Patents

Literature

60results about How to "Improve oxygen removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire-proof device of pressurizing nitrogen-making oil tank and working method thereof

ActiveCN107954001AIncrease bleed air pressureIncreased bleed air pressureFuel tank safety measuresWeight reductionAutomatic controlExplosion protection

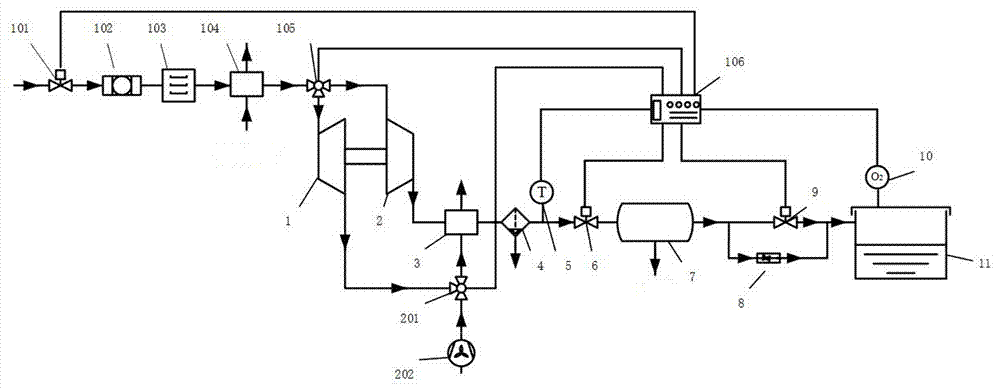

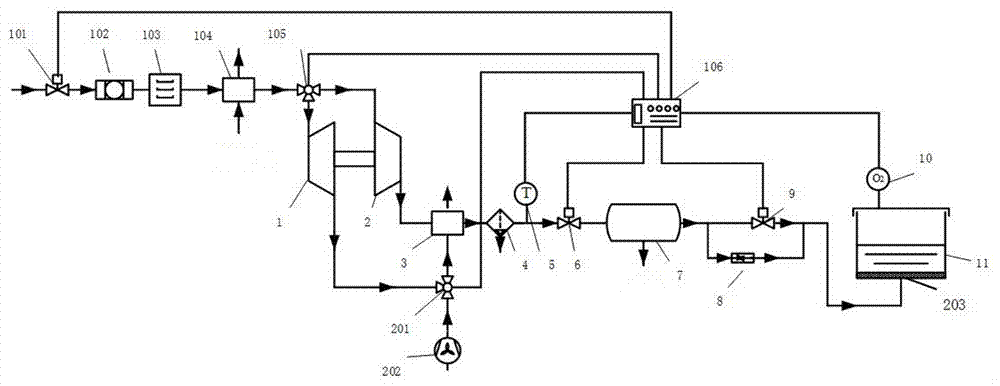

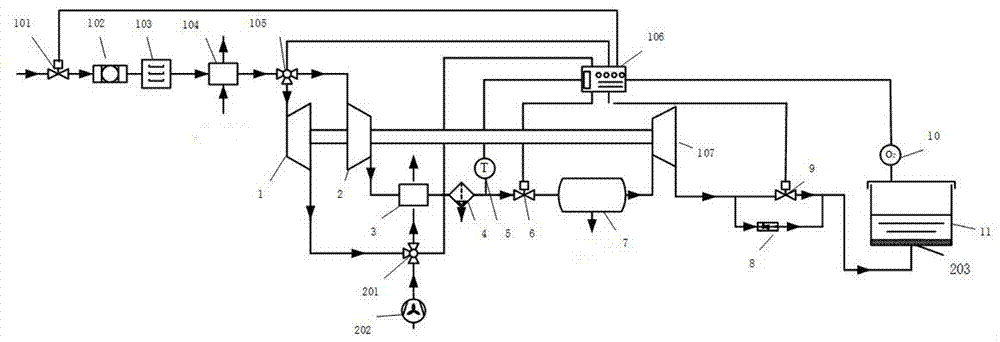

The invention discloses a fire-proof device of a pressurizing nitrogen-making oil tank and a working method thereof, and belongs to the technical field of fire and explosion protection. Bleed air pressure of an engine is increased by using a self-pressurizing mode, and a nitrogen gas with high concentration is separated from the bleed air through a hollow fiber membrane after impurity removing anddrying and is injected to the oil tank through a control system according to the need so that oxygen gas in the oil tank is removed; in addition, a turbo expander and a compressor are combined for generating expansion work, the work output by the expander drives the compressor to compress the bleed air of the engine, the gas pressure is further increased so as to reach the needed pressure of thehollow fiber membrane for separation, and nitrogen-making efficiency is improved. Nitrogen-enriched gas is charged into the oil tank, oxygen content in the oil tank is reduced, and a flow of the gas can be regulated by automatically controlling devices in a nitrogen-charging process, so that needed inert gas is generated. The oil tank is located in a non-combustion state, and the purpose of fire and explosion protection is achieved. The fire-proof device can be automatically controlled, and has the advantages of high inerting efficiency, less energy consumption and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

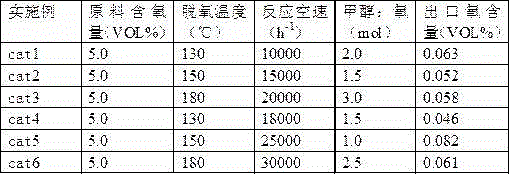

Preparation method and application of unconventional natural gas deoxygenation catalyst

ActiveCN103599775ALower requirementLow reaction temperatureMolecular sieve catalystsGaseous fuelsIridiumMass content

The invention discloses a preparation method and application of an unconventional natural gas deoxygenation catalyst. The catalyst is composed of an active component and a carrier. The catalyst active component is one or more of metal platinum (Pt), palladium (Pd), ruthenium (Ru) and iridium (Ir), and the catalyst carrier is one or more of titanium dioxide, alumina, silica, molecular sieve, zeolite, kaolin and the like. Calculated according to metal elementary substances, the mass content of the catalyst active component is 0.01-0.1% and the balance is the carrier. Methanol is employed as a deoxidizer. The catalyst provided by the invention has the advantages of stable properties, high activity, low deoxygenation operation temperature and the like, and is capable of processing the unconventional natural gas such as coal bed gas and the like with an oxygen volume content of 0.1-5% and reducing the oxygen volume content in the unconventional natural gas to a number less than 0.1%.

Owner:CHENGDU ZHONGKE ENERGY & ENVIRONMENTAL PROTECTION CO LTD

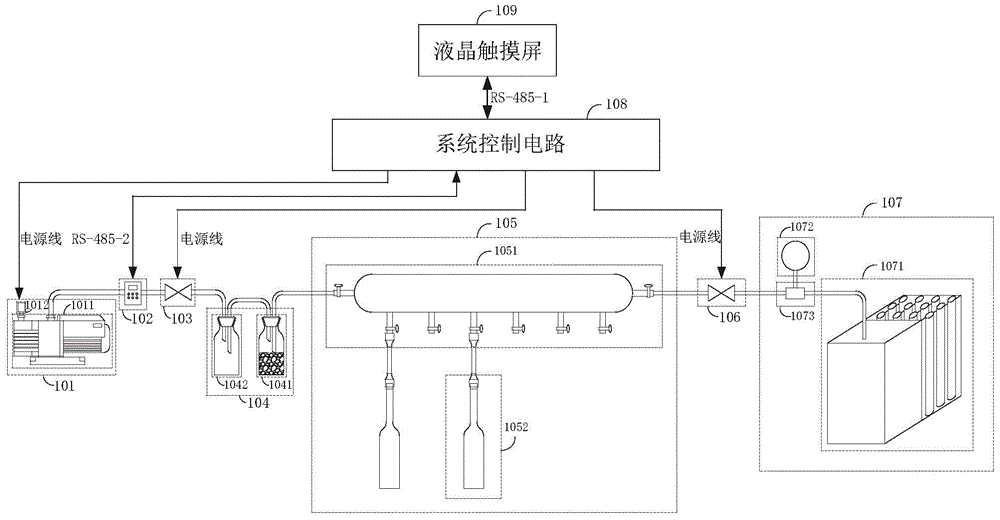

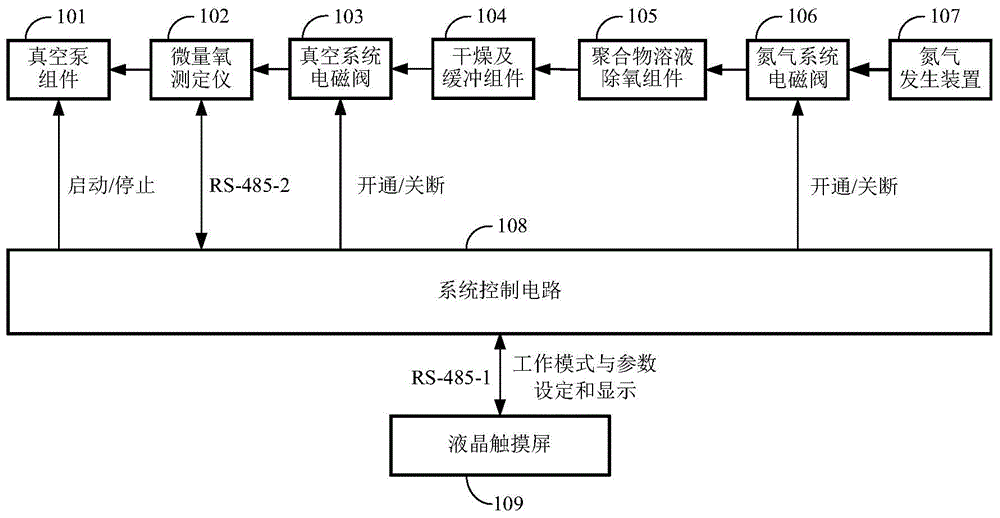

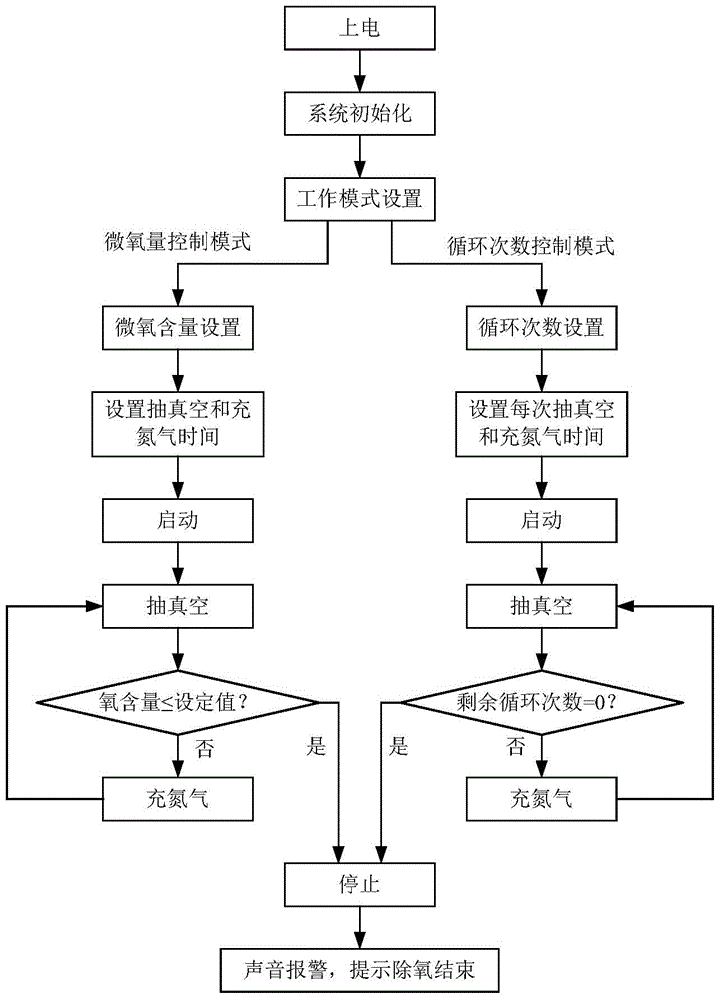

Novel intelligent efficient polymer solution deoxidizing system

InactiveCN104964867AGuaranteed accuracyImprove efficiencyPreparing sample for investigationNitrogen generatorOxygen meters

A novel intelligent efficient polymer solution deoxidizing system comprises a vacuum pump assembly, a trace oxygen meter, a vacuum system electromagnetic valve, a drying and buffering assembly, a polymer solution deoxidizing assembly, a nitrogen system electromagnetic valve, a nitrogen generator, a system control circuit and a liquid crystal touch screen. The intake end of the vacuum pump assembly is connected with the output end of the trace oxygen meter through a stainless steel pipe. The input end of the trace oxygen meter is connected with one end of the vacuum system electromagnetic valve through a stainless steel pipe, and the other end of the vacuum system electromagnetic valve is connected with the output end of the drying and buffering assembly through a silicone tube; the input end of the drying and buffering assembly is connected with the suction end of the polymer solution deoxidizing assembly; the charge end of the polymer solution deoxidizing assembly is connected with one end of the nitrogen system electromagnetic valve; the other end of the nitrogen system electromagnetic valve is connected with the output end of the nitrogen generator through a stainless steel pipe; a system control circuit is connected with the vacuum pump assembly, the vacuum system electromagnetic valve and the nitrogen system electromagnetic valve through power lines.

Owner:北京东航科仪仪器有限公司

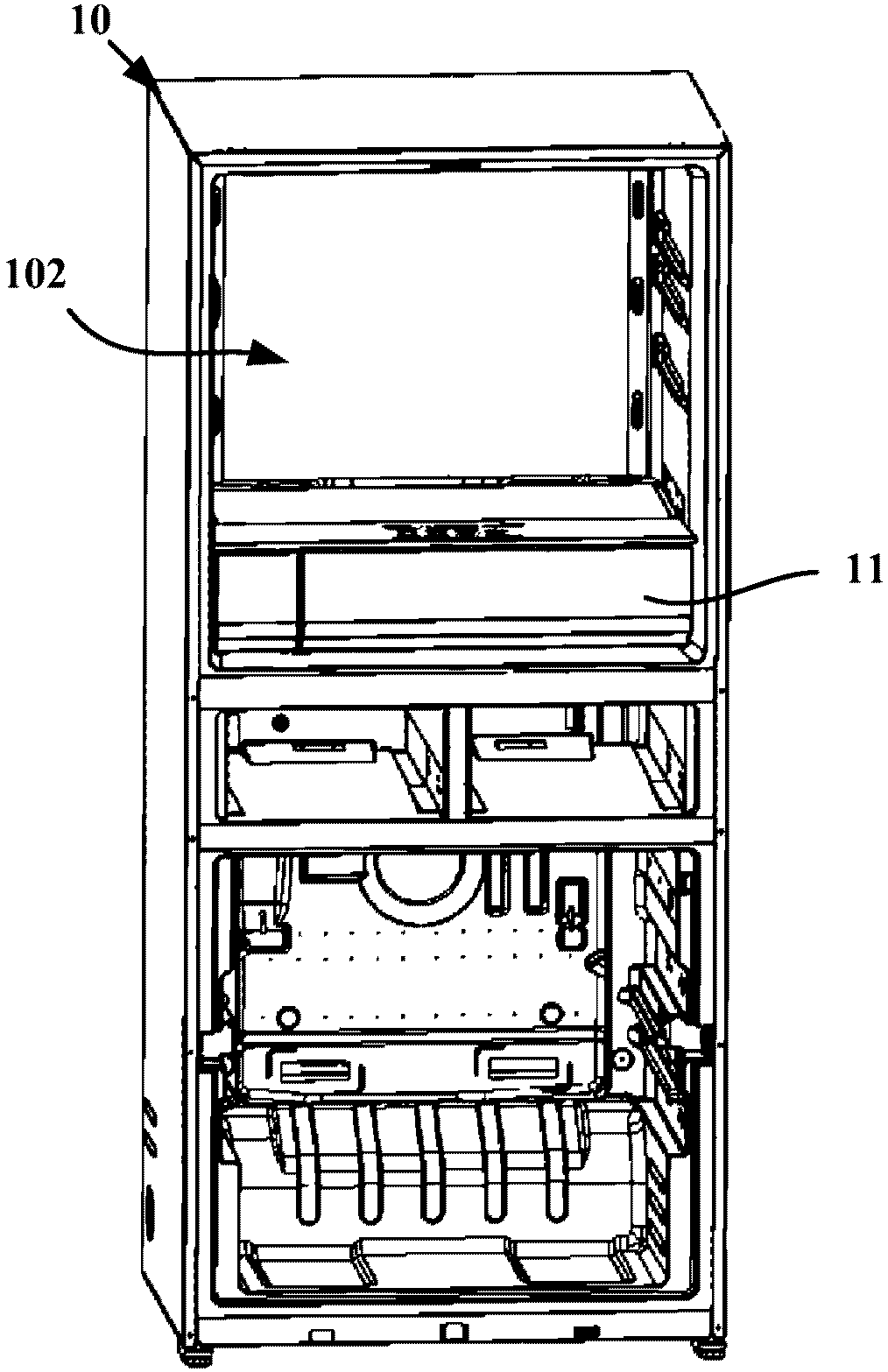

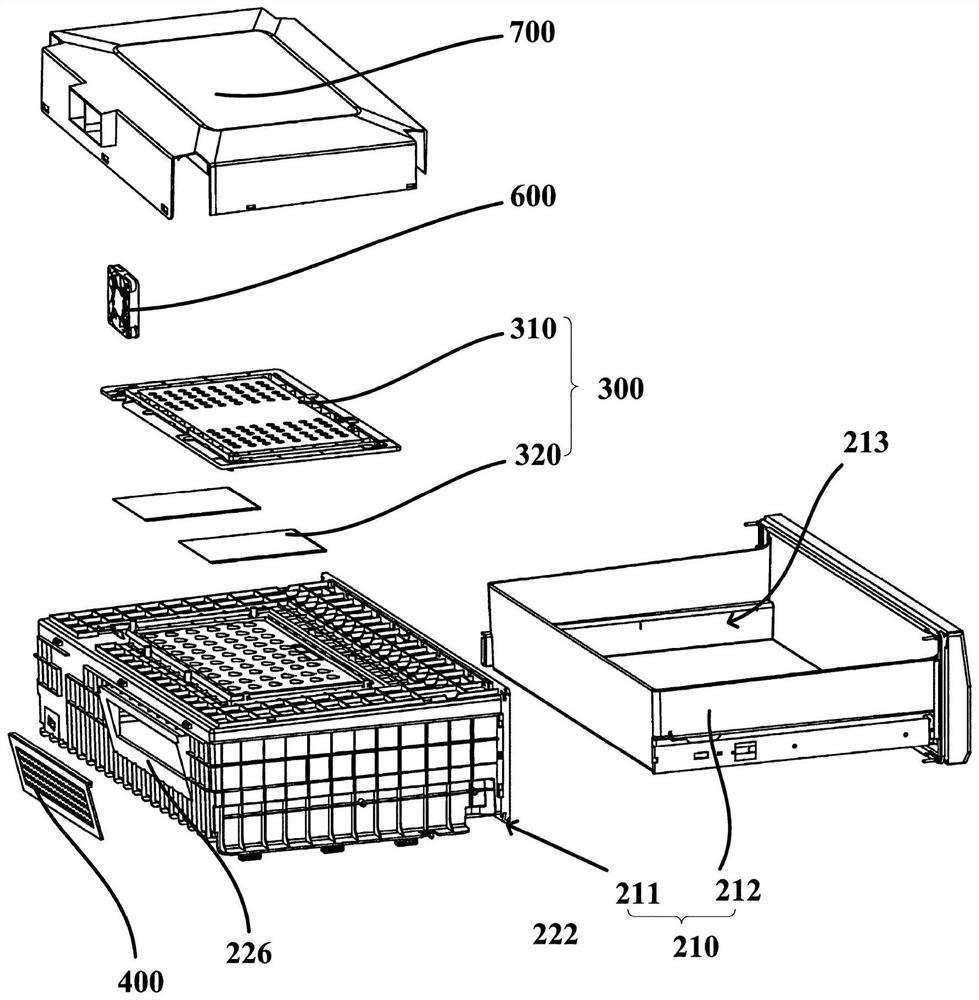

Refrigeration and freezing equipment

InactiveCN109579403AReduce oxygen concentrationReduce energy consumptionElectrolysis componentsLighting and heating apparatusElectrolysisPotassium hydroxide

The invention provides refrigeration and freezing equipment, comprising a box body, a door body, and a gas regulating membrane assembly, wherein a storage space is limited in the box body; a storage container is arranged in the storage space; a fresh-keeping space is limited in the storage container; the door body is arranged on the front surface of the box body so as to seal the storage space; the gas regulating membrane assembly is installed on the storage container and the surrounding space of the gas regulating membrane assembly communicates with the fresh-keeping space; the gas regulatingmembrane assembly comprises a proton exchange membrane and a hydrogen production device; the gas regulating membrane assembly is configured to make hydrogen generated by the hydrogen production device flow to the proton exchange membrane and react with oxygen in the fresh-keeping space after being decomposed into hydrogen ions and electrons so as to reduce the oxygen concentration in the fresh-keeping space, and the hydrogen production device generates hydrogen by electrolyzing a potassium hydroxide solution. The refrigeration and freezing equipment provided by the invention can effectively reduce the whole energy consumption of the deoxidization process, rapidly reduce the oxygen concentration in the fresh-keeping space, and greatly improve the deoxidization efficiency.

