Deoxygenation head

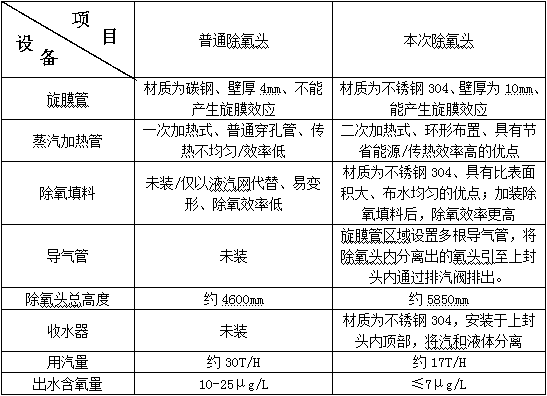

The technology of deaerator head and cylinder is applied in the field of deaerator for boiler feed water, which can solve the problems of high production cost and complex structure, and achieve the effects of less stringent requirements on water temperature, good adaptability and lower heat consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

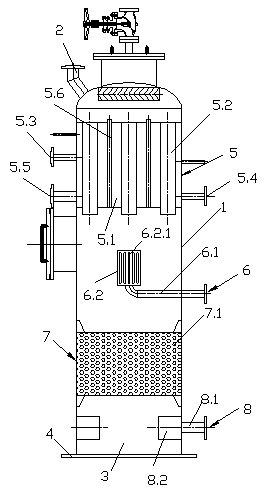

[0016] Embodiment 1: a kind of deoxygenation head, comprises cylinder body 1, cylinder body 1 top exhaust port 2, the water outlet 3 of cylinder body 1 bottom end, water outlet 3 is provided with connecting flange 4, cylinder body 1 includes from top to bottom The spin-film deoxygenation layer 5, the first steam layer 6, the filter layer 7 and the second steam layer 8 are arranged in sequence. The spin-film deoxygenation layer 5 includes the spin-film group water chamber 5.1, the setting and spin-film group water chamber 5.1 The three spiral membrane tubes 5.2 arranged vertically at intervals in the inner tube and the hydrophobic water inlet 5.3, the desalted water inlet 5.4, and the condensed water inlet 5.5, which are arranged on the cylinder wall and communicate with the water chamber 5.1 of the spiral membrane group, the hydrophobic water inlet 5.3 , desalted water inlet 5.4, and condensed water inlet 5.5 are all connected tangentially to the wall of the water chamber 5.1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com