Method for removing oxygen in chlorination reaction gas

A chlorination reaction and gas technology, applied in the field of chlor-alkali chemical gas treatment, can solve the problems of complex operation process and low oxygen removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

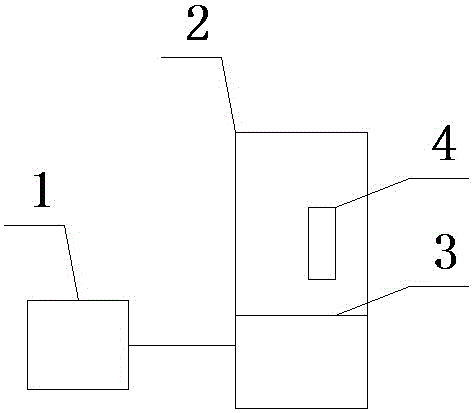

[0044] The device for removing oxygen in the chlorination reaction gas by applying a method for removing oxygen in the chlorination reaction gas as described above includes a gas buffer tank 1, a reactor 2, a gas distribution device 3, and an external field trigger are installed in the reactor 2. Condition 4. The outlet of the buffer tank 1 is connected to the inlet of the reactor 2 .

[0045] The second substance is sulfur dioxide gas, and the application of the above-mentioned device to remove the oxygen in the chlorination reaction gas includes the following process:

[0046] (1) The chlorination reaction gas including chlorine, hydrogen chloride and oxygen and sulfur dioxide gas enter the gas buffer tank 1 , and the chlorination reaction gas and sulfur dioxide gas are mixed uniformly in the gas buffer tank 1 .

[0047] (2) Mix evenly in the gas buffer tank 1, and at the same time, the pressure-stabilized chlorination reaction gas and sulfur dioxide gas leave the gas buffe...

Embodiment 2

[0051] The device for removing oxygen in the chlorination reaction gas by applying a method for removing oxygen in the chlorination reaction gas as described above includes a gas buffer tank 1, a reactor 2, a gas distribution device 3, and an external field trigger are installed in the reactor 2. Condition 4. The outlet of the buffer tank 1 is connected to the inlet of the reactor 2 .

[0052] The second substance is sulfur dioxide gas and hydrogen sulfide gas, and the removal of oxygen in the chlorination reaction gas by using the above-mentioned device includes the following process:

[0053] (1) The chlorination reaction gas including chlorine, hydrogen chloride and oxygen, sulfur dioxide gas, and hydrogen sulfide gas enter the gas buffer tank 1 together, and the chlorination reaction gas, sulfur dioxide gas, and hydrogen sulfide gas are mixed uniformly in the gas buffer tank 1;

[0054] (2) Mix evenly in the gas buffer tank 1, and at the same time, the pressure-stabilized...

Embodiment 3

[0058] The device for removing oxygen in the chlorination reaction gas by applying a method for removing oxygen in the chlorination reaction gas as described above includes a gas buffer tank 1, a reactor 2, a gas distribution device 3, and an external field trigger are installed in the reactor 2. Condition 4. The outlet of the buffer tank 1 is connected to the inlet of the reactor 2 .

[0059] The second substance is sulfur dioxide gas, hydrogen sulfide gas, hydrogen gas, and the application of the above-mentioned device to remove the oxygen in the chlorination reaction gas includes the following process:

[0060] (1) The chlorination reaction gas including chlorine, hydrogen chloride and oxygen, sulfur dioxide gas, hydrogen sulfide gas, and hydrogen enter the gas buffer tank 1 together, and the chlorination reaction gas, sulfur dioxide gas, hydrogen sulfide gas, and hydrogen are in the gas buffer tank 1 mix evenly;

[0061] (2) Mix evenly in the gas buffer tank 1, and at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com