Owner:HAIER SMART HOME CO LTD

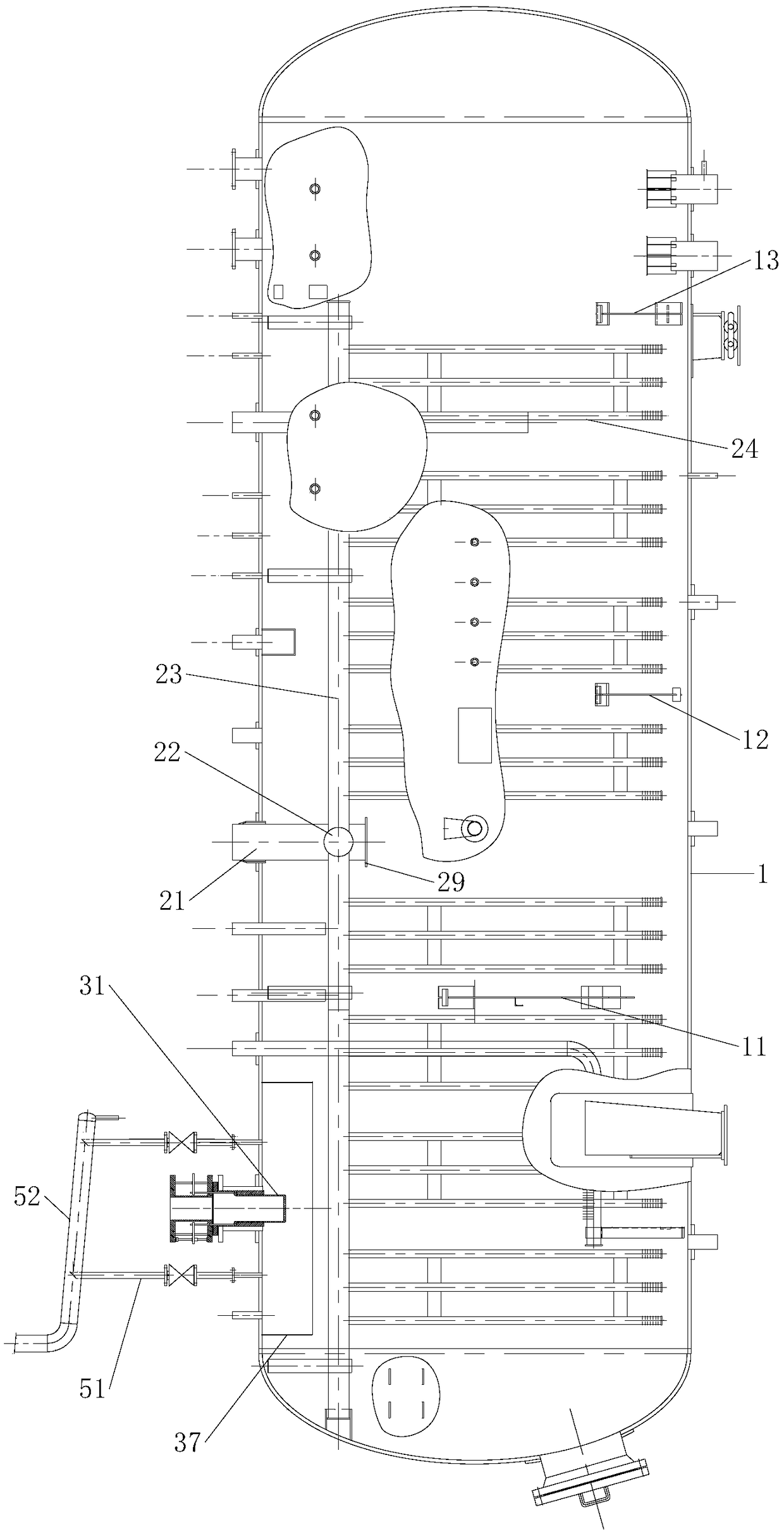

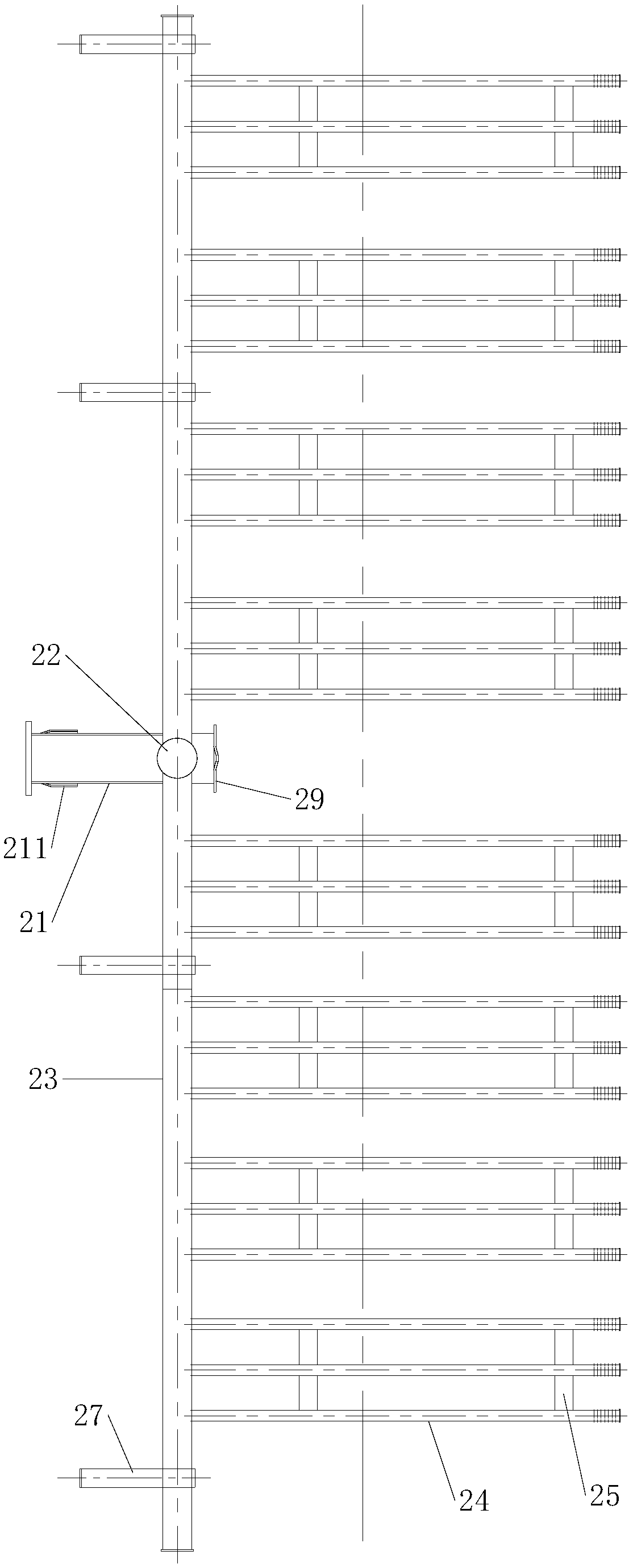

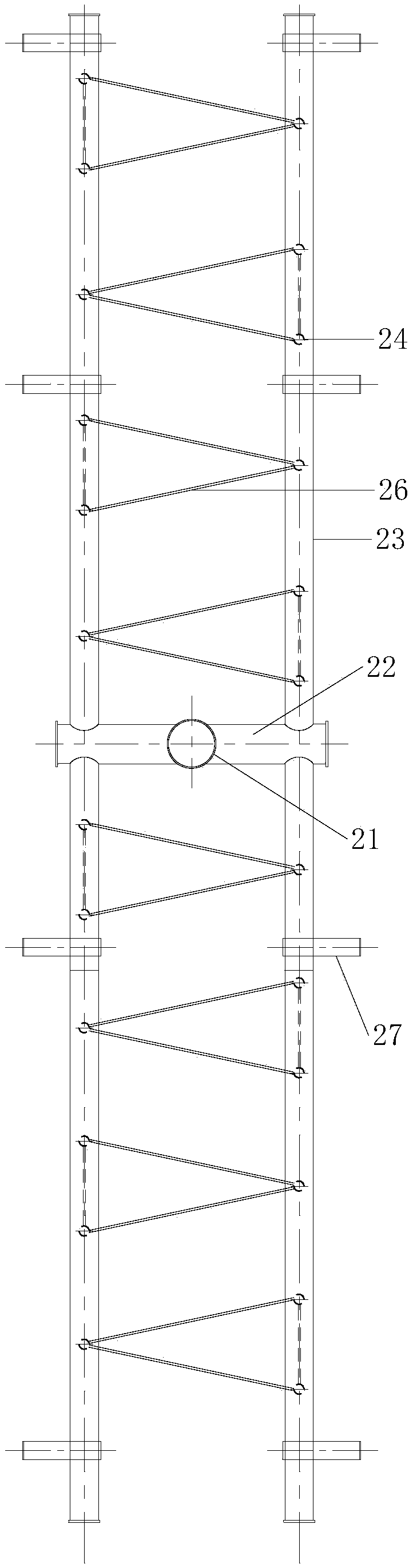

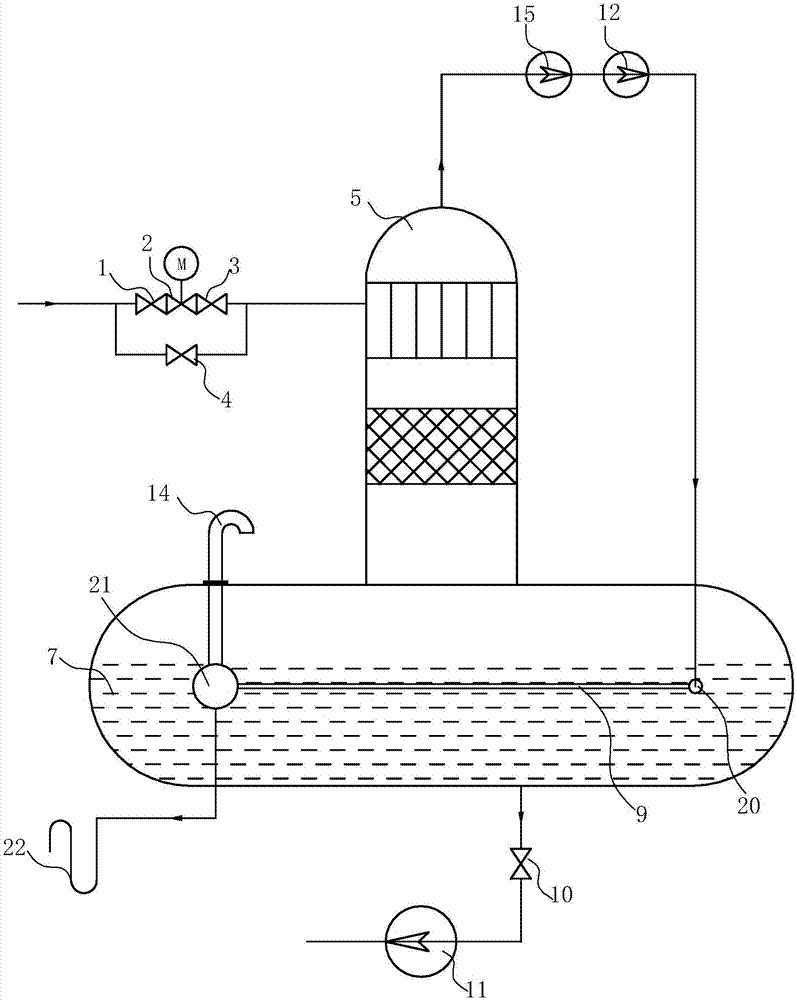

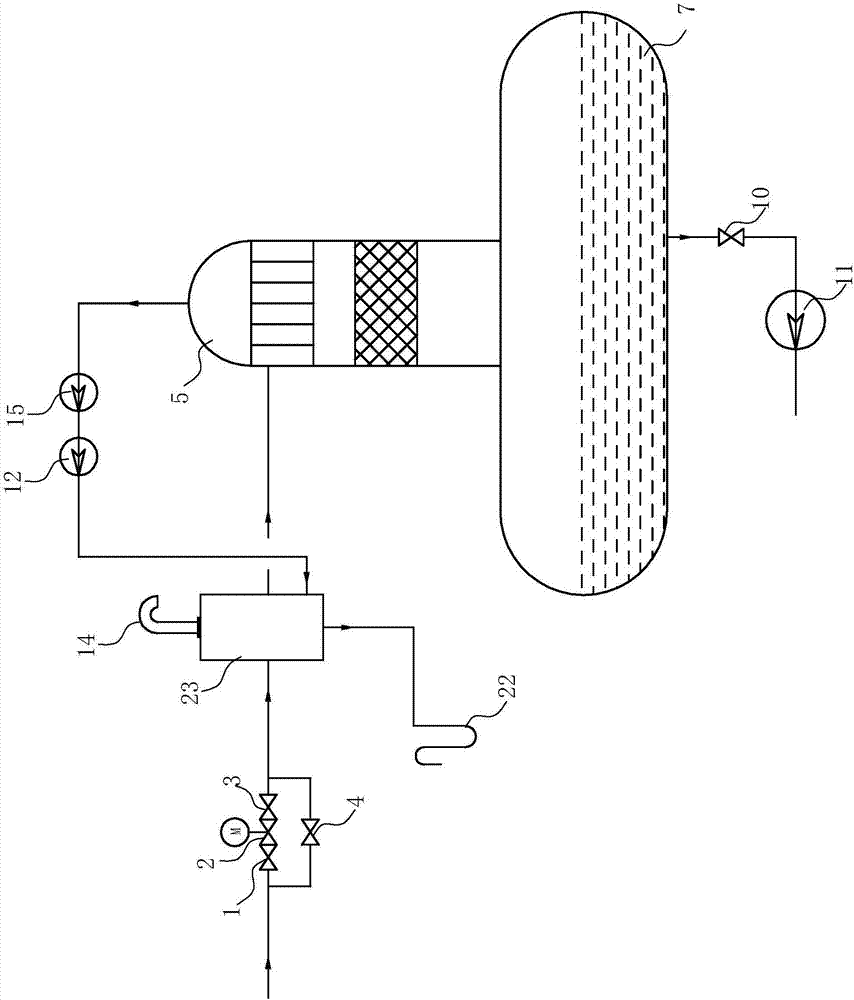

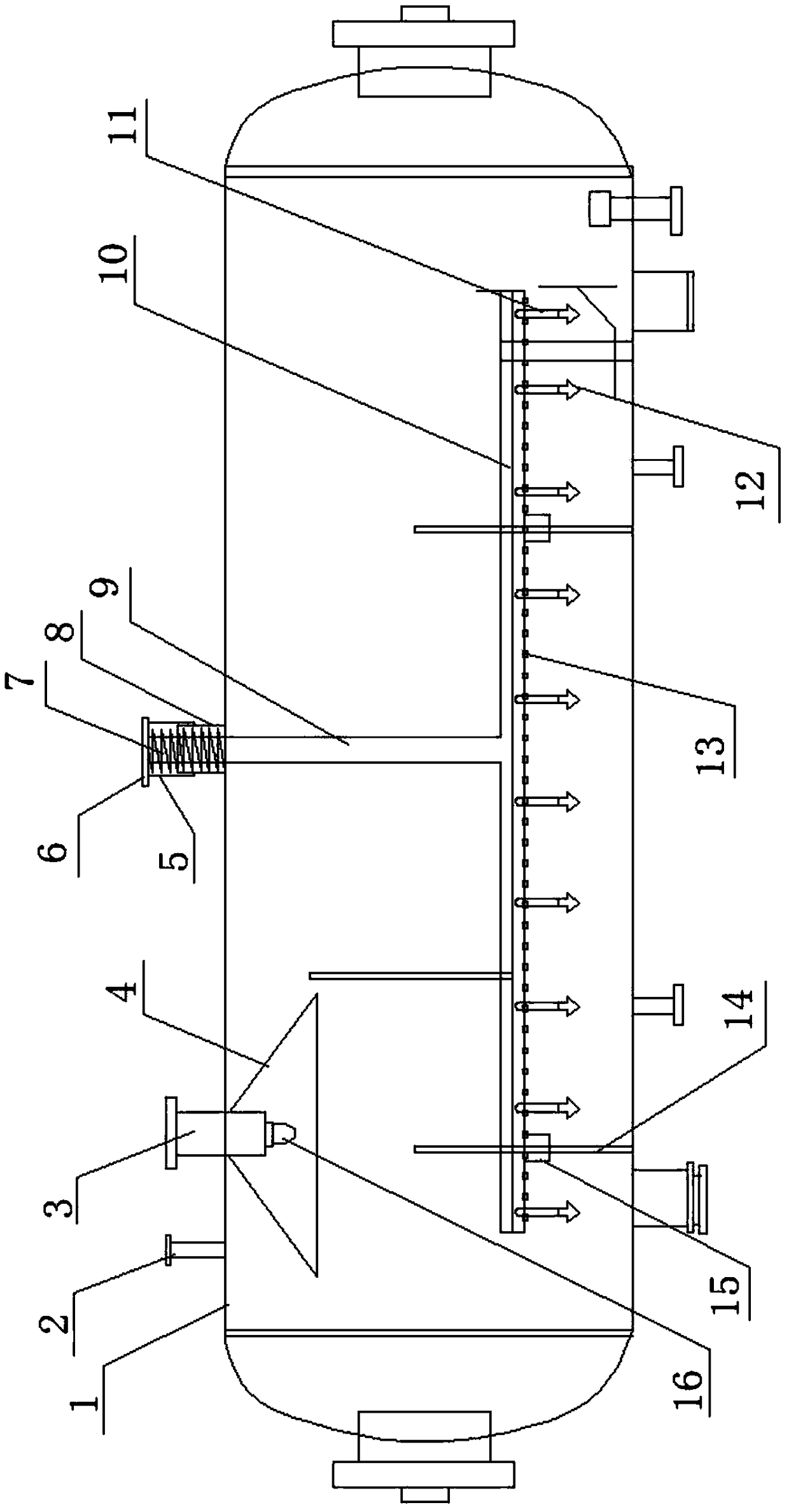

Internal type headless higher-pressure deaerator and deaeration method

PendingCN106996556AAvoid redissolutionHeating fastLiquid degasificationWater/sewage treatment by degassingDeaeratorEngineering

The invention discloses an internal type headless high-pressure deaerator. The internal type headless high-pressure deaerator comprises a barrel body, wherein an internal barrel body, a water-spraying inner barrel, a re-boiler, a steam mixing outer barrel, a heating steam tube, a re-boiling heating tube and a deaerated water outlet are mounted inside the barrel body; a water feeding tube, a water return tube and a gas exhaust tube are arranged on a barrel body surrounded by the internal barrel body; and a spraying device and a filler layer are further arranged inside the internal barrel body from top to bottom. The invention further provides a deaeration method which separates oxygen in water through a tertiary device. Compared with a conventional system with a deaeration head, the internal type headless high-pressure deaerator has the beneficial effects of reducing equipment height, greatly reducing civil engineering cost, reducing lift of a water inlet pump, achieving the energy-saving effect, being more complete in deaeration, and being capable of achieving effect of 0.05 ppm, and being applicable when a steam temperature ranges from 104 DEG C to 190 DEG C. The internal type headless high-pressure deaerator is simple and compact in structure, and is convenient to mount and maintain.

Owner:山东岱星金属设备有限公司

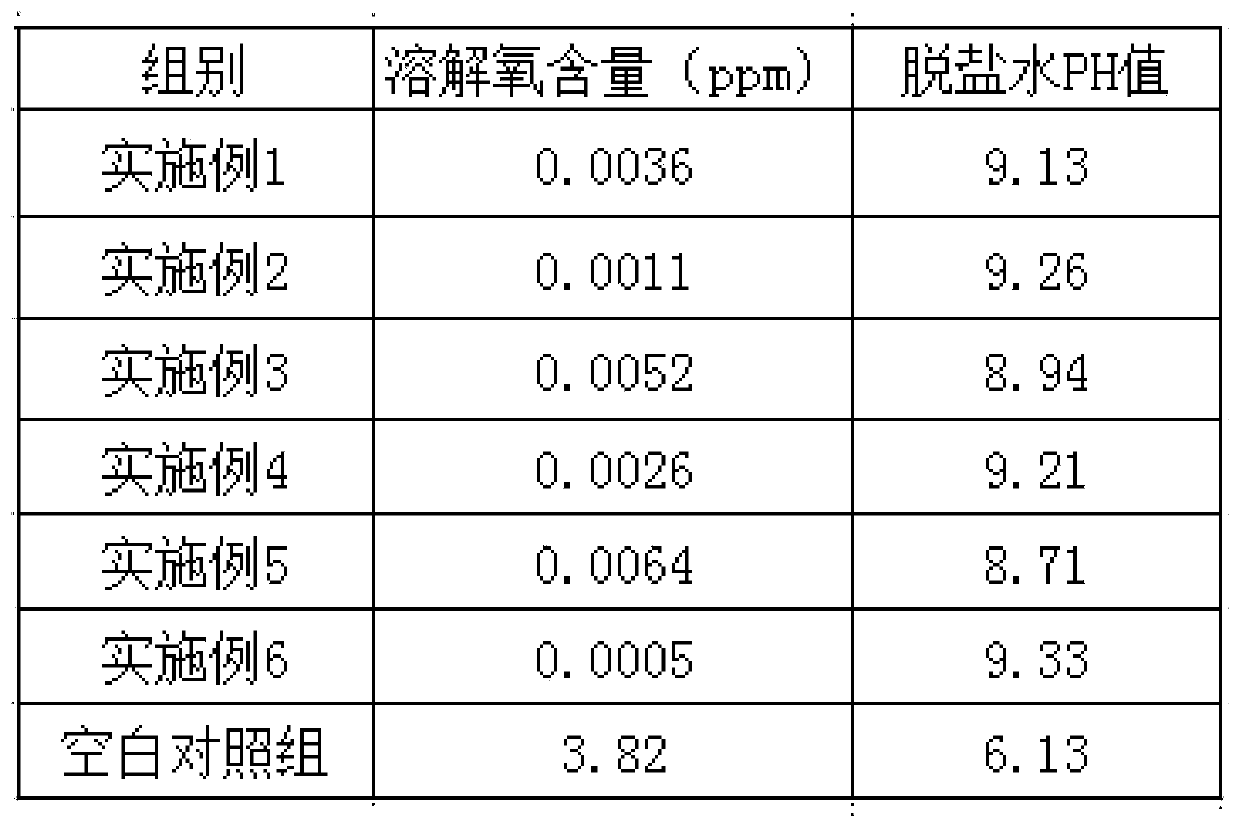

Environmental-friendly boiler deoxidizer

InactiveCN110156105AImprove oxygen removal efficiencyLow environmental requirementsWater treatment parameter controlWater/sewage treatment by neutralisationEnvironmental resistanceHydroxylamine Hydrochloride

The invention relates to the technical field of boiler water treatment and in particular discloses an environmental-friendly boiler deoxidizer. The environmental-friendly boiler deoxidizer is preparedfrom the following raw materials in parts by weight: 10-30 parts of oxime-containing compounds, 6-12 parts of amino heterocyclic compounds, 6-15 parts of hydrazide derivatives, 2-8 parts of hydroxylamine compounds, 12-20 parts of neutralizing amine, 0.2-3 parts of a catalyst and 15-70 parts of desalted water. The environmental-friendly boiler deoxidizer disclosed by the invention overcomes the defects in the prior art, has effects of passivating boiler pipes and equipment, and prevents corrosion damage of the boiler caused by accumulation of metal deposits. The product is nontoxic, harmless and emission-free, and is environmental-friendly and safe to use.

Owner:安徽省力皖节能环保科技有限公司

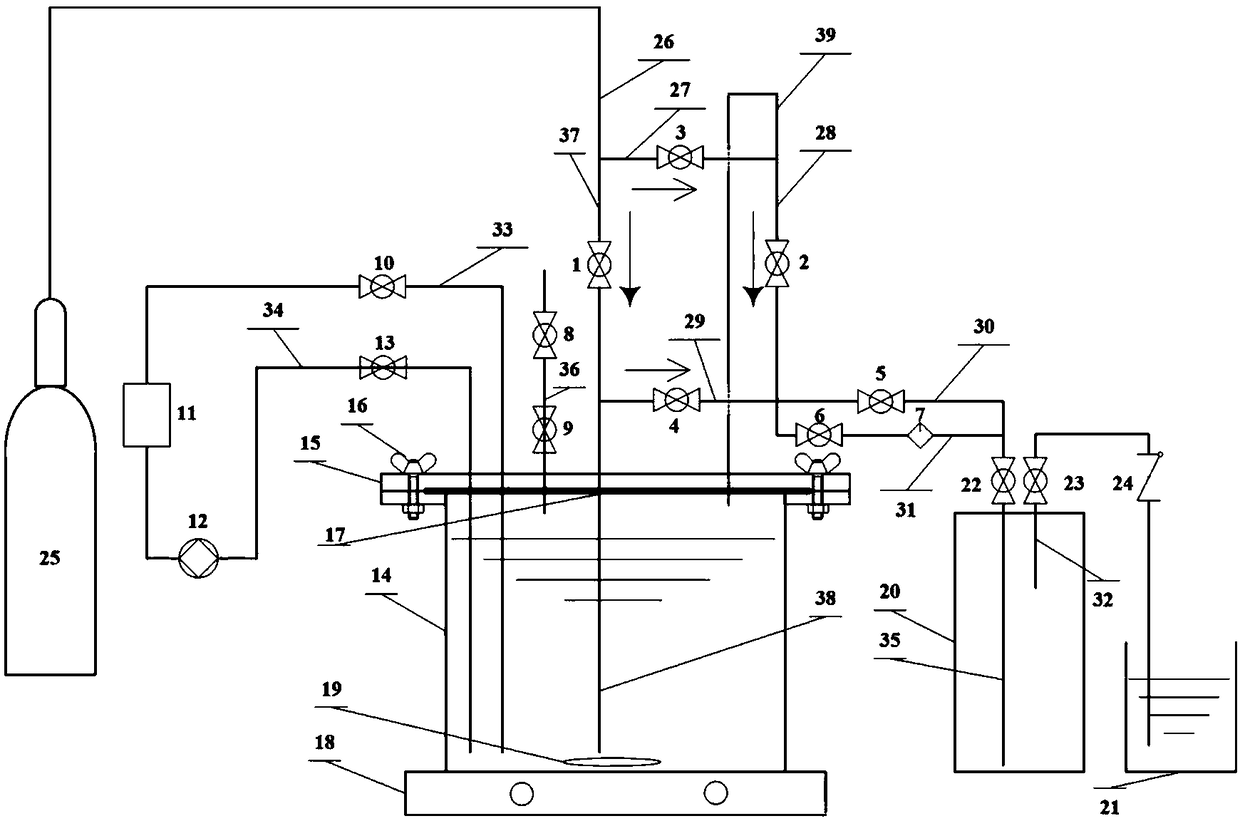

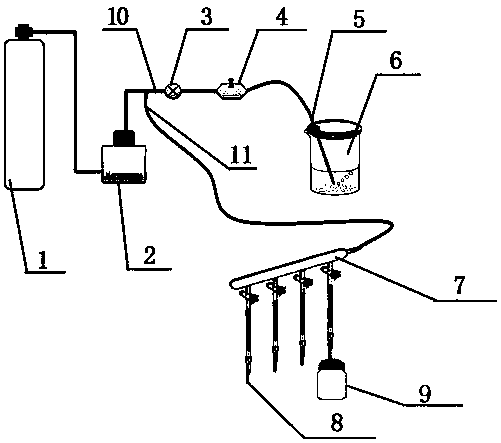

Detecting and dosing device and method for pre-removing oxygen in solution for corrosion test

PendingCN108872055AEliminate volatility and other problemsCorrosion Test GuaranteeWeather/light/corrosion resistanceMedicineNitrogen

The invention discloses a detecting and dosing device and method for pre-removing oxygen in a solution for corrosion test. The detecting and dosing device comprises an oxygen pre-removing and liquid pouring system, a dissolved-oxygen detection system, a corrosion-test container, a dosing system, a high-purity nitrogen bottle and a tail-gas collecting container. The detecting and dosing device andmethod disclosed by the invention have the beneficial effects that the device and the method are used for completely pre-removing the oxygen in the test solution, and monitoring whether the content ofthe dissolved oxygen in the solution meets the test requirements, meanwhile after a pipeline is connected once in place till completion of oxygen pre-removal, the test solution is led into a test device to carry out corrosion test, the disassembling work of the pipeline is not needed, so that the problems of mixing of the dissolved oxygen, easy volatilization of a corrosion inhibitor and the likein a switching process of oxygen pre-removal and liquid pouring are avoided, and the conduction of the corrosion test in a completely-controllable no-oxygen environment is ensured from all aspects.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

