Detecting and dosing device and method for pre-removing oxygen in solution for corrosion test

A corrosion test and dosing device technology, which is applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the poor repeatability of test operations, the inability to monitor dissolved oxygen content in real time, and the influence of dissolved oxygen corrosion test results, etc. problems, to achieve the effect of improving oxygen removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

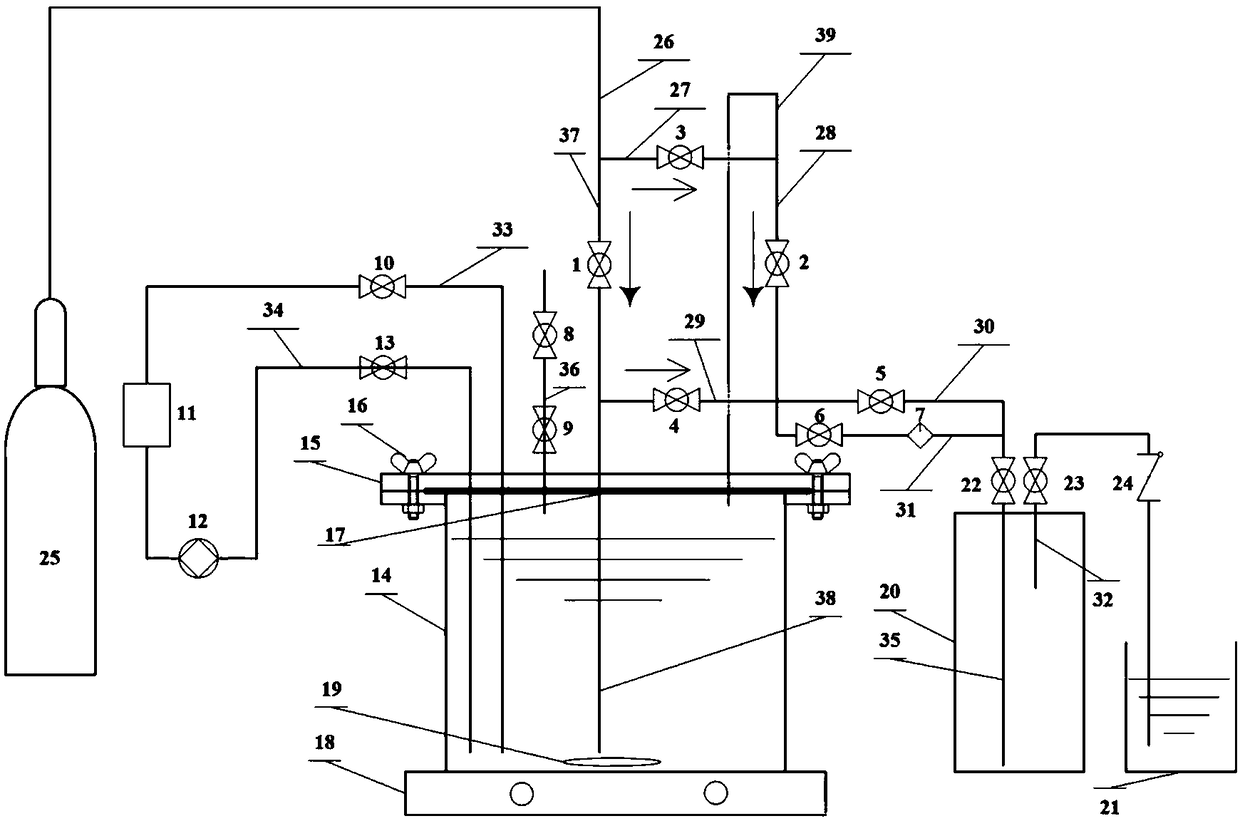

[0042] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0043] refer to figure 1 , a corrosion test solution pre-deoxygenation detection and dosing device, including pre-deoxygenation, liquid pouring system, dissolved oxygen detection system, corrosion test container 20, dosing system, magnetic stirrer, tail gas collection container 21. Among them, the pre-deoxygenation and liquid pouring system is connected to the high-purity nitrogen cylinder 25 through the pre-deoxygenation inlet pipeline 26; The container inlet line 35 is connected. The dosing pipeline 36 of the dosing system is connected with the pre-deaeration container cover 15 of the pre-deaeration and pouring system through a sealing thread. The dissolved oxygen test inlet pipeline 33 and the dissolved oxygen test outlet pipeline 34 of the dissolved oxygen test system are respectively connected with the pre-deoxygenation container cover 15 of the pre-deaeration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com