Preparation method for low-oxygen spherical aluminum nitride powder

A low oxygen content, aluminum nitride technology, applied in the field of high-temperature liquid-phase assisted trimming of aluminum nitride powder morphology, can solve the problems of increasing the contact area of inorganic/organic materials, reducing material performance, and difficulty in achieving high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

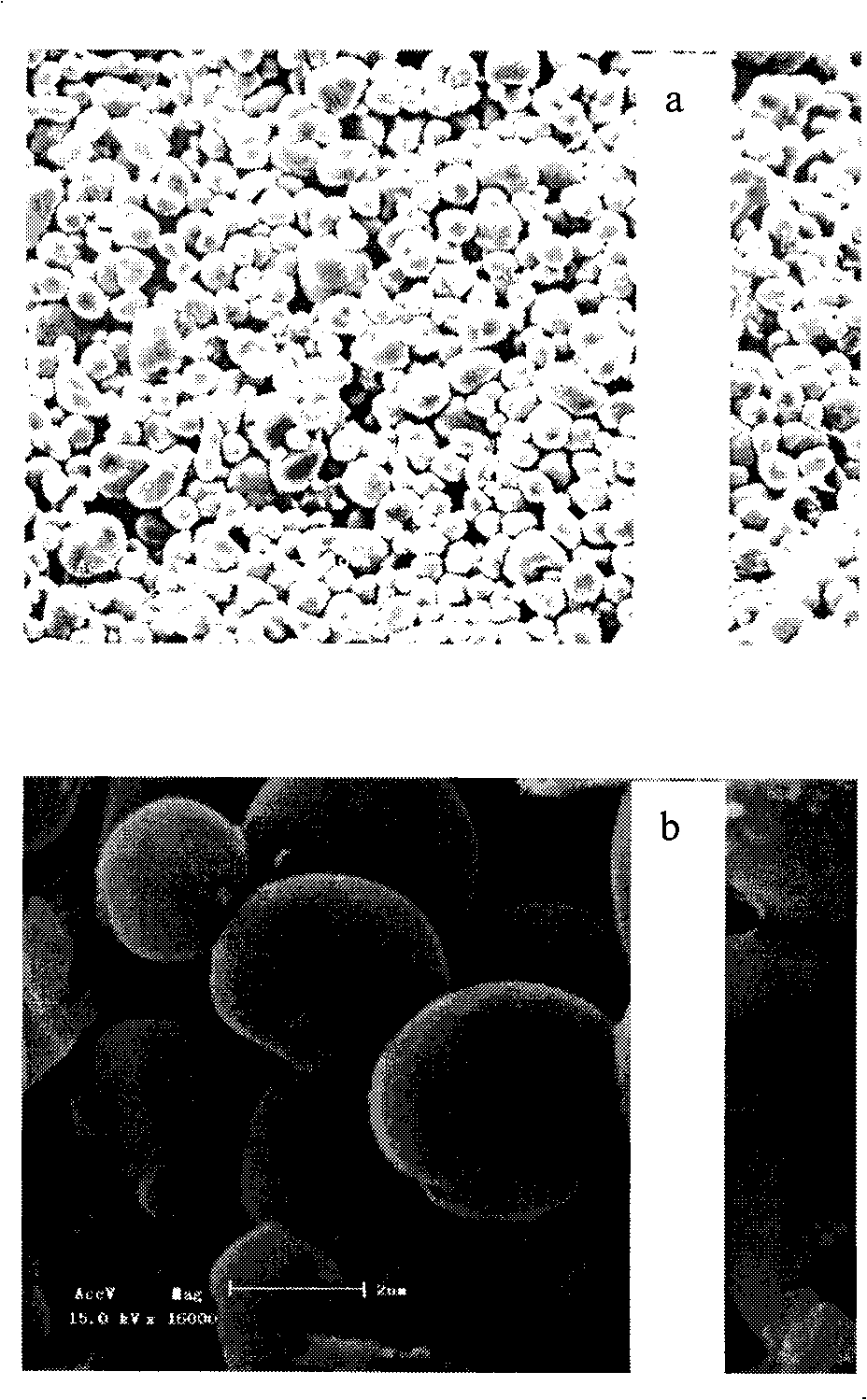

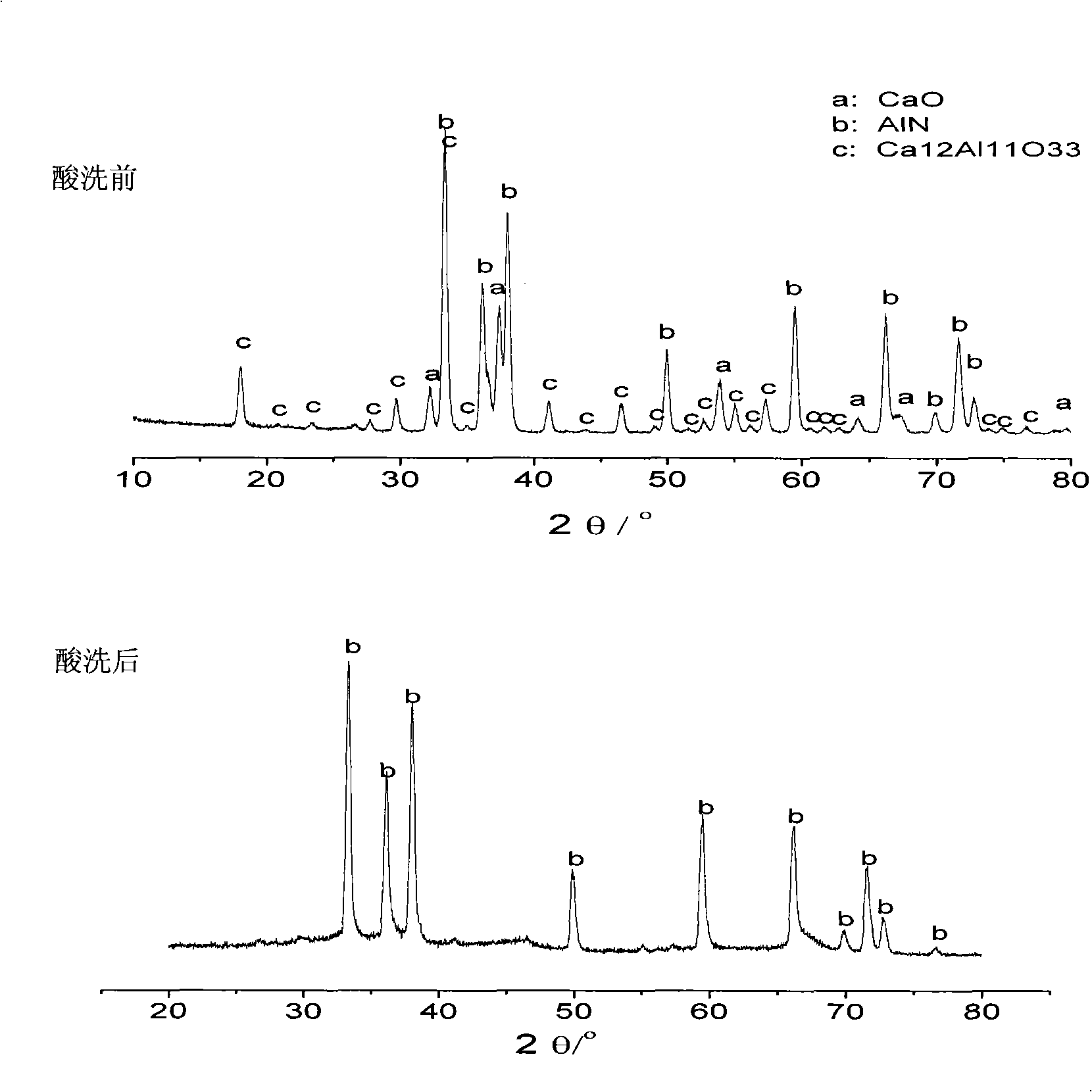

Embodiment 1

[0024] Aluminum nitride accounting for 60% of the total weight (self-propagating synthetic aluminum nitride powder, nitrogen content 32.12wt%, oxygen content 2.02wt%, average particle size 1.2um); accounting for 40% of the total weight of spheroidized oxygen removal After the auxiliary material (calcium carbonate, analytically pure) is mixed (ball milled for 24 hours), it is packed into a graphite crucible with a certain density (calculated in terms of porosity, loose packing, and the porosity is about 45%). 2 Heated to 1800 degrees Celsius in the atmosphere and kept for 3 hours. After the product was crushed and decarbonated, the test results showed that the average particle size of the obtained aluminum nitride particles was 6.8um, the nitrogen content was 33.72wt%, and the oxygen content was 0.25wt. %, the carbon content is 0.09%. The sphericity is 95%. The XRD collection of collections (before and after pickling) of the product obtained in the present embodiment is shown ...

Embodiment 2