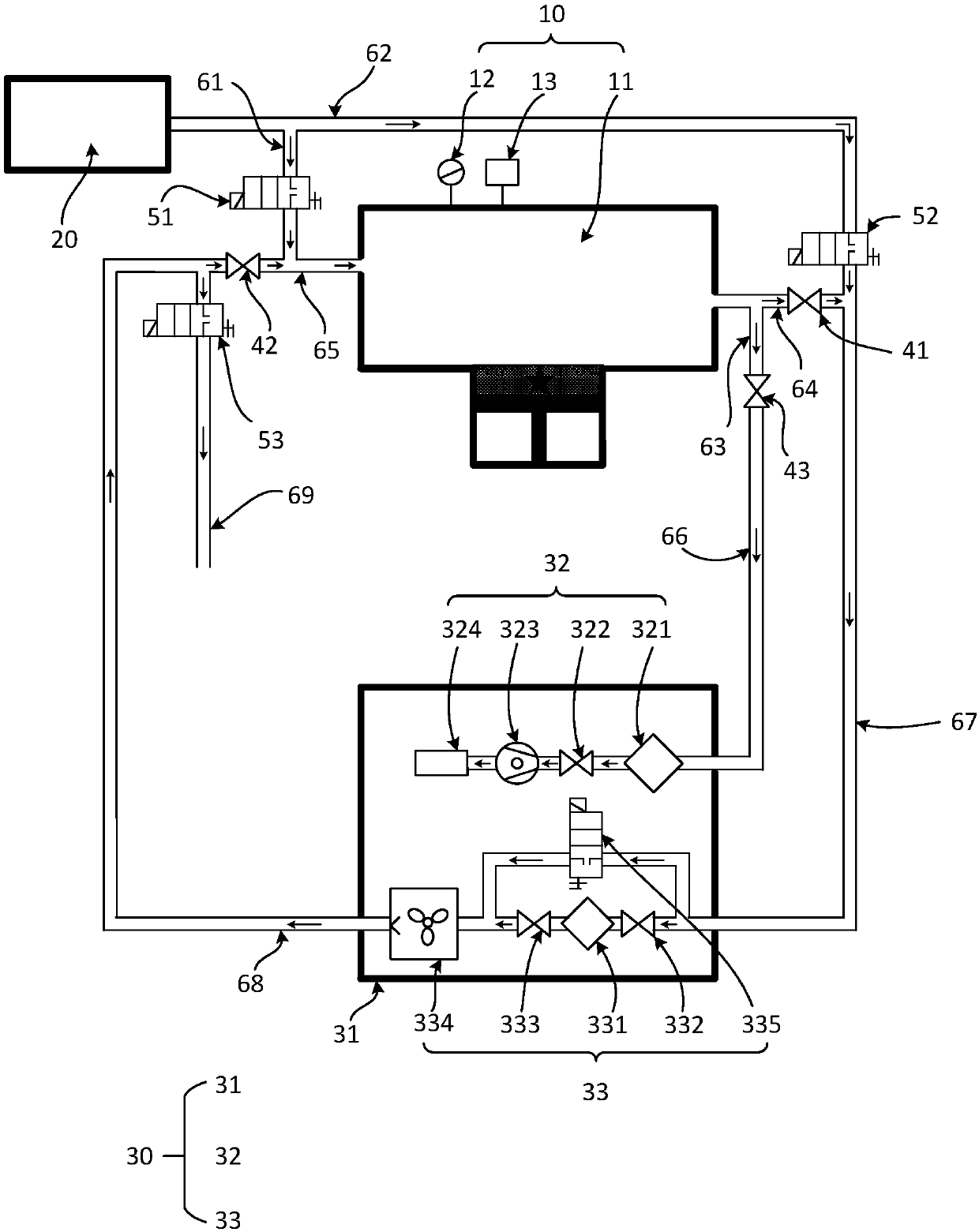

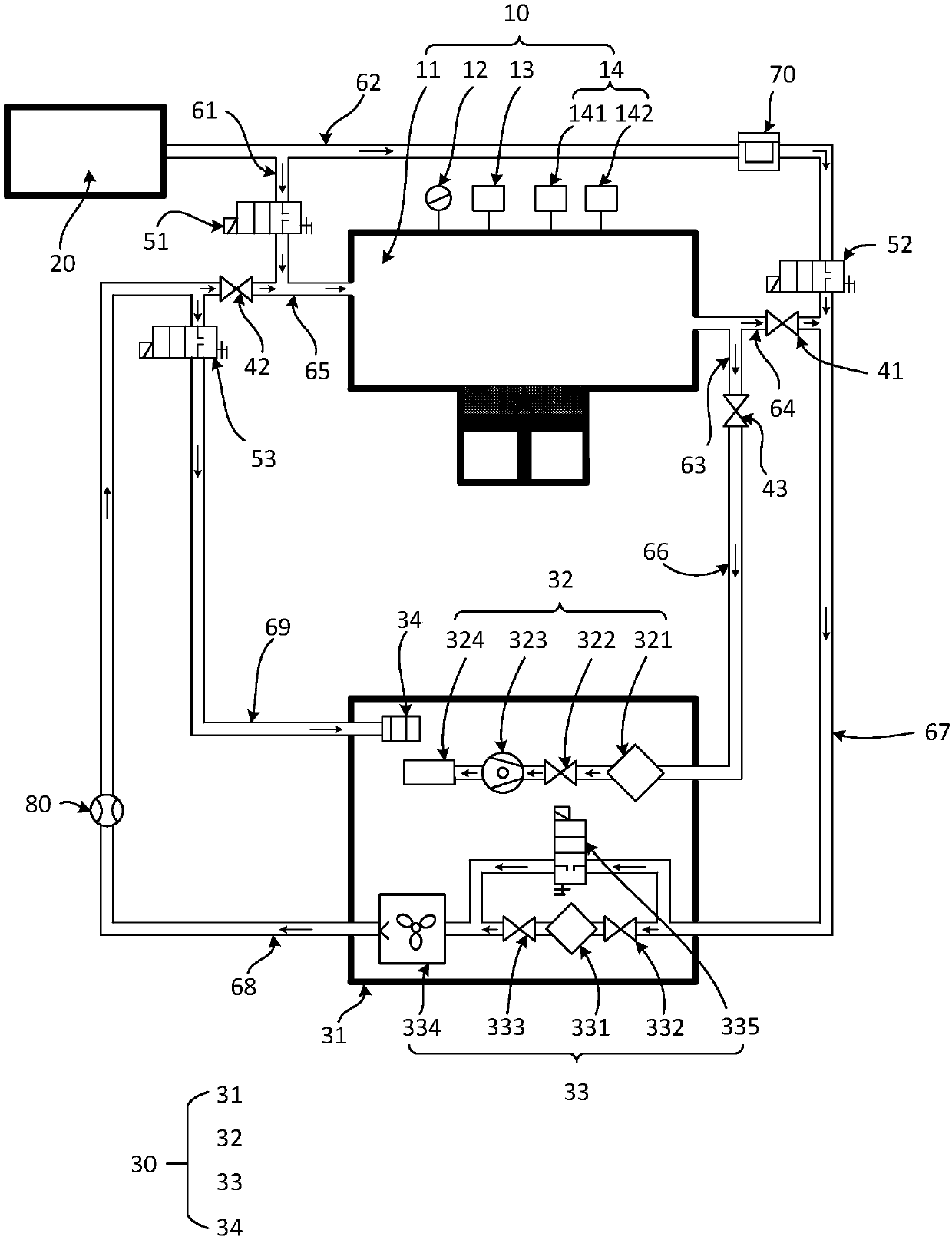

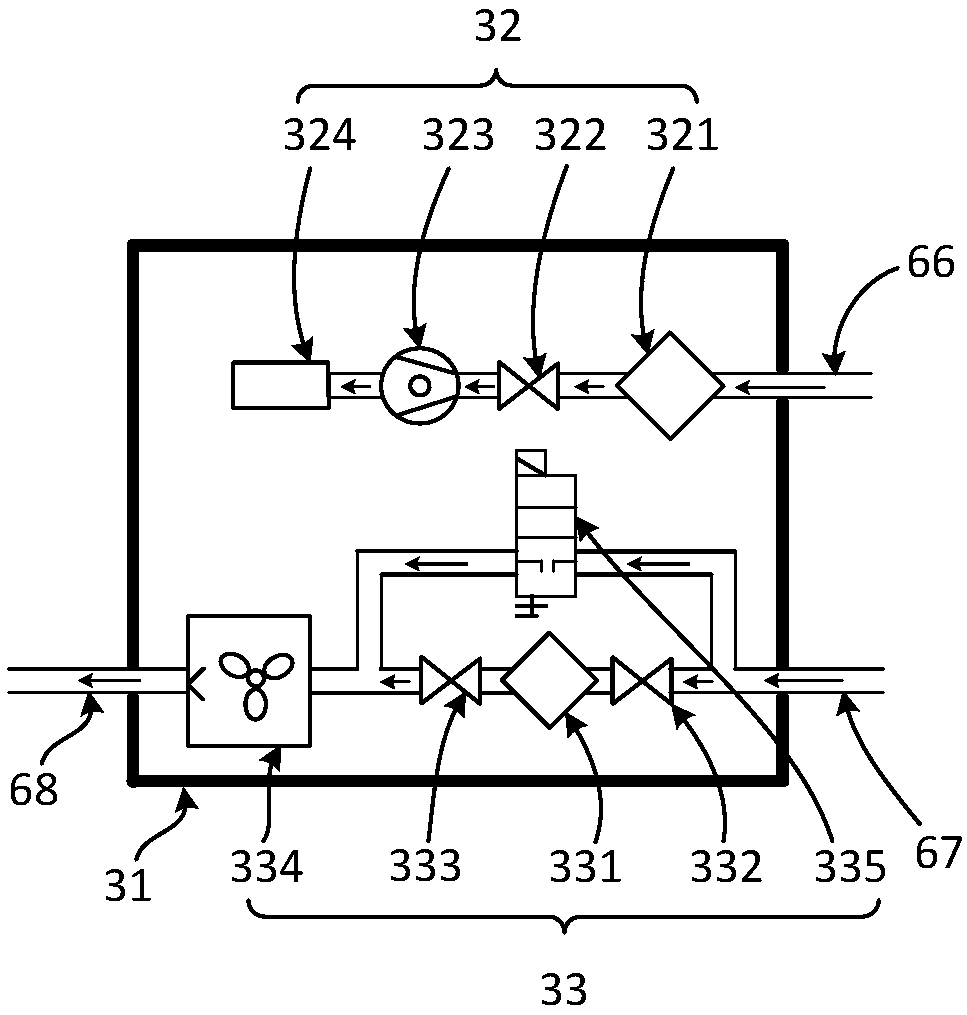

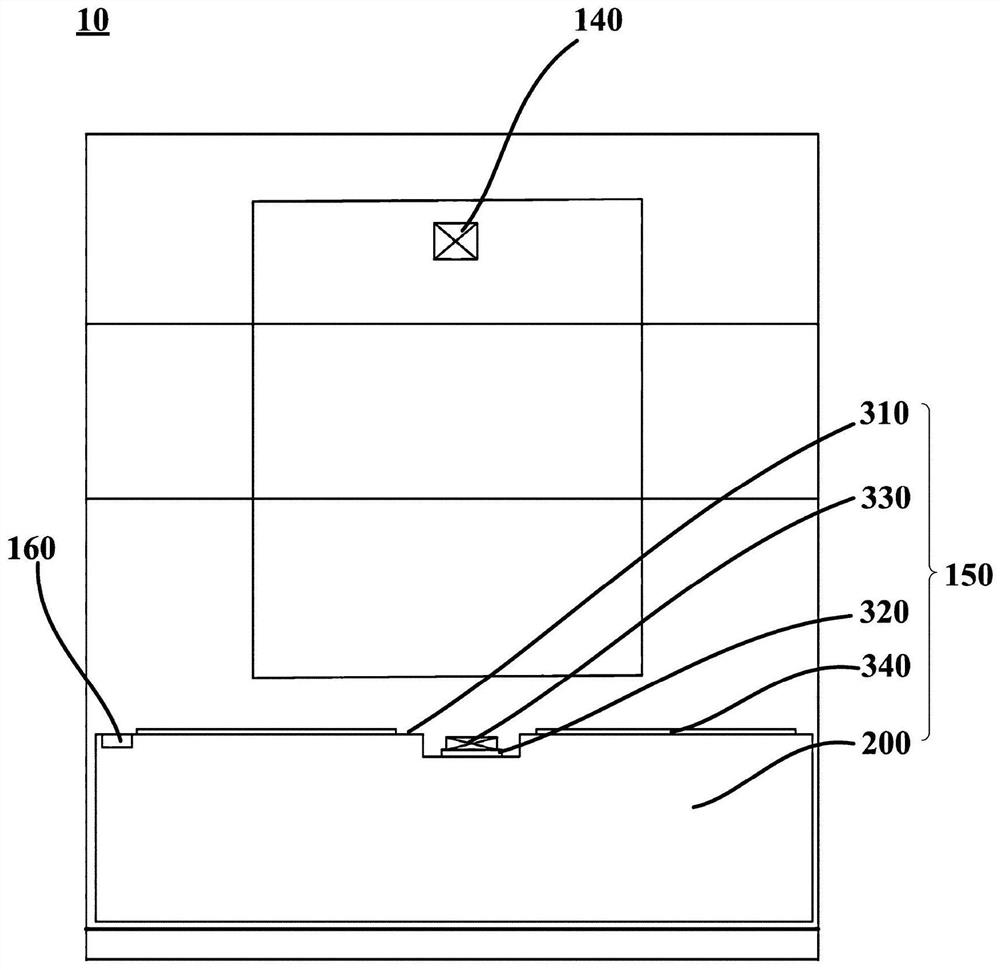

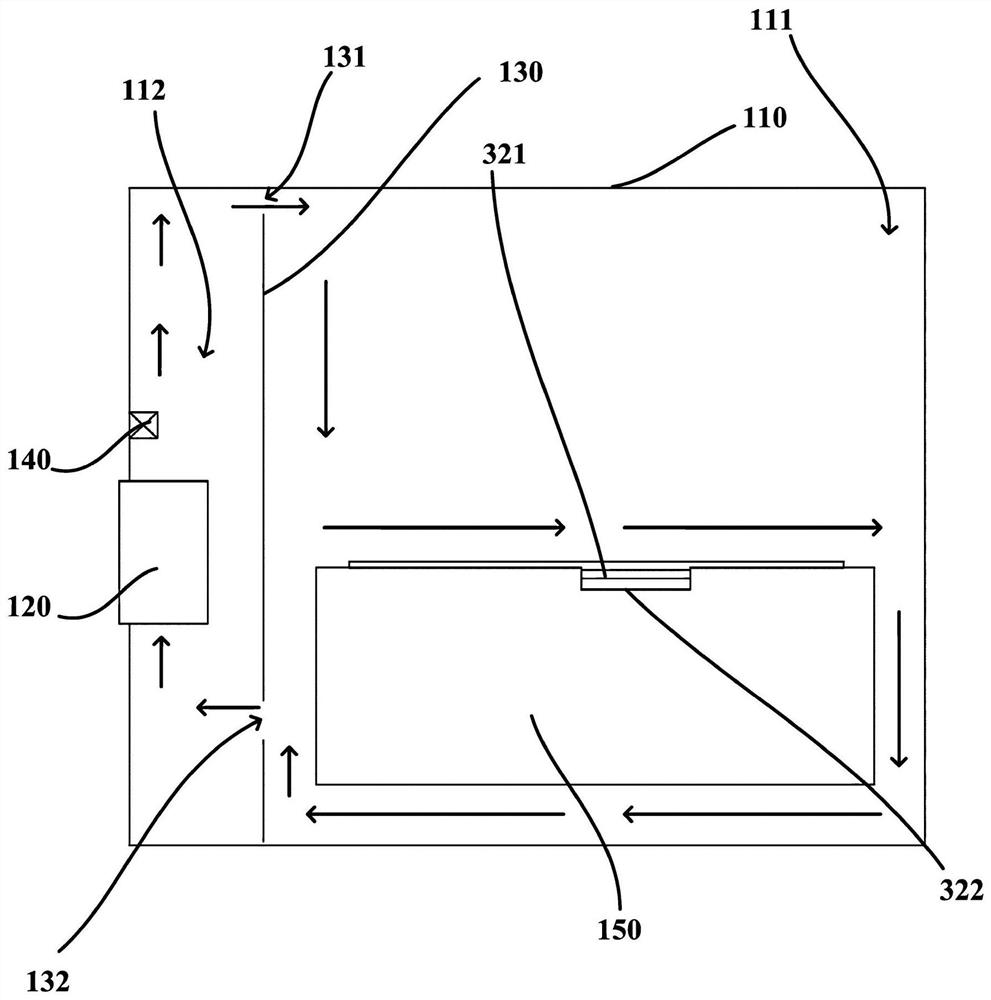

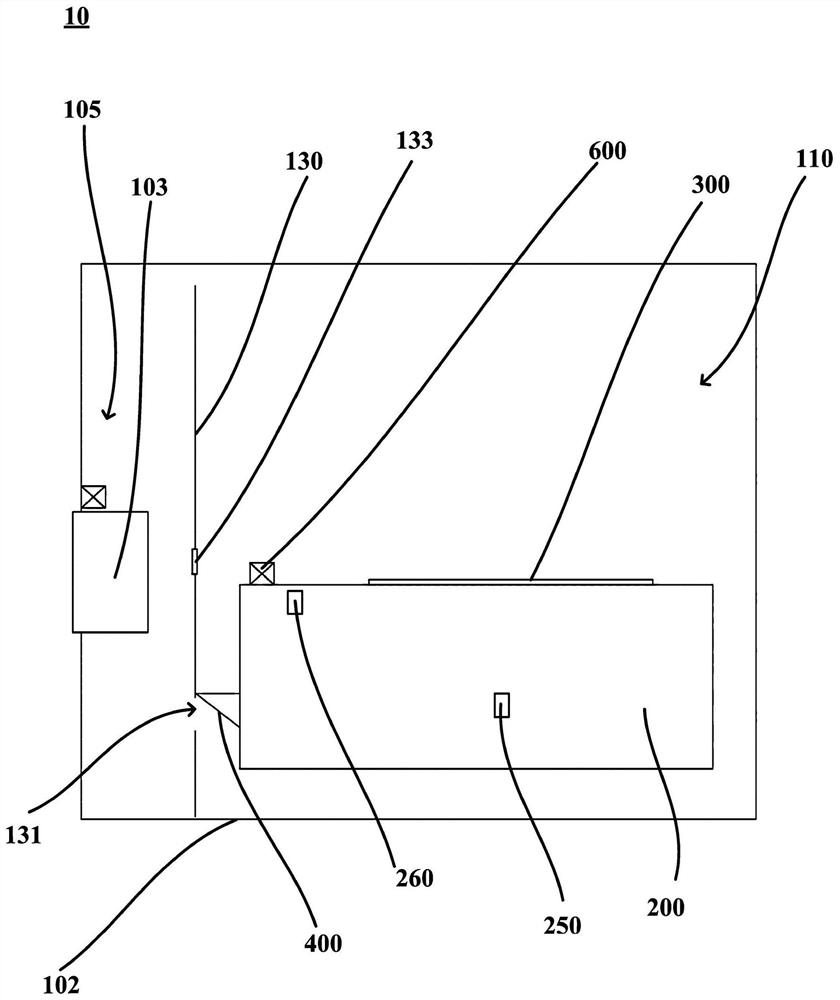

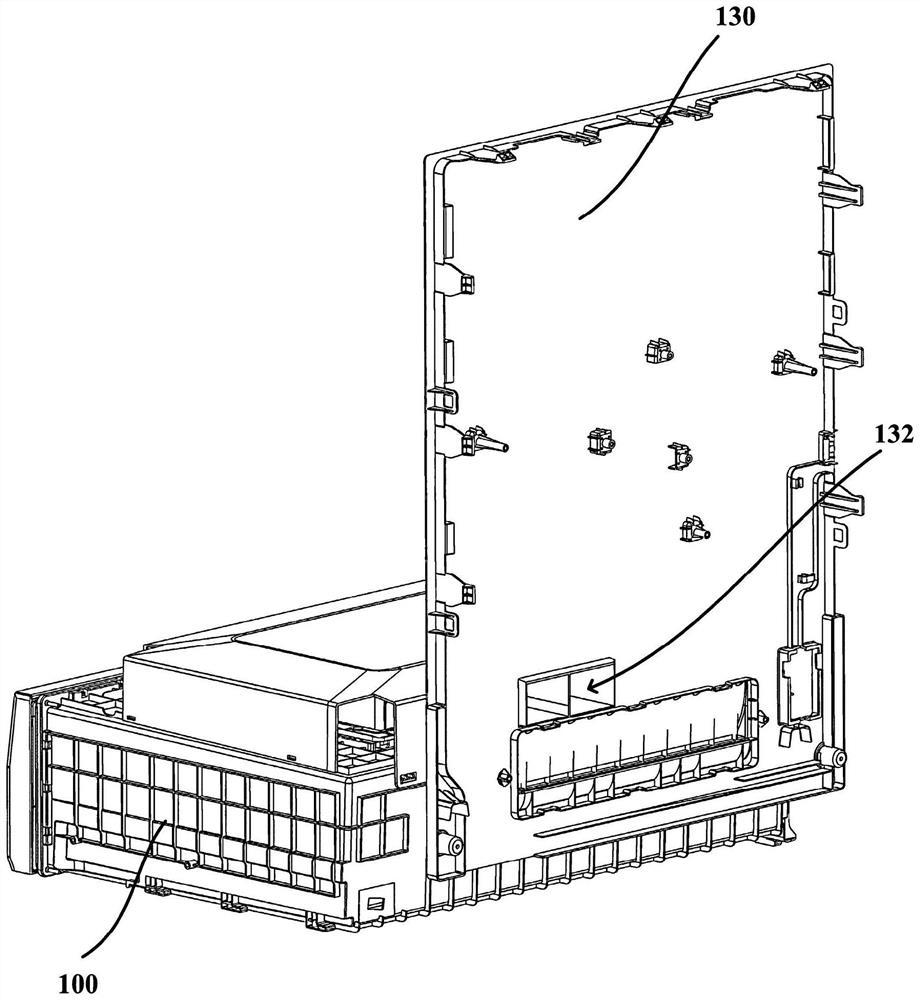

Selective laser melting system, gas circulating device and printing method

ActiveCN109807328AAchieve reuseImprove oxygen removal efficiencyIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention belongs to the technical field of additive manufacturing equipment, and relates to a selective laser melting system. The selective laser melting system comprises selective laser meltingequipment, a protective gas output device and a gas circulating device, wherein the selective laser melting equipment comprises a forming cavity, a pressure meter and an oxygen transmitter; the gas circulating device comprises a shell, a vacuumizing assembly and a gas circulating filtering assembly; the forming cavity and the gas circulating filtering assembly forms a first gas path, the protective gas output device, the forming cavity and the vacuumizing assembly form a second gas path, the protective gas output device and the gas circulating filter assembly form a third gas path, each gas path comprises a plurality of connecting pieces, and the first gas path, the second gas path and the third gas path are interconnected through a common part of the connecting pieces. According to the selective laser melting system, the oxygen removal efficiency in the forming material inside the forming cavity can be improved, and the overall oxygen removal speed is accelerated; in addition, the invention further provides a gas circulating device and a printing method applied to the system

