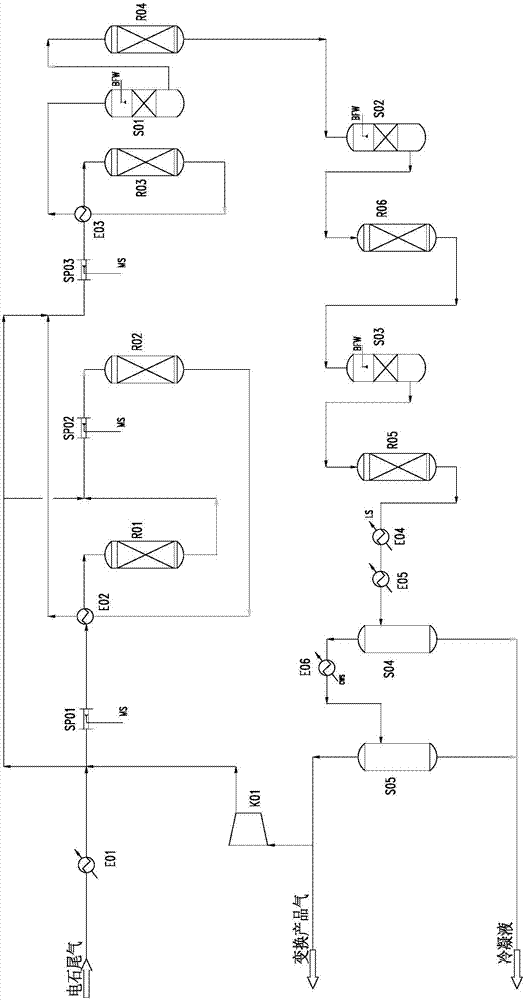

Sulfur-phobic process for deeply transforming calcium carbide tail gas

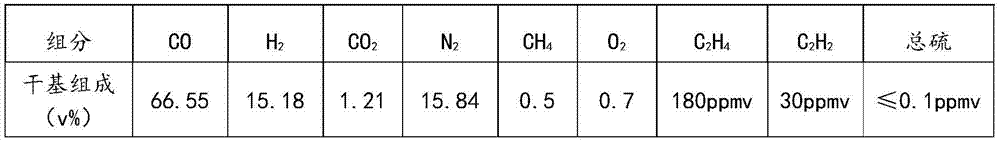

ActiveCN105692550ASolve the problem of difficult deep conversion of high-concentration COMeet the use requirementsHydrogenChemical industryThermal energySulfur

The invention relates to a sulfur-phobic process for deeply transforming calcium carbide tail gas.By the aid of the sulfur-phobic process, problems of complicated procedures and high investment cost and running cost of existing processes can be solved.The technical scheme includes that the sulfur-phobic process comprises steps of preheating the calcium carbide tail gas, then dividing the calcium carbide tail gas into three branches, mixing the first branch of calcium carbide tail gas and partial transformation product gas with each other to obtain a first mixture, filling the first mixture with steam, preheating the first mixture and the steam by a No.1 tail gas preheater, and then delivering the first mixture and the steam into a No.1 transformation furnace to transform the first mixture and the steam; mixing transformed gas exhausted from the No.1 transformation furnace with the second branch of calcium carbide tail gas to obtain a second mixture, filling the second mixture with steam, delivering the second mixture and the steam into a No.2 transformation furnace to transform the second mixture and the steam, delivering transformed gas exhausted from the No.2 transformation furnace into the No.1 tail gas preheater, carrying out heat exchange cooling on the transformed gas and mixed gas before the mixed gas is delivered into the No.1 transformation furnace, then mixing the transformed gas with the third branch of calcium carbide tail gas to obtain a third mixture, filling the third mixture with steam by the aid of a No.3 mixer, preheating the third mixture and the steam by the aid of a No.2 tail gas heat exchanger, feeding the third mixture and the steam into a No.3 transformation furnace, further transforming transformed gas exhausted from the No.3 transformation furnace, recycling heat of the transformed gas, or directly recycling the heat of the transformed gas without further transforming the transformed gas and separating condensed liquid from the transformed gas to obtain transformed product gas.The sulfur-phobic process has the advantages of simplicity and low investment cost and running cost.

