Medical waste comprehensive treatment method

A technology for comprehensive treatment of medical waste, which is applied in the field of comprehensive treatment of medical waste, can solve problems such as non-adoption, complex components of medical waste, and inability to handle medical waste, achieve efficient and high-quality treatment, and achieve the effect of solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

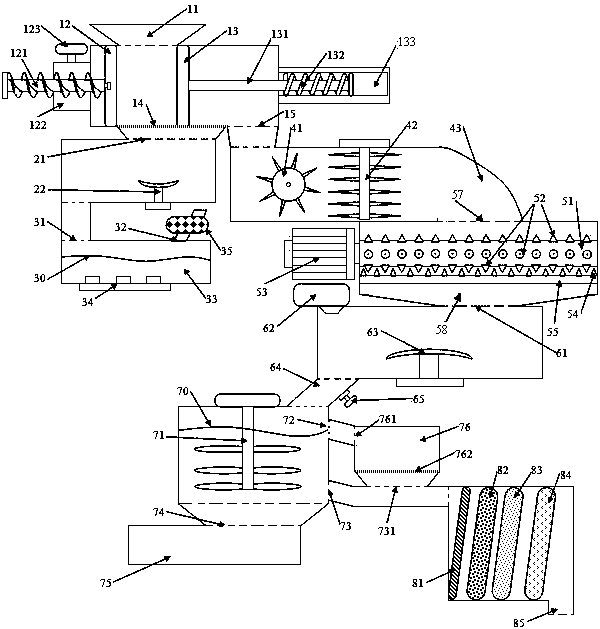

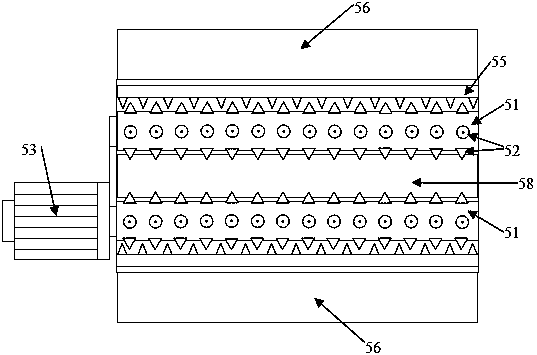

[0038] Such as figure 1 and 2 A comprehensive treatment device for medical waste is shown, which includes a compression chamber, a liquid stirring chamber, a liquid alloy processing chamber, a primary crushing chamber, a fine crushing chamber, a solid disinfection chamber, a classification chamber and a water treatment chamber.

[0039] The compression chamber includes a compression chamber casing, a garbage inlet, an active compression component, a passive compression component, a liquid drain plate in the compression chamber and a discharge port of the compression chamber; the garbage inlet is arranged on the top of the compression chamber casing, directly below the garbage inlet The bottom wall of the compression chamber casing is provided with a compression chamber liquid leakage plate, the compression chamber liquid leakage plate is a dense through-hole plate, and the active compression components include an active compression plate, an active compression screw, an active...

Embodiment 2

[0053] The comprehensive treatment method for medical waste using the device of Example 1, the comprehensive treatment method for medical waste is carried out using the above-mentioned comprehensive treatment device for medical waste, and specifically includes the following steps:

[0054] 1) Throw medical waste into the compression chamber through the waste inlet, and drive the active compression screw to rotate through the active compression plate rotation control rod to push the active compression plate to move towards the passive compression plate, so that the waste that enters the compression chamber The garbage is compressed. During the compression process, the liquid squeezed out from the medical waste leaks from the liquid floor of the compression chamber into the liquid mixing chamber. The passive compression plate is pushed by the medical waste compressed by the active compression plate. The spring is Compression, when the medical waste is compressed and pushed above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com