Owner:HANS LASER TECH IND GRP CO LTD

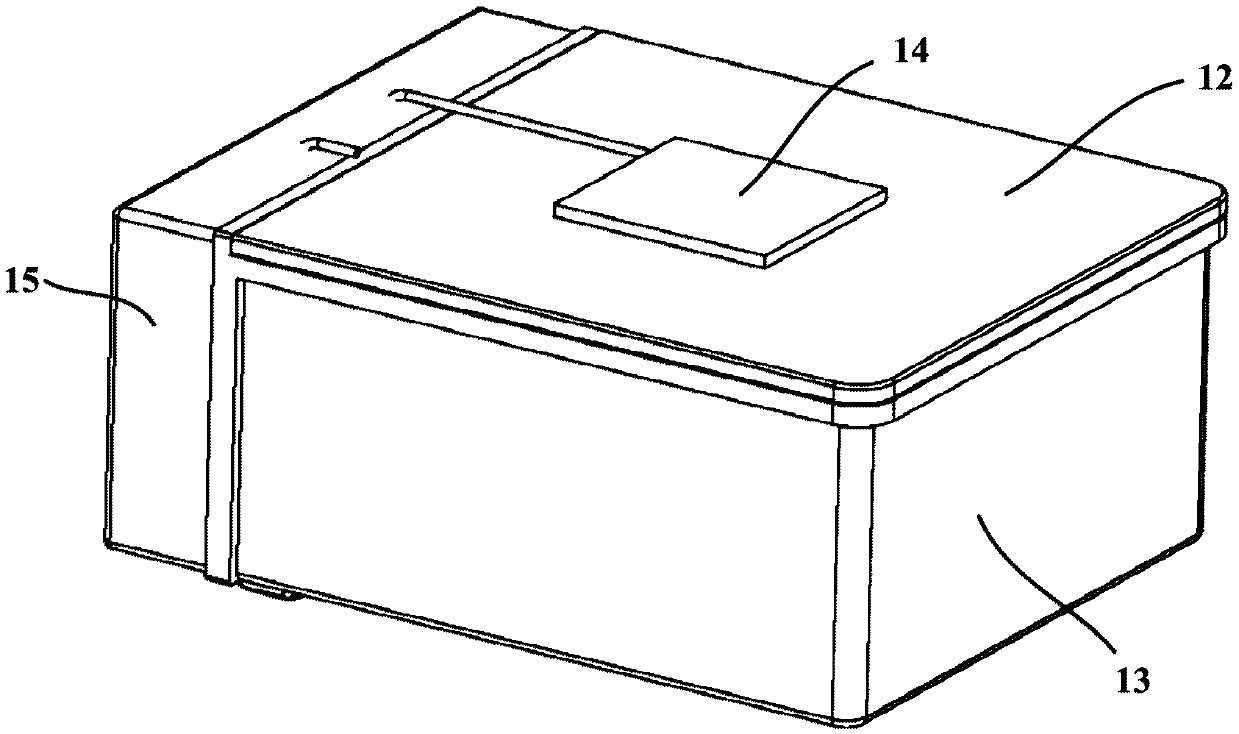

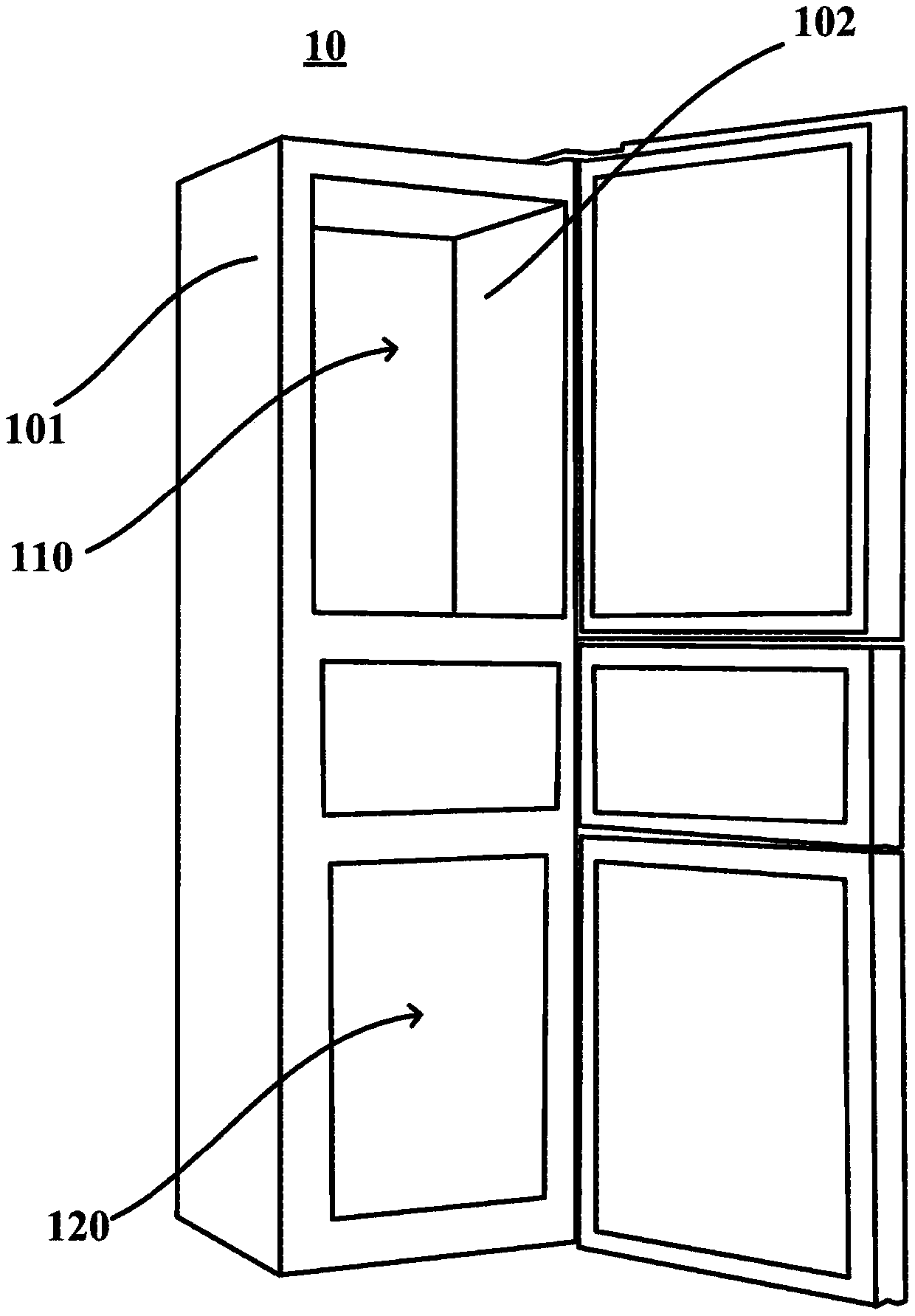

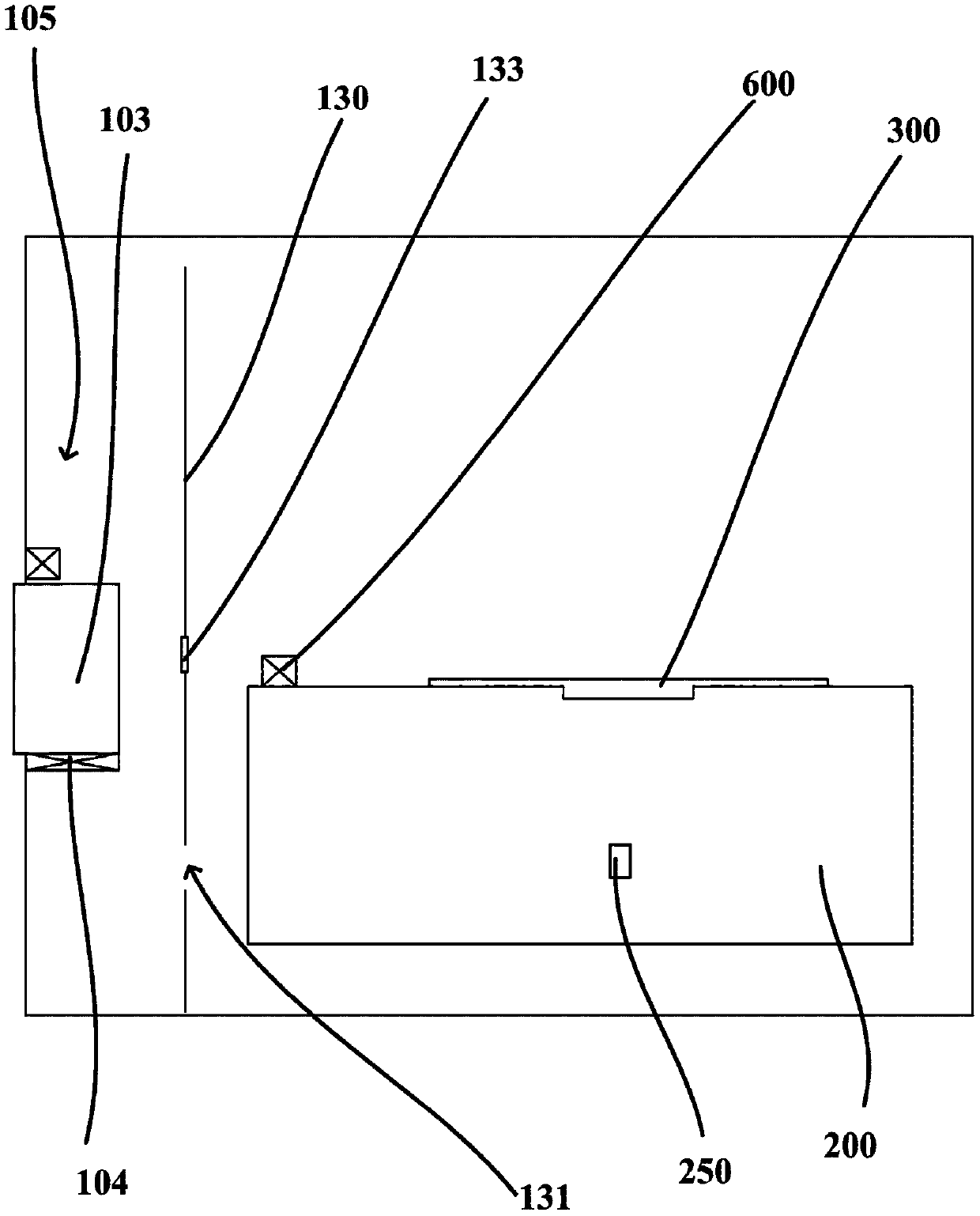

Refrigerator

ActiveCN111059829AIncrease humidityImprove oxygen removal efficiencyLighting and heating apparatusDomestic refrigeratorsElectrochemical responseElectrolysis

The invention provides a refrigerator. The refrigerator comprises: a liner, in which a storage chamber, an air supply duct and an evaporator mounting cavity are formed; an evaporator, which is mountedin the evaporator mounting cavity; a defrosting heating wire, which is arranged corresponding to the evaporator and is used for heating and melting frost deposit on the evaporator in a defrosting mode; a storage container, which is arranged in the storage chamber; a deoxygenization and moisture permeable assembly, which is arranged on the storage container, and is provided with an oxygen consumption part which faces the inside of the storage container and is used for consuming oxygen through electrochemical reaction and an electrolysis part which faces the outside of the storage container andis used for electrolyzing water vapor outside the storage container; wherein the air supply duct is provided with an air inducing port for supplying air to the electrolysis part, and the defrosting heating wire is further configured to improve the humidity of airflow fed through the air inducing port by heating in a humidifying mode, so that water vapor required by reaction can be supplemented tothe deoxygenization and moisture permeable assembly, and the deoxygenization efficiency is improved.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

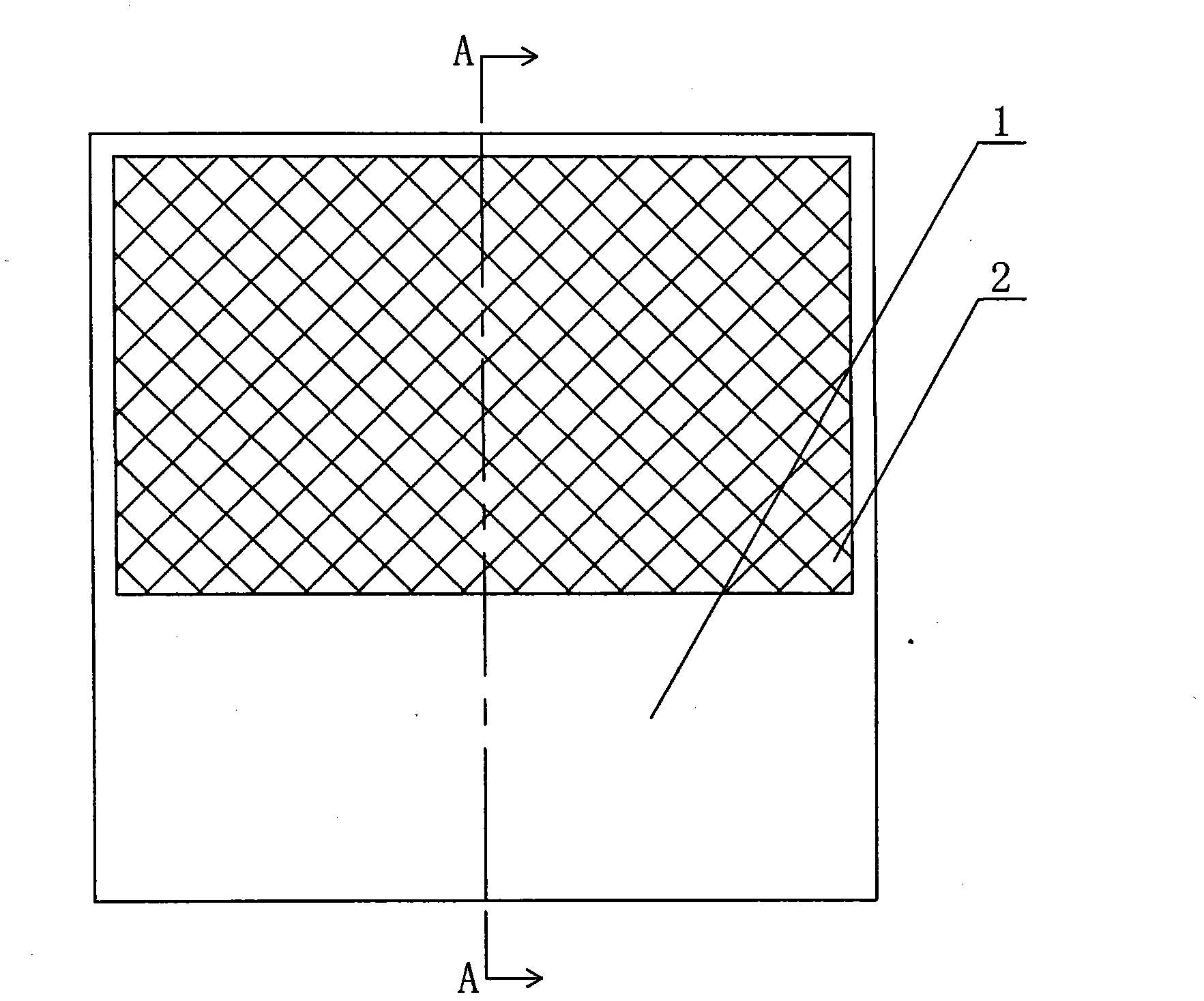

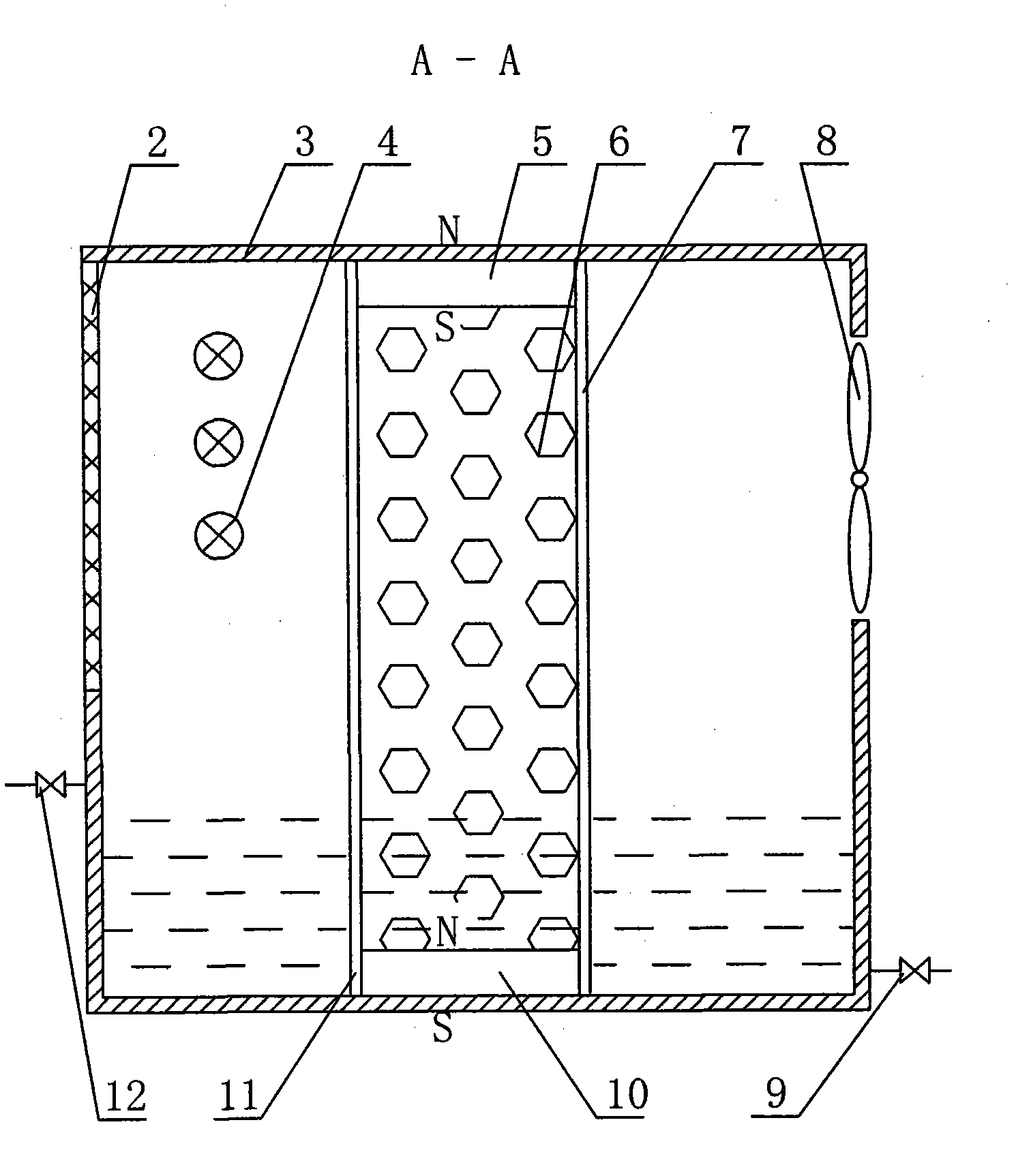

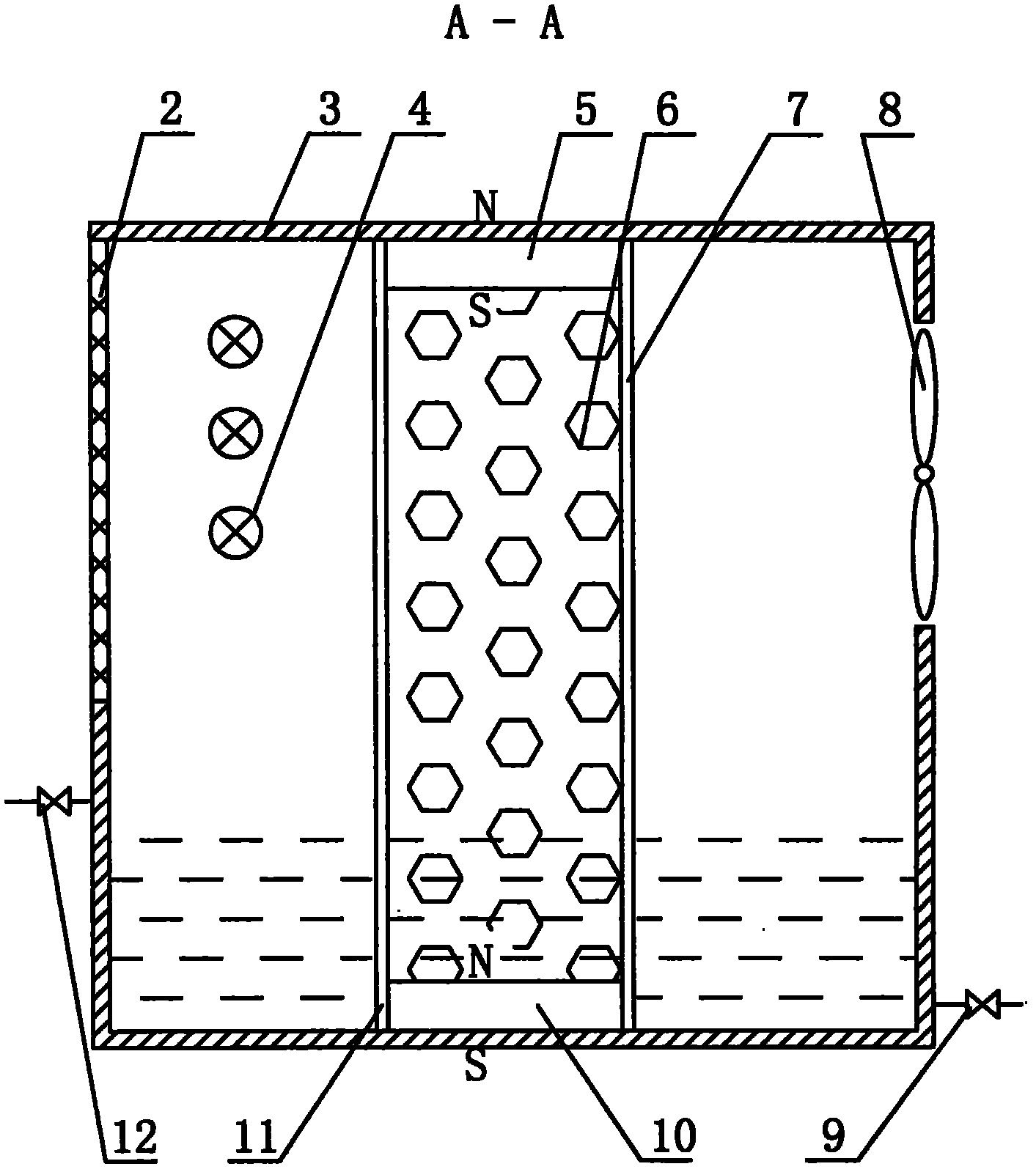

High-gradient magnetic field oxygen separation adsorption fresh-keeping device

InactiveCN102283278ALower oxygen levelsImprove oxygen removal efficiencyFruit and vegetables preservationElectrical polarityPrism

The invention discloses a high-gradient magnetic field oxygen separation and adsorption preserving device. An air inlet fixing net is arranged at an air inlet at the upper end of a shell, and an exhaust pipe is arranged on an air outlet at the lower end of the shell, wherein an axial flow fan is arranged in the exhaust pipe; an air outlet fixing net is arranged between the exhaust pipe and the lower end of the shell; at least two permanent magnets are arranged on each side surface of the shell; the inner surfaces of the permanent magnets on the same side surface have the same polarity; the inner surfaces of the permanent magnets on two opposite side surfaces have different polarities; the inner surfaces of the permanent magnets on two adjacent side surfaces have the same polarity or different polarities; a baffle is arranged between a permanent magnet and an adjacent permanent magnet which are arranged on the same side surface; the baffles on the same layer are sticked together; and the shell is filled with magnetic-conductive stainless steel fur. The shell is of a reverse even prism frustum cylindrical structure, and the taper angle of the shell is between 80 degrees and 150 degrees. The high-gradient magnetic field oxygen separation and adsorption preserving device has the advantages of reasonable design, simple structure, high oxygen removal efficiency, dehumidifying function and the like, and can be popularized to refrigerating equipment.