Owner:WUHUAN ENG

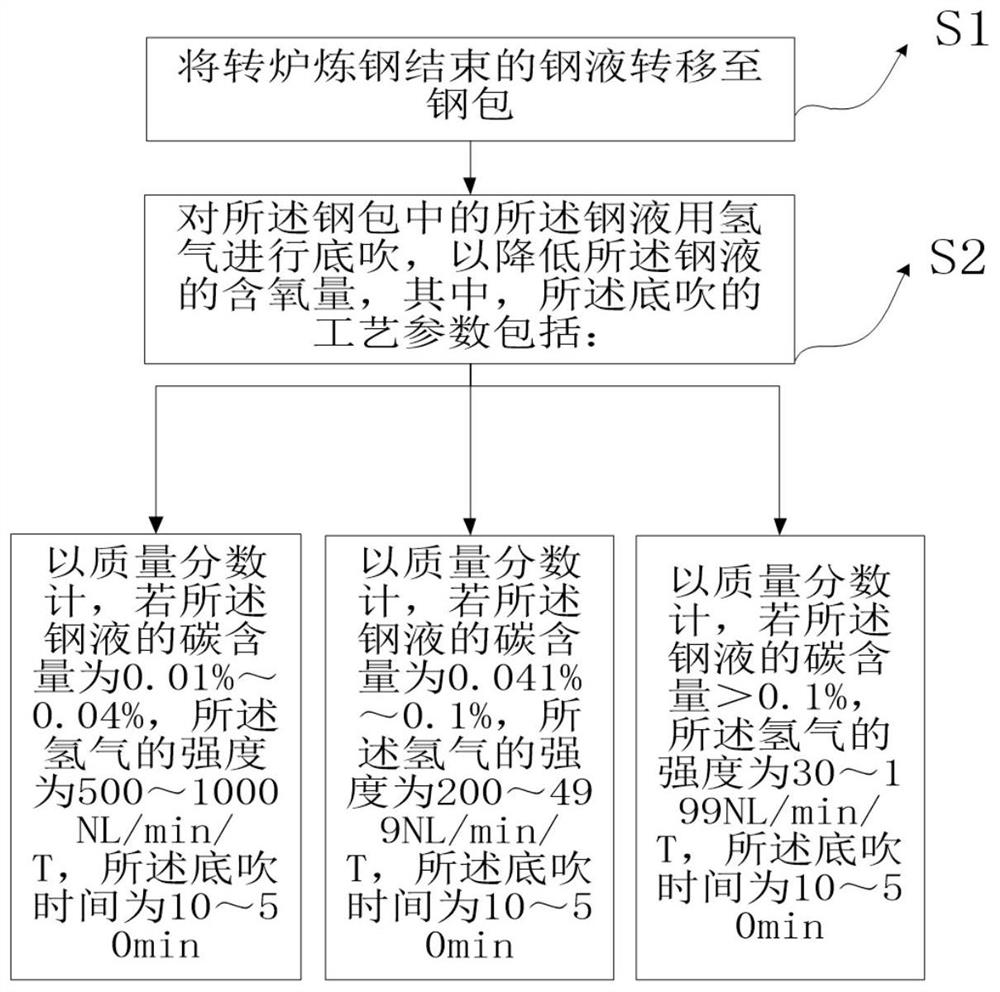

Foaming system for air foam flooding and its preparation method and application

ActiveCN110591681BGood foam stabilization effectFunction increaseFluid removalDrilling compositionActive agentProcess engineering

The invention discloses a foaming system for air foam flooding. The components and their weight percentages are: 30%-50% of surfactant, 2%-13% of stabilizer, 20%-25% of deoxidizing aid, The amount is water. The foaming system for air foam flooding of the present invention is suitable for oil reservoirs with a temperature of 40-80 DEG C, and has strong foaming performance, foam stabilizing performance and oxygen removal ability. It also discloses its preparation method, in which a stabilizer is added during the preparation process, no additional stabilizer is needed during construction, no need to add an oxygen removal device at the wellhead to deoxidize the air, and after being injected into the formation alternately or together with the air, it has a relatively Strong plugging performance, and can greatly reduce the risk of oxygen intrusion into the oil well, and realize the safe, efficient and low-cost operation of air foam flooding.

