Preparation method and application of unconventional natural gas deoxygenation catalyst

An unconventional natural gas and oxygen catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve high deoxygenation efficiency, easy automatic control, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

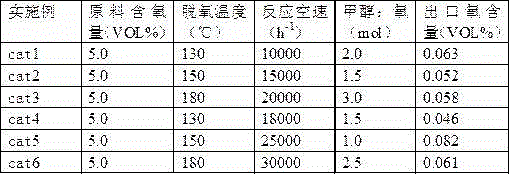

Examples

Embodiment 1

[0031] The active component of the catalyst in this example is metal palladium, and titanium dioxide is used as a carrier to finally obtain an unconventional natural gas deoxygenation catalyst with a mass content of about 0.01% of the active component of the catalyst, numbered cat1. The specific preparation method is:

[0032] (1) Dissolve palladium chloride in deionized water to make 50ml palladium chloride impregnation solution with a concentration of 0.1mol / L;

[0033] (2) Take 10.000g of titanium dioxide carrier and immerse it in the impregnating solution prepared in step (1) for 10 minutes at room temperature to prepare unconventional natural gas deoxygenation catalyst precursor a1;

[0034] (3) Dry the catalyst precursor a1 prepared in step (2) at 110°C for 3 hours, repeat steps (2)-(3), and finally obtain an unconventional natural gas deoxygenation containing about 0.01% palladium by mass Catalyst precursor b1;

[0035] (4) Immerse the catalyst precursor b1 prepared i...

Embodiment 2

[0037] The active component of the catalyst in this example is metal palladium, and silica is used as a carrier to finally obtain an unconventional natural gas deoxygenation catalyst with a mass content of about 0.03% of the active component of the catalyst, numbered cat2. The specific preparation method is:

[0038] (1) Dissolve palladium chloride in deionized water to make 50ml palladium chloride impregnation solution with a concentration of 0.1mol / L;

[0039] (2) Take 10.000g of silica carrier and immerse it in the impregnating solution prepared in step (1) for 10 minutes at room temperature to make unconventional natural gas deoxygenation catalyst precursor a2;

[0040] (3) Dry the catalyst precursor a2 prepared in step (2) at 100°C for 3 hours, repeat steps (2)-(3), and finally obtain unconventional natural gas deoxygenation containing about 0.03% palladium element mass catalyst precursor b2;

[0041] (4) Immerse the catalyst precursor b2 prepared in step (3) in the for...

Embodiment 3

[0043] The active component of the catalyst in this example is metal platinum, and gamma alumina is used as the carrier to finally obtain an unconventional natural gas deoxygenation catalyst with a mass content of about 0.01% of the active component of the catalyst, numbered cat3. The specific preparation method is:

[0044] (1) Dissolve platinum nitrate in deionized water to make 50ml of platinum nitrate impregnation solution with a concentration of 0.1mol / L;

[0045] (2) Take 10.000g of γ-alumina carrier and immerse it in the impregnating solution prepared in step (1) for 10 minutes at room temperature to prepare unconventional natural gas deoxygenation catalyst precursor a3;

[0046] (3) Dry the catalyst precursor a3 prepared in step (2) at 120°C for 3 hours, repeat steps (2)-(3), and finally obtain unconventional natural gas deoxygenation containing about 0.01% platinum element mass Catalyst precursor b3;

[0047] (4) Immerse the catalyst precursor b3 prepared in step (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com