Owner:SHAANXI NORMAL UNIV

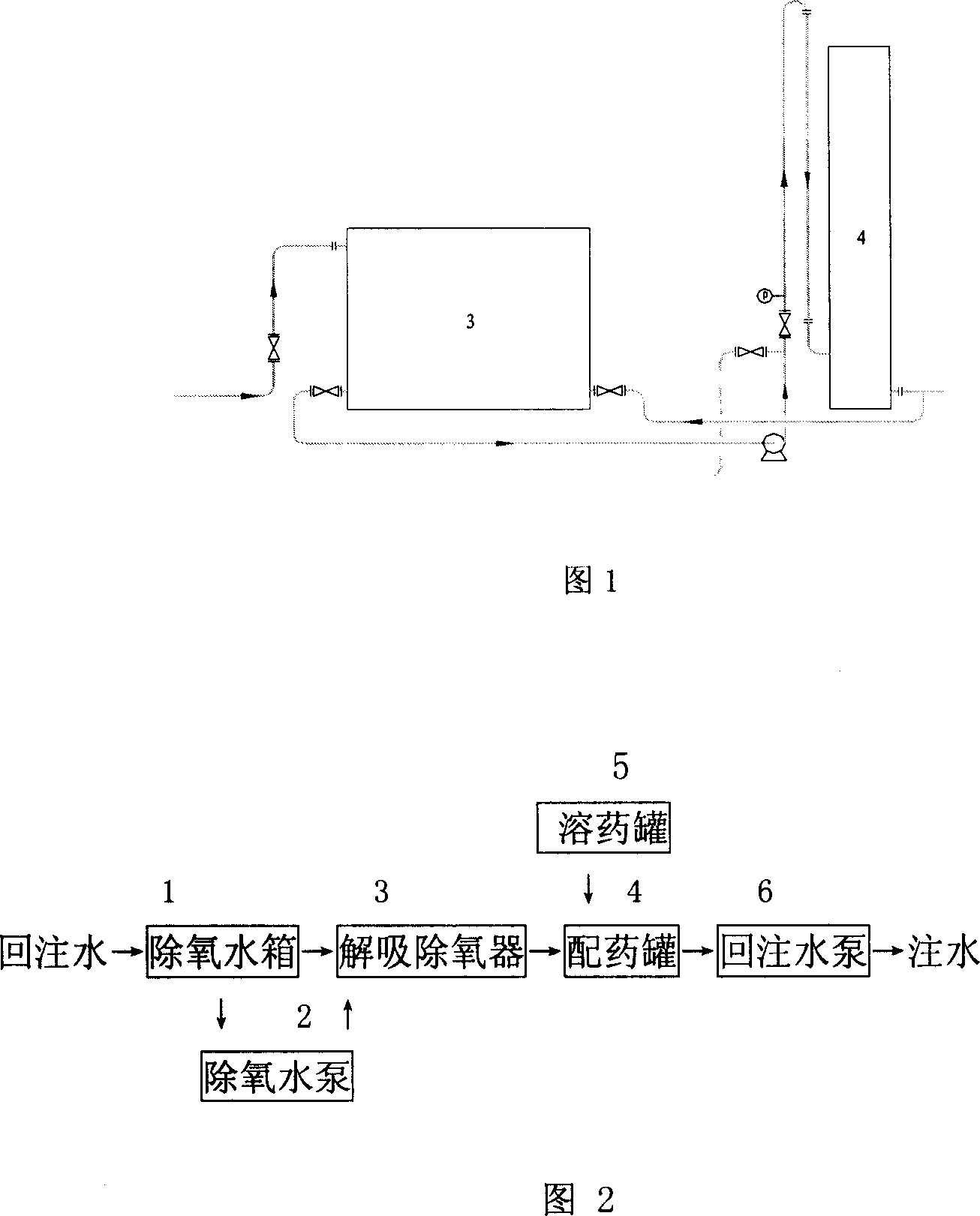

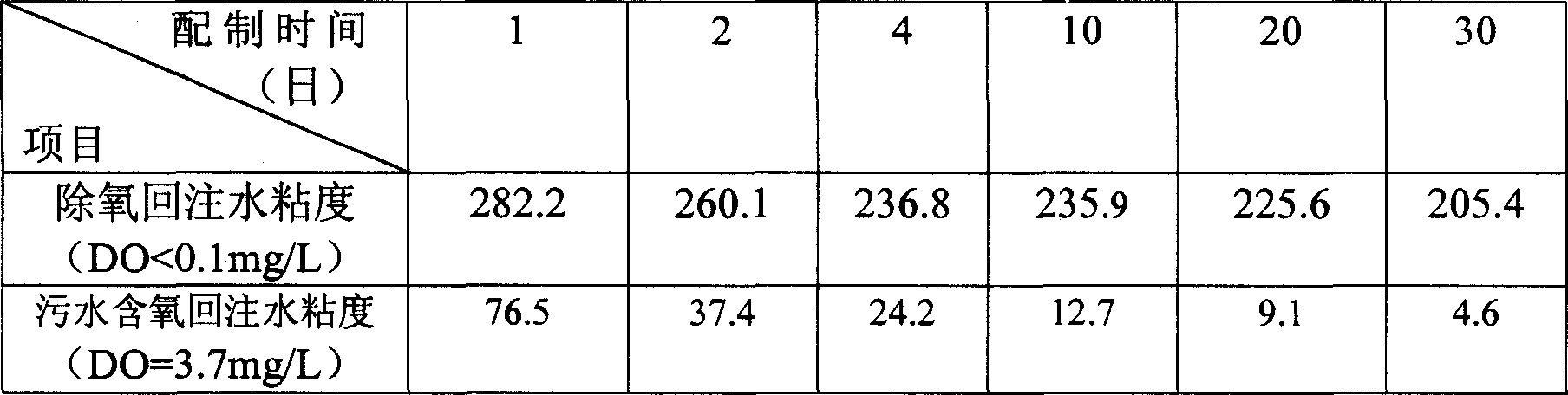

Re-injection method for produced-water desorption oxygen-removal mixing polymer for improving petroleum recovery efficiency

InactiveCN1995695AGuaranteed uptimeSmall footprintFluid removalDrilling compositionDrugs solutionPolymer dissolution

The invention relates to a sewage deoxidizing process and polymer injection method for enhancing tertiary oil recovery effect and improving the viscosity of polymer solution made up by oil sewage. Low-temperature desorptive deoxygenization process is adopted in reinjection deoxygenization, which comprises cycling deoxygenization water tank, deoxygenization water pump and desorptive deoxygenization in turn. The polymer injection process for improving the polymer solution made up by oil rejecting water comprises sewage deoxygenization process, polymer dissolution, mixed preparing sewage and injecting process of high-pressure water pump. PAM is applied in polymer solution made up by sewage. PAM is added from drug solution tank by metering pump. After mixed the polymer reinjecting solution is prepared, which is injected into stratum for oil recovery by high-pressure water pump. The test result shows that the desorptive deoxygenization technology treat the oil water, the serious degradation of polymer generated by oxygen active substance in sewage is eliminated, the viscosity of jetting solution is improved and the oil recovery effect of polymer is enhanced. The method is provided with simple operation and big practical applicable value. It is especially suitable for reinjection after the treatment for waste water with high oxygen content in oil. The running cost is low and the equipment is simple. There is no secondary pollution.

Owner:NANKAI UNIV

Refrigerator

PendingCN112747531AIncrease water vapor contentGood oxygen removal efficiencyLighting and heating apparatusDomestic refrigeratorsPhysicsElectrochemical response

The invention provides a refrigerator. The refrigerator comprises an inner container, an air supply fan, a storage container and an oxygen removal assembly; a storage chamber as well as an evaporator cavity and an air supply duct which are located on the back side of the storage chamber and used for containing an evaporator is formed in the inner container; the air supply fan is arranged in the air supply duct and is configured to promote formation of air flow circulating among the evaporator cavity, the air supply duct and the evaporator cavity; the storage container is arranged in the storage chamber; the oxygen removal assembly is arranged above the storage container and is provided with an electrolysis part which faces the outside of the storage container and is used for electrolyzing water vapor outside the storage container through electrochemical reaction and an oxygen consumption part which faces the inside of the storage container and is used for consuming oxygen through electrochemical reaction; and the air supply fan is further configured to continuously operate at the first preset rotating speed after a refrigeration system of the refrigerator completes refrigeration to supplement the storage chamber with the water vapor, so that enough water vapor can be provided for the oxygen removal assembly to serve as a reactant, and the electrolytic oxygen removal efficiency can be improved.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

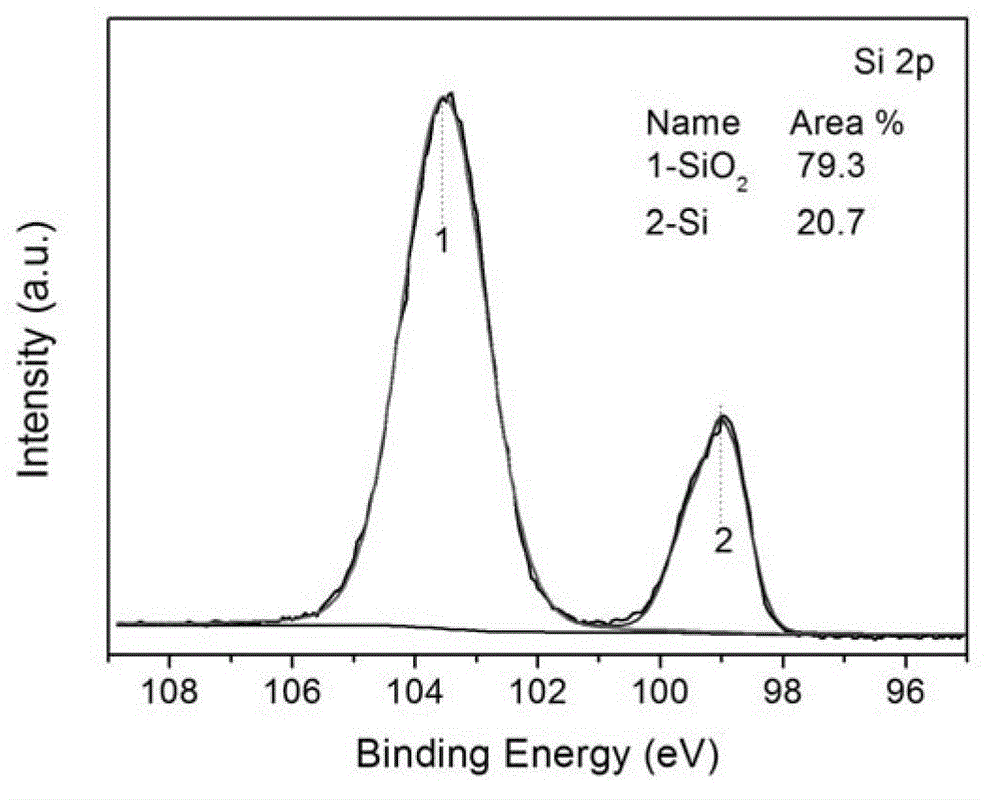

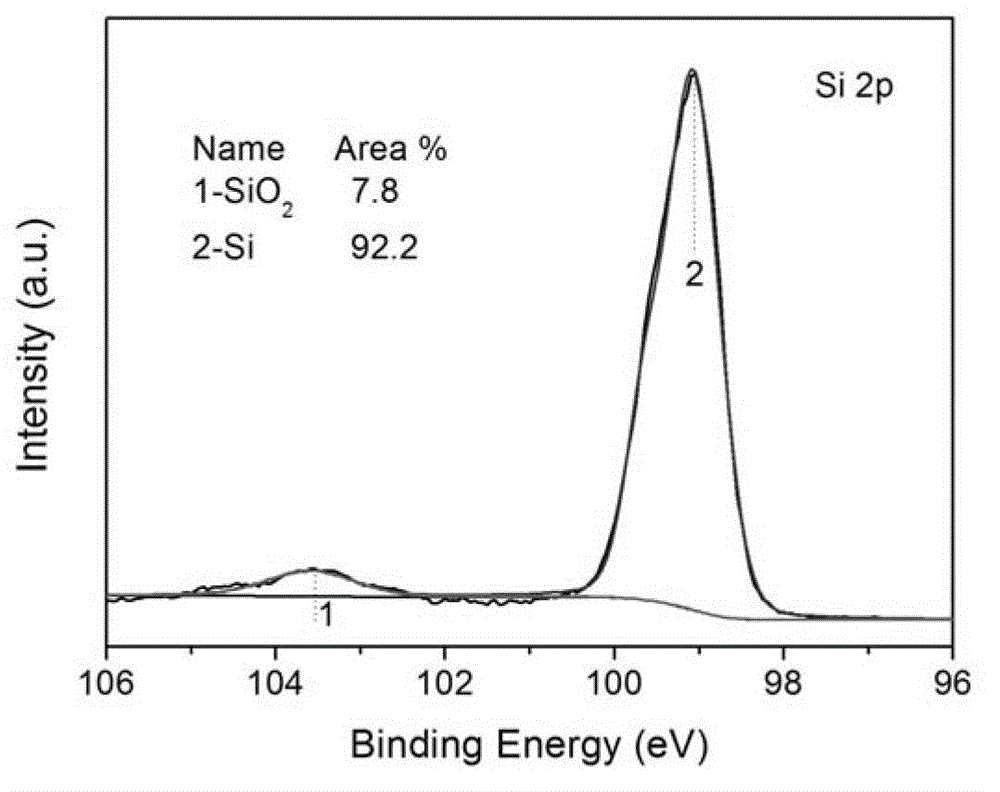

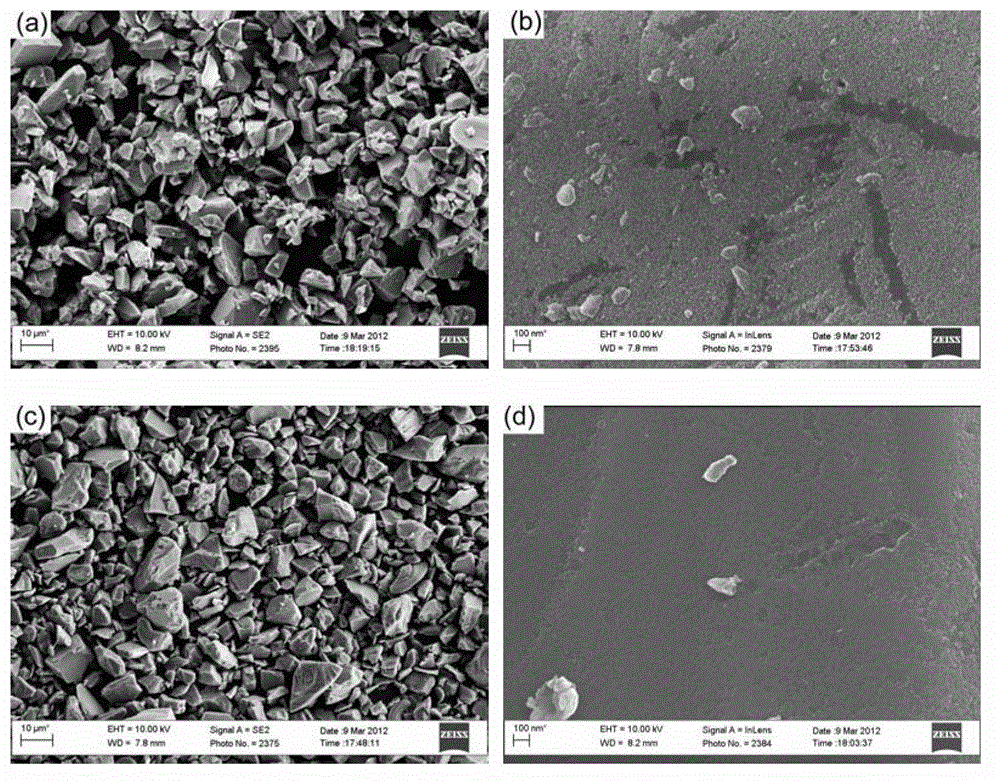

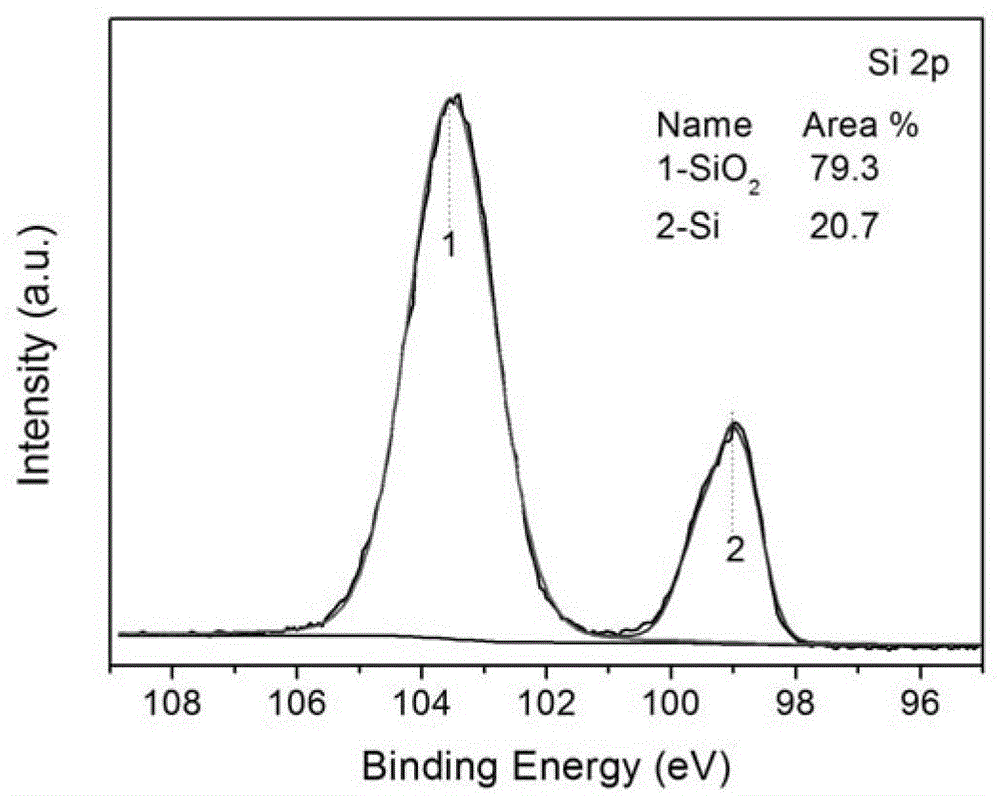

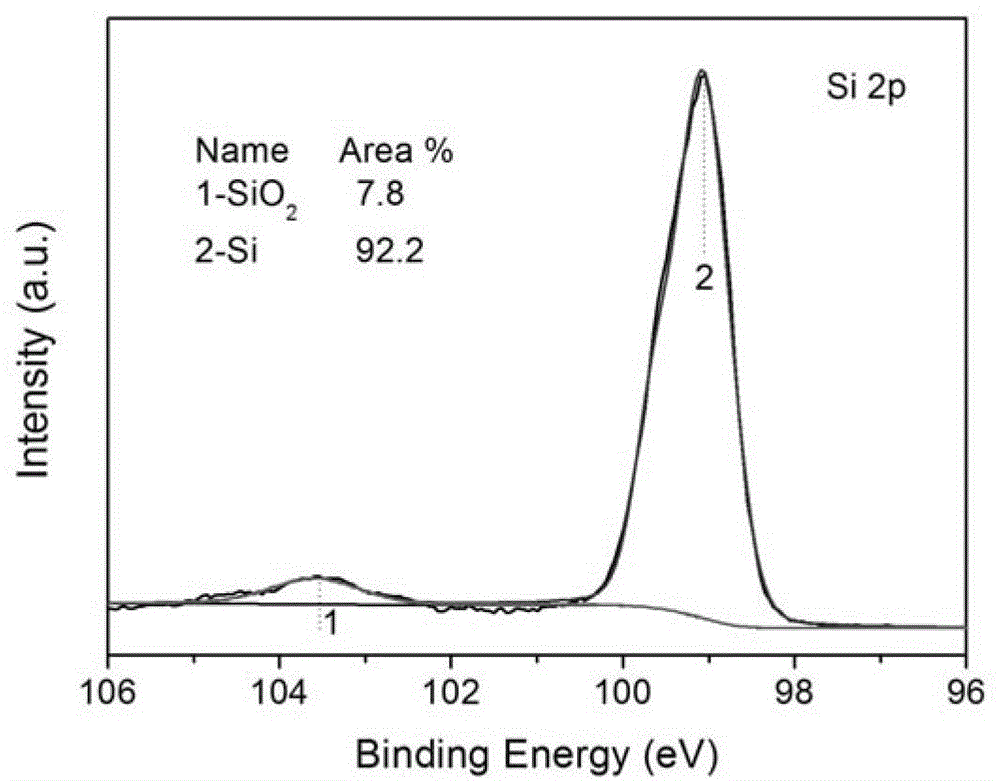

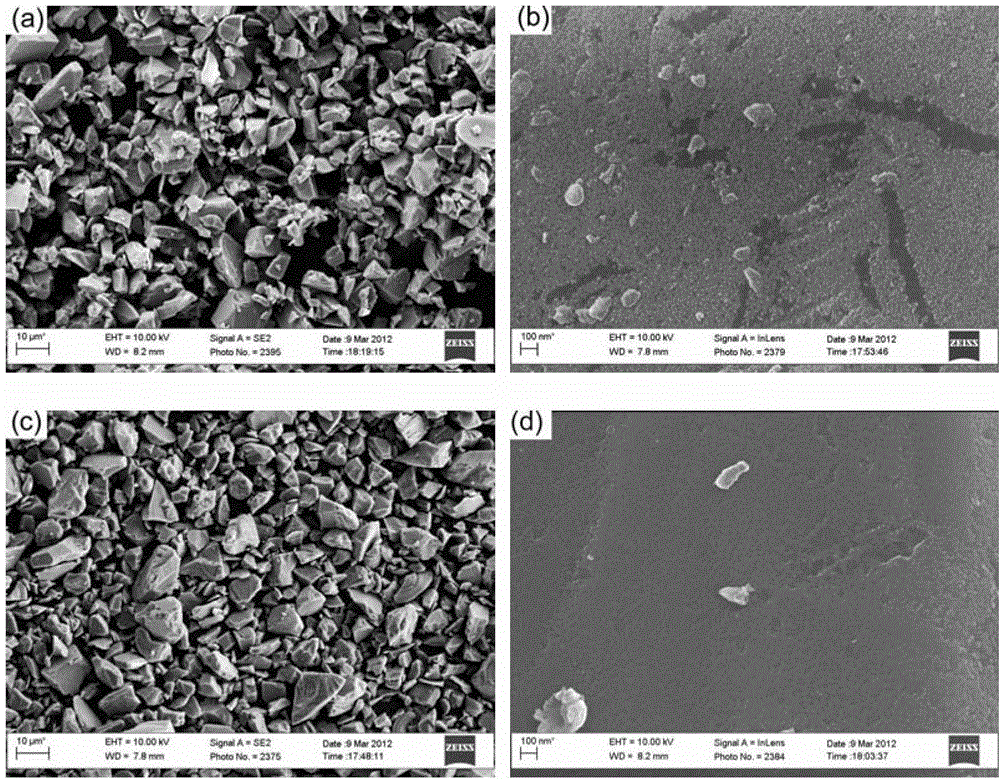

Silicon powder surface deoxidizing method

InactiveCN103058198ALower contact angleImprove wettabilitySilicon compoundsHydrogen fluorideHazardous substance

The invention discloses a silicon powder surface deoxidizing method, and belongs to technical field of powder surface treatment. The silicon powder surface deoxidizing method is characterized by improving silicon powder surface wetting ability by adding a neutral solvent of absolute ethyl alcohol into hydrofluoric acid and controlling the proportion and the concentration of the absolute ethyl alcohol, and promoting H+, HF2- and H2F2 and the like to rapidly diffuse towards silicon atoms. The silicon powder deoxidizing technology includes: preparing needed deoxidizing liquid by using hydrogen fluoride (HF), the absolute ethyl alcohol and deionized water according to a proportion, placing the deoxidizing liquid in a water bath with a constant temperature from 25 DEG C to 60 DEG C, fetching out a proper amount of silicon powder to be processed, then placing the silicon powder into the deoxidizing liquid, ceaselessly stirring for 15-60 minutes, using deionized water to wash and filter the silicon powder for 3-8 times through a vacuum filter, drying the silicon powder at a temperature of 25-70 DEG C in a vacuum, and immediately sealing the silicon powder for preservation in the vacuum. The silicon powder surface deoxidizing method has the advantages of being high in deoxidizing efficiency, and simultaneously the deoxidizing liquid contains no hazardous substance such as sulfuric acid, causes no damage on a silicon substrate, and furthermore the powder after being processed is good in uniformity and dispersibility, simple in technology and easy to control.

Owner:UNIV OF SCI & TECH BEIJING

Boiler deoxidizer and application thereof

PendingCN108529709AReduce dosageImprove oxygen removal efficiencyWater treatment parameter controlLiquid degasificationCarbazideButanone

The invention discloses a boiler deoxidizer and application thereof. The boiler deoxidizer comprises acetone oxime, carbazide, diacetylmonoxime and deionized water and respectively comprises the following raw materials in percentage by mass: 8-15% of acetone oxime, 10-25% of carbazide, 15-25% of diacetylmonoxime and the balance of deionized water. The boiler deoxidizer disclosed by the invention is capable of rapidly reacting with dissolved oxygen in water, has the characteristics of being small in usage amount, high in deoxidizing efficiency, non-toxic, free in environmental pollution and thelike, does not influence salt content in boiler water after decomposition, is an optimum medicine for shutdown protection and passivating treatment of a subcritical boiler, and is also an ideal product for replacing the traditional chemical deoxidizer in medium and high-pressure boiler water supply. The boiler deoxidizer disclosed by the invention can be applied to boiler water supply deoxidizingin refinery enterprises.