Owner:PETROCHINA CO LTD

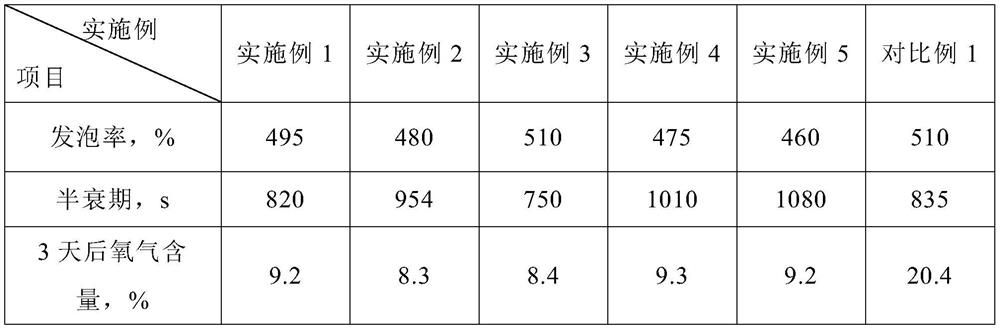

Process for hydrogen blowing deoxidation of molten steel

The invention relates to the technical field of steelmaking, in particular to a process for hydrogen blowing deoxidation of molten steel. Molten steel obtained after converter steelmaking is finished is transferred to a steel ladle; the molten steel in the steel ladle is subjected to bottom blowing through hydrogen so that the oxygen content of the molten steel can be reduced, and according to the technological parameters of bottom blowing, if the carbon content of the molten steel ranges from 0.01% to 0.04% by mass, the strength of the hydrogen ranges from 500 NL / min / T to 1000 NL / min / T, and the bottom blowing time ranges from 10 min to 50 min; if the carbon content of the molten steel is 0.041%-0.1% by mass, the strength of the hydrogen ranges from 200 NL / min / T to 499 NL / min / T, and the bottom blowing time ranges from 10 min to 50 min; if the carbon content of the molten steel is larger than 0.1% by mass, the strength of the hydrogen ranges from 30 NL / min / T to 199 NL / min / T, and the bottom blowing time ranges from 10 min to 50 min. According to the process, the content of dissolved oxygen in the steel is reduced to 20 ppm or below, and the molten steel subjected to deoxidization treatment is subjected to a subsequent process, so that pollution of inclusions to the molten steel can be effectively avoided, the purpose of deoxidization is achieved, and meanwhile, the molten steel is subjected to ultra-purification.

Owner:SHOUGANG CORPORATION

Condensed water desalination water indirect heat exchange exhaust steam recovery primary deaeration device

ActiveCN104085942BDoes not affect normal operationAvoid pressure suffocation and poor drainage of condensateFeed water supplyWater/sewage treatment by degassingSaline waterBuffer tank

The invention relates to a primary deoxidizing device for performing indirect heat exchange on condensed water and desalted water and recovering exhaust steam. A pressure-bearing buffer tank is provided with first and third water inlet pipes positioned on an upper layer as well as second and fourth water inlet pipes positioned on a lower layer; mixed condensed water is introduced into the second and fourth water inlet pipes respectively after undergoing indirect heat exchange with synthetic ammonia desalted water and transformed desalted water through third and fourth heat exchangers respectively; the synthetic ammonia desalted water and the transformed desalted water are introduced into the first and third water inlet pipes respectively after undergoing heat exchange through the third and fourth heat exchangers; buffer tank exhaust steam enters a first heat exchanger to be cooled into buffer tank exhaust steam condensed water, the buffer tank exhaust steam condensed water is replenished into the pressure-bearing buffer tank through a condensed water collecting tank and a second water pump, and meanwhile non-condensable gas is exhausted; a water outlet pipe of the buffer tank is connected with the inlet of a first water pump; the outlet of the first water pump is connected to a water replenishing pipe of a boiler; a bottom plate of the pressure-bearing buffer tank is connected with a blow-off pipe. The device is high in residual heat utilization ratio of condensed water, and runs reliably.

