Production process of automobile leather with infrared heat reflecting cooling function

A production process, infrared heat technology, applied in leather surface treatment, special leather manufacturing, small raw leather/big raw leather/leather/fur treatment, etc., can solve the problems of car leather hardening, unstable color, easy aging, etc., to achieve Good color fixation, improved physical properties of finished leather, soft leather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

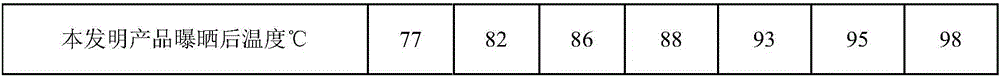

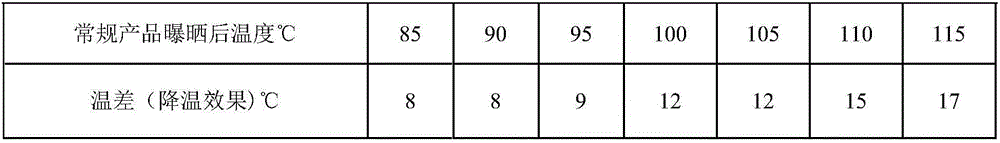

[0017] A production process of automobile leather with infrared heat reflection and cooling function, including fleshing → deliming → softening → tanning → shaving → retanning, dyeing, fatliquoring → drying → softening → covering layer finishing → embossing → color layer Finishing→Functional layer coating and other steps, for the steps mentioned in particular, follow the normal operation, and the tanning steps are followed by salting and pickling and chrome powder tanning, salting and pickling is: the skin after softening and washing, the liquid ratio is 25% , taking skin as the mass of 100 parts, add 25 parts of water, control the temperature at 20±2°C, add 5 parts of sodium chloride, control the Baume degree to 6.0-7.0, react for 20 minutes, add 0.5 parts of 10wt% dilute Formic acid, add 0.3 parts of 10wt% dilute formic acid after reacting for 10 minutes, add 0.7 parts of 5wt% dilute sulfuric acid after reacting for 10 minutes, add 0.7 parts of 5wt% dilute sulfuric acid twice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com