Owner:廊坊明泉化工建材有限公司

Method for removing oxygen in chlorination reaction gas

InactiveCN106582235ASimple processImprove oxygen removal efficiencyGas treatmentDispersed particle separationSulfite saltNitric oxide

The invention discloses a method for removing oxygen in chlorination reaction gas. The specific technological process includes that the chlorination reaction gas and second matter enter a reactor, the oxygen in the chlorination reaction gas and the second matter spontaneously react or a reaction happens under the outer field initiating condition to generate third matter, and third matter plays no role on a chlorination reaction or the generated role is not as remarkable as the role on the oxygen. The second matter is gas containing any one or two or more of sulfur dioxide, nitric oxide, hydrogen sulfide and the like; and the second matter can also be composed of any one or two or more of iron, sodium sulfite, an oxime type deoxidant, an amine type deoxidant, quinoline compounds, erythorbic acid and sodium salt thereof, and the like. The method for removing the oxygen in the chlorination reaction gas has the beneficial effects of being simple in technological process, high in deoxidizing efficiency, good in deoxidizing effect and the like, and is especially suitable for removing oxygen in chlorination reaction gas in the process of preparing chlorinated high polymer resin through a gas-solid phase method.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

Refrigerator

InactiveCN112747528AReduce condensationReduce drippingLighting and heating apparatusDomestic refrigeratorsElectrochemical responseElectrolysis

The invention provides a refrigerator, which comprises an inner container, a storage compartment is formed in the inner container, and an air supply duct is formed on the rear side of the storage compartment; a storage container arranged in the storage compartment; an oxygen removal assembly arranged on the storage container and provided with an oxygen consumption part facing the interior of the storage container and used for consuming oxygen through an electrochemical reaction and an electrolysis part facing the exterior of the storage container and used for electrolyzing water vapor outside the storage container through the electrochemical reaction; a moisture-permeable assembly arranged on the storage container, the moisture-permeable assembly and the deoxidizing assembly are arranged at an interval, and the moisture-permeable assembly is configured to allow the water vapor in the storage container to seep out; and an air inducing opening for supplying air to the moisture-permeable assembly is arranged on the air supply duct, and the air inducing opening is configured to allow airflow in the air supply duct to enter the storage compartment and flow through the face, back to the interior of the storage container, of the moisture-permeable assembly in a moisture-permeable mode, so that a dry environment is formed outside the storage container, and the moisture-permeable efficiency of the moisture-permeable assembly is improved. and therefore, the phenomenon of condensation or water dripping in the storage container is reduced or avoided.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

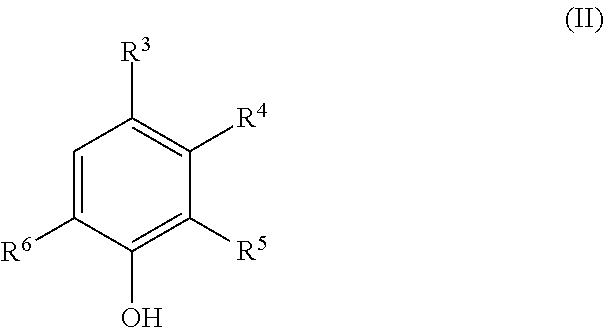

Deoxidizing agent for boilers and method for deoxidizing boiler water system

InactiveUS20190144314A1Improve oxygen removal efficiencyAvoid corrosionSpecific water treatment objectivesScale removal and water softeningM-aminophenolThermodynamics

The present invention provides a deoxidizing agent for boilers excellent in an oxygen removal effect under wide temperature conditions. The deoxidizing agent for boilers comprises (A) a hydroxylamine compound represented by the following general formula (I), (B) a heterocyclic compound having an N-substituted amino group, and (C) an aminophenol derivative represented by the following general formula (II),wherein R1 and R2 each independently represent an alkyl group having 1 to 5 carbon atoms;wherein R3 to R6 each independently represent any one of (a) the following general formula (III), (b) —OR10 and (c) —R11, at least one of R3 to R6 representing (a), and R10 and R11 each independently represent a hydrogen atom or an alkyl group having 1 to 4 carbon atoms;wherein R7 represents a single bond or an alkylene group having 1 to 4 carbon atoms, and R8 and R9 each independently represent a hydrogen atom or an alkyl group having 1 to 4 carbon atoms.

Owner:KURITA WATER INDUSTRIES LTD

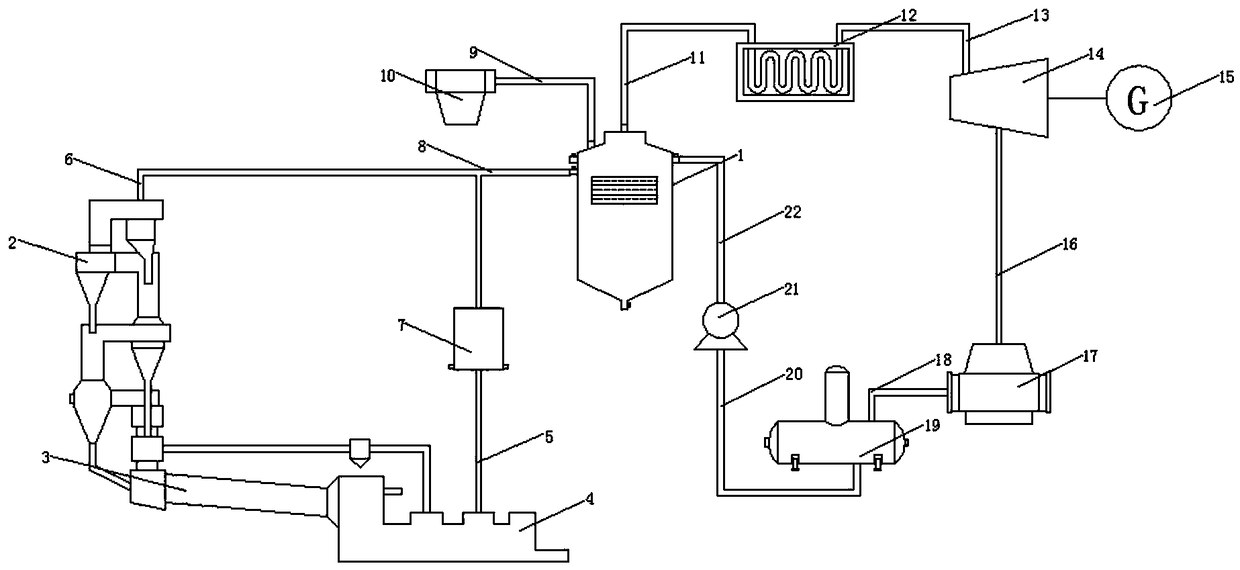

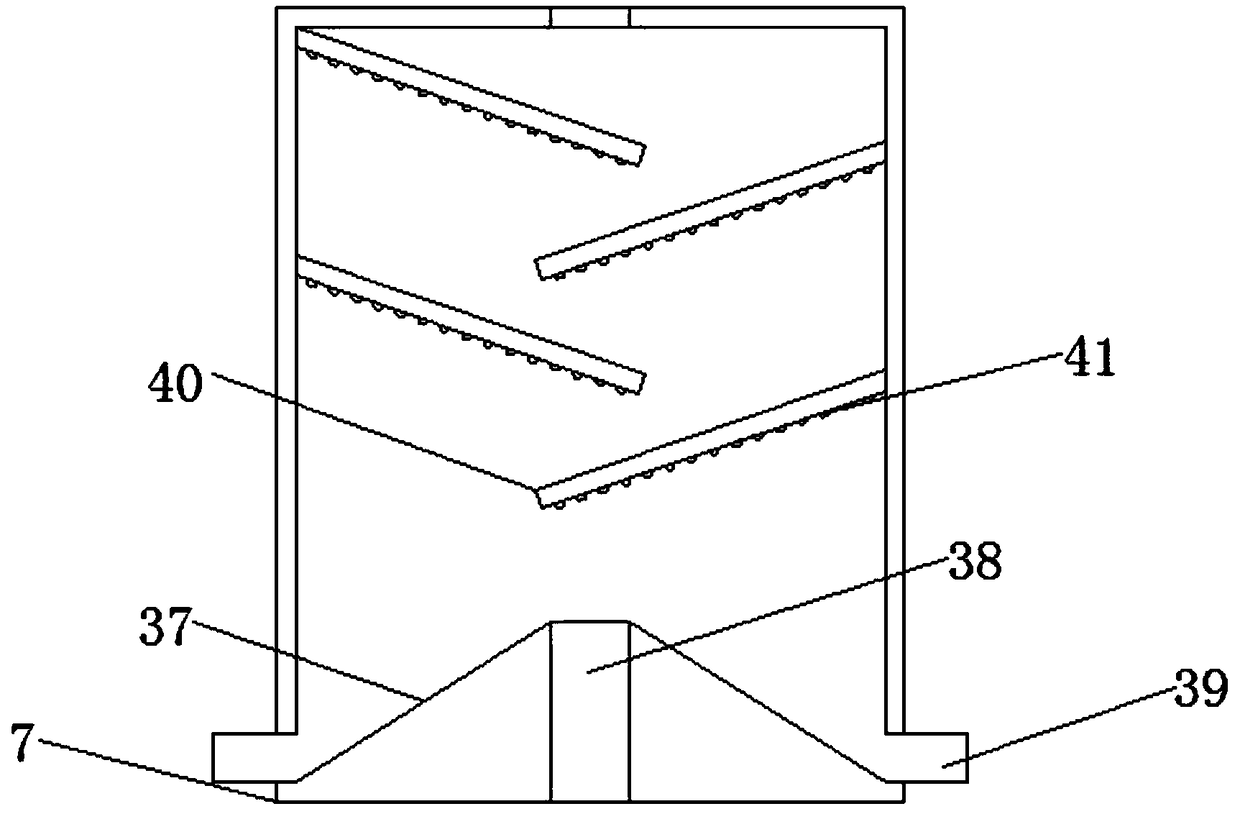

Cement kiln pure low temperature waste heat generator

ActiveCN109028980AGuaranteed to blockWhile blocking, it is also convenient for the rapid fall of clinker particlesIncreasing energy efficiencyClinker productionEngineeringCement kiln

The invention discloses a cement kiln pure lowtemperature waste heat generator.One end of a preheater is provided with a rotary kiln, one end of the rotary kiln is provided with a cooling machine, oneend of the cooling machine is fixedly connected with a waste gas pipe of a pit head, the middle of the waste gas pipe of the pit head is provided with a settling box, and inclined blocks are arrangedon both sides of the bottom end of the settling box. Bafflesare installed on both sides of the top of the inclined block, and a cellar tail exhaust pipe is fixedly connected with one end of a cellarhead exhaust pipe, and a mixed exhaust pipe is fixedly connected with one end of the cellar tail exhaust pipe, and a generator body is installed at one end of the mixed exhaust pipe. The top of the generator body is provided with a tank body, the inside of the tank body is provided with a steam generating chamber, and the bottom of the tank body is equipped with a dust exhausting bucket. Accordingto the a cement kiln pure lowtemperature waste heat generator, the bottom end of the bafflesareprovided with a plurality of elastic bumpswhich play a certain buffering role and can weaken the impactof waste gas from the pit head containing clinker particles on the baffles in the flow process, is simple and practical, service life of the baffles are prolonged, and later maintenance cost is reduced.

Owner:SICHUAN MIANZHU AODONG CEMENT CO LTD

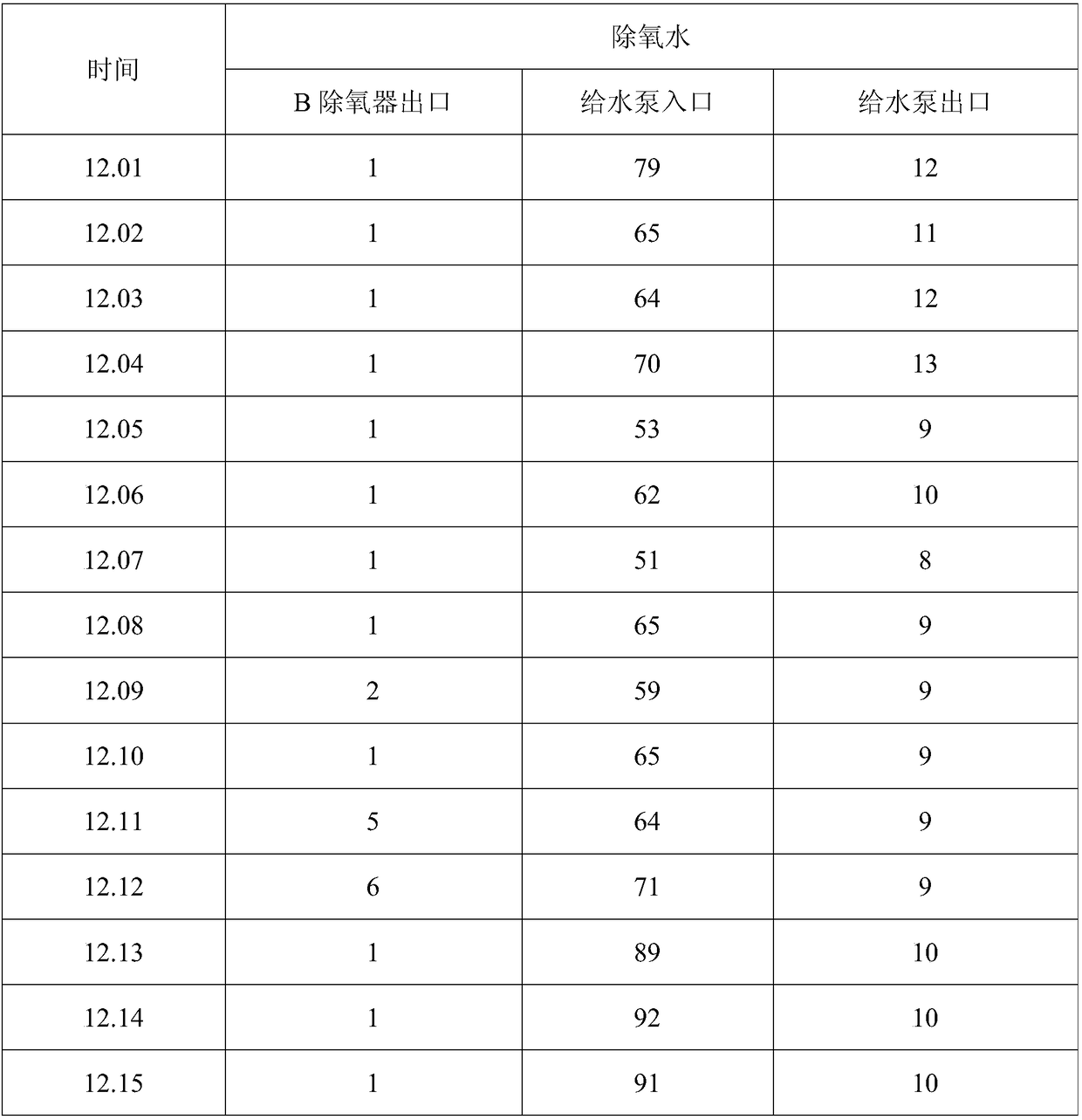

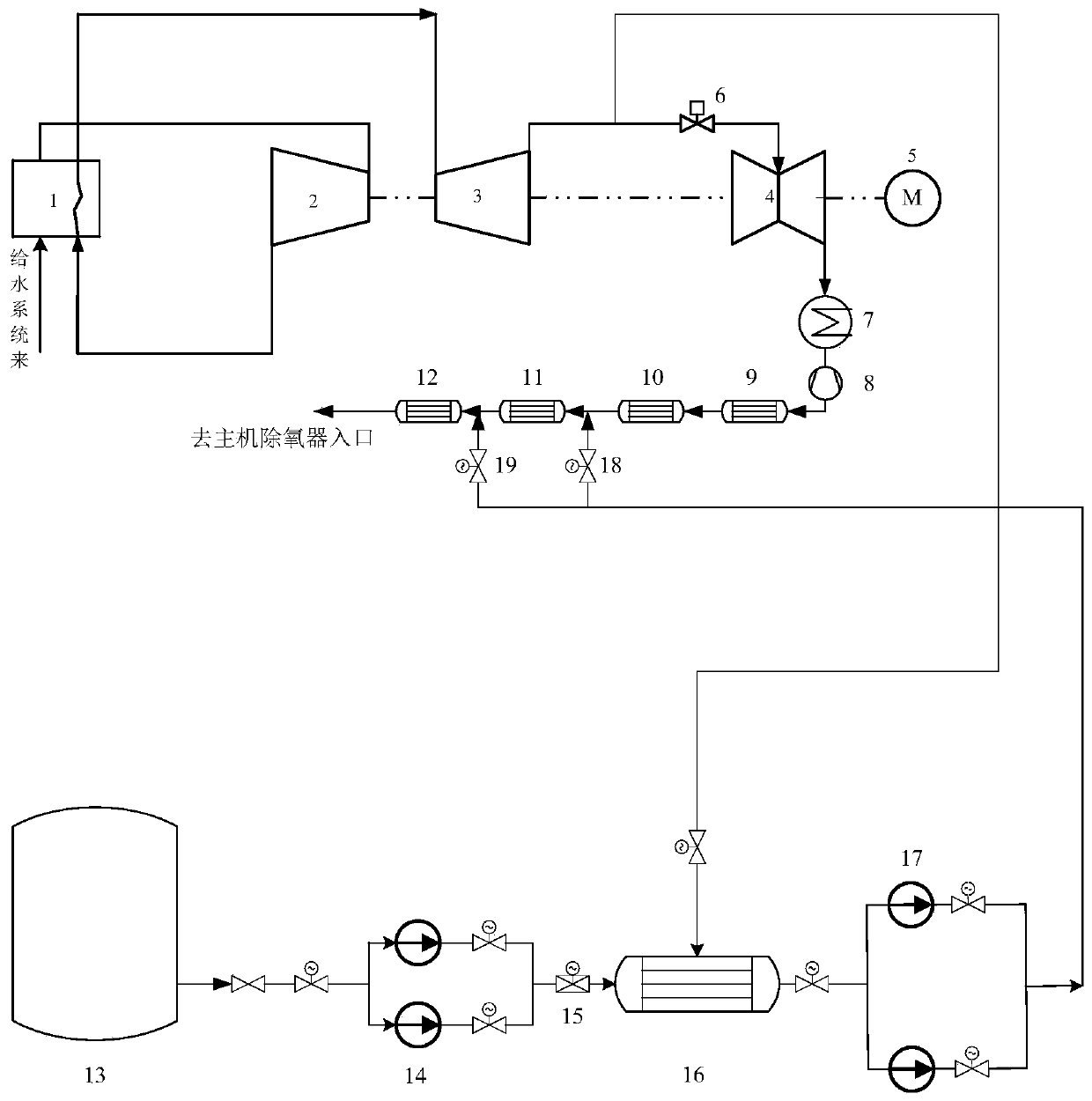

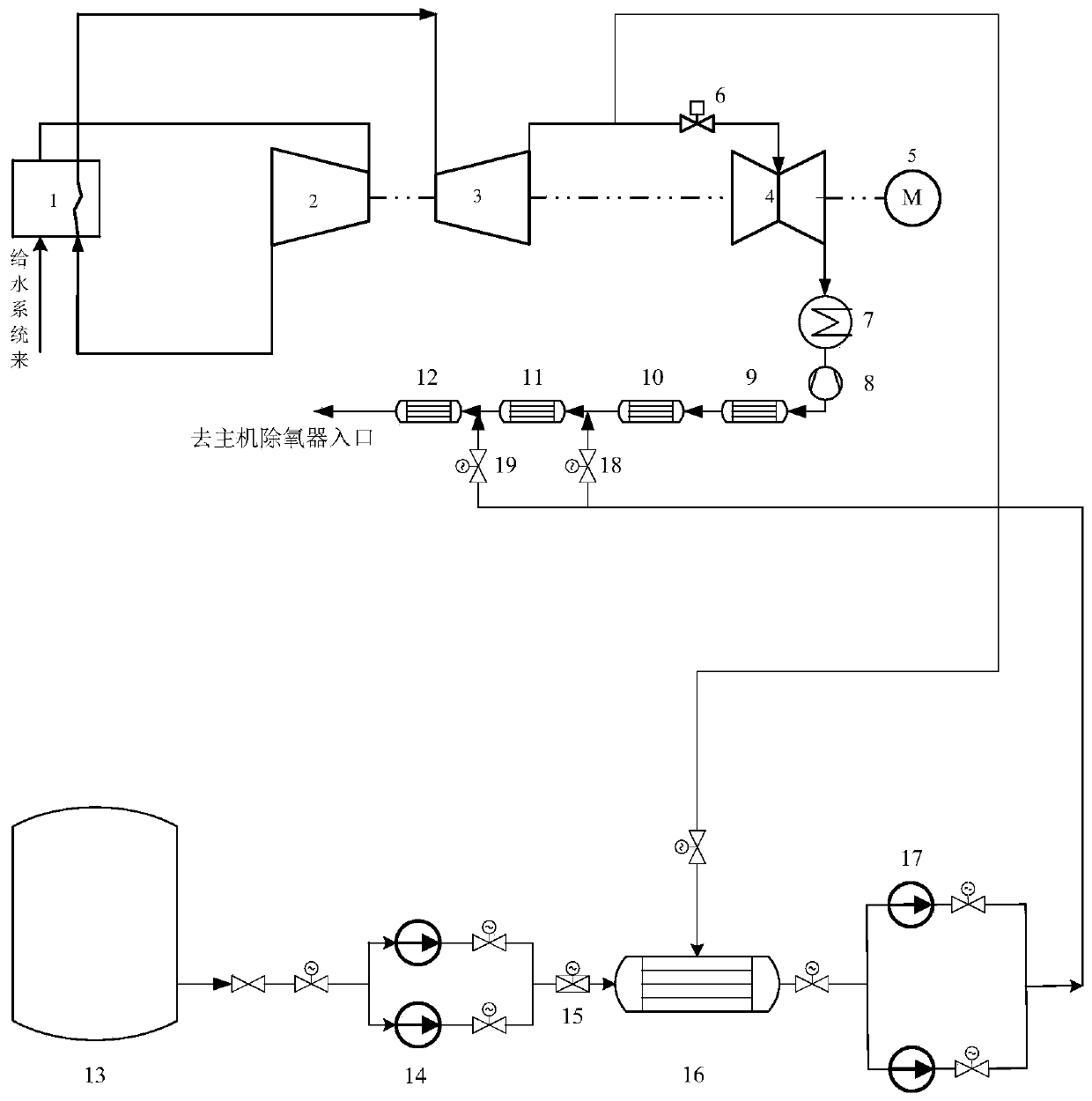

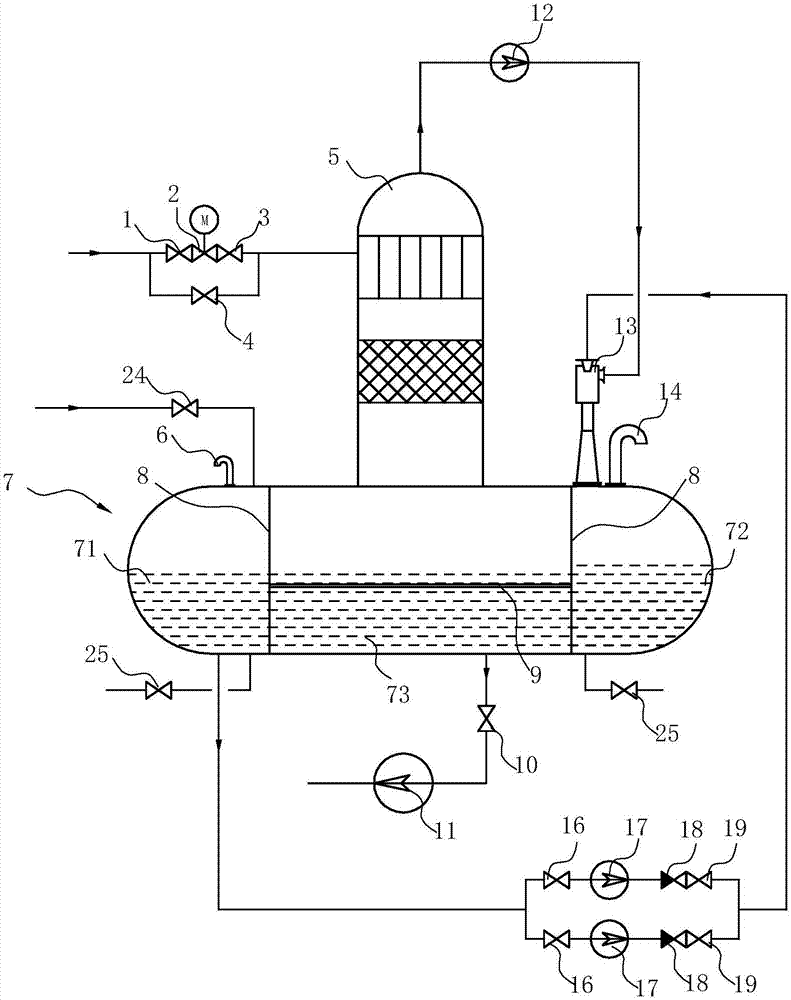

System and method for realizing high-flow water replenishing and high-efficiency deoxidizing of industrial heat supply unit

PendingCN110701601AImprove oxygen removal efficiencyIncrease temperature riseLiquid degasificationFeed-water heatersDeoxidizationEnvironmental geology

The invention discloses a system and a method for realizing the high-flow water replenishing and the high-efficiency deoxidizing of an industrial heat supply unit. The system comprises a boiler, a high pressure cylinder, an intermediate pressure cylinder, a low pressure cylinder and an external deoxidization device, wherein boiler exhaust steam is connected with an inlet of the high pressure cylinder; an inlet of the external deoxidization device is connected with a supplementary water booster pump; an inlet of the supplementary water booster pump is connected with a desalting water tank; an outlet of the external deoxidization device is connected with the booster pump; and an outlet of the booster pump is divided into two paths: one path is connected to an outlet of a second low pressureheater through a first valve group, and the other path is connected to an outlet of a third low pressure heater through a second valve group. According to the system and the method for realizing the high-flow water replenishing and the high-efficiency deoxidizing of the industrial heat supply unit provided by the invention, the external deoxidization device adopts an integrated structure, so thatthe requirements on water replenishing and deoxidizing after the high-flow industrial steam supply of a coal-fired generating unit are met; a host computer can keep high deoxidizing efficiency in a wide load change range section; and the condensation water temperature is increased, an inlet of one class low pressure heater can be flexibly accessed, and the gradient high-efficiency utilization of energy is realized.