Owner:云南能投有能科技股份有限公司

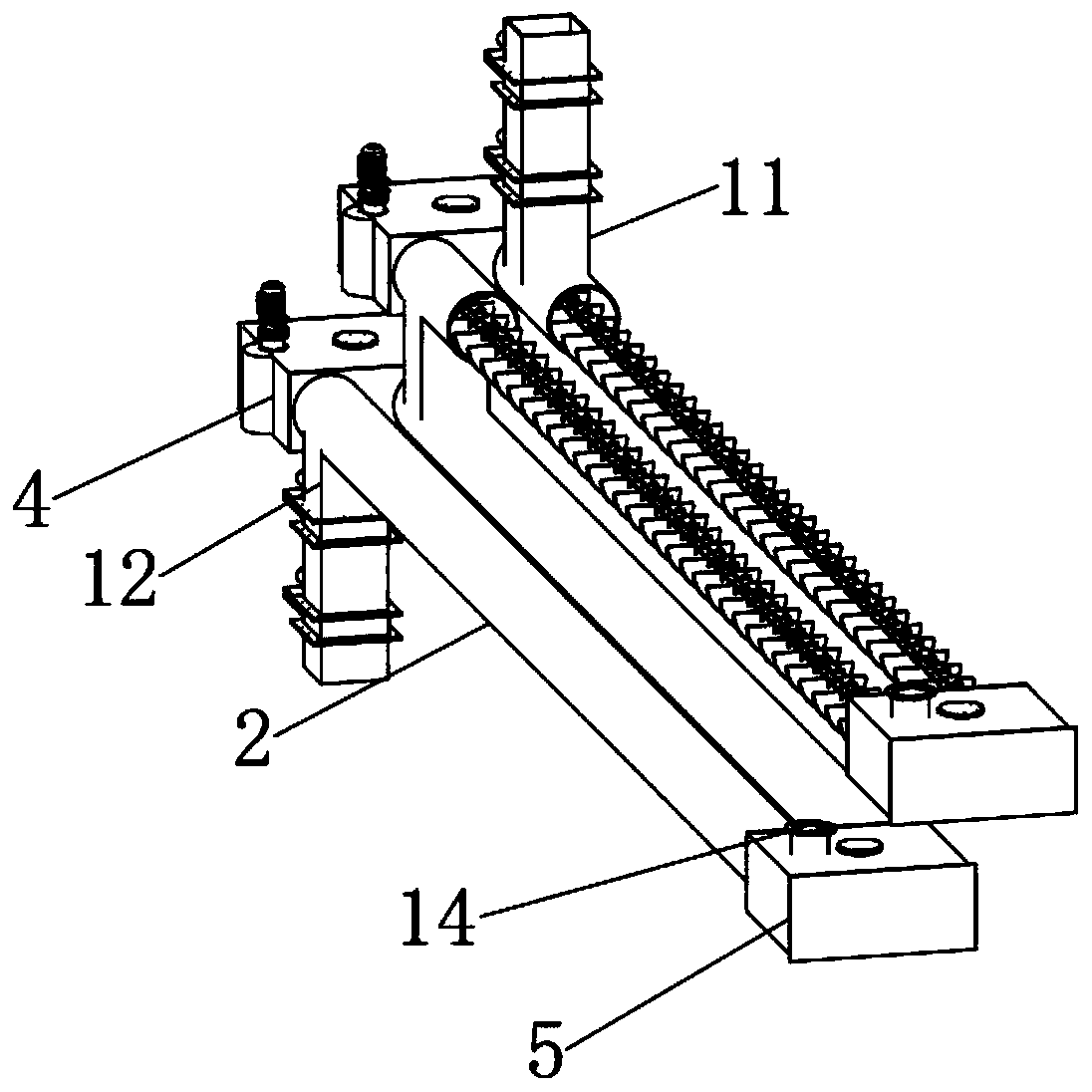

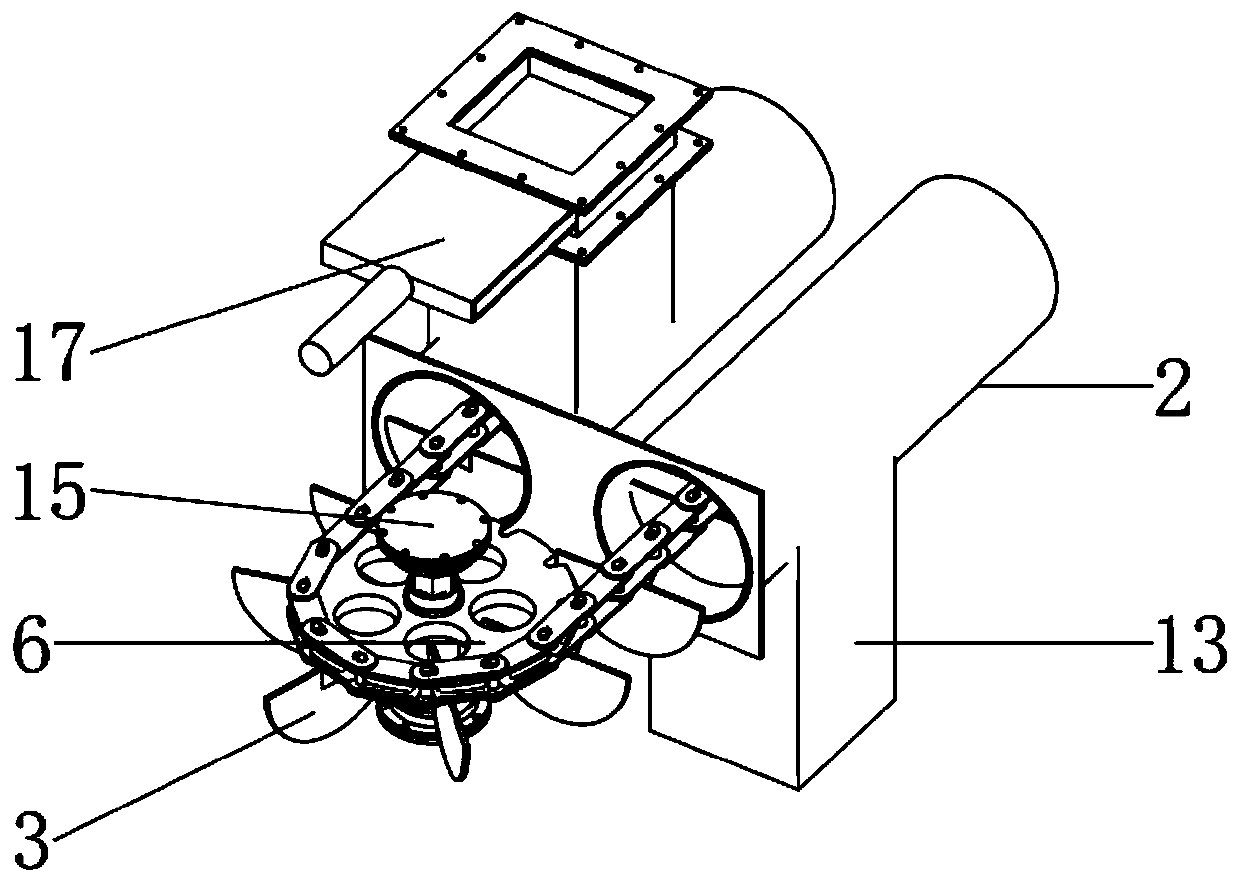

Tubular chain plate pyrolysis dry distillation furnace

InactiveCN110862836ASmall amount of deformationHigh strengthSludge treatment by pyrolysisByproduct vaporizationElectric machineryPyrolysis

The invention discloses a tubular chain plate pyrolysis dry distillation furnace. The tubular chain plate pyrolysis dry distillation furnace comprises a chain and seamless tubes, wherein the chain isin inserted connection to the inner part of the seamless tubes, scraping plates are mounted on the surface of the chain, a main rotating box and a driven box are fixedly connected to the two ends of each seamless tube, a capstan is in transmission connection to the surface of the chain, a connecting shaft is in clamping connection to the axle center of the capstan, a driving gear and a driven gearare in clamping connection to the surface of the connecting shaft, one end of the driving gear is fixedly connected with the output end of a motor, the driving gear and the driven gear are wholly mounted in a driven box, and a feed opening and a discharge opening are fixedly connected to the upper side and the lower side of each seamless tube. According to the tubular chain plate pyrolysis dry distillation furnace, through cooperative arrangement of the chain and the scraping plates, the chain drives the scraping plates to orderly move in the seamless tubes, so that the purposes that materials are not wound together and are not stuck to walls when the materials are transported for work can be achieved, greenhouse effects cannot appear in the production process, the pyrolysis time is accordingly shortened, and the treatment capacity in unit time is accelerated and increased.