[0026] Aluminum nitride (self-propagating synthetic aluminum nitride powder, nitrogen content 32.12wt%, oxygen content 2.02wt%, average particle size 1.2um) accounting for 50% of the total weight; spheroidized oxygen removal accounting for 50% of the total weight The auxiliary material (which is 80wt% calcium carbonate + 20wt% boron oxide mixed, analytically pure) is mixed (ball milled for 24 hours) and packed into graphite with a certain density (calculated by porosity, loose packing, porosity about 45%) inside the crucible, at N 2 Heated to 1750 degrees Celsius in the atmosphere and kept for 3 hours. After the product was crushed and decarbonated, the test results showed that the average particle size of the obtained aluminum nitride particles was 5.2um, the nitrogen content was 33.52wt%, and the oxygen content was 0.35wt. %, the carbon content is 0.10%. The sphericity is 97%.

Embodiment 3

[0028] Aluminum nitride (self-propagating synthetic aluminum nitride powder, nitrogen content 32.12wt%, oxygen content 2.02wt%, average particle size 1.2um) accounting for 80% of the total weight; spheroidized oxygen removal accounting for 20% of the total weight The auxiliary material (which is 70wt% calcium carbonate + 30wt% boron oxide mixed, analytically pure) is mixed (ball milled for 24 hours) and packed into graphite with a certain density (calculated by porosity, loose packing, porosity about 45%) inside the crucible, at N 2 Heated to 1600 degrees Celsius in the atmosphere and kept for 16 hours. After the product was crushed and decarbonated, the test results showed that the average particle size of the obtained aluminum nitride particles was 7.2um, the nitrogen content was 33.42wt%, and the oxygen content was 0.38wt. %, the carbon content is 0.13%. The sphericity is 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com