Owner:XIAN XIRE ENERGY SAVING TECH +1

Deoxidizing device and deoxidizing method for polymer solution

ActiveCN108579133ADegradation will notReduce oxygen contentLiquid degasificationInert gas productionPolymer solutionNarrow mouth

The invention belongs to the technical field of liquid degassing, and particularly relates to a deoxidizing device and deoxidizing method for a polymer solution. The device comprises a gas source steel cylinder, a buffer bottle, a spherical valve, a gas flow meter, a glass guide pipe, a reagent bottle, a gas dispenser, puncture needle heads, and a narrow-mouth glass bottle; and the method for deoxidization by adopting the device comprises deoxidization in an early stage and advanced deoxidization. The method disclosed by the invention solves the problem that a general deoxidizing method does not reach thorough deoxidization and is not suitable for a high-viscosity aqueous solution; and the device and method disclosed by the invention are applied to deoxidization of a polymer solution having high viscosity, have low costs and convenient operation, and can reduce an oxygen content to 20 ppb or less, wherein the oxygen content can be reduced to a minimum of within 5 ppb.

Owner:CHINA PETROLEUM & CHEM CORP +1

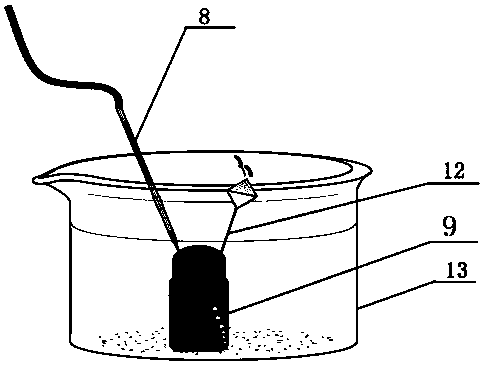

Sponge iron modified atmosphere fresh keeping device for refrigeration space

InactiveCN102318660AGuaranteed to continueIncrease humidityFruits/vegetable preservation by freezing/coolingInlet valveEngineering

The invention relates to a sponge iron modified atmosphere fresh keeping device for a refrigeration space. An upper cover is arranged at the upper end of a casing, a nanometer TiO2 foam nickel net is coated on the upper surface of an air inlet of the left side wall of the casing, an axial flow fan is arranged on an air outlet of the right side wall, a water inlet valve communicated with the inside of the casing is arranged under the left side of the casing, a water outlet valve communicated with the inside of the casing is arranged under the right side, an ultraviolet light emitting diode is arranged on the inner side wall of the casing, water is contained at the bottom inside the casing, an upper permanent magnet is arranged on the upper cover, a lower permanent magnet is arranged at the bottom of the casing, N poles and S poles of the upper permanent magnet and the lower permanent magnet are in opposite arrangement, the upper end of a left non-magnetic-conducting stainless steel net is arranged on the left end surface of the upper permanent magnet arranged on the upper cover, the lower end of the left non-magnetic-conducting stainless steel net is arranged on the left end surface of the lower permanent magnet arranged on the inner bottom plate of the casing, the upper end of the right non-magnetic-conducting stainless steel net is arranged on the right end surface of the upper permanent magnet arranged on the upper cover, the lower end of the right non-magnetic-conducting stainless steel net is arranged on the right end surface of the lower permanent magnet arranged on the inner bottom plate of the casing, and sponge iron particles are filled in a space formed by the two non-magnetic-conducting stainless steel nets and the two permanent magnets.

Owner:SHAANXI NORMAL UNIV

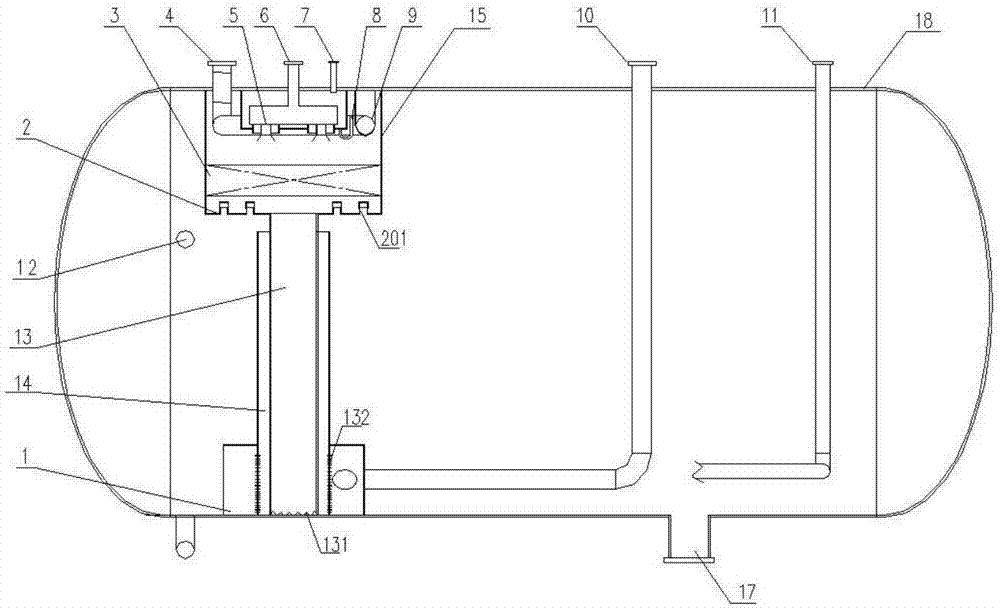

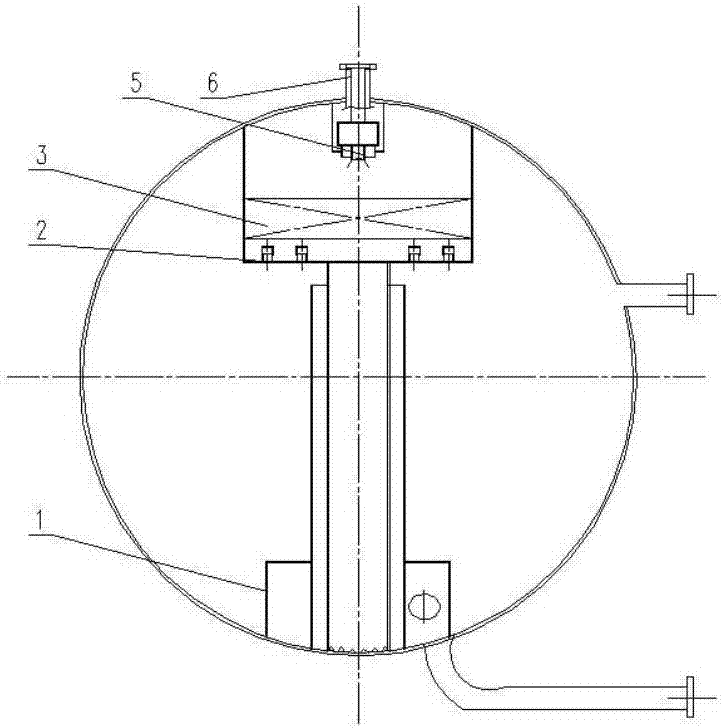

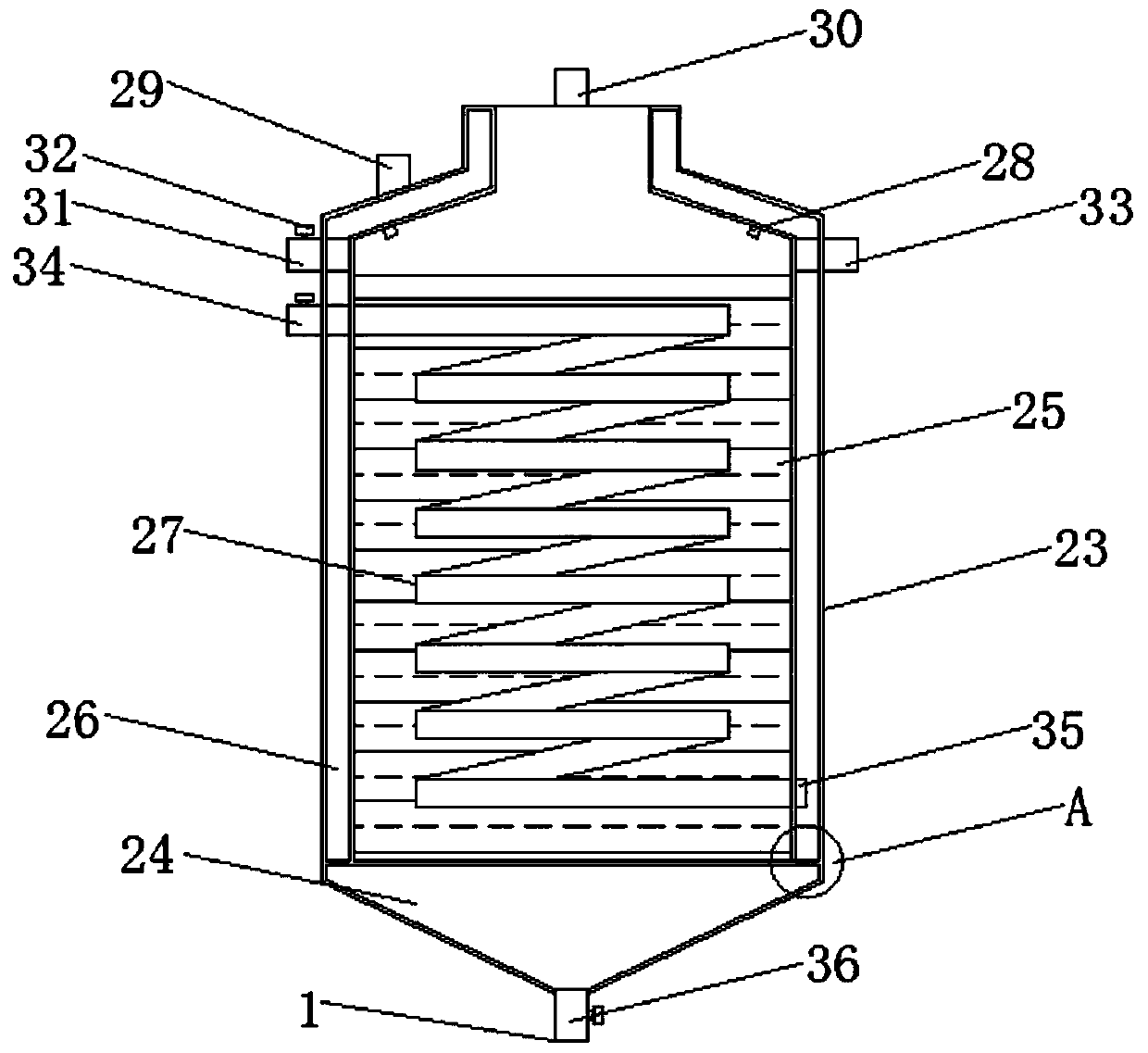

Built-in type deoxygenization machine

PendingCN108658149ADeoxygenation stabilityCompact structureWater/sewage treatment by heatingWater/sewage treatment by degassingEngineeringWorkload

The invention relates to a deoxygenization machine, in particular to a built-in type deoxygenization machine. The built-in type deoxygenization machine comprises a deoxygenization tank, a condensed water inlet device and an air exhausting device mounted at the top of the deoxygenization tank, and a heating steam pipe located in the deoxygenization tank; the deoxygenization tank is a horizontal tank, the condensed water inlet device is located at one end of the deoxygenization tank, and the air exhausting device is located on the side face of the condensed water inlet device; and an air inlet of the steam pipe is fixed to the top of the deoxygenization tank, and an air outlet is located below the liquid level. The built-in type deoxygenization machine is compact in structure and small in size, can control the flux and maintain the constant pressure, and is high in heat exchange efficiency, high in deoxygenization efficiency, stable in deoxygenization, convenient to operate, good in loadadaptability, low in maintenance workload, low in cost and high in efficiency.

Owner:XUELANG ELECTRIC POWER EQUIP XISHAN

Heat regeneration type vacuum deaerator

ActiveCN107238072AImprove oxygen removal efficiencySatisfied with oxygen removal efficiencyLiquid degasificationFeed-water heatersThermodynamicsEngineering

The invention relates to a heat regeneration type vacuum deaerator. The heat regeneration type vacuum deaerator comprises a deoxidization head connected with a water inlet pipe, and a water tank connected to the bottom of the deoxidization head and provided with a deoxidized water outlet. A steam exhaust port in the upper portion of the deoxidization head is connected with a vacuum pump through an exhaust pipe. The heat regeneration type vacuum deaerator is characterized by further comprising a heat exchange device arranged in the water tank or at the position of the water inlet pipe and used for heating water in the water tank or water at the position of the water inlet pipe. An outlet of the vacuum pump is connected with an inlet of the heat exchange device through a pipeline. Compared with the prior art, the heat regeneration type vacuum deaerator has the beneficial effects that a gas-steam mixture pumped through the vacuum pump can exchange heat with deoxidized water in the water tank or fed water in the water inlet pipe through the heat exchange device, the temperature of the deoxidized water in the water tank or the fed water in the water inlet pipe is increased, and the deoxidization efficiency is further improved while energy is saved. Thus, the satisfying deoxidization effect can be achieved without heating the fed water through additionally arrangement of a heat source, energy is saved, and the beneficial effects of reliable running and convenient control and operation are achieved.

Owner:宁波健益检测科技有限公司

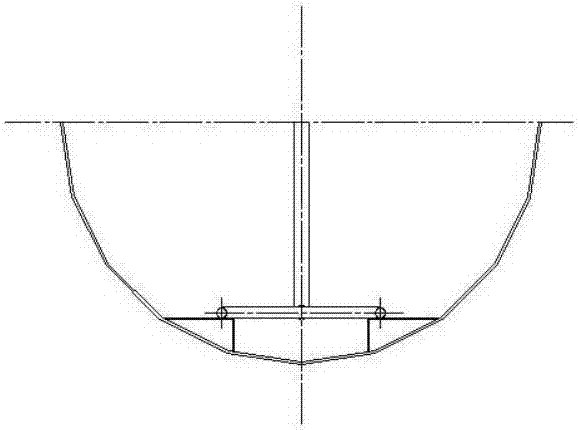

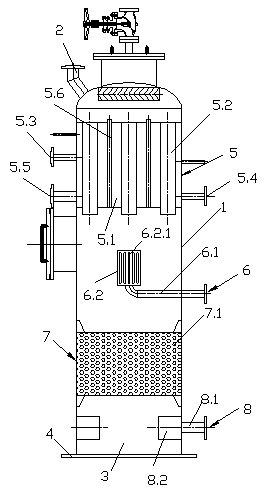

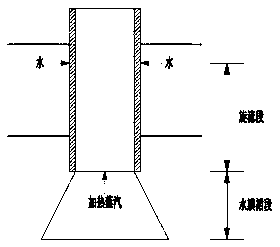

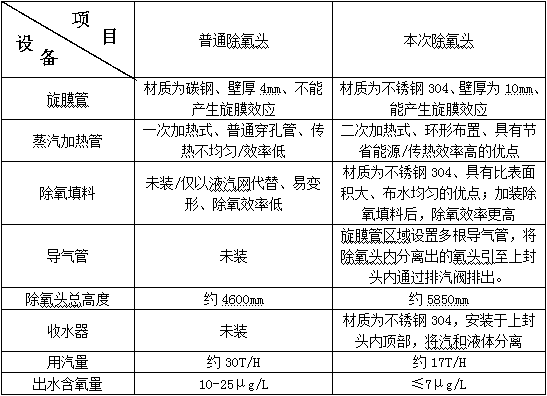

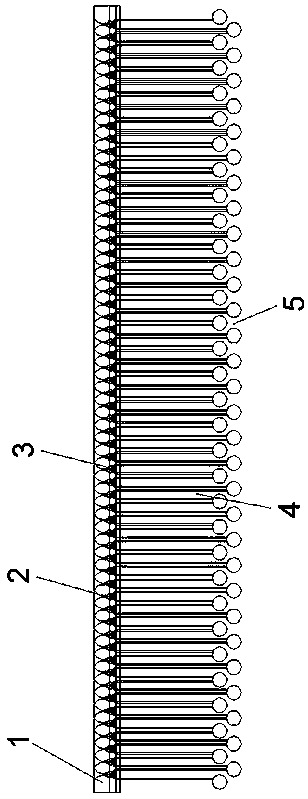

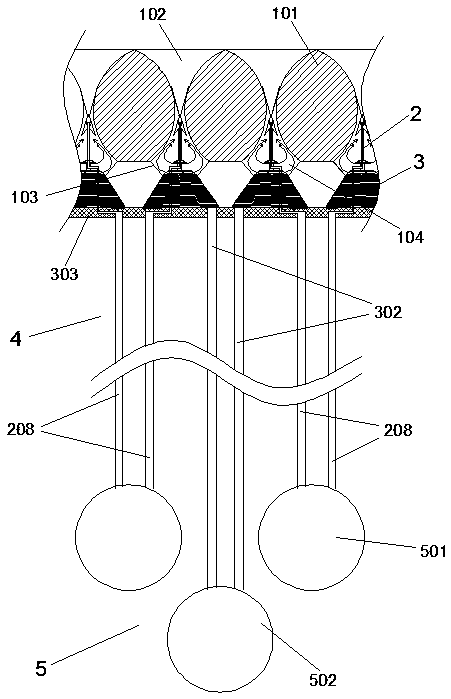

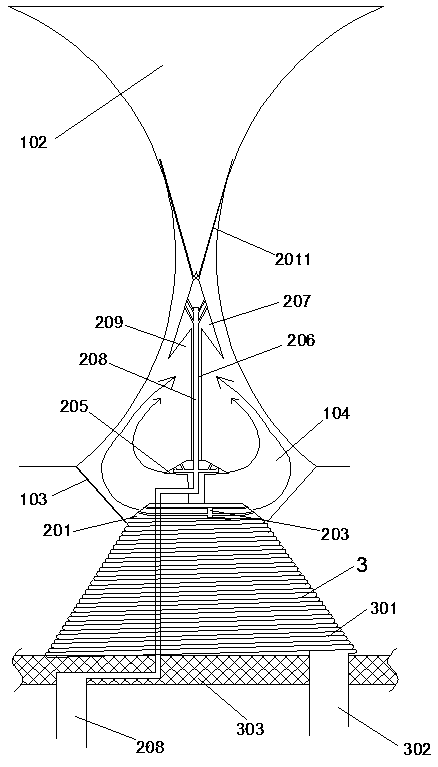

Deoxygenation head

InactiveCN105502546ASimple structureImprove oxygen removal efficiencyWater/sewage treatment by heatingWater/sewage treatment by degassingFiltrationDeoxygenation

The invention discloses a deoxygenation head. The deoxygenation head comprises a barrel body, an exhaust outlet formed in the top end of the barrel body and a water outlet formed in the bottom end of the barrel body, the water outlet is provided with a connection flange, the barrel body is internally provided with a rotary membrane deoxygenation layer, a first steam layer, a filtration layer and a second steam layer in sequence from top to bottom, the rotary membrane deoxygenation layer comprises a rotary membrane set water chamber, multiple rotary membrane pipes which are vertically arranged in the rotary membrane set water chamber at intervals and a lyophobic water inlet, a demineralized water inlet and a condensed water inlet which are formed in the barrel wall and communicated with the rotary membrane set water chamber, and water permeation holes are formed in the rotary membrane pipes. The deoxygenation head is simple in structure, deoxygenation is conducted twice through the rotary membrane deoxygenation layer and the filtration layer, deoxygenation efficiency is greatly improved, and the deoxygenation head is adapted to industrialized application.

Owner:JIANGSU SAIOU ENVIRONMENTAL PROTECTION EQUIP

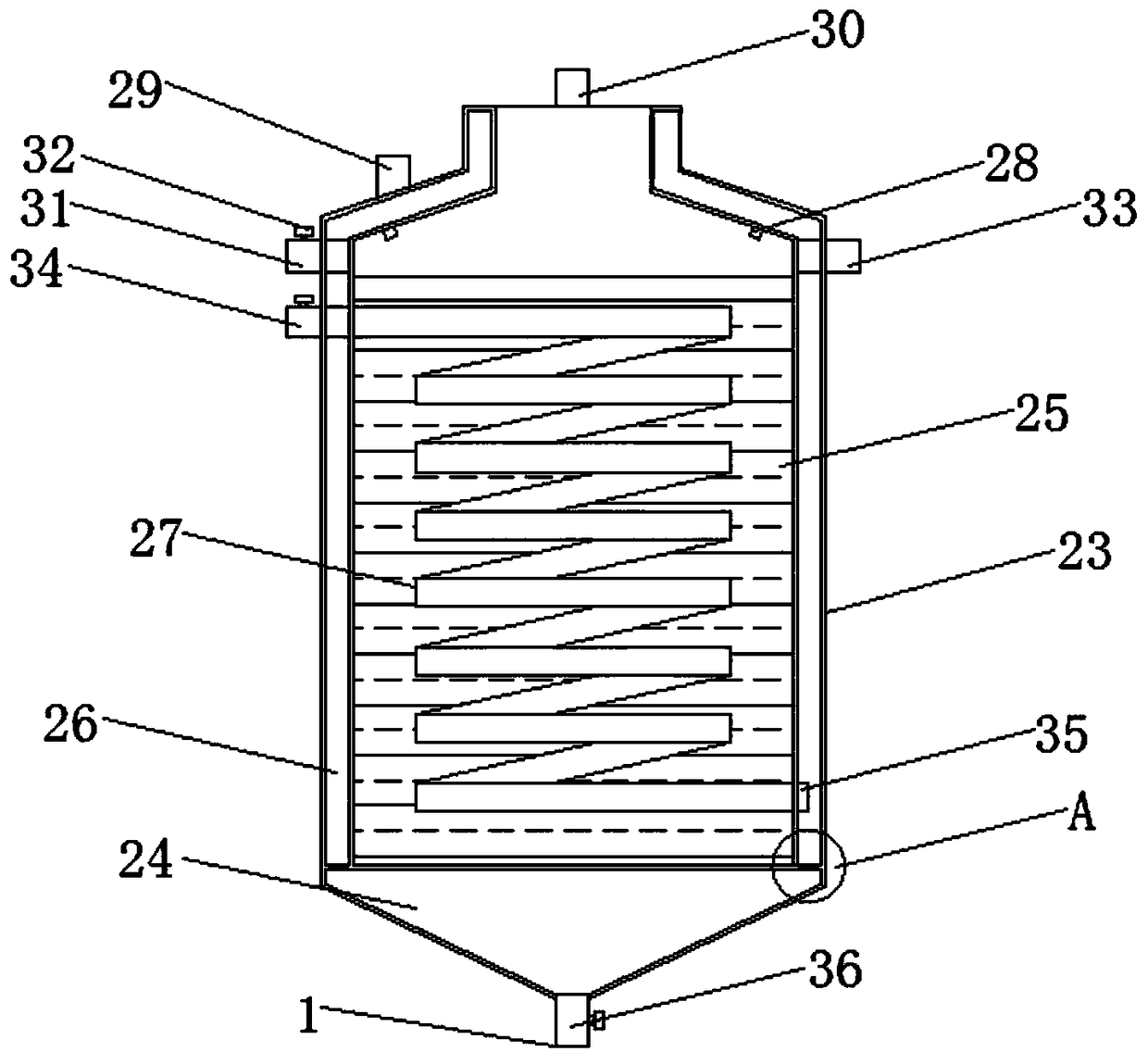

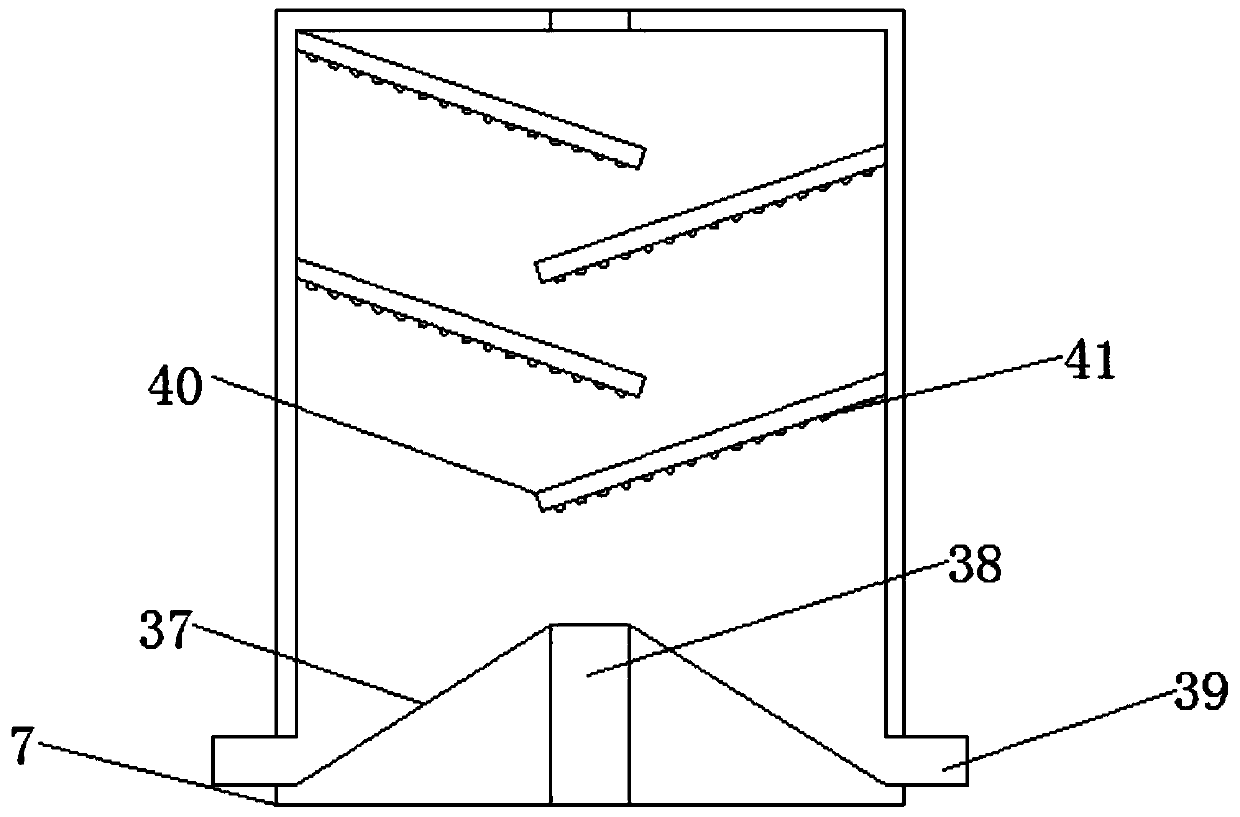

Multi-stage heat exchange structure for deaerator

InactiveCN111380047AImprove oxygen removal efficiencyImprove oxygen removal effectFeed-water heatersThermodynamicsDeaerator

The invention discloses a multi-stage heat exchange structure for a deaerator, and belongs to the field of thermal power generation. The multi-stage heat exchange structure comprises a water distributor, the water distributor comprises a water partition plate, wherein water distribution holes are densely distributed in the surface of the water partition plate, the cross section of each water distribution hole is in a two-curve shape, an inverted-cone-shaped gas collecting cover surrounding the water distribution holes is arranged at the bottom of each water distribution hole, each gas collecting cover is matched with the lower part of the corresponding water distribution hole to form a gas gathering cavity, a gas jet assembly is arranged in each gas gathering cavity and comprises a first gas jet disc and a second gas jet disc arranged on the first gas jet disc through a connecting rod, and an upward semi-annular steam flow along each water distribution hole is formed by using the corresponding gas jet disc, so that heating is conducted on deoxidized water entering each water distribution hole. The core of the multi-stage heat exchange structure is the water distribution holes in the water partition plate in a water distribution tank and the gas jet assembly arranged in each water distribution hole, and the special structure of each gas jet assembly is matched with the shape andstructure of the corresponding water distribution hole to form multiple heating and deaeration of the deoxidized water in the water distribution tank, so that the deaeration efficiency and the deaeration effect are improved.