Owner:商丘市祥和机械设备制造有限公司

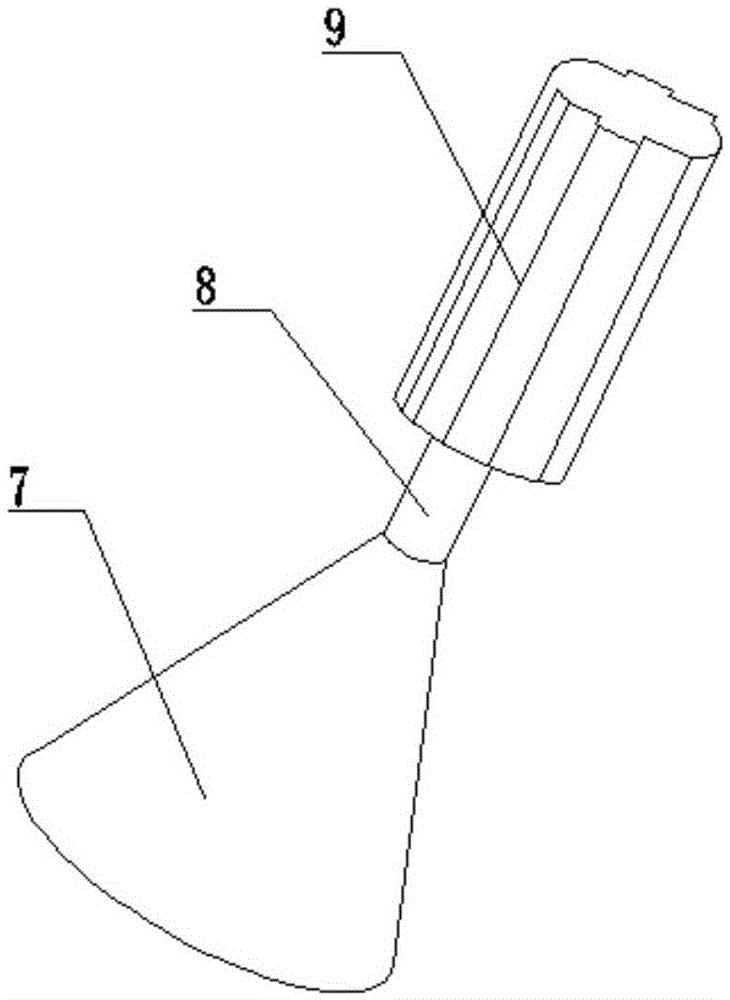

Process of catalytic deoxidation of oxygen-containing coal bed methane and comprehensive utilization of reaction heat

ActiveCN102994185BReduce energy consumptionTo achieve the purpose of deoxygenationGaseous fuelsSteam generation using hot heat carriersPtru catalystCoal

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method and complete set of equipment for reducing oxygen content in gasification process of CO2 gas of brewery

ActiveCN103253666BEmission reductionImprove protectionCarbon compoundsAir quality improvementAtmospheric airSorbent

The invention relates to a method and a complete set of equipment for reducing oxygen content in gasification process of CO2 gas of a brewery. The equipment is characterized in that an adsorbent is filled in an oxygen removal device, the adsorbent can adsorb trace oxygen from the carbon dioxide gas during the using process under a normal temperature and pressure state, and the CO2 gas is not affected by the process so as to ensure that the oxygen content in the CO2 gas at the end use end can reach a very low standard. According to the method and the equipment, disclosed by the invention, the different physical and chemical properties of the carbon dioxide and the oxygen in the carbon dioxide are fully utilized, the oxygen removal device can smoothly separate oxygen from the carbon dioxide, the energy consumption is very low, and the emission of the carbon dioxide into an atmosphere can be simultaneously reduced, which is favorable for environmental protection.

Owner:NANJING YITAN SCI & TECH

High-oxygen-resistant medium-temperature hydrolysis catalyst and preparation method thereof

ActiveCN111744500AImprove bindingIntegrity guaranteedHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsIon exchangeComposite oxide

The invention discloses a high-oxygen-resistant medium-temperature hydrolysis catalyst and a preparation method thereof. According to the catalyst, a TiO2-SiO2-MnO2 composite oxide is used as a carrier, Li-W-Cs is used as an active component, and Cu is used as an auxiliary agent. Under certain temperature and pressure conditions, a titanium source, a silicon source, a manganese source, a templateagent and the like react in a high-pressure synthesis kettle to prepare the carrier, then active components are added for ion exchange, and the catalyst is obtained after filtering and roasting. The catalyst has the characteristics of high hydrolysis conversion rate and long service life, and can be used for hydrolysis removal of COS in various oxygen-containing industrial raw materials such as water gas, semi-water gas, coke-oven gas, blast furnace gas and the like.

