Novel intelligent efficient polymer solution deoxidizing system

A polymer solution, intelligent technology, applied in the polymer solution dissolved oxygen removal system, new intelligent high-efficiency polymer solution oxygen removal system field, can solve the problem that the oxygen removal rate can only be judged according to experience, and the final oxygen content of the solution cannot be controlled , Inaccurate experimental data and other problems, to achieve the effect of visible micro-oxygen content, low micro-oxygen content, and high oxygen removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A novel intelligent high-efficiency polymer solution oxygen removal system of the present invention, its specific implementation method is:

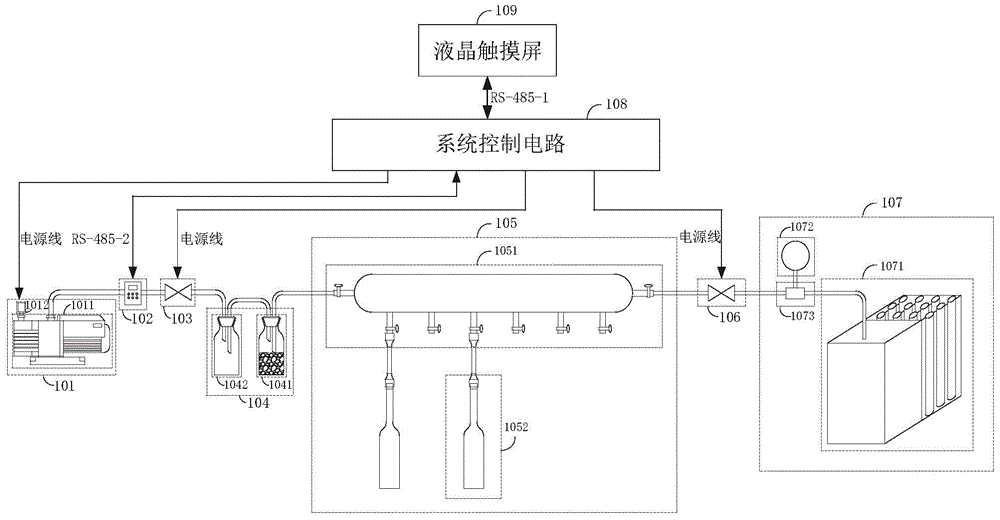

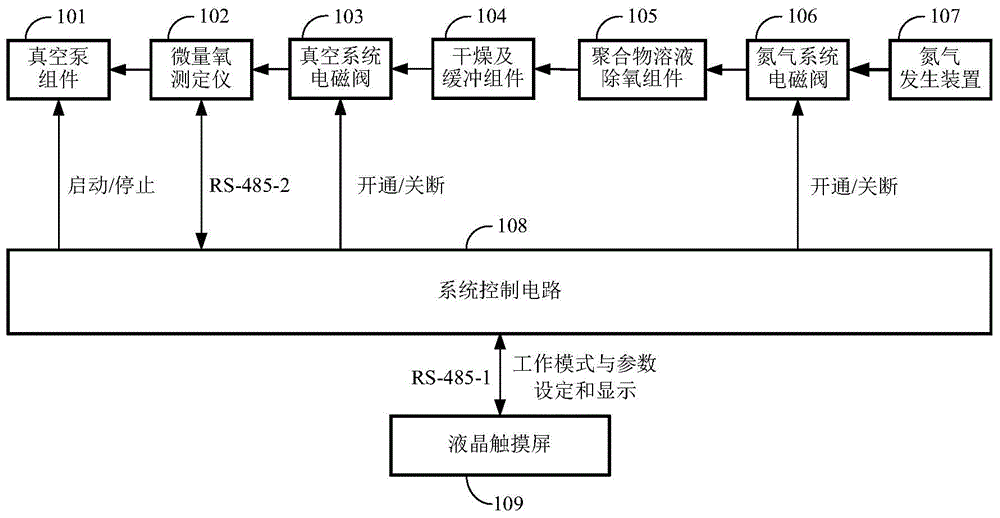

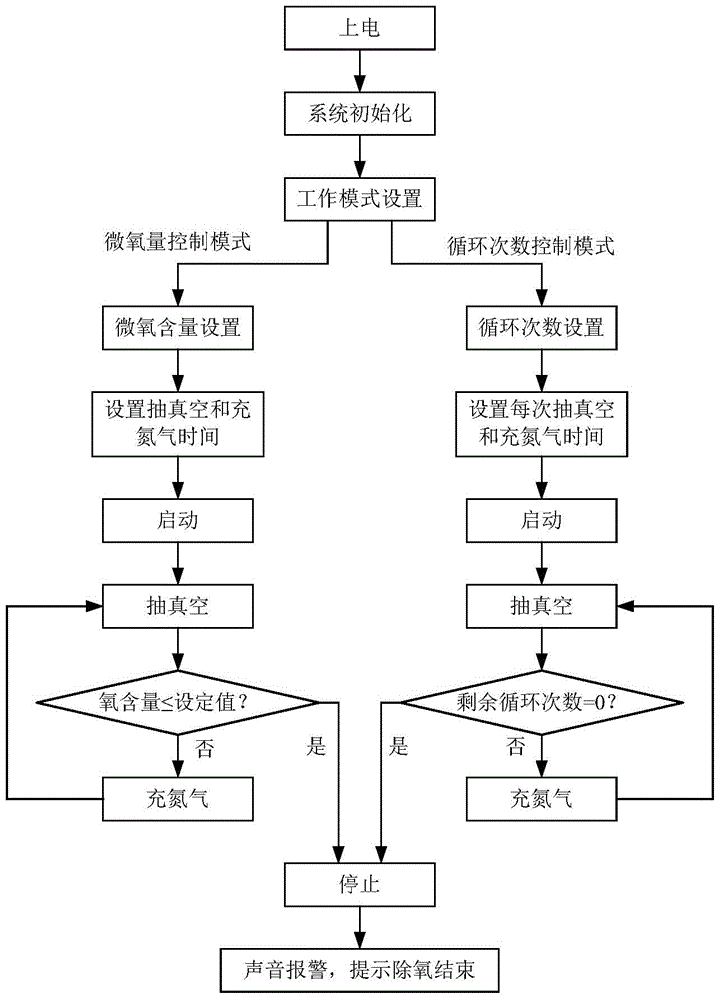

[0030] see figure 1 As shown, the novel intelligent high-efficiency polymer solution oxygen removal system includes: vacuum pump assembly 101, trace oxygen measuring instrument 102, vacuum system solenoid valve 103, drying and buffer assembly 104, polymer solution oxygen removal assembly 105, nitrogen gas System solenoid valve 106, nitrogen generator 107, system control circuit 108 and liquid crystal touch screen 109. The inlet end of the vacuum pump assembly 101 is connected to the output end of the trace oxygen measuring instrument 102 through a stainless steel tube, the input end of the trace oxygen measuring instrument 102 is connected to one end of the vacuum system solenoid valve 103 through a stainless steel tube, and the other end of the vacuum system solenoid valve 103 is connected to the other end of the vacuum system so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com