Owner:张晓波

A method and device for setting interval time of boiler deoxidizing agent injection

ActiveCN112678893BLow costReduce steam consumptionWater/sewage treatment by heatingWater/sewage treatment by degassingEnergy technologyProcess engineering

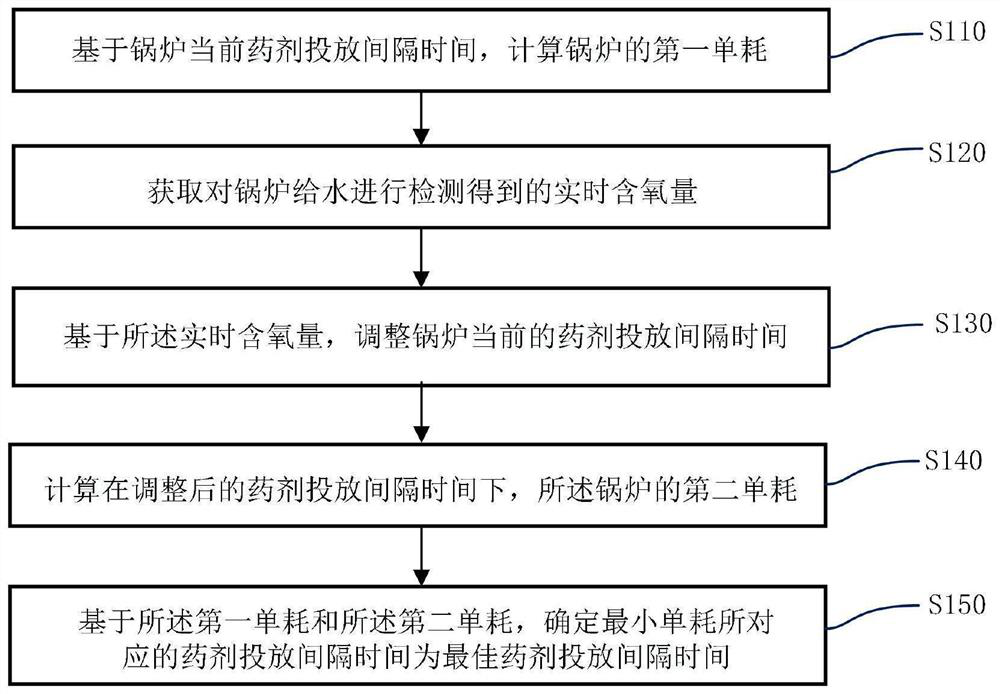

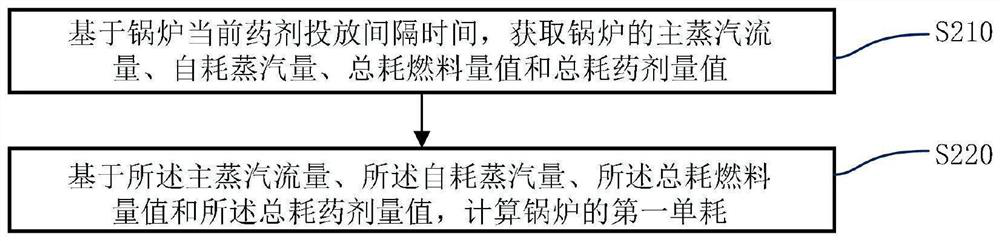

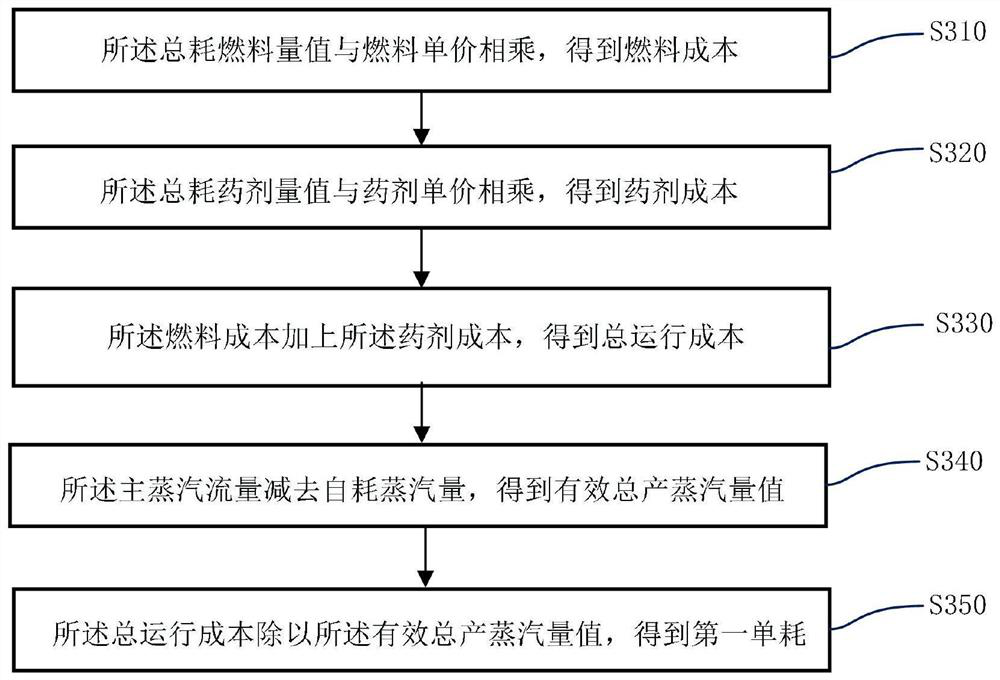

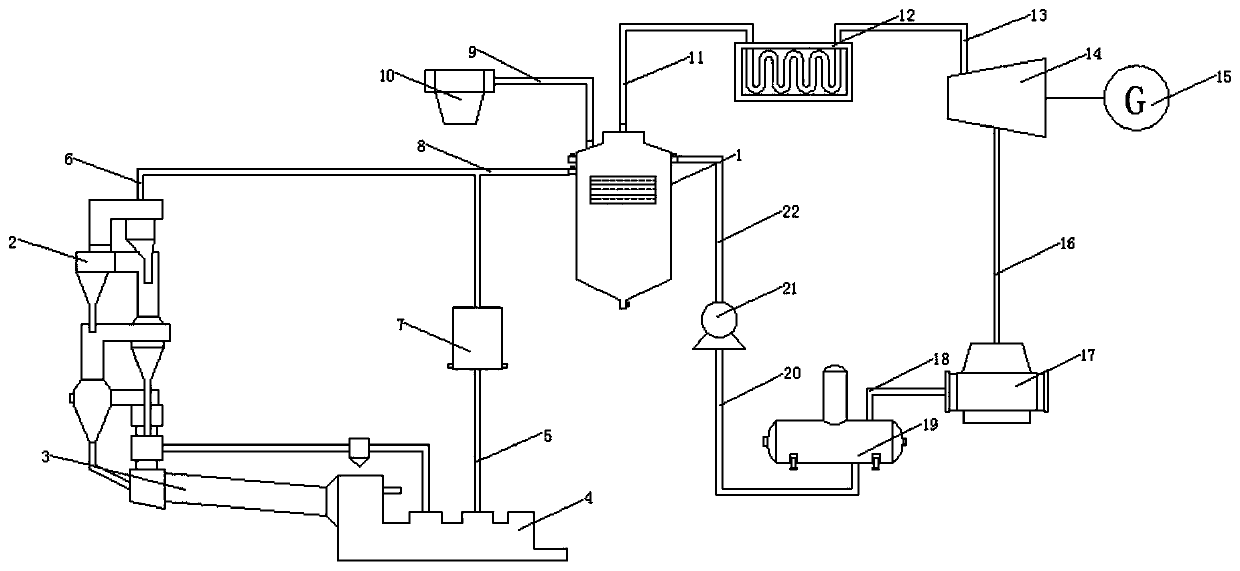

The present invention is applicable to the field of energy technology, and provides a method and device for setting the interval time of boiler oxygen-scavenging chemical dosage, wherein, the method includes: calculating the first unit consumption of the boiler based on the current boiler dosage interval time; obtaining The real-time dissolved oxygen content obtained by detecting the boiler feed water; based on the real-time dissolved oxygen content, adjust the boiler’s current medicament delivery interval; calculate the second unit consumption of the boiler under the adjusted medicament delivery interval; based on For the first unit consumption and the second unit consumption, it is determined that the medicament dosing interval corresponding to the minimum unit consumption is the optimal medicament dosing interval. The invention provides scientific guidance for the operation of specific industrial boilers by setting a reasonable time interval for medicament delivery, improves the deaeration efficiency, reduces the steam consumption and exhaust loss of the deaerator, saves the cost of the deaerator, and thus achieves equipment safety. The effect of operation and energy saving and consumption reduction.

Owner:XINAO SHUNENG TECH CO LTD

A pure low temperature waste heat generator for cement cellar

ActiveCN109028980BGuaranteed to blockConvenient whereaboutsIncreasing energy efficiencyClinker productionEngineeringCement kiln

The invention discloses a cement kiln pure lowtemperature waste heat generator.One end of a preheater is provided with a rotary kiln, one end of the rotary kiln is provided with a cooling machine, oneend of the cooling machine is fixedly connected with a waste gas pipe of a pit head, the middle of the waste gas pipe of the pit head is provided with a settling box, and inclined blocks are arrangedon both sides of the bottom end of the settling box. Bafflesare installed on both sides of the top of the inclined block, and a cellar tail exhaust pipe is fixedly connected with one end of a cellarhead exhaust pipe, and a mixed exhaust pipe is fixedly connected with one end of the cellar tail exhaust pipe, and a generator body is installed at one end of the mixed exhaust pipe. The top of the generator body is provided with a tank body, the inside of the tank body is provided with a steam generating chamber, and the bottom of the tank body is equipped with a dust exhausting bucket. Accordingto the a cement kiln pure lowtemperature waste heat generator, the bottom end of the bafflesareprovided with a plurality of elastic bumpswhich play a certain buffering role and can weaken the impactof waste gas from the pit head containing clinker particles on the baffles in the flow process, is simple and practical, service life of the baffles are prolonged, and later maintenance cost is reduced.

Owner:SICHUAN MIANZHU AODONG CEMENT CO LTD

Silicon powder surface deoxidizing method

InactiveCN103058198BLower contact angleImprove wettabilitySilicon compoundsHydrogen fluorideHazardous substance

The invention discloses a silicon powder surface deoxidizing method, and belongs to technical field of powder surface treatment. The silicon powder surface deoxidizing method is characterized by improving silicon powder surface wetting ability by adding a neutral solvent of absolute ethyl alcohol into hydrofluoric acid and controlling the proportion and the concentration of the absolute ethyl alcohol, and promoting H+, HF2- and H2F2 and the like to rapidly diffuse towards silicon atoms. The silicon powder deoxidizing technology includes: preparing needed deoxidizing liquid by using hydrogen fluoride (HF), the absolute ethyl alcohol and deionized water according to a proportion, placing the deoxidizing liquid in a water bath with a constant temperature from 25 DEG C to 60 DEG C, fetching out a proper amount of silicon powder to be processed, then placing the silicon powder into the deoxidizing liquid, ceaselessly stirring for 15-60 minutes, using deionized water to wash and filter the silicon powder for 3-8 times through a vacuum filter, drying the silicon powder at a temperature of 25-70 DEG C in a vacuum, and immediately sealing the silicon powder for preservation in the vacuum. The silicon powder surface deoxidizing method has the advantages of being high in deoxidizing efficiency, and simultaneously the deoxidizing liquid contains no hazardous substance such as sulfuric acid, causes no damage on a silicon substrate, and furthermore the powder after being processed is good in uniformity and dispersibility, simple in technology and easy to control.

Owner:UNIV OF SCI & TECH BEIJING

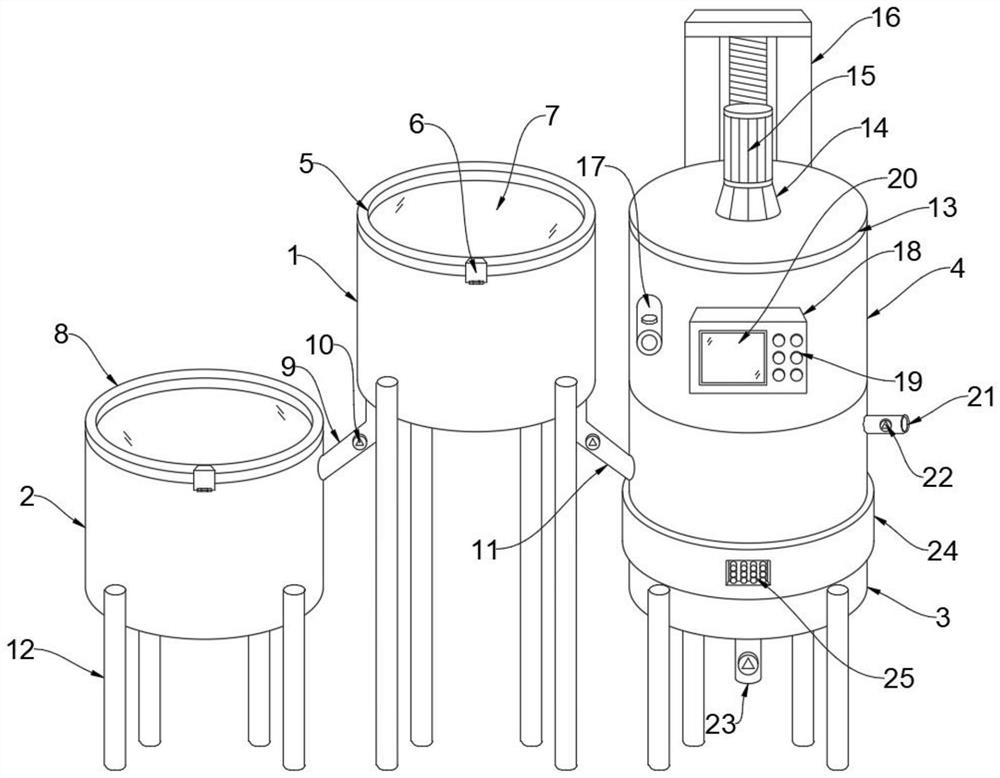

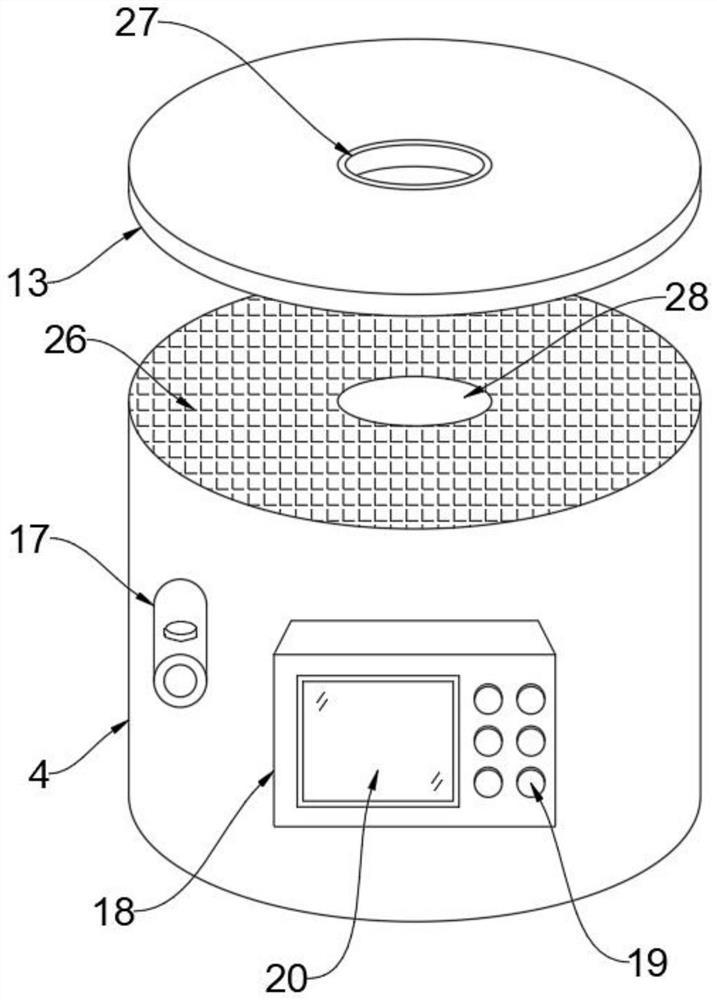

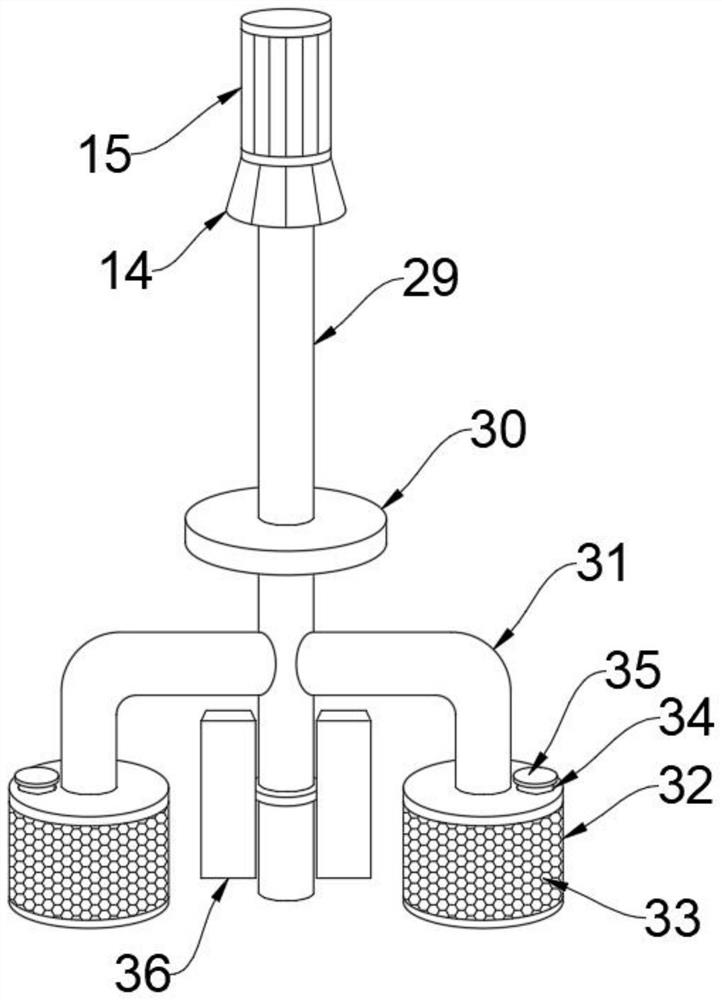

Solution deoxygenization device for potential step method and deoxygenization method thereof

ActiveCN113856606APromote full accessEfficient removalChemical/physical/physico-chemical stationary reactorsProcess efficiency improvementElectric machineryEngineering

The invention discloses a solution deoxygenization device for a potential step method and a deoxygenization method thereof, relates to the technical field of solution deoxygenization for the potential step method, and aims to solve the problem of serious resource waste caused by the fact that a deoxidant is mostly added for reaction deoxygenization during deoxygenization of a solution for the potential step method in the prior art. A residue collecting tank is arranged below a primary reaction tank, a secondary reaction tank is arranged on one side of the residue collecting tank, a high-temperature reduction tank is arranged at the upper end of the secondary reaction tank, a coupler mechanism is arranged on the high-temperature reduction tank, and a stirring motor mechanism is arranged at the upper end of the coupler mechanism; a stirring shaft is arranged at the lower end of the coupling mechanism, deoxygenization storage tanks are arranged on the two sides of the stirring shaft, holes are formed in the outer walls of the deoxygenization storage tanks, the holes and the deoxygenization storage tanks are of an integrated structure, a heating control mechanism is arranged at the front end of the high-temperature reduction tank, and a protective cover is arranged outside the secondary reaction tank.

Owner:YANCHENG INST OF TECH

Towerless deaerator

PendingCN109052535AImprove oxygen removal effectAvoid it happening againWater/sewage treatment by degassingWater treatment flow arrangementsEngineeringWater circulation

The invention discloses a towerless deaerator. The towerless deaerator comprises a deoxidization water tank; a water inlet, a vapor inlet and an oxygen exhaustion port are formed in the top of the deoxidization water tank; a water inlet pipe is mounted at the water inlet; a water inlet nozzle is mounted in the water inlet pipe in the deoxidization water tank; a vapor distribution mechanism is mounted in the deoxidization water tank; a height adjustment mechanism of the vapor distribution mechanism is arranged at the top of the deoxidization water tank; the vapor distribution mechanism comprises a vapor inlet pipe connected with the vapor inlet in a sealing manner; a vapor distribution pipe is fixed at the bottom end of the vapor inlet pipe; vapor branch pipes are mounted on the steam distribution pipe; and a rotation spray head is mounted at the outer end of each vapor branch pipe. According to the towerless deaerator, the height adjustment mechanism can be used for adjusting the height of the whole vapor distribution mechanism according to water level condition in the deoxidization water tank, so that vapor can be reasonably distributed to everywhere in the deoxidization water tank; the rotation spray head can be used for driving the water in the deoxidization water tank to move circularly while spraying out vapor, so that the deoxidization effect of the water at everywhere isimproved, the generation of incrustation can be avoided and the deoxidization effect is high.

Owner:连云港市连云区墟沟经济发展总公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com