Owner:WUHAN KELIN FINE CHEM

Automatic condensation water return system

ActiveCN105570871AAdjust working pressureRealize liquid level automatic controlLiquid degasificationFeed water supplyAutomatic controlSteam pressure

The invention discloses an automatic condensation water return system which is characterized in that a condensation water recovery tank is connected with a boiler through a deaerator; the deaerator comprises a deaeration head and a water storage tank; the deaeration head is connected with the condensation water recovery tank through a steam pipeline; the bottom of the water storage tank is provided with a communicating pipeline; the bottom of the condensation water recovery tank communicates with the bottom of the deaerator through the communicating pipeline; an electric valve is arranged in the middle of the communicating pipeline; the top of the condensation water recovery tank is provided with an automatic pressure regulating device; the automatic pressure regulating device is used for regulating the steam pressure of the condensation water recovery tank through a pressure regulating valve; the side end of the condensation water recovery tank is provided with a liquid level meter. By using the automatic condensation water return system, the self working pressure of the condensation water recovery tank can be regulated, and the pressure difference between the condensation water recovery tank and the deaerator is made artificially, so that the automatic control of liquid levels of the condensation water recovery tank and the deaerator can be realized; and the deaerator head is used for carrying out thermal deaeration on reverse-osmosis water entering the deaeration head by virtue of flash vaporization steam generated by returned condensation water, and the communicating pipeline is used for returning condensation water to the deaerator, so that the equipment fault is reduced, water and electricity are saved, and equipment operation safety is greatly improved.

Owner:BEIJING NEW BUILDING MATERIALS PLC +1

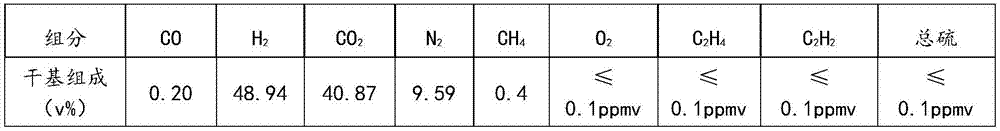

Propylene gas catalytic deoxygenation device and method with temperature and tail oxygen concentration control

ActiveCN110559842BTo achieve the purpose of deoxygenationSuppress generationGas treatmentHydrocarbon purification/separationPtru catalystFluid phase

The invention discloses a propylene gas catalytic deoxidation device and method with temperature and tail oxygen concentration control, and relates to the technical field of chemical tail gas treatment. After the raw material propylene tail gas is heat-exchanged by the heat exchanger, it is further heated by the electric heater to the reaction operating temperature, and then enters the deoxidation reactor. The deoxidation reactor is equipped with a catalyst bed. The air condenser cools down and enters the gas-liquid separation tank to separate the liquid phase generated during the reaction. The gas phase enters the non-condensable gas separation tower after being boosted by the compressor, and the non-condensable gas is separated from the gas phase, and pure propylene is obtained from the liquid phase; in the fourth The outlet pipeline is equipped with a tail oxygen analyzer, which can detect the tail oxygen content. If it is higher than the normal value, it will be refluxed through the fourth outlet branch pipeline. The invention is especially suitable for process treatment such as bed overheating, tail oxygen content exceeding standard and the like which may be caused by oxygen content fluctuation, catalyst activity decline and other reasons in the olefin deoxygenation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

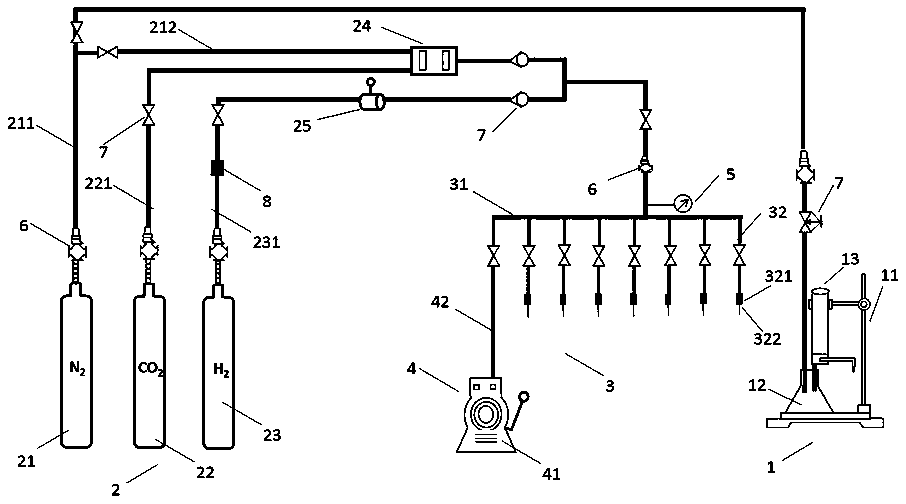

Anaerobic culture bottle inflatable vacuum cleaning system

ActiveCN107175242BFast fillTo achieve the purpose of deoxygenationHollow article cleaningEngineeringBottle

The invention discloses an anaerobic culture bottle inflation and vacuumizing cleaning system. The system comprises an anaerobic culture medium rapid split charging module, a gas component matching module, a branch terminal culture bottle cleaning module and a vacuumizing module. The gas component matching module is connected with the anaerobic culture medium rapid split charging module and the branch terminal culture bottle cleaning module. The vacuumizing module is connected with the branch terminal culture bottle cleaning module. The anaerobic culture medium rapid split charging module and the branch terminal culture bottle cleaning module are connected with a culture bottle. The anaerobic culture bottle inflation and vacuumizing cleaning system has the advantages that the system has the adjustable anaerobic degree and the pressure index, and can achieve free matching of N2 / CO2 and H2 quantitative supply.

