Fire-proof device of pressurizing nitrogen-making oil tank and working method thereof

A fire prevention device and fuel tank technology, applied in the direction of fuel tank safety measures, etc., can solve the problems of reducing the concentration of nitrogen-rich gas in the engine bleed air and affecting the deoxygenation efficiency of the fuel tank, so as to improve energy utilization efficiency, improve nitrogen production efficiency, and reduce oxygen concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

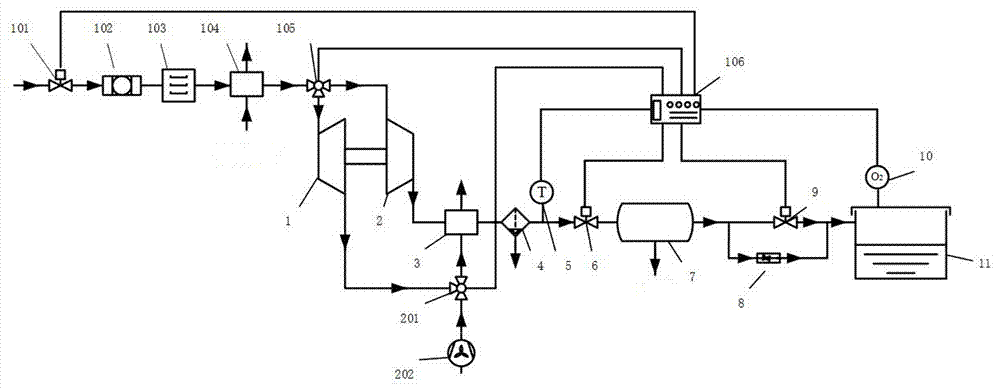

[0040] Such as figure 1 as shown, figure 1It is a self-pressurized separated air flushing system for deoxygenating the aircraft fuel tank of the pressurized nitrogen-generating fuel tank fire prevention device of the present invention. The system includes a first cooler 3, a water separator 4, a temperature sensor 5, a first flow regulating valve 6, Hollow fiber membrane 7, second flow regulating valve 9, oxygen concentration sensor 10, fuel tank 11, stop valve 101, second cooler 104, first three-way valve 105, controller 106, second three-way valve 201, fan 202. Wherein the first cooler 3 and the second cooler 104 are provided with a hot side channel and a cold side channel, the water separator 4 is provided with a gas channel and a liquid water channel, and the hollow fiber membrane 7 is provided with a gas inlet, a nitrogen outlet and an oxygen outlet, The outlet of the shut-off valve 101 and the inlet of the first three-way valve 105 are connected by pipelines, followed b...

Embodiment 2

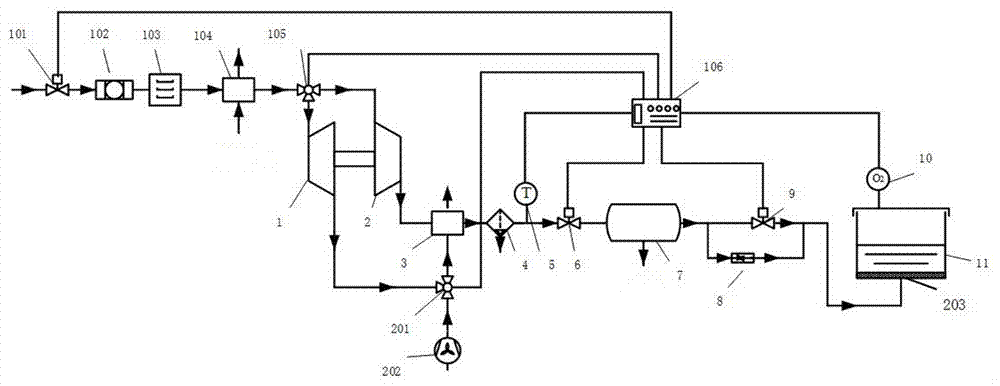

[0045] Such as figure 2 as shown, figure 2 It is a system diagram of the device of the present invention using the gas pan stone to wash the aircraft fuel tank to remove oxygen. In this embodiment, the gas outlet of the second flow regulating valve 9 is connected to the gas inlet of the gas pan stone 203 through a pipeline, and the gas pan stone 203 is installed at the bottom of the fuel tank 11. And the gas pan stone 203 is installed at the bottom of the oil tank 11; the gas pan stone is made of white corundum and silicon carbide which can be sintered at high temperature.

[0046] The difference between this embodiment and Embodiment 1 is that the gas leaving the nitrogen outlet of the hollow fiber membrane 7 no longer enters the gas inlet of the upper part of the oil tank 11 but enters the gas inlet of the gas pan stone 203 and generates a large number of fine bubbles in the gas pan stone 203. The fuel is washed to replace the oxygen in the fuel, reduce the oxygen concent...

Embodiment 3

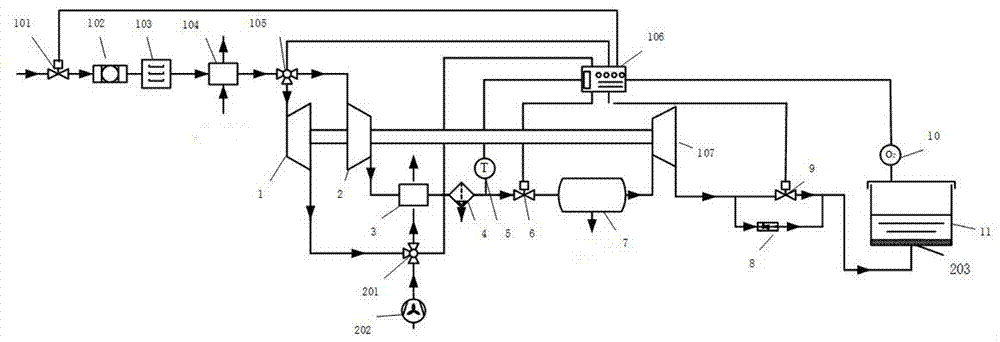

[0048] image 3 It is a system diagram of the combined deoxygenation system of gas pan stone and turbo expander of a kind of pressurized nitrogen-generating fuel tank fire protection device of the present invention. This embodiment adds the system diagram of deoxygenation of aircraft fuel tank of turbo expander 107 in Embodiment 2. In the embodiment, a turbo expander 107 is connected between the nitrogen outlet of the hollow fiber membrane 7 and the second flow regulating valve 9 through a pipeline, and the turbo expander 107 is connected to the compressor 2 through a connecting rod.

[0049] The difference between Embodiment 3 and Embodiment 1 and Embodiment 2 is that the high-pressure nitrogen gas generated at the nitrogen outlet of the hollow fiber membrane 7 first passes through the turbo expander 107 to expand, cool down, and then enter the second flow regulating valve 9, and at the same time, the high-pressure nitrogen gas passes through the turbo expander 107. The power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com