Method for continuously converting and casting oxygen-free copper ingot

A technology of oxygen-free copper and copper liquid, which is applied in the field of metal smelting and casting, can solve problems such as inability to reduce, and achieve the effects of being beneficial to storage, reducing oxygen content, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

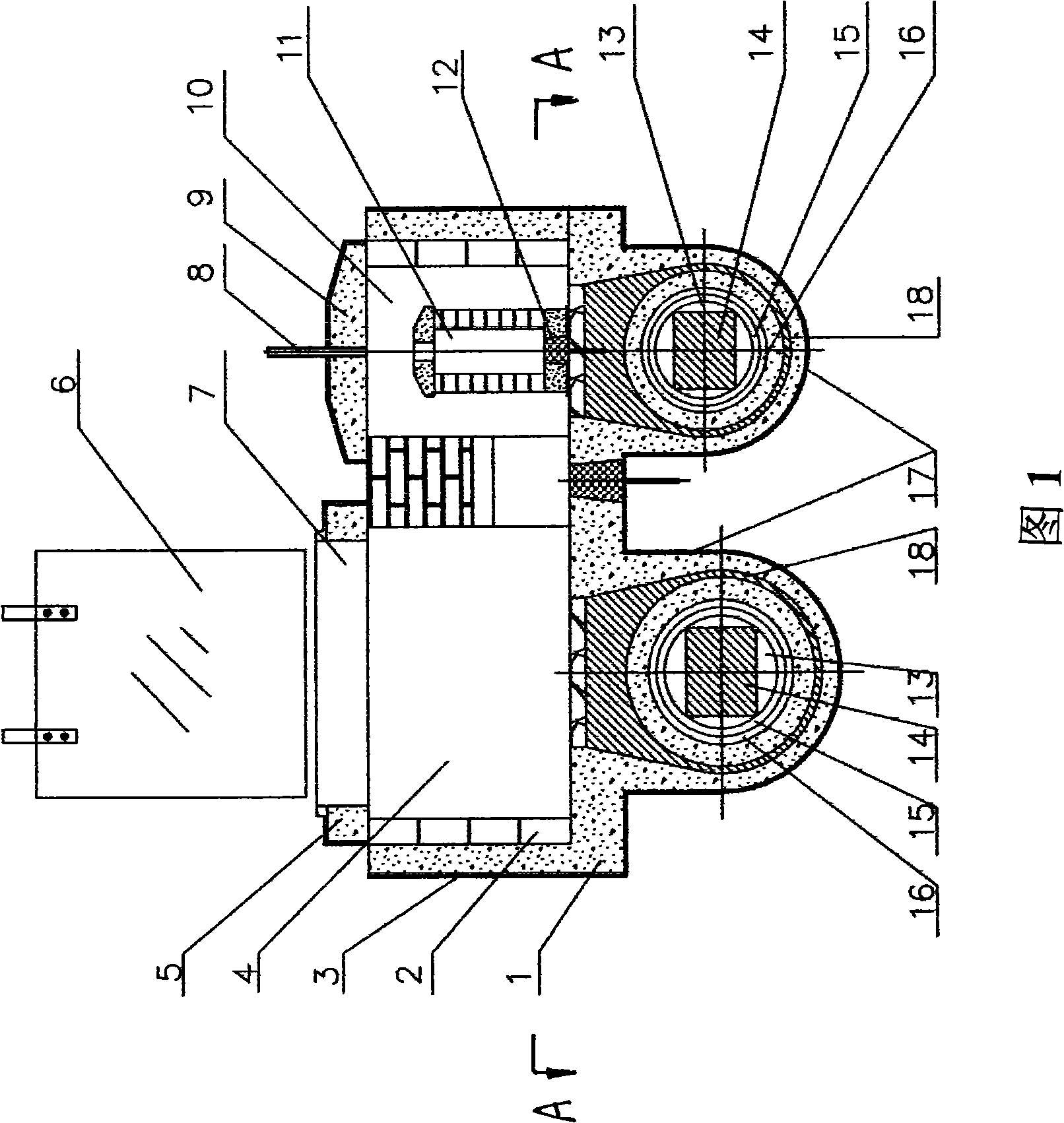

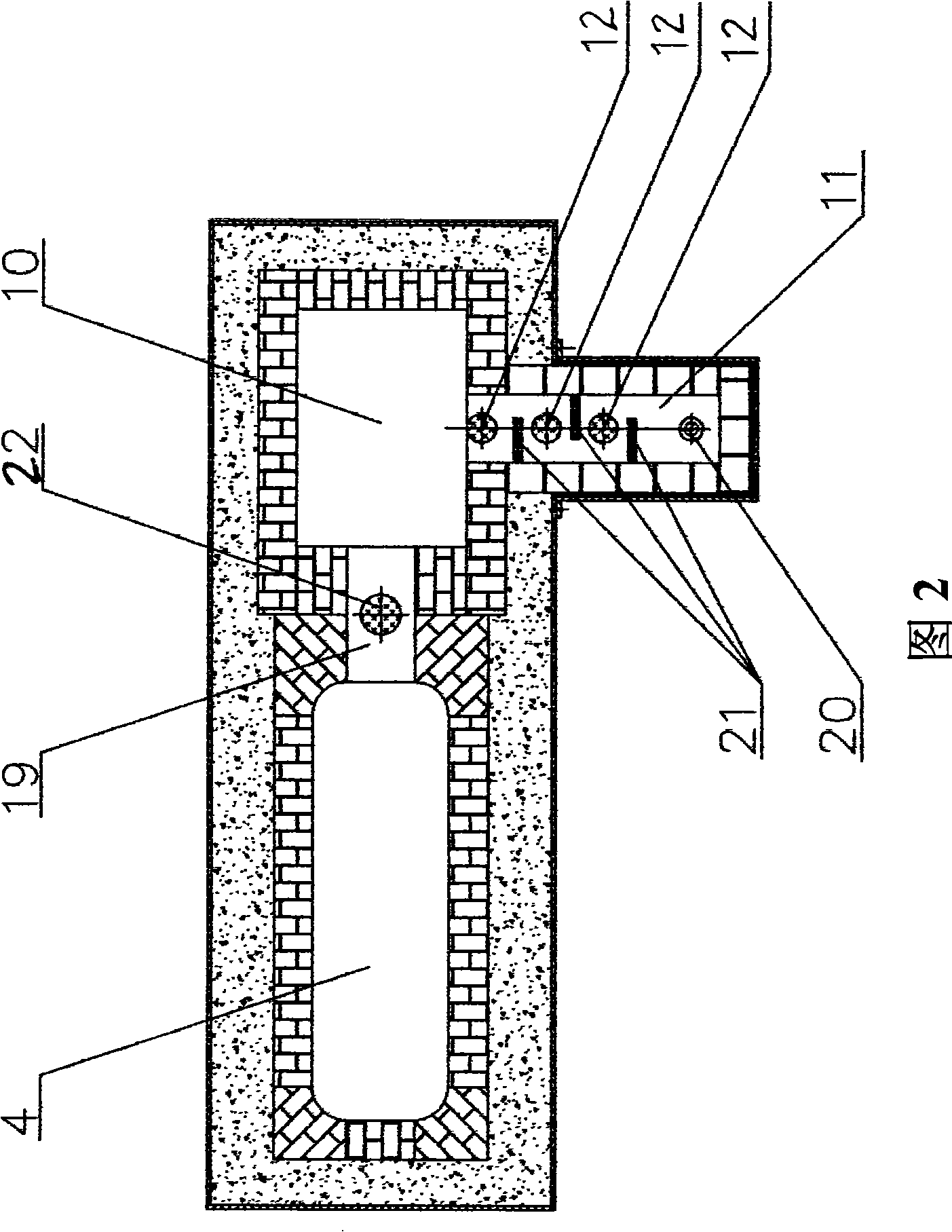

[0023] The present invention adopts an oxygen-free copper ingot continuous blowing casting furnace, which is mainly composed of a furnace shell 3 with refractory bricks 1 and refractory materials 2, a smelting furnace 4 with an electric induction heater 17 at the bottom and a deoxidation furnace arranged side by side in the furnace shell 3 10, placed between the smelting furnace 4 and the deoxidation furnace 10, the bottom blowing launder 19 with the breathable brick 22 at the bottom, connected with the deoxidation furnace 10, the bottom blowing furnace head 11 with the casting port 20 and the bottom blowing brick 12 at the bottom, placed in the bottom blowing The diversion groove 21 distributed in an "S" shape in the furnace head 11, the melting furnace cover 5 placed on the upper part of the melting furnace 4, and the deoxidizing furnace cover 9 with an exhaust port 8 placed on the upper part of the deoxidizing furnace 10 are formed. The electric induction heater 17 is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com