Rosin processing method

A processing method and rosin technology, which are applied in the field of rosin production, can solve the problems of uneven color and low purity of rosin, and achieve the effects of good effect, high purity and light and uniform color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

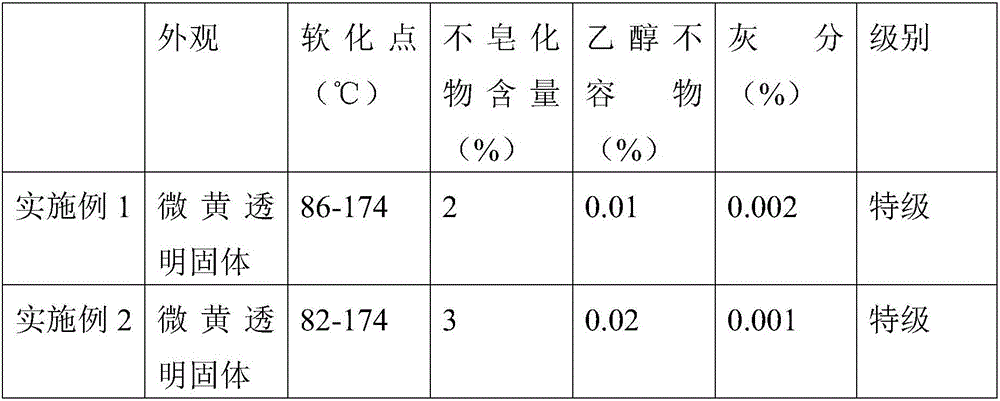

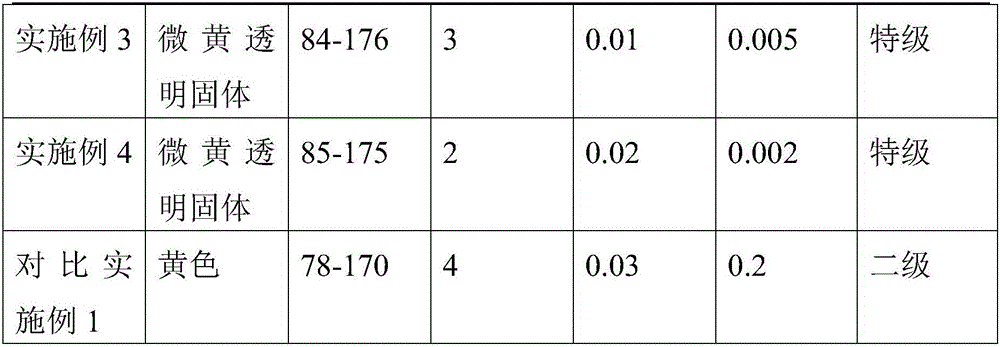

Examples

Embodiment 1

[0022] A processing method of rosin, comprising the steps of:

[0023] (1) pine resin is pulverized, crosses 100 mesh sieves;

[0024] (2) 10kg of rosin after pulverization is transferred to a meterable reactor, drop into ethanol with 2 times of rosin volume, and 3% pimaric acid of rosin weight, at a stirring speed of 500r / min, heat to 60-80 ℃, keep warm for 45 minutes to fully melt;

[0025] (3) at 0.5-1.5kg / cm 2 Under the condition of steam pressure and temperature of 60-80°C, pass the melted rosin through the filter layer to remove coarse impurities to obtain filtrate;

[0026] (4) at 0.5-1.5kg / cm 2 Under the condition of steam pressure and temperature of 60-80°C, the filtrate in step (3) is further purified by tangential flow membrane separation technology to obtain the permeable membrane liquid; the tangential flow membrane adopts a flat plate made of inorganic ceramic material Membrane with a pore size of 200um;

[0027] (5) transfer the permeation solution to a ste...

Embodiment 2

[0030] A processing method of rosin, comprising the steps of:

[0031] (1) pine resin is pulverized, crosses 50 mesh sieves;

[0032] (2) 10kg of turpentine after pulverization is transferred to a meterable reactor, drop into turpentine with 3 times of turpentine volume, and abietic acid with 1% rosin weight, and heat to 60-80°C at a stirring speed of 800r / min , keep warm for 30 minutes to fully melt;

[0033] (3) at 0.5-1.5kg / cm 2 Under the condition of steam pressure and temperature of 60-80°C, pass the melted rosin through the filter layer to remove coarse impurities to obtain filtrate;

[0034] (4) at 0.5-1.5kg / cm 2 Under the condition of vapor pressure and temperature of 60-80°C, the filtrate in step (3) is further purified by tangential flow membrane separation technology to obtain permeable membrane liquid; the tangential flow membrane adopts organic material tubular membrane , the membrane pore size is 100um;

[0035] (5) transfer the permeation solution to a stea...

Embodiment 3

[0038] A processing method of rosin, comprising the steps of:

[0039] (1) pine resin is pulverized, crosses 100 mesh sieves;

[0040] (2) 10kg of rosin after pulverizing is transferred in a meterable reactor, drop into the rosin water equal to the volume of rosin, and the abietic acid of 5% rosin weight, under the stirring speed of 300r / min, be heated to 60- 80°C, keep warm for 60 minutes to fully melt;

[0041] (3) at 0.5-1.5kg / cm 2 Under the condition of steam pressure and temperature of 60-80°C, pass the melted rosin through the filter layer to remove coarse impurities to obtain filtrate;

[0042] (4) at 0.5-1.5kg / cm 2 Under the conditions of vapor pressure and temperature of 60-80°C, the filtrate in step (3) is further purified by tangential flow membrane separation technology to obtain the permeable membrane liquid; the tangential flow membrane adopts a roll type of inorganic ceramic material Membrane with a pore size of 500um;

[0043] (5) transfer the permeation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com