Owner:HUNAN UNIV

Calcium carbide tail gas desulfurization type depth conversion process

ActiveCN105692550BSolve the problem of difficult deep conversion of high-concentration COMeet the use requirementsHydrogenChemical industryThermal energySulfur

The invention relates to a calcium carbide tail gas desulfurization type deep conversion process, which solves the problems of complex flow, high investment cost and high operation cost in the existing process. The technical solution includes the following steps: Divide the calcium carbide tail gas into three strands after preheating, the first strand of calcium carbide tail gas and part of the converted product gas are mixed and mixed into steam steam, preheated by the 1# tail gas preheater, and then sent to the 1# converter for conversion; The shift gas from the 1# shift furnace is mixed with the second calcium carbide tail gas, and then sent to the 2# shift furnace for shift after being mixed with steam. The shift gas from the 2# shift furnace is sent to the 1# tail gas preheater and into #The mixed gas in front of the conversion furnace is mixed with the third calcium carbide tail gas after heat exchange and cooling, and then mixed with steam through the 3# steam mixer, preheated by the 2# tail gas heat exchanger, enters the 3# conversion furnace, and exits the 3# conversion furnace After the shifted gas has been further transformed or not, the shifted product gas is obtained through heat energy recovery and condensate separation. The invention has simple process, low investment cost and low operation cost.

Owner:WUHUAN ENG

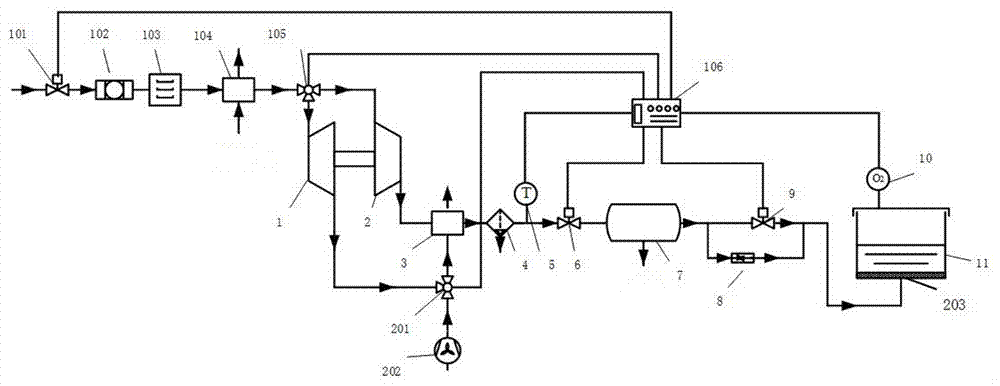

A propylene gas catalytic deoxygenation reaction device and safety control method

ActiveCN110559843BTo achieve the purpose of deoxygenationGas treatmentDispersed particle separationPtru catalystFluid phase

The invention discloses a propylene gas catalytic deoxygenation reaction device and a safety control method, and relates to the technical field of chemical tail gas treatment. After the raw material propylene tail gas is heat-exchanged by the heat exchanger, it is further heated by the electric heater to the reaction operating temperature, and then enters the deoxidation reactor. The deoxidation reactor is equipped with a catalyst bed. The air condenser cools down and enters the gas-liquid separation tank to separate the liquid phase generated during the reaction. The gas phase enters the non-condensable gas separation tower after being boosted by the compressor, and the non-condensable gas is separated from the gas phase, and pure propylene is obtained from the liquid phase; in the fourth The outlet pipeline is equipped with a tail oxygen analyzer, which can detect the tail oxygen content. If it is higher than the normal value, the backflow treatment will be carried out through the fourth outlet branch pipeline, and an alarm value will be set. The invention is especially suitable for accident scenarios such as super-high concentration of tail oxygen and over-temperature of a reactor that may occur during operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com